Abstract

Timber cladding has been used since historical times as a locally available, affordable weather protection option. Nowadays, interest in timber cladding is again increasing because of ecological reasons as well as naturalistic viewpoints. This review presents a comprehensive report on timber cladding in a European context, beginning with a brief overview of the history before considering contemporary use of timber cladding for building envelopes. The basic principles of good design are considered, paying attention to timber orientation, fixings and environmental risk factors. The relationship of timber with moisture is discussed with respect to sorption behaviour, dimensional instability and design methods to minimise the negative consequences associated with wetting. The behaviour of timber cladding in fires, the effects of environmental stresses and weathering, as well as the cladding properties and the variation thereof with different types of wood and anatomical factors (including exposure of different timber faces), are examined. The review then moves on to considering different methods for protecting timber, such as the use of coatings, preservatives, fire retardants and wood modification. A brief discussion of various environmental considerations is also included, including life cycle assessment, embodied carbon and sequestered atmospheric carbon. The review finishes by making concluding remarks, providing a basis for the selection of appropriate cladding types for different environments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The use of timber for cladding and other building functions was originally driven by a need to use what was locally available and affordable for the purpose, rather than any aesthetic, or other, consideration, and was therefore much more prevalent in forested regions. Before the advent of brick as a cheap building material, timber was the material of choice for weather protection in many regions of Europe. The use of timber as a building material confers many logistical advantages in construction, since it is readily adaptable to off-site and automated construction methods, considerably reducing on-site construction time and materials wastage [1,2,3,4]. There is also great interest in using timber cladding systems for retro-fitting and refurbishment of old buildings to improve energy performance [5,6,7,8,9,10]. Furthermore, there has been a renewed interest in using timber in construction for environmental reasons, linked to the ability to store atmospheric carbon and the reduced environmental impact associated with producing timber compared with other construction materials.

The building sector accounts for more than 40% of global primary energy demand, and 36% of global greenhouse gas (GHG) emissions are due to operational energy demands of buildings in industrialised countries. This impact is even larger if the embodied energy associated with the building materials is included [11]. Embodied energy is the primary energy that is used in the manufacture and transportation of materials, but may also include maintenance and installation [12]. Embodied energy is not to be confused with operational energy, which is the primary energy that is used to maintain the functional services of the building, such as heating and lighting. The embodied energy associated with the materials used in a building can be as much as 30% of the total lifetime energy demand. This inevitably means that more attention is currently paid to operational energy use, but there is increasing interest in the whole lifetime energy use, including the embodied energy associated with materials used. As building efficiency increases, the embodied energy of the fabric will come under increasing scrutiny [13]. Given the concern regarding the impact of human activities upon the global climate, much attention has been given to the increasing use of timber in construction as a potential climate change mitigation strategy, due to potential reductions in environmental impact and because it can be used as a long-term store of sequestered atmospheric carbon dioxide [14,15,16,17,18,19,20,21].

The use of timber cladding in the domestic housing sector has seen a renaissance in Europe over the past 20 years [22], but tends to be much less common in non-residential and large multi-storey residential buildings [23,24,25]. The reasons for this include perceptions regarding the need for recurring maintenance, durability, the regulatory environment (especially concerning fire), aesthetics and lack of technical knowledge regarding detailing and installation [26, 27]. The non-uniformity of the material confers advantages, in that the aesthetics of a building structure may be improved [28, 29], as well as disadvantages associated with variable (and potentially, unpredictable) performance. The use of timber cladding on low-rise buildings poses fewer technical challenges, but still requires specialist knowledge to ensure optimum performance in service [30]. Moisture sensitivity is an important issue that affects the behaviour and durability of wood cladding materials [31, 32] and requires particular attention to be given to design details, such as openings, overhangs and corners [33, 34]. Unfortunately, it is all too easy to find examples, where the necessary considerations have not been given to material properties or design principles, resulting in poor aesthetics or expensive remedial measures having to be undertaken.

Protection of wooden cladding materials has often relied upon the use of coatings, particularly in traditional buildings [30]. However, there has been an increasing trend to use uncoated wood in cladding applications, because this has much reduced (or zero) maintenance requirements and consequently a reduced environmental impact [35]. Uncoated wood is obviously susceptible to weathering, which includes biotic (moulds, fungi) and abiotic (water, solar radiation) degradation [36]. The changes that weathering processes cause are inevitable and good design will take these into account, by avoiding (as far as is possible), any uneven weathering effects, such as shadowing, local microclimates encouraging mould growth, as well as taking account of prevailing winds [29]. As wooden surfaces weather, they erode and develop cracks, but with appropriate choice of timber species and orientation it is possible to minimise these effects [37]. In the past, protection systems against biological attack have relied upon the use of preservatives, but there are increasing quantities of modified wood used for cladding materials, because of enhanced performance resulting in lower maintenance costs, which compensates for the higher ‘up-front’ costs [38].

Increased interest in the use of timber as a cladding material in the built environment has directed attention to ensuring that technical specification is correctly managed. At a national level, this has resulted in the development of many country-specific standards [30]. At a pan-European level, the use of solid wood for external cladding comes within the scope of the European Standard EN 14,915 [39]. EN 14,915 describes the information required for CE marking and labelling to comply with the EU Construction Product Regulations (EU 305/2011) which came into force on 1 July 2013.

An extensive search of the literature has revealed the need for an up-to-date review of the subject area, and the results for this are reported herein. Search terms used were:

-

[WOOD, or TIMBER] plus [CLADDING, COATING, DIMENSIONAL STABILITY, DURABILITY, FIRE, REFERENCE SERVICE LIFE, WEATHERING],

-

[WOOD plus CLADDING] plus [FIXING, DESIGN, FIXING, HERITAGE, LIFE CYCLE ASSESSMENT].

Databases searched were Google Scholar and Web of Science. The context was restricted to a European geographical error, but much of the information reviewed is generic and for this reason references were not restricted to European in origin. Specifically excluded from the search was information on wood-based composites.

Historical perspectives

The main problem with tracing the origins of the use of timber cladding in buildings is the perishability of the material, with the preservation of organic material in an archaeological context requiring charring or water-logging [40]. Nonetheless, examples for the use of cleaved timbers for external walls have been found which date back to the Stone Age. The Neolithic settlement at Niederwil (about 3600 Before Common Era, BCE) in Switzerland had walls constructed of horizontal planks, which were held in place by upright posts [41]. A Stone-Age house over 5000 years old was excavated at Horton, near Windsor in the UK, which provided evidence of external walls made from cleaved timbers [42]. There are many surviving historical structures where timber has been used as a cladding. The Anglo-Saxon church at Greensted-juxta-Ongar in the UK, dating back to 1000 After Common Era (ACE), uses vertical oak staves for the external walls, acting both as cladding and having a support function (Fig. 1) [43]. Timber cladding was also used in Norwegian stave churches dating from the 12th Century, an example being the Borgund stave church dated between 1180 and 1250 ACE (Fig. 1) [44]. Many surviving examples of historical buildings having horizontal, or vertical cladding boards can be found across Europe. Originally, these boards would have been riven, that is, vertically split from the trunk, to produce feather-edged planks having a wedge-shaped section, with the thin edge fitted upwards and the thicker section at the bottom to shed water (with horizontal boards). These planks would have been fixed to the timber framework, using wooden dowels, or metal nails when these became more common. This labour-intensive technology might be supposed to restrict the use of timber cladding to high-status buildings, but there is extensive evidence of use in more ‘common’ dwellings. For example, the Grubenhäuser excavated at the site of the Anglo-Saxon village of West Stow in the UK showed clear evidence of the use of cleaved timber for wall cladding as well as flooring [45]. The advent of powered sawmills saw the demise of the wedge-shaped planks produced by cleaving, although many sawmills produced the characteristic feather-edged cladding boards by using radial (quarter) sawing patterns. As mineral-based and metal-based materials became more available, the use of timber cladding declined in Europe, although some countries (especially Finno-Scandinavia) continue to have a strong tradition of using timber for such applications, especially for family dwellings. However, there is currently a European revival in the use of timber elements for building envelopes underway.

The use of solid timber for building envelopes

Design considerations for timber cladding

Most timber cladding uses long straight boards that are oriented vertically or horizontally (sometimes diagonally), using tongue and groove, overlapping or a planned gap with a backing screen (Fig. 2). Vertical timber cladding is extensively used in Scandinavian countries, was common in urban Scotland in the sixteenth century [46] and is often used to facilitate the run-off of driving rain. Vertical cladding employs board-on-board geometries where the alternate boards may be the same or different dimensions, or sometimes a ‘shiplap’ configuration. A disadvantage with the vertical cladding system is that any decay occurring at the bottom of the board (the most susceptible region) requires that the entire length of cladding board is replaced, whereas with the horizontal oriented boards, only the lower few boards need to be replaced.

Detailing is a very important factor that affects moisture performance of timber elements in exterior environments [47,48,49] and the development of microclimates due to design features, such as overhangs must be taken into consideration when predicting performance [50]. Defects, piercings and other disturbances in the envelope are very important considerations when designing cladding details [51, 52], since such discontinuities in the envelope present a high risk of degradation or disfigurement of the cladding [33] and potentially create water-trapping contact faces [31]. Good design will take into account how water will behave when it encounters door and window openings, etc., and make suitable provision for sealing/preventing water ingress and/or ensuring effective drainage and ventilation. Shadowing effects should be taken account of, as well a possible staining ‘tide-marks’ caused by the movement of water-soluble extractives. The microenvironment in the vicinity of the timber cladding is important for determining the durability of the material as well as influencing the growth of mould [53]. Paying insufficient attention to these openings and transitions in building envelopes can lead to premature failure with additional environmental burdens associated with maintenance or replacement [54]. Water traps at joints present high-risk areas for the onset of decay (duration of wetness is a major risk factor) [55]. Ensuring that cladding elements are a sufficient distance from the ground to avoid water-splashing, or direct contact with liquid water is important and sometimes overlooked in modern constructions [34]. Allowances for timber movement should also be made when designing, specifying and installing timber cladding. Provided these principles are adhered to, timber cladding can provide a reliable and durable means of providing weather protection for a building [29].

Irrespective of what cladding material is used for the outer skin of buildings, there needs to be a system for fixing and restraining the facing materials to ensure that they are not damaged by wind loadings [56, 57]. Lower-density softwoods are often fixed to the wall by nailing, but pre-drilling and screw fixing is commonly used for higher-density and higher-value applications. Modified woods (such as thermally modified timber, TMT) tend to be brittle and require pre-drilling to prevent splitting if nails are employed [38], although the use of screws is to be preferred. Corrosion is an issue that needs to be taken account of when specifying the composition of the metal fixings to be used for timber cladding [58]. Untreated wood contains chemical compounds that can react with metal fixings and flashings, and treatment with biocides, fire retardants or other substances can also increase the corrosion risk [59,60,61,62]. Some modified woods, such as TMT, or acetylated wood, contain residual acids which can result in corrosion of fixings, or leachates that can react with metal flashings [63, 64], making the use of stainless steel fasteners essential. Rates of corrosion of the metals are determined by wood species, wood moisture content, temperature, any wood treatments used and depth into the wood [65], and chloride aerosols near the sea or air pollution will accelerate the degradation reactions [62]. The staining of oak (and other species, e.g. cypress, cedar) with iron due to reaction with tannins is very well known as a problem, but although it is often recognised that stainless steel fixings should be used with oak cladding, it is sometimes overlooked that the proximity of steel scaffolding during erection can result in staining on the envelope due to rain splash. This may require expensive remedial treatment using oxalic acid washing. Western red cedar yields water-soluble extractives that can react with copper and zinc [66]. Apart from staining, corrosion products from metals can also contribute to degradation of the wood material. But, interactions of timber cladding with metals can also be exploited as part of the design. For example, treatment with iron (II) sulphate can be used to treat wood surfaces to produce an artificial weathering effect, which eliminates problems caused by shadowing effects [67].

Timber is a material that lends itself to off-site prefabrication construction methods [68], but cladding is often added at a later stage in the construction process, necessitating the installation of scaffolding with associated disruption. There has accordingly been interest in the development of an off-site construction system where the cladding is installed in the factory [4] (Table 1).

Timber cladding and moisture

The environment in which timber is exposed has a major influence on its performance in service conditions. In particular, the exposure of timber to water or water vapour has a profound influence on performance. Timber durability for exterior cladding is defined according to the intended Use Class, which is defined in EN 335 [69] (Table 2) and is Use Class 3 (above ground) using either coated or uncoated timber. Use Class 3 is divided into Use Class 3.1, where the wood will not remain wet for long periods and where water will not accumulate, or Use Class 3.2, where the wood will remain wet for long periods and water may accumulate. With timber cladding, it is important to ensure that Use Class 3.1 conditions are obtained through good design, something that is regrettably not always realised in practice. In building envelope applications, Use Class 3.2 may be encountered if the cladding boards are too close to the ground, or there is risk of extended exposure to water in situations such as leaking gutters or downpipes. Careful design is required in order to avoid moisture traps, which can often occur as a result of poor detailing, or bad construction techniques.

Wood is a hygroscopic material due to the abundance of hydroxyl groups associated with the cell wall polymers, and the material exhibits dimensional changes with variation in moisture content (MC) and atmospheric relative humidity (RH) [70, 71]. In order to minimise the effects of movement after installation, timber for external cladding is normally dried to a MC of around 15%, although unseasoned ‘green oak’ may sometimes be specified and allowances made in the design for subsequent movement upon drying in situ. Correct timber selection for cladding applications is important. Wood species exhibit differing movement when the moisture content varies and the presence of reaction wood (compression, or tension wood) and juvenile wood, as well as other anatomical factors all affect movement behaviour. The type of movement that occurs in the cladding depends upon the grain orientation, which is determined by the sawing pattern of the board (i.e. through sawing, or quarter sawing), as well as grain spacing [72]. Selection of wood for cladding should attempt to ensure that the grain is oriented as nearly as possible parallel to the long direction of the board, but due to the variable nature of the material, this is not always possible in practice. Depending on the grain orientation, a board may deform by crooking, twisting, bowing and cupping (Fig. 3) [73,74,75,76]. Swelling in the longitudinal direction of the wood is normally insignificant and changes in dimension mainly occur across the grain, with tangential movement exceeding radial [77, 78] and cladding installation needs to allow for this movement. Selection to minimise distortion and defects inevitably leads to higher costs, but this leads to an overall lower life cycle cost because it eliminates (or reduces) the need to replace distorted cladding boards in service, which can have significant costs.

Modification of wood (thermal or chemical—discussed later in this paper) [38], or some wood treatments (such as reactive fire retardants) can improve the dimensional stability of wood [79]. Correct design such as ensuring that end grain is not exposed and allowing for dimensional movement of the cladding board are essential to ensure good performance and end grain sealing should always be undertaken. Allowing for dimensional movement is a particular concern with tongue and groove cladding systems, and if sufficient gap is not provided, the boards will be forced off the wall. Despite the importance of understanding and designing for the dimensional changes in wood elements in response to environmental changes, there is no agreed standard for measuring and reporting this behaviour [71].

When studying the relationship of wood with water vapour, laboratory experiments are generally limited to the measurement of sorption isotherms under carefully controlled conditions by determining the equilibrium moisture content (EMC) at different stable RH steps, with a constant temperature throughout the experiment [80]. Such experiments establish boundary curves showing the relationship between EMC and RH. However, these are not conditions that are encountered by timber cladding material in the real world. Instead, there can be very rapid changes in temperature and atmospheric RH, with the relationship between wood MC and RH being better represented by scanning curves (although with constantly changing temperature and relative humidity, equilibrium will seldom be established) [81].

With exposed wood, fluctuating environmental exposure conditions lead to concomitant changes in wood moisture content and dimensions, a response that is most pronounced at the wood surface [37]. Wood below the surface is not subject to such rapid changes and acts to restrain shrinkage at the surface. This creates tensile stresses with a magnitude depending upon the moisture content difference between the surface and sub-surface layers of the wood. Furthermore, there are differences in the sorption behaviour between earlywood and latewood in some species, which can vary depending on where the rings were located within the tree [82], plus an influence on swelling behaviour due to the presence and orientation of rays cells [83]. As a result of this, differential shrinkage at the micro-scale is experienced at the wood surface.

As a consequence of fluctuating environmental conditions, micro-checks occur in the wood cell walls, which grow to form surface cracks [84], very often at points of discontinuity in the surface structure, such as earlywood–latewood boundaries, or areas around knots. These cracks then provide points of entry of water further into the wood, which may then lead to localised regions of higher moisture content below the surface, potentially allowing for microbiological decay to occur. Weathering of a wood surface also has a major influence on its propensity to hold water for extended periods of time, which negatively affects the durability [85].

Water uptake in the interior of wood is a function of the combination of diffusion and capillary flow processes, and the capillary structure of the wood has a major influence on the permeability [75], since in wood above the fibre saturation point (FSP), free water is transported in the cell lumens or pores by capillary flow. The rate of penetration of water into the wood material and the residence time of this water is affected by the permeability of the wood and has a major influence upon the durability of timber cladding in service [86, 87]. The diffusion of water molecules in cell lumens is much more rapid than in the cell wall, and wood permeability is a function of the density of the wood and the geometry of the interconnections between the different void spaces within the wood structure [88,89,90]. In some softwoods (such as spruces), bordered pits between adjacent tracheids become aspirated when the wood is dried and permeability is markedly reduced, making the wood ‘refractory’. The heartwood of many species exhibits high resistance to the transport of water. Refractory species and heartwood are therefore to be preferred for cladding applications.

Approximate moisture contents of timber building products in Europe are listed in the European Standard EN 942 [91]. For external joinery, an average moisture content of 12–19% is to be expected. However, there are many variables that can affect this ‘expected’ value, including detailing [92], but especially fluctuations in outer few mm of uncoated wood (i.e. surface region) which occur due to rapidly changing weather conditions.

The prevalence of wind driven rain (WDR) at an exposure site is especially important for building envelopes, and in a European context, the sites with the highest risk of exposure are situated in (or close to) western coastal regions with prevailing westerly winds. Wind-driven rain is rain that has a horizontal velocity component and has a much greater potential for penetrating a building envelope compared with rain falling vertically [93].

Although the impact of climate change on the thermal performance of buildings has received considerable attention in the scientific literature, the effects of wind, rain and other climatic factors which influence water penetration of building envelopes have, until recently, received less comment. It has been shown that higher amounts of moisture will accumulate in walls in the future, due to the increased occurrence of WDR as a result of climate change [94], encouraging studies of the influence of cladding design upon the rain tightness of different wooden cladding systems [51]. It is good practice to ensure that rainscreen cladding systems are designed on the assumption that WDR will always penetrate the envelope to some extent and that the penetrating water will run down the inner face of the cladding. Provision should therefore be made to allow for escape of this water at the bottom of the cladding. There is always a risk that water accumulation behind the rainscreen cladding will result in localised high relative humidity (RH), making mould growth and fungal attack at the rear face of the cladding likely. For this reason, cavity ventilation behind the rainscreen is considered essential. Historically, this was understood where horizontal cladding was used in older buildings in Norway. By using fixings at the top of the planks and choosing the appropriate orientation of the wood, this allowed for the structure to ventilate in dry weather and close in wet weather as the boards reversibly distorted with changes in moisture content (Fig. 4). In order for this principle to work, the grain orientation of the boards should ensure that they will distort by cupping.

Traditional Norwegian wooden panelling utilising cupping distortion for ventilation a: drying causes the boards to cup outwards, allowing air into construction. Wet weather causes reverse cup, closing the gap. Modern wooden panelling b with nails close to the lower end leaves the structure weather tight in all conditions. Reproduced with permission from [95]

A common method of estimating the moisture content of wood in service conditions is to determine conductivity, by using pin electrodes connected to a resistance meter [96], (EN 13,183–2 [97]), or by capacitance (EN 13,183–3 [98]). Although the use of resistance or capacitance methods can be subject to error and require correct calibration [99], embedded electrodes in wood are often used for long-term determination of moisture behaviour in cladding systems [100]. However, conductometric techniques are not suitable for determining the moisture content at mm length scales. For this reason, the potential for studying the variation of moisture content in the underlying surface of wood has been explored using nuclear magnetic resonance [101, 102]. The use of X-ray computed tomography (CT) also shows promise for the determination of three-dimensional moisture distribution in wood panels [103].

Cavity ventilation

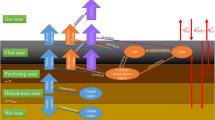

As noted above, although ideally, a rainscreen cladding should completely prevent penetration of water, this is very unlikely to be achieved in practice, especially under conditions of driving rain. In order to provide a capillary break and to allow for drying of the inner surface of the rainscreen of a building envelope, a cavity between the envelope and wall is usually provided (Fig. 5). Heat and moisture can transfer into the region between the external façade and main wall of the construction from the exterior or interior of the building. The relative contributions from the interior and exterior depend on a number of factors. The transfer of heat from the interior will occur when the outside ambient temperature is lower than the temperature of the internal space and vice versa. The transfer of heat and moisture through the wall structure and into the region between the timber cladding and wall is a particular problem in the winter, and there is a risk of interstitial condensation occurring if moisture is able to travel from the warm interior towards the outside of the building. This risk can be minimised by reducing the vapour pressure in the living space by, for example, ensuring good indoors ventilation or by using a barrier with high vapour resistance and/or high thermal resistance near the colder side of the wall [34, 92]. The exact details of the behaviour of ventilated cavities are complex and difficult to model [104].

The presence of moisture within the cavity requires ventilation to limit, or preferably prevent, interstitial condensation which can lead to mould growth or fungal attack [105]. Ventilation (where there is an airflow) is to be preferred to a vented cavity (where there is a connection to the exterior air, but no airflow) [106], but the drying behaviour of the cavity needs to take account of the sorption behaviour of the wood as well as air exchange properties [107]. However, cavity ventilation may result in a decrease in the overall thermal insulation efficiency of the building envelope. In order to maximise thermal efficiency, the inner wall is usually covered with a relatively impermeable layer (vapour control layer, VCL). In this way, it is possible to ensure adequate ventilation of the interior surface of the cladding, but also allow for air-tightness of the building.

It is important to note that drying of the cavity will only occur if the exchange occurs with air that has a lower relative humidity compared with the air in the cavity [108]. Consequently, long periods of rainfall can result in the risk of high moisture levels developing in the cavity, even when adequate ventilation is provided. Thus, under some circumstances, cavity ventilation systems may actually lead to interstitial condensation being worse. Air exchange of the cavity is enhanced by the use of vertical cladding boards and ventilation provision at the top and bottom of the cladding [109], and thermal bridging is considerably reduced and airflow enhanced if horizontal battens are fixed to vertical battens allowing for vertical external cladding boards (Fig. 5). Other factors affecting the air change rate behind a timber rainscreen cladding are the orientation and the area of the ventilation openings [109]. Ventilation rates can be determined using pressure differences, tracer gas methods [110, 111], pressure measurements, airflow (anemometers) [112], or temperature and relative humidity determination [113, 114].

Modern energy efficient buildings have high levels of insulation and air-tightness which makes them prone to over-heating, but passive cooling methods can be used to avoid the use of air-conditioning systems [115]. These are broadly classified into solar and heat protection, heat modulation using thermal storage materials and thermal dissipation using evaporative, radiative or convective cooling. Ventilative cooling can be achieved by the use of double skin facades [116], but there is a lack of consensus on what the optimum air gap should be to achieve optimum airflow rates, although it is known that smaller gaps reduce airflow and lead to a greater risk of over-heating [117].

A ventilated cavity may be required to prevent condensation occurring at the interior face of timber cladding, especially where exposure to WDR is likely. However, there has been, and continues to be, interest in the development of systems with no cavity, since the walls are thinner, cost less to build and the risk of a two-sided fire is much reduced [108]. There has been some research on the performance of a timber cladding systems using a capillary break rather than a ventilated cavity [118]. In traditional timber-clad log houses (e.g. in Finland), the timber cladding was fixed directly to the log walls with no cavity being provided, although a vapour-proof barrier of tar-coated paper was placed between the cladding and the log wall. The functioning of this kind of wall relies on sufficient vapour penetration through the coating, in practice necessitating the use of traditional oil paints instead of film-forming coatings. This ensures that any rain that penetrates into the timber itself will subsequently be removed through evaporation in dry conditions. The tar-coated paper is intended to provide both a vapour- and water-proof barrier below the timber cladding. It is unlikely that such a system would function well in a maritime climate.

Fire performance

The fire performance of timber cladding is a subject of particular interest when used in multi-storey buildings. Fire can spread on external walls due to an adjacent building being on fire, a fire directly outside of the building, or due to fire in a room with an opening through the cladding. Depending on the distance between the timber cladding and the adjacent fire, the external wall may be exposed to heat radiation and burning embers and possibly direct flame if close enough. Fire can spread on the external cladding if it is flammable, or has a flammable coating, with the presence of cavities behind the cladding also providing a ‘chimney’ effect if horizontal barriers are not provided [119,120,121].

The combustion process of wood can be considered to involve three distinct phases [122]. During heating of a wood sample, the initial stage is an endothermic process which mainly involves evaporation of sorbed water, plus the more volatile extractives (such as monoterpenes) if these are present. When wood reaches a temperature of around 200 °C, it starts to pyrolyse, producing gases that comprise a mixture of organic compounds (e.g. acetaldehyde, propenal, methanol, butanedione, acetic acid) [123] that will produce a burning flame if the ignition temperature is reached, or there is a source of ignition such as a burning ember [124]. Timber above approximately 12 mm thickness cannot support self-sustaining combustion and burning will only continue if there is a constant radiant heat input, such as an adjacent fire [125]. Below 250 °C, the decomposition reactions are endothermic, but above this temperature, exothermic reactions occur accompanied by the formation of a char layer [126], and above 300 °C, rapid pyrolysis occurs [127]. The low thermal conductivity and slow rate of charring of wood provide a degree of fire protection that is exploited in the use of wood in fire protection applications, such as fire doors [128]. The char layer will tend to self-extinguish, but will undergo smouldering, or flaming combustion, depending on heat flux, availability of oxygen and airflow characteristics around the combustion zone [129,130,131]. The char layer acts to protect the interior of the wood from radiant heat and limits oxygen flow, but its effectiveness in limiting or extinguishing combustion depends upon the density of the wood [132, 133]. Furthermore, the development of cracks in the char layer increases the rate of penetration of heat into the pyrolysis zone [134]. Oxidative erosion of the char layer can also occur if the heat flux continues, even with the absence of flaming combustion [135].

The Construction Products Regulation (CPR, EU 305/2011) ensures that there are harmonised rules for the use and marketing of construction products throughout the EU. The standards covering the use of timber in construction are embodied within Eurocode 5 (EN 1995 [136]). As stated in EN 14915 [39], the fire performance of solid wood cladding must be classified in accordance with EN 13501–1 [137]. If the cladding product meets the requirements stated in EN 14915, it may be classified without the need for further testing.

Fire performance is often determined by the use of small-scale tests, but these may not be directly applicable to real-life fire conditions [138]. The only way to be certain about how cladding materials will behave in service is through the use of full-scale tests, which are expensive. There is particular concern regarding the use of timber cladding for multi-storey buildings [139]. The fire regulations regarding the use of timber as a cladding material vary from country to country and are in state of flux. Many countries place restrictions upon the use of timber cladding for multi-storey buildings, or if there are neighbouring dwellings closer than a specified distance, unless the timber has been treated such that it meets specified requirements and there has been revised guidance published by the European Commission recently [140].

Timber properties affecting cladding behaviour

Species choice

Factors that are considered when specifying wood species for cladding applications include durability, dimensional stability, price, availability, ease of processing and sustainable sourcing.

The most durable species used for timber cladding in Europe are considered to be western red cedar (Thuja plicata), European larch (Larix decidua), Siberian larch (Larix sibirica), Douglas fir (Pseudotsuga menziesii) and European oak (Quercus robur). Other species, such as fir (Abies spp.), spruce (Picea spp.) and pine (Pinus spp.), are usually considered to be insufficiently durable for use unless they are treated in some way to protect or preserve them. However, with spruces, the drying process causes the bordered pits in the tracheid walls to irreversibly close (pit aspiration), which significantly reduces the permeability. Thus, although spruces are not suitable for ground contact applications, they generally perform well in Use Class 3.1 (Table 1) cladding applications.

The main European-grown timbers used for cladding are spruce, larch and pine. Norway spruce (Picea abies) is commonly used in Scandinavia. Slow-grown Norway spruce is considered preferable to fast-grown, but this is becoming less readily available with changes in forestry practices. The refractory nature of dried spruce can be an advantage because it limits the uptake of moisture in uncoated cladding materials. Scots pine (Pinus sylvestris) has a more durable heartwood, but the sapwood is more permeable and is less resistant to decay [90] and is more susceptible to cupping and to developing cracks compared with Norway spruce [76]. This permeability allows for treatment of the timber with biocides, but the permeability varies and hence the uptake of biocides is, as a consequence, also variable [89].

The dimensional stability of wood is a factor that must be taken into account when installing timber cladding, and this applies even to modified wood, although the dimensional stability of modified wood is superior to unmodified. Failure to take account of this fact can result in very expensive remedial work having to be undertaken to rectify issues related to distortion [34, 92]. It is essential that adequate allowance is made for the cladding boards to change dimension and that the fixings employed also allow for this movement. The dimensional changes and type of distortion depend on wood species, wood treatment (especially wood modification), grain orientation and presence of reaction wood.

Price and availability are closely related and an important factor in deciding what timber is most suitable for a given purpose [141]. Higher-quality timber, which has been selected specifically for purpose, or is more durable, or has desirable aesthetic qualities, will command a higher price, and this has to be balanced against the requirements of the client and what the overall life cycle cost of the installation will be [142]. Modified wood is more expensive than unmodified in many cases, but may have reduced maintenance costs, especially if coatings are applied. Apart from economic factors affecting availability, there are also geopolitical factors. Witness the recent embargo on Siberian larch by many countries of the world.

Ease of processing of wood is affected by density, occurrence of reaction wood and in some species the presence of silica (especially tropical hardwoods). In general, softwoods are easier to process than hardwoods, which is a major factor affecting the speed at which the cladding boards are processed, which will also affect the economics [78, 125].

Although much timber used for cladding in Europe is derived from the EU, there is also a reliance on imported timber from other parts of the world, including Siberian larch (from Russia) and western red cedar from the USA and Canada. The importation of timber into the EU is subject to strict controls. Although the EU Forest Law Enforcement Governance and Trade (FLEGT) Action Plan introduced in 2003 tackled illegal logging, it did not deal with deforestation. A key element of FLEGT is the EU Timber Regulation (EUTR), which came into force in March 2013, with the purpose of preventing the import of illegal timber products. This requires ‘operators’ to exercise due diligence in ensuring that the timber originates from legal sources. In November 2021, the European Commission also adopted a proposal to develop regulations that would curb deforestation caused by EU demand for agricultural products (resulting in land-use change), but also including demand for wood and wood products. The new EU forest strategy for 2030 includes as one of its objectives, promotion of the sustainable forest bioeconomy for long-lived forest products. It is, therefore, essential that timber used for cladding (and indeed, all) applications should be procured from sustainable sources, which requires effective certification of forest management practices as well as transparent and auditable supply chains [143,144,145,146].

Wood anatomical factors

Timber for cladding requires selection by visual grading to ensure that it is fit for purpose [147]. As noted previously, grain orientation is a very important factor influencing crack development during weathering [84, 148], with cladding timber ideally having annual ring orientation perpendicular to the exposed wood surface, thereby minimising crack formation and reducing distortion. This is achieved by the use of quarter sawing or cleaving, but this is not economically viable for high-throughput sawmills and poor practice exists where timber that has not been graded specifically for cladding purposes is used in service. Obtaining good quality boards with parallel grain is further complicated by the presence of spiral grain in trees [149, 150], presenting further challenges for the recovery of good quality timber from the forest resource. Tangential surfaces show a much greater susceptibility to crack formation compared with radial surfaces and a greater tendency to undergo cupping deformation [84]. Cupping is also more prevalent in sapwood, due to higher moisture uptake [76]. Growth stresses in trees also contribute to distortion of sawn wood [151].

The presence of reaction wood (compression wood in softwoods, tension wood in hardwoods) affects the dimensional behaviour of wood [152]. For example, with Norway spruce the ratio between tangential and longitudinal shrinkage was 49 in normal wood, but this reduced to 13 when compression wood was present [153]. Compression wood exhibits higher lignin contents and higher microfibrillar winding angles in the S2 layer of the cell wall, the latter contributing to much higher-dimensional changes in the longitudinal direction [154].

According to EN 14915 [39], if sapwood is not excluded from cladding material, it must be identified. For some wood species (e.g. spruce, ash), visual differentiation of heartwood and sapwood is problematical. There are laboratory methods, which use different dyes, or spectroscopy, but heartwood is rarely separated from sapwood in modern high-throughput sawmills for economic reasons. Nonetheless, there is an advantage to doing this for timber cladding from the point of view of performance in service, in order to enhance durability. If it is present in the cladding boards, it is preferable to ensure that the sapwood is located on the non-exposed face. With radially sawn timber, it is unlikely that sapwood can be entirely excluded, whereas a board that presents a tangential face is more likely to exhibit cupping. With a tangential oriented board, orienting the outer-exposed surface in the opposite orientation as in the tree (i.e. pith-side outwards) would minimise the sapwood content on the external face, but cupping may be an issue to consider when deciding on placing of fixings. The only way to ensure the absence of sapwood is through careful visual selection where this is possible; some information on visual grading of cladding is given in the European Standards EN 15146 [155], EN 14519 [156] and EN 14951 [157], but if heartwood is not distinguishable no guidance is available.

Depending upon the design employed, the thermal conductivity of the outer skin of the building may have a significant influence upon the energy efficiency of the building. If there is a ventilated cavity behind the exterior envelope, then the thermal conductivity of the timber cladding is not of major influence. However, if there is thermal bridging, or the outer envelope is otherwise closely connected to the inner core of the building, then the thermal conductivity of the timber cladding is of greater significance. The thermal conductivity of timber is related to the density, structure and moisture content [158,159,160] and varies depending upon the direction of heat flow, being greater in the longitudinal compared with the radial direction [161]. Since the heat flow occurs through the wood material, the presence of voids in the structure will reduce the thermal conductivity. Thermal modification of wood reduces its thermal conductivity [162,163,164], an effect that is partly related to the lower MC of the thermally modified wood compared with unmodified wood when conditioned in the same environment, as well as the lower density after modification.

As the trunk of the tree expands in girth with new material being laid down by the vascular cambium each growing season, it will envelop branches. If the branches are composed of living wood, the sawn timber will show features which are referred to as live knots (or, sound knots), which are bound into the structure of the wood, whereas if the branch was dead, a dead knot will result. Because they remain fixed in the wood, live knots present less of a problem than dead knots, although they are likely to show through coatings, due to resin-bleed and they can contribute to distortion due to rapid changes in grain angle around the knot, as well as being more susceptible to forming cracks. Dead knots are not bound to the wood and will always fall out in service allowing routes for water behind the cladding, which must be avoided. Ideally, timber cladding boards should not exhibit any knots, but this can be very difficult to achieve in practice. The production of high-quality, knot-free timber requires expensive forestry management interventions to prune branches at various stages of the growth of a tree and is normally only economically justified for the production of high-grade veneer logwood [165, 166]. Juvenile wood is associated with the interior and upper parts of a tree and is particularly prone to distortion on drying, and its presence in timber is to be avoided [167].

Since modern high-throughput sawmills are optimised to maximise volume conversion of logs to timber for economic reasons [78], it is very unlikely that sawing patterns will be customised to produce boards which meet all the criteria required for cladding applications. The only option is therefore to select the best boards through a process known as grading [125]. This inevitably means that high-quality cladding boards will have a higher price.

Durability

The property of durability is not simply related to resistance to attack by biological agents. Indeed, ISO 15686–1 [168] defines durability as the ‘capability of a building or its parts to perform its required function over a specified period of time under the influence of the agents anticipated in service’. This is clearly a much broader definition and is related purely to performance. This chapter begins with considering biological degradation and natural durability before considering other aspects, such as photodegradation and weathering. Finally, the chapter considers how all of this information can be used in predictive models to estimate service life.

Biological degradation of wood

Under suitable conditions, wood can be colonised by bacteria, fungi or moulds, or a combination of these microbiological agents [169,170,171]. Bacterial degradation of wood exposed under conditions commonly experienced by cladding materials is minor and of little consequence. Mould growth occurs on surfaces of materials that are moist for extended periods of time, and although it does not damage the wood, it can lead to a poor surface appearance. Moulds can usually be removed by vigorous washing and brushing of the surface. Although these staining fungi cause only minor damage to the wood, they may adversely affect permeability. From a structural perspective, decay by xylophagous fungi is much more serious and involves direct metabolism of the wood polymeric constituents. Regions of high risk of decay are associated with moisture trapping or continuous wetting.

Fungal decay is loosely classified into white rot, brown rot and soft rot attack. Wood inhabiting fungi require the presence of moisture, oxygen, a favourable temperature range (15–45 °C), a favourable pH range (about 3–6), a digestible substrate (wood) and the ability to access or translocate nitrogen compounds and other essential elements. There are various reports of a minimum wood moisture content required by such fungi, often expressed in terms of water potential [169]. The minimum MC is invariably quoted as being 20%, although the reliability of this assumed threshold may be in doubt and different values have been quoted [172]. Irrespective of the actual MC value, there is a requirement for the threshold to be exceeded for a period of time for decay to be initiated and for decay to proceed this threshold MC needs to be maintained.

Factors affecting colonisation and growth of moulds on wood surfaces include wood species, moisture dynamics of the wood, relative humidity and temperature [173]. Mould fungi mainly belong to the fungi imperfecti group and do not affect the strength of wood, although they have a negative impact upon the aesthetics of the surface. Mould spores are easily dispersed and will colonise many types of surfaces if the conditions are favourable [174, 175]. The optimal growth of mould fungi occurs at a wood MC between 30 to 150% and temperatures between 0 °C and 40 °C [176, 177], and heavy colonisation of surfaces can occur within a few years of installation under favourable growing conditions [178]. Heartwood is less susceptible to mould growth compared with sapwood [179], presumably because the heartwood generally has a lower MC, but there can be a large variation between different wood samples of the same species when exposed under identical conditions. Sapwood is also particularly susceptible to being colonised by sap-staining fungi [180], which preferentially metabolise accessible and non-structural wood components, such as starch [181]. Thermally modified timber (TMT) is less susceptible to moulds and stains, which is probably due to a lack of nutrients (due to thermal degradation) and which also may be related to the reduced hygroscopicity of the TMT [182]. The moisture content of the top 3 mm of the surface is an important factor indicating prevalence of mould colonisation [53]. The length of time that the wood is wet is a significant factor in determining the likelihood of growth of mould or stains and surfaces that are rapidly dried because of prevailing winds are much less likely to show mould growth. Sheltered parts of a building where there is little airflow and a high humidity microclimate are areas of high mould susceptibility [183].

Although uncoated wood is more susceptible to mould growth because the porous wood material can act as a moisture reservoir, coated wood can also be colonised by moulds, especially if the coating does not contain biocides [178]. With the declining use of biocides in coating products as a result of the introduction of the Biocidal Products Regulation, there is an increased risk of coatings being susceptible to mould growth [184]. There are differences in the rate and extent of mould growth between different coating systems (e.g. solvent-based, water-based), surface roughness and hardness are also important factors [185]. Moulds can penetrate some coatings and colonise the interface between the paint film and the substrate [186].

Natural durability

The natural durability of timber is defined according to the European standards as being ‘the inherent resistance of wood to attack by wood-destroying organisms’ EN 350 [187] and is determined based upon field tests (EN 252 [188], EN 330 [189], DD CEN/TS 12,037 [190]), or laboratory tests against basidiomycete fungi in pure culture (EN 113 [191]) or fungal cellar (ENV 807 [192]), against insects (EN 20–1 [193], EN 20–2 [194], EN 46–1 [195], EN 46–2 [196], EN 49–1 [197], EN 49–2 [198], EN 118 [199]) or marine organisms (EN 275 [200]) [201, 202]. Natural durability against biological agents is determined from these experimental tests by comparison to a reference wood species, and the durability is calculated, based upon a ratio of the property changes of the test species against the reference species using methodologies explained in EN 350. Classifications of natural durability to wood-destroying fungi are given using a five-class system (EN 350). It is important to note that these Durability Classes relate to heartwood only and that the sapwood of all species should be considered to be in Durability Class 5 (non-durable) unless there are specific data indicating otherwise. It is also necessary to be aware that the classification of the durability of species gives an indication of the performance of the wood in ground contact situations (Use Class 4 as defined in EN 335 [69]). In terms of insect attack, species are classified as being durable or susceptible. For resistance to marine organisms, species are classified as durable (D), moderately durable (M) or susceptible (S). The use of standards which determine performance in conditions which are more appropriate to ground contact situations is not readily applicable to building envelope situations, and there is a need to develop tests which are more representative of the actual exposure conditions and hazards encountered [203, 204].

Wood in service is subject to microbiological attack, and the risk of decay is increasing as the effects of climate change become more influential [205]. Although there is clearly a link between the moisture content of wood and susceptibility to decay, the relationship is complex and not fully understood [172]. In order to properly understand and predict the durability of wood in service conditions, it is necessary to take account not only the inherent durability of the wood, but also environmental conditions and the ability of wood to take up and hold water [206]. The modelling of durability using a dose–response model requires knowledge of the daily averages of wood temperature and wood moisture content [86]. The exposure dose depends upon factors describing the effects of driving rain, local climate, shadowing effects, distance from ground, as well as design features. Moisture content fluctuations, especially in the surface layers, are particularly influenced by driving rain conditions, but these data require hourly rainfall and mean wind speed data, which are not usually obtainable from weather observing stations [207]. Service life prediction is one of the most important research challenges in this subject area, especially developing predictive methods that do not require constant monitoring of the structure.

Photodegradation

Of the macromolecular constituents of wood (cellulose, hemicellulose, lignin), only lignin strongly absorbs UV and visible light [208]. Lignin contains a number of chromophoric groups that are responsible for this sorption behaviour (α-carbonyl, biphenyl and ring conjugated double bonds) [209, 210] (Fig. 6).

Chromophoric groups associated with the lignin polymer [211]

Although lacking chromophores initially, the oxidation of carbohydrate content in the wood leads to the gradual yellowing of these components due to the presence of the created carbonyl chromophores. Nonetheless, the principal photodegradation pathways of wood involve the lignin [212], although extractives can also participate in photodegradation reactions in ways that are not fully understood [213]. Irradiation of lignin with UV light creates long-lived radicals which are able to migrate through the structure [214]. The principal species created are phenoxy radicals which readily transform into quinoid structures [215]. Photodegradation is accompanied by cleavage of β-O-4 linkages, resulting in the creation of lignin fragments; this reaction is accelerated in the presence of oxygen [216]. Chain scission results in the formation of a lignin network with higher mobility, which accounts for the observation that photo-degraded lignin exhibits increased fluorescence compared with undegraded [217]. Water sorption behaviour is also affected by UV exposure or outdoor weathering [218]. The simplest way of protecting wood from photodegradation is to apply opaque coatings, but this conceals the appearance of the underlying wood, which is often used as part of the design aesthetics of the building. There is an unfulfilled demand for clear coatings which preserve the appearance of the underlying wood for extended periods of time without regular maintenance. Furthermore, there is currently much more interest in using uncoated timber for building envelopes.

Weathering of wood

Weathering is a combination of biotic and abiotic degradation mechanisms acting on the wood surface. Although during initial stages of outdoor exposure the wood may darken and the colour move towards yellower or browner hues, this is only a temporary development and the wood will begin to bleach after a few months’ exposure to solar radiation. The rate at which these changes occur depends very much upon the location of the wood (e.g. shaded, full-sunlight, vertical, angled), the species, the intensity (e.g. location with respect to latitude, altitude, as well as effects due to clouds or mist, etc.) and time of exposure to solar radiation (including seasonal factors) [219]. Continued exposure to solar radiation leads to degradation of the lignin with the production of fragments which act as nutrients for moulds and disfiguring fungi [220] and also leads to an increase in crack formation in the exposed wood [37]. As weathering progresses, the bleached surface region of the wood develops a grey colour as the wood is colonised by moulds and staining fungi (e.g. Aureobasidium pullulans, Sclerophoma pithyophila). The extent to which this occurs depends upon exposure conditions. As was previously noted, in early stages of exposure, the starches remaining in the parenchyma cells of fresh wood can act as a nutrient source for blue stain fungi, leading to characteristic discolouration of the sapwood.

As photodegradation of the wood proceeds, the loss of lignin from the wood surface results in the loosening of cellulose-rich wood fibres leading to gradual erosion of the wood surface. This erosion process is accelerated somewhat by the removal of the loosened wood fibres by wasps which use the fibres for the material for nests [221] as well as abiotic factors, such as rainfall and wind erosion, including wind-blown sand in maritime and desert regions [222]. In colder climates, surface erosion occurs through the abrasive action of wind-blown ice particles. The rate of erosion is higher in softwoods (5 to 10 mm a century) compared with hardwoods (2 to 5 mm a century) [223] and leads to ‘grain raising’, especially in softwoods, where the earlywood is eroded faster than the latewood [224]. Vertically oriented boards show lower rates of erosion, compared with horizontally or angled boards [225].

The overall result of weathering is the creation of what is often referred to as a silvery-grey driftwood appearance of the wood; an aesthetic that is sometimes deliberately encouraged, especially if a low environmental impact cladding system is required. However, achieving even weathering may be challenging and often the surface remains a mix of different shades of brown, grey and black (Fig. 7).

Mould growth on wood surfaces is a very important factor which can negatively affect the appearance of wood cladding and does not normally feature as part of accelerated weathering tests, which is a major disadvantage, especially when relying on such tests for prediction of service life [226]. Mould growth is discussed in detail earlier in this chapter in the section ‘Biological degradation of wood’.

Constant wetting and drying cycles result in the formation of surface cracks which permits the ingress of water further into the material. In uncoated wood, changes in moisture content of the surface occur rapidly with varying weather conditions, but deeper layers are not subject to such rapid changes, resulting in stresses between the surface and bulk. Depending upon the geometry of the wood element [84], these cracks can eventually penetrate quite deep into the wood and provide pathways for moisture ingress and microenvironments for the development of fungi. The formation of checks in exterior exposed wood can be moderated by the application of micro-machined grooves of a specific geometry [227], which reduces the strains that develop at wood surfaces during wetting and drying cycles [228].

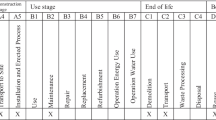

Service life prediction

When choosing building cladding systems, it is important to have knowledge of the performance implications so that this can be factored into life cycle costing (LCC) and life cycle analysis (LCA). In order to inform these choices, it is necessary to have reliable predictive models. The prediction of service life of timber products requires the use and interpretation of accelerated tests, where the risk factors, such as moisture content and temperature, can be combined with timber durability indices to determine performance [31, 229]. There is considerable variation in the predicted service life for timber claddings, and many factors can influence the performance, with wide variations reported. For example, estimated service lives of timber cladding have been quoted which vary from ‘more than 10 years’ to ‘more than 60 years’ [27]. These uncertainties will inevitably negatively impact the accuracy of LCC and LCA. This may cause specifiers to choose other materials which have more predictable performance.

Estimates of service life can be made by the use of accelerated tests and applying the appropriate correction factors [230]. Such models are based upon the known durability properties of the material, environmental factors and design considerations. Simple approaches to determining the service life of building elements include the factor method, as described in ISO 15686–1 [168], which are readily applied [231]. However, factor-based methods have been criticised because they do not adequately consider nonlinear relationships between such things as detail design and climatic variation. For this reason, a study was conducted on the development of a semi-empirical moisture model for service life prediction of wooden elements. A model based upon Fick’s second law was developed to predict the moisture content of rain-exposed wood [232], and the onset of decay was determined by using two dose–response models.

More realistic and complex predictive tools adopt probabilistic approaches, which may be too complex to apply in real-life situations. In both cases, the relevant information may not be available, or available in sufficient detail to make accurate predictions. In Europe, the WOODEXTER project developed a useable performance-based model taking into account climatic conditions and material durability [48]. In this model, a limit state was defined which represents the onset of wood decay. Using this approach, the exposure can be expressed in a function that takes into account the local and global climate, the design of the element and the surface treatment employed. Meanwhile, the material resistance can be represented as a response to the exposure conditions independent of the design, using a dose–response model [233]. These attempts to predict service life by applying dose–response models consider wood moisture content and temperature as factors influencing wood decay [234]. However, the fluctuating moisture content of cladding boards in real-life service conditions does not necessarily reflect assumptions made about durability, which are based upon laboratory conditions of constant moisture [92]. Furthermore, differences in moisture content in exterior cladding depend on factors such as roof overhang and distance from ground [50], and these details must be incorporated into the models. Other predictive models for wood structures have been developed in the European project ‘DuraTB’ (Durable timber bridges) and the Swedish ‘WoodBuild’ project. These models are very much influenced by the wetting behaviour (influenced by weather and specifics of design) and susceptibility to moisture of different wood species and treatments; although for timber bridges, other factors, such as dynamic and static loads, are also important [235].

Wood degradation can be affected by many other factors than biological agents, and these can influence the ability of a wood-based product to perform its required function. Once the product cannot fulfil its required function, it is taken out of service. This defines its service life. This is a much broader and more appropriate definition of durability. The wood may be susceptible to the effects of moisture, which can lead to decay, or warping, resulting in the loss of function of a floor covering, or cladding (for example). The wood may weather in such a way that it is no longer aesthetically pleasing. The owner of a property may simply not wish to repaint the house every few years and timber cladding may be replaced for aesthetic reasons even though it remains fit for purpose. This is a major factor in determining service life. The use of a product may be terminated long before its designed service life because of a decision based upon a qualitative appraisal by the owner of the product [234]. The main criteria leading to a poor perception of wooden cladding materials subjected to weathering are the development of mould and colour changes, especially where the visual changes are localised or uneven [226].

The long-term decay risk of timber products is often predicted through the use of a climate index, which will change as a result of global warming [236,237,238,239,240]. However, when modelling of weathering was undertaken using a climate index, poor correlation was found using most indices for different sites in Europe in a round robin study for nine different locations in Europe [241]. Although a climate index may potentially be used to predict an overall decay risk in a population of buildings in a country or region, and undoubtedly has an influence, much more detailed approaches are actually required in order to accurately predict the decay risk in a building, due to many confounding factors [242]. The importance of design details and location is hugely influential.

As noted earlier, the choice of material for a building envelope has to take into account many factors apart from up-front economic costs. The whole life cycle cost includes issues, such as service life, maintenance and replacement, influence on building energy performance, as well as environmental burdens associated with these choices. For this reason, there has been research conducted into the potential for the use of multi-criteria decision-making (MCDM) tools in order to inform these decisions [243]. Factors influencing the choice include cost of materials, installation costs, availability, maintenance requirements, aesthetics, environmental impact, end of life and energy performance of the building [244]. Although, in principle, the use of such tools leads to an optimal decision regarding the façade system that is chosen, in fact it has been shown that different MCDM methods can produce different ranking outcomes, so that value judgement still plays a role [245].

Methods for protecting wood

Coatings to protect against weathering

Moisture content of the wood is an important factor affecting the durability, and one way of moderating moisture uptake of wood in service is to apply a protective coating [246], preferably prior to installation, but as soon as possible thereafter if this is not possible [247]. Fluctuations in MC in coated wood cladding systems are influenced by the film thickness, porosity, durability and colour of the coating systems employed [248]. According to EN 971–1 [249] (superseded by ISO 4618 [250]) a coating is defined as: ‘a product, in liquid, in paste, or powder form, that, when applied to a substrate, forms a film possessing protective, decorative and/or other specific properties’. Coatings may be broadly divided into paints, varnishes and lacquers, stains and lasures, oils, polishes and patinas [251]. Coatings on exterior wood surfaces have two main functions: (i) to give an aesthetically acceptable appearance and (ii) to provide protection of the wood against degradative agents. The ideal coating for a wood surface in exterior conditions should have the following properties [252]:

-

be permanently flexible but tack-free,

-

show excellent blocking resistance and hardness (or ‘stackability’),

-

exhibit good adhesion to the wood surface in both wet and dry conditions,

-

ease of formulation,

-

low environmental impact,

-

long-term weathering stability,

-

have high resistance to blushing in the case of clear coatings,

-

have low maintenance requirements.

Raw materials for wood coatings comprise natural resins/oils/waxes, cellulosic-based film formers, alkyds, isocyanates, amino resins, polyester resins, acyclic resins, vinyl resins and epoxy resins/esters, which are used as binders [251].

Modern formulations used for exterior wood coatings are often based upon water-borne acrylic dispersions, water-borne alkyd emulsions, or high solids (low volatile organic compound, VOC) alkyd systems and oil-based paints [253]. High VOC solvent-based systems have been mostly replaced in many European countries [254], because of environmental and health concerns [255]. The use of VOCs in paints and varnishes is covered in European Directive 2004/42/CE (on the limitation of emissions of volatile organic compounds due to the use of organic solvents in certain paints and varnishes and vehicle refinishing products and amending Directive 1999/13/EC). This requires that the VOC content of paints and varnishes should: ‘be reduced as much as is technically and economically feasible taking into account climatic conditions’. Use of high VOC paints is not banned, but it is mainly restricted to use in industrial applications with controlled environments.

In order to prevent cracking of the film, the coating should be able to cope with dimensional changes of the wood substrate, but this can be a challenge. If the coating is sufficiently flexible, then it will be able to follow the dimensional changes in the wood. However, there is a risk that a more flexible film will be softer (low glass transition temperature, Tg), less resistant to abrasion and tacky or exhibit blocking (where overpainting results in removal of a lower painted layer), so there is a balance to be struck. To some extent, the contradictory requirements can be met by introducing some cross-linking in the film structure, but this can increase costs and adversely affect pot life. Furthermore, exposure to environmental stressors, such as solar radiation and rain, will lead to irreversible changes in the properties of the coatings, which may consequently lose flexibility over time.

Acrylic binders for wood coatings are usually synthesised from a ‘soft’ (e.g. ethyl acrylate) and a ‘hard’ monomer (e.g. methyl methacrylate). By appropriate selection of the monomer composition, it is possible to control the polarity of the binder. Low polarity binders exhibit good water resistance, but the introduction of functional groups which are capable of hydrogen bonding will improve adhesion to the wood substrate [256, 257]. Adhesion is also promoted by the use of small particle sizes (smaller than 100 nm) which allows for penetration into the wood surface to some extent. By appropriate design of particle morphology, it is possible to include both ‘hard’ and ‘soft’ polymers in a core/shell system. Other particle structures are also available [252]. Film forming in acrylic systems occurs by evaporation of water followed by coalescence of the particles accompanied by interdiffusion of the polymers [258].

Alkyd paint systems are based upon polyester backbones, produced from difunctional carboxylic acids and polyfunctional alcohols, which have pendant fatty acids attached. Film forming in alkyd systems is due to solvent evaporation and oxidative cross-linking to form a polymeric network, which takes place due to the presence of bound unsaturated fatty acid ester moieties [259]. However, this cross-linking process is slow and to produce acceptable drying times various catalysts are added to the paint formulation, of which cobalt (II) carboxylates are widely used. However, these compounds are under investigation due to health concerns [260], prompting paint manufacturers to seek alternatives [261]. Modified alkyd hybrid systems are also available, phenolic resins or poly-siloxanes are grafted onto the polyester. Substitution of the fatty acid tails with styrene, acrylates or isocyanates is also used to produce modified alkyds [262, 263].

Historically, most paint systems used naturally derived oils which were delivered in a solvent-based system and an example of this is the use of linseed oil in combination with starch, in Falun red paint (Falu Rodfarg), which is still used for painting wooden clad buildings in Finno-Scandinavian countries. These naturally derived oils still find considerable use today in applications for exterior use. Oils for paints are derived from triglycerides from seed oils which are composed of a glycerol backbone to which are attached unsaturated fatty acids, containing various number of double bonds [264,265,266,267] (Fig. 8). These glyceride esters are characterised by three main properties:

-

The chain length of the fatty acids,

-

The number of double bonds on the fatty acids,

-

The conjugation between the double bonds.

The oils contain differing amounts of various fatty acids, and depending on the composition (number and location of double bonds), they are classified as drying oils, semi-drying oils and non-drying oils. Only drying oils are capable of forming cohesive paint films on wood, of which the most commonly used is linseed oil, which can be used alone, or as an ingredient in alkyd or polyurethane paint systems. Tung oil is a very reactive oil that is used in exterior varnishes and penetrating oil systems. The drying process with these oil systems involves reaction with oxygen to form hydroperoxides and radicals, which then participate in film-forming cross-linking reactions. [259]. Because the air-drying is a slow process, catalysts (primary driers) are added, which are usually based upon cobalt carboxylates, with the same environmental concerns noted previously [259,260,261].

Apart from the solvent (water, or organic) and drying agents (if used), all paint formulations contain a range of additives to improve performance. These include additives to improve the ‘in-can’ performance and application performance of the coating system (e.g. anti-skinning agents, anti-foaming agents, wetting agents, rheology modifiers, coalescing agents, biocides, pH modifiers and buffers) and additives to improve the coating film performance (matting agents, levelling agents, radical scavengers, biocides, flame retardants, plasticisers, UV absorbers, UV filters, pigments) [251, 268].

Factors that affect the performance of coatings include: dimensional stability of the wood, photostability of the wood surface (with clear coatings), moisture ingress through the coating, coating flexibility (crack formation), coating photostability, coating thickness, bio-resistance, and penetration into the wood surface [269,270,271,272,273,274,275]. Coating performance can also be significantly affected by prior preservative treatment of the wood [276]. In general, solvent-based coatings show lower water-surface contact angles and water uptake compared with water-based coatings [277]. Moisture permeability of the coating is a significant factor since a less permeable coating will reduce the rate of diffusion of moisture into the underlying substrate and thereby slow the rate of dimensional changes.