1. Introduction

In response to evolving environmental challenges, the European Commission (EC) introduced the Circular Economy Action Plan (CEAP) in March 2020. This plan serves as a strategic framework, aiming to foster sustainable growth, reduce the strain on natural resources, and mitigate waste generation. By implementing the CEAP, the EC intends to create a more sustainable and resource-efficient economy [

1].

The utilisation of marine side-streams presents a promising opportunity to implement the principles of the circular economy. Marine side-streams encompass byproducts that are currently considered waste, arising from diverse marine industries including fisheries, aquaculture, and shipping. These byproducts, instead of being discarded, can be repurposed and transformed into valuable resources, thereby promoting sustainability within the marine sector. The circular economy approach encourages the efficient use of these side-streams, reducing waste and maximising their potential value [

2]. The untapped potential of marine side-streams represents a valuable resource that can be harnessed to generate new value while simultaneously minimising waste within the marine sector [

3]. It is possible to create a more sustainable and resilient marine economy by embracing circular economy principles for the use of marine side-streams [

4].

According to the Food and Agriculture Organization (FAO), since 1961, the global consumption of aquatic foods, excluding algae, has witnessed a steady average annual growth rate of 3%. As a result, per capita consumption reached 20.2 kg in 2020. This surge in consumption has led to a remarkable expansion in the total production of fisheries and aquaculture, reaching a record-breaking 214 million tonnes. Notably, aquaculture contributes to 56% of this total production, highlighting its significant role in meeting the growing demand for aquatic foods [

5]. Given the substantial growth in the consumption of aquatic foods, it is becoming crucial, both from a social and environmental standpoint, to minimise discards and effectively utilise the waste generated within the fishery and aquaculture industries [

6].

In light of the growing concern over waste generated from fisheries and aquaculture, there has been a notable surge in the development of initiatives aimed at reusing and repurposing this substantial amount of waste within the marine ecosystem. The focus is on implementing more sustainable processes that valorise bio-waste, thus fostering circularity within the economy [

7]. In the past decade, a variety of research has been conducted to use the by-products from the aquaculture industry as feed because they contain proteins, minerals, and fatty acids crucial for fish growth [

8].

In marine ecosystems, there are a wide range of organisms that produce a wide range of biomolecules, including high-value compounds. Among the strategies that promote sustainability in the aquaculture industry there are the valorisation of aquaculture waste streams and the production of high-value products such as astaxanthin [

7].

Astaxanthin is a high-value ketocarotenoid that can be synthesised naturally by algae, cyanobacteria, and yeasts [

9,

10,

11]. Providing red pigmentation to aquatic species is a characteristic property of astaxanthin used in the aquaculture industry [

10]. From 2022 to 2027, the global carotenoid market is forecast to grow from USD 2.0 billion to USD 2.7 billion, at a compound annual growth rate of 5.7% [

12]. The global market for astaxanthin is predicted to experience significant growth between 2023 and 2032, with an estimated compound annual growth rate of 9.46%. This surge in demand and market value is expected to propel the market from USD 864.22 million in 2022 to USD 2133.92 million by 2032 [

13]. With a market share of 95%, synthetic astaxanthin currently holds a prominent position in the astaxanthin market. Priced competitively at USD 1000/kg, it outperforms natural astaxanthin, which maintains a smaller market share of 5% [

14].

The use of petrochemical ingredients in the production of synthetic astaxanthin has raised concerns about its safety for food consumption. In response, there has been a remarkable rise in consumer demand for natural astaxanthin in the global market. This surge positions natural astaxanthin as a potentially formidable competitor within the astaxanthin market [

9]. Two major companies, namely Hoffmann-La Roche and BASF, are engaged in the commercial-scale production of synthetic astaxanthin using this process [

10].

The feasibility of producing natural astaxanthin has been established through the utilisation of different organisms. Notably, microalgae species such as

Chlorella zofingiensis,

Chlorococcum sp., and

Haematococcus pluvialis have gained recognition as prominent natural sources of astaxanthin [

15]. Additionally, the red yeast

Phaffia rhodozyma [

16], as well as the bacteria

Paracoccus carotinifaciens [

17] and

Agrobacterium aurantiacum, have also been recognised as astaxanthin producers [

16]. Their unique biosynthetic pathways empower these organisms to accumulate astaxanthin, making them highly valuable for sustainable astaxanthin production [

18]. Out of these organisms,

H. pluvialis and

P. carotinifaciens have been discovered to accumulate the highest levels of astaxanthin [

19]. Currently, only a few companies, like Algatechnologies Ltd., BioReal AB and Cyanotech Corp and ANCI Inc. (Panaferd), are producing natural astaxanthin from algae or bacteria on a commercial scale [

17].

While

H. pluvialis has been extensively studied as a source of natural astaxanthin, there are difficulties in growing it on a large scale. These challenges include slow growth rates, sensitivity to the environment, and the need for labour-intensive extraction processes [

10,

20,

21]. To overcome these limitations and minimise the environmental impact, scientists have investigated alternative approaches utilising microbial production systems.

One particular method involves utilising

Corynebacterium glutamicum, a bacterium that naturally produces a yellow pigment called decaprenoxanthin and which has been genetically modified to produce astaxanthin [

22]. Through the utilisation of the endogenous carotenoid biosynthetic pathway and the introduction of foreign enzymes,

C. glutamicum showcases its ability to efficiently produce natural astaxanthin. This microbial production system brings forth benefits such as controlled and scalable production, offering potential solutions to the challenges associated with microalgal cultivation [

23].

Significantly, the utilisation of

C. glutamicum for producing natural astaxanthin can be combined with the use of byproducts from aquaculture. This integration helps to minimise the environmental impact even further [

24]. Aquaculture side-streams, which consist of waste materials from aquaculture, contain essential nutrients that can be harnessed as a nutrient substrate for the cultivation of

C. glutamicum [

24,

25]. Through the utilisation of these waste streams, the production of natural astaxanthin using

C. glutamicum becomes a more sustainable and resource-efficient process.

The integration of natural astaxanthin production using C. glutamicum and the utilisation of aquaculture side-streams offers an optimistic pathway for reducing the environmental impact of astaxanthin production. This strategy aligns with the principles of the circular economy, emphasising the conversion of waste into valuable resources. It promotes sustainability within the aquaculture industry and reduces the reliance on traditional sources like H. pluvialis.

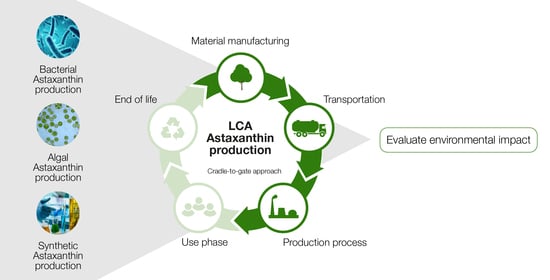

To demonstrate the notable benefits of producing natural astaxanthin with sidestreams and its role in promoting a circular bio-economy, it is essential to employ a methodology that quantifies the sustainability of this process. Quantitatively assessing the environmental sustainability of the product and the processes involved is a key step in achieving the transition to a circular economy [

26]. Employing the Life Cycle Assessment (LCA) as a methodology supports this assessment. With a “cradle to grave” perspective, LCA quantitatively assesses the environmental sustainability of the entire system [

27].

This paper discusses three distinct approaches for astaxanthin production on a laboratory level: the conventional chemical synthesis process, as well as two alternative methods that harness bio-based sources and bio-conversion processes to obtain astaxanthin.

This study focuses on the utilisation of LCA as a tool to assess and compare the environmental implications of three astaxanthin production methods: the innovative bacterial production process with C. glutamicum using aquaculture side-streams, the chemical synthesis process, and the algal astaxanthin production methods. Currently, the literature lacks an analysis of the environmental impacts generated by the production of astaxanthin using bacteria and wastewater as part of the process inputs. The work reported in this paper allows a direct and objective comparison of the environmental performance of the three process solutions modelled using both primary and secondary data. The sensitivity analysis relating to the type of energy source used also allows for a clear indication of the relevance of aspects external to the process (e.g., the source of energy supply) with respect to the final impacts produced. The upcoming sections provide a comprehensive overview of the methodology employed, including the steps, assumptions, and the software utilised for the analysis.

Finally, conclusions are briefly presented.

2. Materials and Methods

In this section, a short description of the procedure and methods which have been used in this analysis are presented.

Employing life cycle assessment (LCA) methodology allows the quantifying of the environmental impacts of products, processes, or services over their entire life cycle. In this study, the LCA was conducted based on the framework provided in the ISO 14040-44 standard for LCA studies [

28,

29]. LCA is composed of four steps: (1) Goal and Scope definition; (2) Life Cycle Inventory (LCI), (3) Life Cycle Impact Assessment (LCIA), and (4) interpretation of results [

30].

The LCA was performed using OpenLCA software v1.11, which is a free and open-source tool for LCA modelling and analysis. For this study, the Ecoinvent v3.7 database has been used as the primary LCA database. This database encompasses a comprehensive collection of life cycle inventory data for a diverse range of materials, processes, and technologies, providing a valuable resource for conducting the LCA.

2.1. Goal and Scope Definition

The goal of the study was to analyse and compare three different methods of astaxanthin production, two of which include producing natural astaxanthin through bioconversion; the third one is the chemical synthesis procedure of producing astaxanthin.

These production methods are: (1) bacterial bioconversion of natural astaxanthin, (2) algal bioconversion of natural astaxanthin, and (3) chemical synthesis of astaxanthin. The different steps which have been used for the analysis are shown in

Figure 1,

Figure 2 and

Figure 3. Moreover, a more detailed description for each method is presented in the Inventory Analysis section.

For the bioconversion processes, the system boundary for the analysis included all the stages of the astaxanthin production process, from raw material production to pigment extraction. The data for each stage of the life cycle according to the “from cradle to gate” approach were collected and analysed by considering all the mass-energy upstream flows. The Ecoinvent database v.3.7 and other public sources were used as secondary input data. Since the analysis was conducted based on the technical unit, equal to 1 g of astaxanthin produced, it is important to note that the data collected for the chemical synthesis of astaxanthin were obtained at an industrial level and downscaled to a laboratory level. Conversely, the data for bacterial and algal astaxanthin bioconversion had already been obtained at a laboratory scale.

A regionalised analysis was carried out by identifying specific energy mixes and investigating different sources of energy feeding the bioconversion and synthesis processes, i.e., conventional energy mix and renewable energy from hydropower plants. The analysis did not take into account the burdens arising from logistics and transportation in the supply chain of raw materials.

2.2. Inventory Analysis

The inventory analysis was conducted using the Ecoinvent database version 3.7. The materials and energy inputs and outputs for each processing method were identified and quantified.

In order to conduct a comprehensive analysis, various inputs were involved including the production of specific chemicals, water consumption, and the electricity consumption during different production stages, the distribution of inputs up to the production plant gate, the procurement of ware supplies, and the management of waste disposal. A comprehensive description of the three astaxanthin production methods aligned with the dedicated list of the input flows and corresponding amounts that were taken into account for the analysis is provided below.

2.2.1. Astaxanthin Production from Aquaculture Side-Streams with C. glutamicum

C. glutamicum is known as a natural producer of carotenoids, particularly recognised for its ability to synthesise the rare yellow carotenoid, decaprenoxanthin.

C. glutamicum exhibits great potential as a carotenoid production host since it already possesses most of the biosynthetic pathway required for synthesising multiple carotenoids. Consequently, over recent years, significant advancements have been achieved to expand the range of carotenoids that can be heterologously synthesised by

C. glutamicum, such as the production of the valuable C40 carotenoid astaxanthin [

22]. In order to improve Astaxanthin production in

C. glutamicum, several genetic engineering strategies has been implemented including improved precursor production [

23], carotenoid biosynthesis deregulation, the prohibition of competing pathways [

22,

23], and the utilisation of a fusion protein of the responsible enzymes CrtZ and CrtW [

31].

Benefitting from

C. glutamicum’s extensive track record as a well-established host for industrial-scale fermentative amino acid production, the first experiments to scale up astaxanthin production from shaken small-scale systems to lab-scale bioreactors were carried out. The outcome of these trials was the successful co-production of astaxanthin with L-lysine in a 15 L fed-batch process [

32].

Unlike astaxanthin production from algae, the C. glutamicum is independent of light or a stress-induced second phase. Consequently, this process can be executed in closed-system stirred tank bioreactors that can be sterilised after each production cycle, minimising the risk of contamination.

To evaluate whether it is possible to turn astaxanthin production using

C. glutamicum into a more sustainable process or not, a liquid aquaculture side-stream was studied as a medium component by Schmitt et al., 2023 [

24]. The utilisation of an aquaculture side-stream for the production of the fish feed additive astaxanthin would open the possibility for circular-economy-based astaxanthin production.

To meet the growing global demand for sustainable seafood production, a significant number of Recirculating Aquaculture Systems (RAS) have been implemented. These systems primarily concentrate on the cultivation of salmon and other Salmonid species, including rainbow trout, which require a combination of freshwater and saltwater environments [

33]. Despite the implementation of internal water treatment cycles in RASs, there is still a residual waste stream generated from the discharged exhausted water that is eventually released into the environment [

34].

Aquaculture side-streams, also referred to as aquaculture effluents, encompass fluids containing solid, liquid, or gaseous waste. These effluents contain organic compounds such as proteins, lipids, carbohydrates, vitamins, and minerals. Additionally, inorganic waste products like NH

4+, NO

2−, NO

3−, bicarbonates, and phosphates tend to accumulate. Notably, nitrogen (N) and phosphorus (P) are the key components originating from the effluents that contribute to environmental pollution [

35].

In the study by Schmitt et al., 2023, [

24] Lumarine AS (Tjeldbergodden, Norway) supplied the liquid aquaculture side-stream derived from an RAS for salmon. Prior to its use as a medium component, the aquaculture side-stream underwent pre-processing steps consisting of centrifugation and sterile filtration. The laboratory-scale experiment for producing astaxanthin through

C. glutamicum from a bacterial source using an aquaculture side-stream (AQ) was carried out in a 2 L bioreactor. As shown in

Figure 1, this process can be described in 5 steps. These steps are: (i) pre-processing of the aquaculture side-stream (AQ), (ii) preculturing of the bacteria, (iii) fed-batch fermentation, (iv) phase separation, and (v) extraction of astaxanthin (

Figure 1). The data used as starting point to estimate the actual data used for the LCA in this study were based on a laboratory-scale experiment with a 2 L bioreactor fed-batch fermentation that led to production of 1 g of astaxanthin.

According to Schmitt et al., 2023 [

24], the best conditions for sustainable astaxanthin production with

C. glutamicum are when using CGXII minimal salts medium [

36] supplemented with 20% (

v/

v) AQ as the main medium, using CGXII concentrate [

36] without any supplementation of AQ as the feed.

Table 1 provides a comprehensive list of input flows and their respective quantities that were considered in the analysis of bacterial astaxanthin bioconversion. The data in the table have been extracted from the experiment conducted by Schmidt et al., and it should be noted that the final production yielded 1 g of astaxanthin.

In

Table 1, the materials marked with a star sign (*) at the end are the proxies which have been used for different chemicals which do not exist in the Ecoinvent Database: methane sulfonic acid is a proxy for MOPS, benzoic acid is a proxy for protocatechuic acid, ascorbic acid is proxy for biotin, and non-ionic surfactant is proxy for Antifoam 204.

2.2.2. Algal Production of Astaxanthin

An excellent natural source of astaxanthin is the freshwater green microalga

H. pluvialis [

19]. The life cycle of this unicellular microalga includes a green vegetative stage and a red cyst stage. Astaxanthin accumulation occurs exclusively during the red cyst stage as a protective response to environmental stresses, resulting in extended production times [

37].

In order to develop an optimised and efficient astaxanthin production system from H. pluvialis, finding out the environmental factors that influence microalgal growth and astaxanthin biosynthesis was crucial. Advancements in the field of bioprocess engineering, such as photobioreactor design, nutrient optimisation, and genetic manipulation, offer improving astaxanthin production from H. pluvialis in a sustainable and cost-effective manner.

By focusing on the optimisation of the environmental conditions to boost astaxanthin production in

H. pluvialis, it was found that light intensity and photoperiod duration are important factors that influence microalgal growth, biomass productivity and astaxanthin yield. Studies have revealed that specific light wavelengths, such as red and blue light, can stimulate astaxanthin synthesis and increase its content in

H. pluvialis [

38].

Another key factor which can affect astaxanthin production in

H. pluvialis is temperature. According to scientific investigations, it has an influence on cell growth, lipid metabolism, and astaxanthin accumulation. The findings of these studies show that optimal temperatures ranging from 20 to 30 °C promote high astaxanthin yields in

H. pluvialis cultures [

39]. Furthermore, variations in nutrient availability, such as nitrogen, phosphorus, and carbon sources, have been investigated as a method to enhance astaxanthin production [

40].

To evaluate the environmental impact of natural astaxanthin production from

H. pluvialis, the methodology and process outlined in the publication by Perez-Lopez et al., 2014, were employed. The utilisation of the closed airlift photobioreactors with artificial lighting in this method enables the precise regulation of light conditions. This approach is commonly used for the production of valuable commodities, as it minimises the risk of contamination [

11].

Table 2 represents the data used for analysing the astaxanthin production from

H. pluvialis, consist of four steps which lead to the production of 1 g of astaxanthin. The first step is “Preparation of the culture medium”, and then the second step is “Cultivation of the microalga”; the third step is “Harvesting”, and the last step is the “Extraction” of the astaxanthin. The University of Louvain’s (Belgium) Bioengineering Group at the Earth and Life Institute conducted lab experiments to explore the cultivation of the microalga, and the extraction techniques were formulated and carried out by the Shannon Applied Biotechnology Centre at the Limerick Institute of Technology (Limerick, Ireland) [

11].

2.2.3. Astaxanthin Chemical Synthesis Process

Based on the most up-to-date information, synthetic production methods still dominate the commercial market for astaxanthin. Leading industrial players like BASF and Hoffmann-La Roche are the primary producers of synthetic astaxanthin. Synthetic astaxanthin commands a significant market share, accounting for approximately 95% of the overall astaxanthin market [

14]. Factors like cost-effectiveness and scalability have played a significant role in establishing the dominance of synthetic production methods in the astaxanthin market. One key distinction between synthetic astaxanthin and its natural counterpart lies in their stereoisomer composition. Synthetic production results in a racemic mixture of all stereoisomers, whereas natural processes typically yield a specific stereoisomer [

41].

Various synthetic strategies have been developed for astaxanthin production. One of the oldest and most widely used methods involves the Wittig reaction, which combines two C

15 phosphonium salts with C

10 dialdehyde [

42]. Additional methods include the hydroxylation of canthaxanthin [

43], a C

10 + C

20 + C

10 synthesis via diethyl ether condensation [

44], and the isomerisation of lutein extracted from marigold to zeaxanthin, followed by oxidation to astaxanthin [

45].

The presence of synthetic astaxanthin in the diets of farmed fish provides a distinguishable characteristic that differentiates them from wild fish.

This distinction can be made by analysing the astaxanthin stereoisomer composition in the fish, as farmed fish primarily consume the synthetic version. The stereoisomers (3S,3′S), meso, and (3R,3′R) are present in a 1:2:1 ratio, respectively, while wild fish almost exclusively contain the (3S,3′S) isomer [

41].

In this study, environmental implications associated with a chemical synthesis of astaxanthin have been assessed using a seven-step process described by Erich Widmer and colleagues [

42]. The required data for conducting the LCA were extracted from Ernst, 2002 [

46]

A 14-step chemical procedure yielding (3S,3′S)-astaxanthin was developed by Kienzle and Mayer, 1978 [

47], and refined to a 7-step synthesis for industrial application yielding (3RS,3′RS)-astaxanthin by Widmer at Hoffmann-La Roche [

42].

The synthesis starts from 6-oxo-isophorone (

Figure 4, #1). In the first three reactions, functionalisation and the subsequent protection of this C9 building block are introduced by transforming it to 2,2,4,6,6-Pentamethyl-7,7a-dihydro-2H,6H-1,3-benzodioxol-5-one (

Figure 4, #2). This is afterwards converted to the C15-Dihydroxyketone 6-Hydroxy-3-(5-hydroxy-3-methyl-3-penten-1-inyl)-2,4,4-trimethyl-2-cyclohexen-1-one (

Figure 4, #3) in a reaction with the easily hydrolysable, symmetric, lithium-salt acetal of C6-Vitamin-A. In a reaction flow with zinc, glacial acetic acid, hydrogen bromide, triphenylphosphine, and 1,2-Epoxybutan, [(4E)-5-(4-Hydroxy-2,6.6-trimethyl-3-oxo-1-cyclohexenyl)-3-methyl-2,4-pentadienyl]-triphenyl-phosphonium bromide (

Figure 4, #4) is yielded. Followed by a double Witting-condensation, these are fused to C

10-Dialdehyde (

Figure 4, #5) in the presence of sodium-methanolate and 1,2-Epoxybutane, yielding (3RS, 3′RS)-astaxanthin [

42,

46]. The described synthesis steps have been modelled and used for an environmental assessment of the production of 1g of synthetic astaxanthin.

Since the chemicals which have been mentioned in

Table 3 did not exist in the Ecoinvent database (except for deionised water), they have been modelled based on their specific synthesis.

2.3. Impact Assessment

Using the CML 2001 method, each abovementioned process’s gathered data were individually transformed into environmental impact factors. The impact potentials (or impact categories) assessed according to the addressed CML method were abiotic depletion (ADP), acidification (AP), eutrophication (EP), global warming (GWP), ozone layer depletion (ODP), human toxicity (HTP), freshwater aquatic ecotoxicity (FEP), marine aquatic ecotoxicity (MEP), terrestrial ecotoxicity (TEP), and photochemical oxidant formation (POFP) [

48].

Notably, due to the focus on astaxanthin production, all the environmental burdens associated with each production method were fully allocated to the amount of astaxanthin produced within each process.

3. Results and Discussion

The

Table 4 represents the environmental impact of the production of 1 g of astaxanthin for the complete production process (cradle-to-gate perspective) at a laboratory scale using three different methods: bacterial bioconversion, algal bioconversion and a chemical synthetic process. The first two processes belong to the bioconversion processing type, while the last one refers to the most common chemical process.

According to the result of the LCA, it was found that 1 g of astaxanthin, when produced through chemical synthesis, has a lower environmental impact across all impact categories, except for Ozone Layer Depletion (ODP), when compared to the same quantity of astaxanthin obtained through the other two bioconversion processes.

Since synthetic astaxanthin currently dominates the market due to its established production infrastructure and lower costs [

9,

10], the data used were for a process at the industrial scale, rather than the laboratory one. Therefore, its impacts were proportioned to 1 g of astaxanthin, which represents a dramatic downscaling of the real batch process yield from the industrial scale to the (virtual) lab scale, but still inherently keeping the industrial process efficiency. According to Pérez-López et al., 2014 [

11], in comparison to the lab-scale process, the pilot scale process demonstrated significant improvements in terms of environmental impact, and by upscaling the process from laboratory level to pilot scale the environmental impact of the process will not increase proportionally [

11]. The environmental burdens associated with the pilot-scale operations were found to be substantially lower, ranging between 25 and 122 times less than the corresponding impacts observed at the lab scale. These findings indicate that in the case of the considered bio-conversion lab-scale processing, the process of upscaling from the lab to the pilot scale also has the potential to greatly reduce the specific environmental footprint of astaxanthin production (environmental impacts per product unit mass produced). The significant decrease in environmental impacts can be attributed to various factors, including process optimisation, improved resource efficiency, and enhanced waste management strategies implemented at the pilot scale. This highlights the importance of transitioning from lab-scale to pilot-scale operations to achieve more sustainable and environmentally friendly astaxanthin production. This explains the relevant difference between the environmental impact of astaxanthin production using the chemical synthesis process versus the two production methods for natural astaxanthin.

A direct comparison between the two bioconversion processes (the proposed innovative method based on bacteria and the one exploiting algae) reveals that the bacteria-based processes can be an interesting, sustainable process option.

The most commonly used viable source for natural astaxanthin production is the microalga

H. pluvialis. Its high astaxanthin content and ability to accumulate astaxanthin under stress conditions make it a preferred source for natural astaxanthin production [

10]. Furthermore, the method of Schmitt et al., 2023 [

24], also produces natural astaxanthin from a bacterial source, and therefore a comparison of these two methods from an environmental point of view was conducted and the results are shown in the following diagram (

Figure 5).

This comparison, based on the same 1 g mass, reveals that algal astaxanthin production is associated with more environmental impact categories with higher values, with respect to the

C. glutamicum method, which exploits aquaculture side-streams as a feeding source for bacteria. A deeper comparative analysis aimed at assessing the main source of impacts shows that the processing method proposed by Schmitt et al., 2023 [

24], requires more direct energy input compared to the method proposed by Perez-Lopez et al., 2014, precisely when referring to the unit batch process yield: 159.75 kWh vs. 143.9 kWh, respectively.

When comparing the bacterial bioconversion to the algal process, it can be observed that the former exhibits higher energy consumption, resulting in a significant impact on various environmental categories. Specifically, the bacterial method leads to a 64% increase in eutrophication (EP), a 15% increase in freshwater aquatic ecotoxicity (FEP), a 8% increase in global warming potential (GWP), and a 19% increase in marine aquatic ecotoxicity (MAEP) impact category values.

Bacterial astaxanthin production using aquaculture side-stream can be considered a promising environmentally friendly method because it shows lower environmental impacts on abiotic depletion, acidification, human toxicity, ozone layer depletion, and photochemical oxidants formation compared to algal bioconversion. Within this circularity framework, aquaculture side-streams provide a sustainable source of nutrients, which can be valorised by feeding the astaxanthin production process while avoiding the burden of aquaculture waste management and the waste-associated environmental impacts.

In order to provide a more comprehensive understanding of the comparison between the algal and bacterial sources,

Figure 6 visually depicts the variations in the environmental impact percentages associated with producing 1 g of astaxanthin from these respective sources. The graph is constructed by taking the environmental impact of the algal source as the reference point (0%) and examining the changes that would occur if astaxanthin production were to shift to bacterial resources. The differential impact is represented by the blue bars in

Figure 6, offering a clear visualisation of the disparities between the two sources.

On average, the implementation of Schmitt et al.’s approach [

24] in the production of 1 g astaxanthin leads to a reduction of approximately 12% in negative environmental impacts across all 11 categories analysed, as compared to the use of Pérez-López et al.’s [

11] method.

In order to determine the most significant environmental impact sources and to identify the hotspots for the selected impact categories during the astaxanthin production process with

C. glutamicum employing aquaculture side-streams, a detailed breakdown of the contribution of each production stage was conducted. The following diagram (

Figure 7) illustrates the contributions to impacts associated with the different stages of the bioconversion process.

The analysis results highlight that “Fed-batch Fermentation” (Step 3) plays a dominant role in the environmental impacts associated with astaxanthin production, making a substantial contribution of over 49.7% to all impact categories examined. Following closely, “Bacteria Preculturing” (Step 2) emerges as the second major contributor to the overall environmental impacts. In contrast, the first step of the experiment, “Preprocessing of the Aquaculture Side-stream”, exhibits the least significant impact among the stages assessed.

Figure 7 indicates that the most impactful step is the one requiring more electrical energy, which turns out to be the environmental hot spots, leading to a notable environmental burden. Nevertheless, the positive fact is that these impacts may be considerably reduced by providing a greener energy source to feed the critical processing step (Step 3). Indeed, these environmental impact sources are regarded as “compressible” or avoidable, contrary to inherently unavoidable impacts of other processes associated with specific chemicals essential (unavoidable) to the synthesis process.

In this sense, there is evidence that the bacteria-based processing method exhibits high potential for sustainability improvement. To fully leverage this potential, it is crucial to continue optimising the bacterial process. By doing so, the industry can transition towards more environmentally friendly and sustainable practices, aligning with the broader objective of fostering a greener and more circular economy.

Sensitivity Analysis

In order to address this statement better, a sensitivity analysis has been conducted on the source of the electrical energy which has been used in the production of 1 g astaxanthin. The generation of energy via a hydropower plant that is harnessing water as a renewable resource was assessed as an alternative source of energy and compared with the conventional energy mix.

By using this new source of energy, the same analysis as before was conducted. The following table illustrates the environmental impact of the production of 1 g of astaxanthin for the complete production process (cradle-to-gate perspective) at a laboratory scale using three different methods: bacterial production, algal production, and chemical synthesis.

Table 5 reveals that by optimising the source of energy, the environmental impact of the production of natural astaxanthin will be comparable with the chemical synthetic process. As mentioned before, the higher energy consumption in the production of 1 g of astaxanthin from both natural sources gives the opportunity for optimisation, making it attractive for scaling up.

According to the findings presented in

Table 5, it is evident that the algal method demonstrates superiority in categories such as eutrophication, freshwater aquatic ecotoxicity, and marine aquatic ecotoxicity. On the other hand, the bacterial method excels specifically in the ozone layer depletion category. Consequently, it is no longer valid to assume that chemical synthesis remains the optimal choice for all categories. In light of this, after modifying the energy source, making a well-informed decision on the best production method requires the careful evaluation and consideration of specific requirements.

In

Table 4, the environmental impacts of three methods used to produce astaxanthin modelled using conventional sources of energy are represented. The result of remodelling all the methods by changing the energy source is shown in

Table 5. By calculating the difference between the corresponding values of these two tables, the impact of the switch towards a renewable source of energy was obtained as a percentage. These calculated percentage values are presented in

Figure 8.

The obtained differential percentages provide valuable insights into the comparative environmental performance of the production methods. By analysing the data, it is possible to identify the methods that exhibit higher or lower changes in environmental impacts relative to the baseline values after using renewable sources of energy.

According to

Figure 8, on average the environmental impact of all three methods, bacterial production, algal production, and the chemical synthetic process, decreased by 96.9%, 77.1%, and 12.3%, respectively.

Upon examining the outcomes of this sensitivity analysis, particularly regarding the transition from laboratory-scale to industrial-scale operations, it becomes apparent that there is substantial potential for energy savings and diminished environmental impact in using an aquaculture side-stream for the production of astaxanthin via C. glutamicum.

Furthermore, through the optimisation and upscaling of the proposed process, it becomes feasible to implement more energy-efficient technologies and practices, thereby reducing the electricity consumption per unit of astaxanthin produced. Indeed, energy savings and related environmental impact reduction are expected thanks to the transition from lab-scale to industrial-scale operations (see [

11]). The implementation of more efficient equipment, process modifications, and energy management strategies can lead to a considerable reduction in electricity consumption during the astaxanthin production process.

Overall, these findings provide valuable insights into the environmental performance of the astaxanthin production process. They highlight the importance of optimising specific stages of the production process and promote the systematic application of the life cycle perspective based on quantitative evidence, which will enable effective astaxanthin production process optimisation aiming at minimising the associated environmental impacts.

4. Conclusions

The results of this study indicate that the circular model proposed for astaxanthin production via bacterial bioconversion using an aquaculture side-stream is a promising pathway to a more sustainable future. A scaled-up bacterial astaxanthin production process exhibited significant potential in reducing the specific environmental footprint associated with astaxanthin production, compared to alternative methods. However, according to the results obtained for almost all impact categories, with the exclusion of the ozone depletion potential, the chemical synthesis approach, to date, remains the best environmentally sustainable method for the production of astaxanthin. The bacterial and algal bioconversion methods both exhibited a relatively higher environmental impact, with little disparity between them. This elevated environmental burden primarily stems from their substantial energy consumption.

The primary data of the bacterial bioconversion process presented in this work referred to lab scale process data obtained through experimental direct measurements. Regarding the comparative assessment, data related to the algal and chemical synthesis processes are dependent on previously published cited works on which the comparative assessment of the different bioconversion and chemical synthesis processes addressed relies.

This work was able to shed light on the relevance of optimising specific parameters—firstly energy efficiency, but also bioconversion efficiency and chemical yield—in the production process at industrial levels of astaxanthin. In fact, for all those processes in which energy consumption is not the main cause of environmental impacts, it is of greater importance to increase and aim at optimising the bioconversion efficiency and/or the final chemical yield.

Conversely, it becomes relevant to reduce energy consumption when this parameter is very relevant on the final environmental impact. The impact reduction can be obtained by making the process more efficient, but also by resorting to renewable energy sources. In fact, the environmental performance of astaxanthin’s production process, based on bacterial and algal bioconversion, can be greatly improved by using hydroelectric electricity.

Future developments of this work will be aimed at refining the functional unit definition by identifying astaxanthin’s functional key performance indicator(s) (KPI). The functional unit will therefore be defined based on the actual properties as a colorant and/or antioxidant of this carotenoid. By obtaining direct measurements and an experimental characterisation of such KPIs, a better representative environmental comparative analysis will be possible.