1. Introduction

Arcing can be considered as a complex electromagnetic reaction process. According to the Under Laboratories (UL) Standard UL1699 [

1], an arc fault is defined as a continuous luminous discharge of electricity across an insulating medium and usually accompanied by the partial volatilization of the electrodes. It is caused by the breakdown of the insulation medium in the electrical circuit, the loosening of the electrical connection, the humidity of the air, the reduction of the insulation strength. The high temperature generated by the arc fault discharge phenomenon is very easy to ignite the surrounding combustibles, which is one of the main causes of electrical fires.

According to the statistics of the national fire and rescue situation of the Fire and Rescue Bureau of the Chinese Ministry of Emergency Management in 2019 [

2], a total of 233,000 fires were reported throughout the year, causing direct property losses of 463 million dollars. Although urban and rural residential fires accounted for only 44.8% of the total, the number of casualties caused by the year accounted for 78.3% of the total. In residential fires, electrical fires are still high. In total, 52% of the fires that have been identified are caused by electrical causes, especially the fires caused by various household appliances and electrical lines.

In July 2013, the International Electrotechnical Commission (IEC) published the international standard IEC 62606:2013 [

3]. In 2014, the American Electrical Code (NEC) [

4] further required installing a combined AFCI in all 15A and 20A circuits in residence. By then, China promulgated the national standard GB/T 31143-2014 [

5] and GB14287.4-2014 [

6].

The arc fault detection device (AFDD) is a new type of circuit protection device to detect and identify the arc fault in an electrical network, and make a trip or alarm action in time to prevent electrical fires caused by the arc. An arc fault is an unintentional dangerous arc in electrical circuitry. According to their location in the circuit, arc faults are categorized into three types: ground arc fault, parallel arc fault, and series arc fault.

Parallel arc fault and ground arc fault are usually caused by short circuits between power lines, which have higher current magnitude. So the traditional short circuit or over current protection systems can detect and make protective actions more effectively. In contrast, the current magnitude of series arc fault is limited by the load in the circuits. Series arc fault’s current is generally the same as the normal working current, or even slightly smaller. As a result, the traditional short-circuit, over-current, overload, and leakage protection technologies cannot effectively detect the series arc fault in the circuit. Therefore, the emergence of AFDD and arc fault detection technology makes up for the vacancy in the closed-loop protection system of electrical safety.

When an arc fault occurs in power distribution network, many physical quantities that can characterize it such as arc sound, arc light, arc voltage, and arc temperature [

7,

8]. However, because the location where the arc fault occurs is unknown, the detection of the above physical parameters is more difficult in practical applications because the sensors used to measure these physical parameters must be installed near the position where the fault arc occurs. The convenience of current measurement makes it an ideal parameter for arc fault detection.

Over recent years, relevant researchers have conducted extensive research on series arc fault detection.

The research on the mathematical model of arc fault is helpful to understand the generation principle of arc fault, and it is also the basis of arc fault identification. Liu et al. [

9] and Qu et al. [

10] improved the Mayr and Cassie arc models and optimized the parameters of the original arc models. The simulation results are closer to the experimental results.

The assumption of arc model research is stable arcing or high current. Due to the innovation of various household appliances, especially the use of switching appliances widely, the arc fault in low-voltage distribution systems becomes more complex, which makes the research on the model of low-voltage arc faults mostly stay in the simulation stage.

The interests of arc fault diagnosis applications based on machine learning such as discrete wavelet analysis (DWA), support vector machines (SVM), and artificial neural network (ANN) is increasing [

11,

12,

13,

14]. In [

15], the source data are sampled at a rate of 25 kHz for analyzing five typical loads. According to the linear harmonic combination of the loads, these loads were divided into three classes. By then, a specific fully connected neural network is designed for each class to identify the arc. Yang et al. [

16] analyze the frequency distribution of arc fault features when series arc faults occurred in different loads, and pointed out that the frequency distribution characteristics of arc fault mainly is concentrated in the frequency band of 2 kHz to 20 MHz. In [

17,

18], the voltage waveform at the power source is used to implement series arc fault detection. Tisserand et al. [

19] propose a method for identifying series arcs in an AC or DC electrical installations by the algebraic derivative of the current. Lezama et al. [

20] present an embedded system for series arc detection by evaluating the inter-period correlation coefficient of the line current to determine if an arc fault has occurred.

These methods [

11,

12,

13,

15,

16,

17,

18,

19,

20] determine a trigger threshold according to the change of extracted eigenvalues. They are effective in some applications, but the diversity of load makes them lack of reliability and generalization ability.

Most of the literature reported that the frequency band of arc feature signal extraction is within 200 kHz [

15,

20]. Arc current is an ideal parameter for arc fault detection but the measurement frequency band of common current transformer (CT) and hall sensor (HS) is generally from 0 to 200 kHz [

21,

22]. Another reason is that the processing ability of the embedded system is generally less than 1 MHz. However, it must be noted that the frequency components above 200 kHz are still abundant.

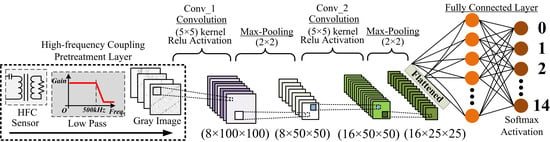

Hence, a novel high-frequency coupling (HFC) sensor is designed for extracting the features of low-voltage series arc faults. It has the advantages of simple structure and wide frequency response range A series arc fault acquisition experimental platform was built, and the HFC sensor is employed to collect the high-frequency feature signals of various loads in arc state and normal state. The signal will be transformed into a two-dimensional gray image. A three-layer artificial neural network based on convolution neural networks is designed to accurately identify series arc and load, as well as the load type.

The following parts of the paper is divided into five sections.

Section 2 presents the characteristics of HFC sensor including working principle, equivalent circuit, frequency response, etc. In

Section 3, the features on series current in time and frequency domain for typical appliances under different working states would be analyzed.

Section 4 designs a detection methodology named HCCNN and introduces its framework, working procedure, and the method for generating data using the HFC sensor.

Section 5 designs the test bench and evaluates the performance of the proposed method with experiments on data sets.

Section 6 presents a comparison between the HCCNN and prior methods.

Section 7 is devoted to the conclusion.

3. Time and Frequency Characteristic Study

In this section, seven different domestic appliances were selected for investigation, including desktop computer, vacuum cleaner, induction cooker, fluorescent lamp, dimmer, heater, and electric drill. Their waveforms in time domain and frequency domain and their grayscale feature image generated from HFC sensor will be analyzed to get multiple perspectives for further identification.

3.1. Time Domain

Figure 3 shows the current waveforms, which have been normalized, for the two circuit states (normal and arcing) from different typical appliances. Current signatures can be downloaded freely on Zenodo. Subgraphs in the left column is the current waveform in normal state, while the right column is that of arcing state. The loads’ working current is obviously different due to different load types.

Figure 3a is the normal working current of the electric heater, with complete sine waveform. When an arc fault occurs, abnormal behaviors such as “flat shoulder” in the zero-crossing, increment of the harmonic component and amplitude distortion impulse might be observed. Particularly, the normal state of dimmer load that has very pronounced “flat shoulder” could imitate the arc state of electric heater, causing misjudgment. An electrical drill may produce several arc features at zero crossing, the same as the vacuum cleaner. The randomness of current variation can also be mimicked by the desktop computer load. Whether in the arc state or normal state, the load of induction cooker has rich frequency components.

Therefore, methods only based on the analysis of the appliances’ current generally cannot content with the requirements of accurate and reliable of arc fault detection, on account of the variety and complexity of arcing.

3.2. Frequency Domain

In order to eliminate the bias issue of instruments and eliminate the influence of power between different load types, the sampling current is Max-Min normalized by (

8) before frequency domain conversion.

where

represents the current time series input,

N is the number of elements in a current series, and

represents the result. The expression of fast Fourier transform (FFT) in discrete form is illustrated by (

9).

where

represents the normalized current time series input,

is the result of FFT operation, and

N is the number of elements in a current series. The current is sampled at a rate of 1 MHz with a digitizer.

Figure 4 gives the spectrum distribution of seven domestic appliances in the arcing and normal current.

It should be noted that the features of arc appear in both low-frequency and high frequency region. In arcing state, the low frequency component for the majority of appliances decreases, while the high-frequency component increases. The change of heater that belongs to the resistive load is the high-frequency region mainly between normal and arcing state. The dimmer is off more than half of the cycle, and its power is relatively small, resulting in a thin line after transform. In arcing state, the frequency of inductive load (vacuum cleaner and electric drill) and induction cooker load shows irregular wave shape.

The spectrum of diverse load types is different in normal and arcing state. If there is switching load or dimmer load in the circuitry, even in normal state, its current also contains quite a lot of harmonic components. It is unreliable to diagnose the arc according to the change of frequency component value in a specific frequency band.

3.3. Gray-Scale Image Generated from HFC Sensor

Seven domestic appliances are sampled with the designed HFC sensor, and the sampling rate is 1 MHz. If the frequency of the residential power distribution network is 50 Hz, 10,000 sampling data will be obtained from every half-cycle, which is considered an identification object. The signal collected by the HFC sensor will generate the feature image through the following three steps. Firstly, the signal data (half-cycle, 10,000 data) are converted into absolute values and normalized. Then the data are mapped to the two-dimensional gray space of 0–255, as shown in (

10):

Finally, the gray image is transposed for better observation and analysis. This step is not necessary and will be removed from the hardware implementation. As shown in

Figure 5, each column represents a kind of load. The normal state sub-images are in the first row, and the arc state sub-images are in the second row.

These sub-images have their own features. For example, there are two stripes on the left and right sides of the arc state image of the heater, which is caused by the “flat shoulder” features of the heater in the time domain, while heater image in the normal state has obvious harmonic fringes and high-frequency noise. The feature image of the electric drill in the arc state will appear pinstripes randomly. However, in the normal state, it is full of noise. The feature images of fluorescent lamps have wide stripes, but there are some harmonics and bottom noise in normal images. The computer characteristic image also has this kind of appearance, but the stripe is lighter. When the induction cooker is in the arc state, its regular image will be destroyed by the arc. With respect to the dimmer, there are obvious cut-off fringes in the middle of the characteristic image of the dimmer due to the switch action of the silicon tube.

Figure 6 and

Figure 7 show the grayscale images of the electrical heater and induction cooker passing through a high pass filter with different cut-off frequencies in normal and arcing state. With the increase of the cut-off frequency of the high pass filter, the background signal brought by the load itself is eliminated in the arc gray image.

If the cut-off frequency is 400 kHz, the characteristic high-frequency signal of the arc becomes weaker, but still exists. Therefore, we can draw a conclusion that although the spectrum of characteristic signal generated by arc fault is vast wide, the rich characteristic information is mainly concentrated within 400 kHz.

5. Experimental Setup and Results

In this section, experiments are carried out to evaluate the performance of the proposed HCCN method. A database consisting of seven domestic appliances was built for training and testing the HCCNN method. In order not to lose generality, the database generated by the electronic load is constructed.

5.1. Experimental Setup

In order to construct a large number of labeled normal samples and fault samples for the convolution neural network, a series arc fault acquisition experimental platform was built according to the Chinese standard GB14287.4-2014 [

6]. The schematic of experimental platform is shown in

Figure 9 The main equipment includes an adjustable arc generator with carbon and copper as electrodes, HFC sensor, PXI Chassis (PXIe-1071, National Instruments, Austin, TX, USA), the digitizer module (PXI-5122, National Instruments, Austin, TX, USA), AC power supply (IT-7626, ITECH, Nanjing, China) and current probe (N2783B, Keysight Technologies, Santa Rosa, CA, USA). A double series EMI filter is used for providing the external trigger signals for the digitizer to collect half-wave data completely, because of the frequency fluctuation of power grid.

The arc generator is ignited between a carbon electrode and a copper electrode, as shown in

Figure 9, is designed. A stepper motor with a programmable logic controller is used to accurately control the distance between electrodes with suitable speed. An IGBT device is connected to two electrodes of arc generator to precisely control the number of series arc by programmable arc generation system.

Figure 10 represents the actual test bench.

The computers used for data processing is a computer with Intel CORE i7-9750H CPU and 16 GB DDR4 memory. The training and test procedure are primarily implemented within PyTorch and achieve comparable results.

5.2. The Arc Fault Database of Typical Appliances

Seven different domestic appliances were selected for experimental verification, including desktop computer, vacuum cleaner, induction cooker, fluorescent lamp, dimmer, heater, and electric drill. Seven typical appliances, corresponding powers, and manufacturers for this platform are illustrated in

Table 2. All raw data are digitized at a sampling rate of 1 MHz using the HFC sensor and each half-cycle signal is considered to be a complete identification object. Because the frequency of the residential power distribution network is 50 Hz, each half-cycle signal will contain 10,000 sampling data, which will be converted into a gray image with a resolution of 100 × 100 pixels. The fully connected layer of the HCCNN method has fourteen output neurons, which correspond to fourteen categories from seven typical appliances.

Each load can be in arc state or normal state. In each state, 1000 half-wave data are collected to form 1000 gray images. Because there are seven typical domestic appliances for experimental verification, the database has a total size of 14,000 gray images. In total, 10% of the images to build the test set were randomly selected, so the size of the test set is 1400, while the size of the training set is 12,600.

5.3. Analysis HCCNN’s Output with t-SNE Method

t-SNE method [

26] is employed to analyze the output of the HCCNN’s ConvNet layer. The output of ConvNet layer is the high-dimensional features of image after convolution operation. The t-SNE method can map each sample into two-dimensional space, and try to separate each category from each other as far as possible.

Figure 11 gives the dimension reduction distribution of the output of the ConvNet layer for seven domestic appliances. The load corresponding to the label of color point group can be found in

Table 2. Odd labels are in arc state (1, 3, 5, 7, 9, 11, 13), and even labels are in normal state (0, 2, 4, 6, 8, 10, 12). The 14 load states shrink into a group and are far away from each other, and even tags and odd tags tend to separate from each other, which indicates that ConvNet layer has a good ability to extract load characteristics and arc features. However, some points are calculated to the wrong location, indicating that a fully connected layer is required for deeper classification.

5.4. The Detection Result of Typical Appliances

The general distribution of the classification confusion matrix of the test data set with exact values is shown in

Figure 12, in which labels and corresponding loads can be found in

Table 2. The green borders indicate that the prediction of the working state is correct, but the prediction of the type is wrong. The red borders indicate that both the working state and the type of appliance are mispredicted.

Table 3 gives the classification results of the HCCNN method. The general prediction accuracy of each sample is 98.36%. In particular, the samples in green borders can be regarded as correct prediction if only concern weather arc fault occurs and ignore the type of appliance. If the type of appliance is not considered, the prediction accuracy of arc detection is further improved to 99.20%.

5.5. The Result of Electronic Load Recognition

Without loss of generality, the HCCNN method is evaluated using a test data set generated by an electronic load (IT-8616, ITECH, Nanjing, China) with adjustable power factor (PF) and CF (CF refers to the ratio of the peak value to the effective value of the periodic waveform). The CF is set to 1.45, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5 and 5.0. The PF is set to 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9 and 1.0. The overall size of the test set is 1600, of which 800 samples are arc state and the other 800 samples are normal state. Under the condition of each parameter, 50 normal and arcing state samples were collected. A script for recording and counting labels will be used to convert fourteen neurons in the HCCNN’s output layer into the arc or normal state.

Figure 13 gives the t-SNE distribution by testing database composed of feature images from the electronic load. The distribution that the selected 500 samples of normal and arcing state cluster into different areas reflects the extensive ability of HCCNN method. The overall recognition accuracy of the test samples is more than 99%.

However, in the multi load’s parallel experiment, the HCCNN can accurately identify the arc and the load type as the load which accounts for the larger proportion of current in the circuit, but the accuracy will be reduced. The probability distribution of the combination of two typical loads is shown in

Figure 14. Four experiments of two load combination (heater and fluorescent lamp, dimmer and fluorescent lamp, vacuum cleaner and desktop computer, electric drill and desktop computer) are used to verify the recognition results of the HCCNN method. For example, the heater load and fluorescent lamp load are combined and an arc fault occurs in the circuit. The predicted value of the heater is about 60% and that of the fluorescent lamp is about 30%. With a high power, the heater can be considered as a masking load.

5.6. Assessment of Embedded System Implementation

The implementation of the HCCNN method is based on a development board NAVIGATOR with a Zynq-7020 chip (xc7z020clg200, Xilinx, San Jose, CA, USA), which is a System-on-Chip (SoC) with a dual-core ARM Cortex-A9 processor and FPGA. Embedded system also employs a high-speed AD (AD9280, Analog Devices, Norwood, MA, USA), which is an 8-bit, 32 MSPS (sampling million times per second) analog-to-digital converter. The embedded system test bench is shown in the

Figure 15.

Figure 16 shows an experimental real-time result. The HCCNN method is able to accurately detect series arc fault generated by the electrical heater and dimmer. The embedded arc detection system will not only send out the tripping signal of the series arc fault but also send out the pulse of the corresponding load type. The proposed diagnosis scheme can detect series arc events at around 40 ms. In fact, a decision is done only after collecting a complete cycle signal, so the average detection time of every half cycle is about 10ms, meeting the requirements of detection time and having a significant margin.

6. Comparison with Prior Methods

Comparison with some related methods in recent literatures, aspects such as the principle, detection accuracy, detection accuracy, sampling rate, etc. are contrasted to evaluate the HCCNN method and show the properties, as summarized in

Table 4.

In respect to principle of diagnosis, HCCNN uses the HFC sensors to collect high-frequency coupling signal. It does not set the threshold value in advance but is based on data supervised learning. It can also detect which load onsets an arcing fault and give a probability distribution. On the one hand, according to the relevant arc fault detection standards, it is not necessary to identify the load type, but it can help users to find the approximate position of the arc fault, which may be a research interest in the future. On the other hand, the load identification method is one of the major technical difficulties of non-intrusive composite load monitoring (NILM). The proposed method can be combined with NILM technology. Through the NILM, the power grid company can understand the actual energy consumption level of various loads of users, master the power consumption situation and behaviors of all kinds of users in real-time, guide users to reasonably arrange power consumption time, and provide energy-saving suggestions.

In the aspect of detection accuracy, the goal of each method is to identify the arc fault perfectly. The HCCNN method has higher precision (above 99%) than other methods and could be even higher by adjusting parameters perfectly. If a diagnosis scheme has an accuracy rate of more than 99%, it is generally believed in meeting the design requirements.

In the aspect of application range, the HCCNN method could be applied to switching, inductive, resistive, capacitive loads—more general than the methods in [

19,

20], which is not available to inductive loads application [

19] or switched mode loads [

20].

With respect to sampling rate, the HCCNN has a high sampling rate, and the highest sampling rate can be set to 16 MS/s because its hardware implementation is based on the FPGA target and high-speed ADC.

7. Conclusions

A study of series arc fault detection using the high-frequency coupling convolution neural network (HCCNN) method has been presented in this paper. The method is dedicated to series arc fault detection in a domestic network (220 V, 50 Hz), and detects arc fault in the following procedure: The gray images of various loads are obtained by using the designed high-frequency coupling (HFC) sensor that has the advantages of simple structure and wide frequency response range. A three-layer artificial neural network based on convolution neural network is designed to accurately identify series arc and load, as well as the load type.

Seven different domestic appliances, including a desktop computer, vacuum cleaner, induction cooker, fluorescent lamp, dimmer, heater, and an electric drill, generate an extensive generalized database for training and testing of the HCCNN method. The identification of arc fault can rely on the frequency information from 10 kHz to 500 kHz.

The experimental results confirm the HCCNN method’s effectiveness and good accuracy for series arc fault detection. If the load type is ignored, the detection accuracy reaches above 99%, and the accuracy of the electronic load test is also more than 99%. Besides, the detection method is currently implemented on an embedded system based around a Zynq-7020 FPGA microcontroller, and the time response is 11 ms for one sample.