Cotton Woven Fabrics as Protective Polymer Materials against Solar Radiation in the Range of 210–1200 nm

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. The Effect of Type of Weave and Relative Fabric Density (Tightness) on Solar Transmittance

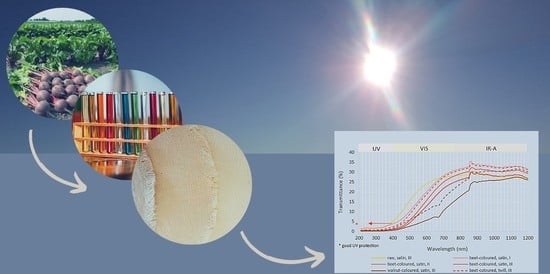

3.2. The Effect of Eco-Friendly Dyeing on Solar Transmittance

- Taking into account the criteria that only those fabrics which transmitted less than 5% of UVA and UVB radiation offer good UV protection, the following samples can be classified as fabrics with adequate solar protection: all beet- and walnut-coloured samples, except plain-coloured woven samples, raw twill samples at level III of relative fabric density, and raw satin fabrics at levels II and III of relative fabric density;

- The walnut-coloured satin woven fabric at level III of relative fabric density provides the best solar protection with the lowest transmittance in all three regions (UV, VIS, IRA);

- Beet- and walnut-coloured twill samples at level III of relative fabric density offer better solar protection in comparison to beet- and walnut-coloured satin samples at level I of relative fabric density;

- Walnut-coloured twill woven fabrics at level III of relative fabric density provide better protection in the VIS region (from 550 nm) in comparison to beet-coloured satin woven fabrics at level III of relative fabric density, although the last-mentioned fabric is woven with a higher nominal warp/weft density. In contrast, within most of the IRA region, the beet-coloured satin woven fabric becomes more suitable as a protective material;

- Walnut-coloured satin samples at level III of relative fabric density (Figure 4) have the lowest transmittance, followed by beet-coloured and raw woven samples in the UV region. The difference in transmittance regarding the colour is more evident in the VIS region. In contrast, the difference is decreased in the IRA region, and from 1100 nm, there is only a slight difference between coloured samples;

- Depending on fabric structure, fabrics with light-shaded colours provide better IRA protection (and thermophysiological comfort). The IRA transmission of raw (beige) satin woven fabrics was lower than beet-coloured (in the whole region) and walnut-coloured (in most of the IRA region) twill fabrics.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hatch, K.L. Textile Science; West Publ.: Minneapolis/Saint Paul, MN, USA, 1993; pp. 2–13, 472. [Google Scholar]

- Zabetakis, A. Textiles for protection against solar UVR, weather conditions and fire. In Proceedings of the International Textile Clothing & Design Conference: Magic World of Textiles, Dubrovnik, Croatia, 5–8 October 2002; pp. 273–296. [Google Scholar]

- Fartasch, M.; Diepgen, T.L.; Schmitt, J.; Drexler, H. The relationship between occupational sun exposure and non-melanoma skin cancer: Clinical basics, epidemiology, occupational disease evaluation, and prevention. Dtsch. Arztebl. Int. 2012, 109, 715–720. [Google Scholar] [CrossRef] [PubMed]

- Apalla, Z.; Lallas, A.; Sotiriou, E.; Lazaridou, E.; Ioannides, D. Epidemiological trends in skin cancer. Dermatol. Pract. Concept. 2017, 7, 5424654. [Google Scholar] [CrossRef] [Green Version]

- Laikova, K.V.; Oberemok, V.V.; Krasnodubets, A.M.; Gal′chinsky, N.V.; Useinov, R.Z.; Novikov, I.A.; Temirova, Z.Z.; Gorlov, M.V.; Shved, N.A.; Kumeiko, V.V.; et al. Advances in the Understanding of Skin Cancer: Ultraviolet Radiation, Mutations, and Antisense Oligonucleotides as Anticancer Drugs. Molecules 2019, 24, 1516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- World Cancer Research Fund International: Skin Cancer Statistics. Available online: https://www.wcrf.org/cancer-trends/skin-cancer-statistics/ (accessed on 8 September 2020).

- Schroeder, P.; Calles, C.; Benesova, T.; Macaluso, F.; Krutmann, J. Photoprotection beyond Ultraviolet Radiation—Effective Sun Protection Has to Include Protection against Infrared A Radiation-Induced Skin Damage. Skin Pharmacol. Physiol. 2010, 23, 15–17. [Google Scholar] [CrossRef] [PubMed]

- Grether-Beck, S.; Marini, A.; Jaenicke, T.; Krutmann, J. Photoprotection of human skin beyond ultraviolet radiation. Photodermatol. Photoimmunol. Photomed. 2014, 30, 167–174. [Google Scholar] [CrossRef]

- Dueva-Koganov, V.O.; Duev, A.; Recht, P. Protection of skin against full solar, visible and infrared radiation by fabrics: New testing methodology and perspective. Househ. Pers. Care Today 2014, 9, 29–34. [Google Scholar]

- Hudson, L.; Rashdan, E.; Bonn, C.A.; Chavan, B.; Rawlings, D.; Birch-Machin, M.A. Individual and combined effects of the infrared, visible, and ultraviolet light components of solar radiation on damage biomarkers in human skin cells. Faseb J. 2020, 34, 3874–3883. [Google Scholar] [CrossRef] [Green Version]

- Algaba, I.; Riva, A.; Pepio, M. Modelization of the influence of the wearing conditions of the garments on the ultraviolet protection factor. Text. Res. J. 2007, 77, 826–836. [Google Scholar] [CrossRef]

- Gabrijelcic, H.; Urbas, R.; Sluga, F.; Dimitrovski, K. Influence of Fabric Constructional Parameters and Thread Colour on UV Radiation Protection. Fibres Text. East. Eur. 2009, 17, 46–54. [Google Scholar]

- Hatch, K.L.; Osterwalder, U. Garments as solar ultraviolet radiation screening materials. Dermatol. Clin. 2006, 24, 85–100. [Google Scholar] [CrossRef]

- Wilson, C.A.; Bevin, N.K.; Laing, R.M.; Niven, B.E. Solar protection—Effect of selected fabric and use characteristics on ultraviolet transmission. Text. Res. J. 2008, 78, 95–104. [Google Scholar] [CrossRef]

- Majumdar, A.; Das, A.; Hatua, P. Ultraviolet radiation protection by cotton fabrics: Role of porous yarn structure, fabric thickness and pore size. J. Text. Inst. 2016, 107, 1159–1168. [Google Scholar] [CrossRef]

- Hatua, P.; Majumdar, A.; Das, A. Comparative analysis of in vitro ultraviolet radiation protection of fabrics woven from cotton and bamboo viscose yarns. J. Text. Inst. 2013, 104, 708–714. [Google Scholar] [CrossRef]

- Algaba, I.; Riva, A.; Crews, P.C. Influence of fiber type and fabric porosity on the UPF of summer fabrics. Aatcc Rev. 2004, 4, 26–31. [Google Scholar]

- Gorensek, M.; Sluga, F. Modifying the UV blocking effect of polyester fabric. Text. Res. J. 2004, 74, 469–474. [Google Scholar] [CrossRef]

- Paul, R.; Bautista, L.; De la Varga, M.; Botet, J.M.; Casals, E.; Puntes, V.; Marsal, F. Nano-cotton Fabrics with High Ultraviolet Protection. Text. Res. J. 2010, 80, 454–462. [Google Scholar] [CrossRef]

- Ghosh, S.B.; Bajaj, P.; Kothari, V.K. Effect of dyes and finishes on UV protection of jute/cotton fabrics. Indian J. Fibre Text. Res. 2003, 28, 431–436. [Google Scholar]

- Xin, J.H.; Daoud, W.A.; Kong, Y.Y. A new approach to UV-blocking treatment for cotton fabrics. Text. Res. J. 2004, 74, 97–100. [Google Scholar] [CrossRef]

- Ozdemir, H. Influence of titanium dioxide finish prepared by sol-gel technique on the ultraviolet protection characteristics of cotton/polyester blend fabrics used for clothing. Ind. Text. 2017, 68, 213–220. [Google Scholar] [CrossRef]

- Ojstršek, A.; Hribernik, S.; Fakin, D. Thermal, Mechanical and Optical Features of Aluminosilicate-Coated Cotton Textiles via the Crosslinking Method. Polymers 2018, 10, 57. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Hurren, C.; Millington, K.; Sun, L.; Wang, X. UV protection performance of textiles affected by fiber cross-sectional shape. Text. Res. J. 2015, 85, 1946–1960. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, T.; Zhang, J. Transmittance of Infrared Radiation Through Fabric in the Range 8–14 mu m. Text. Res. J. 2010, 80, 1516–1521. [Google Scholar] [CrossRef]

- McFarland, E.G.; Carr, W.W.; Sarma, D.S.; Dorrity, J.L. Effects of moisture and fiber type on infrared absorption of fabrics. Text. Res. J. 1999, 69, 607–615. [Google Scholar] [CrossRef]

- Yildirim, K.; Kanber, A.; Karahan, M.; Karahan, N. The solar properties of fabrics produced using different weft yarns. Text. Res. J. 2018, 88, 1543–1558. [Google Scholar] [CrossRef]

- Jiang, S.; Miao, D.; Xu, J.; Shang, S.; Ning, X.; Zhu, P. Preparation and characterization of shielding textiles to prevent infrared penetration with Ag thin films. J. Mater. Sci. Mater. Electron. 2017, 28, 3542–3547. [Google Scholar] [CrossRef]

- Ojstršek, A.; Fakin, D. Natural Dyeing of Wool Using Junglans regia (Common Walnut) Leaf Extract. Tekstilec 2019, 62, 288–298. [Google Scholar] [CrossRef]

- Verma, M.; Gahlot, N.; Singh, S.S.J.; Rose, N.M. UV protection and antibacterial treatment of cellulosic fibre (cotton) using chitosan and onion skin dye. Carbohydr. Polym. 2021, 257, 117612. [Google Scholar] [CrossRef]

- Singh, A.; Sheikh, J. Cleaner functional dyeing of wool using Kigelia Africana natural dye and Terminalia chebula bio-mordant. Sustain. Chem. Pharm. 2020, 17, 100286. [Google Scholar] [CrossRef]

- Čuk, N.; Gorjanc, M. Natural Dyeing and UV Protection of Raw and Bleached/Mercerised Cotton. Tekstilec 2017, 60, 126–136. [Google Scholar] [CrossRef]

- Calogero, G.; Yum, J.-H.; Sinopoli, A.; Di Marco, G.; Grätzel, M.; Nazeeruddin, M.K. Anthocyanins and betalains as light-harvesting pigments for dye-sensitized solar cells. Sol. Energy 2012, 86, 1563–1575. [Google Scholar] [CrossRef]

- Popescu, V.; Blaga, A.C.; Pruneanu, M.; Cristian, I.N.; Pîslaru, M.; Popescu, A.; Rotaru, V.; Crețescu, I.; Cașcaval, D. Green chemistry in the extraction of natural dyes from colored food waste, for dyeing protein textile materials. Polymers 2021, 13, 3867. [Google Scholar] [CrossRef] [PubMed]

- Rotich, V.; Wangila, P.; Cherutoi, J. FT-IR Analysis of Beta vulgaris Peels and Pomace Dye Extracts and Surface Analysis of Optimally Dyed-Mordanted Cellulosic Fabrics. J. Chem. 2022, 2022, 2233414. [Google Scholar] [CrossRef]

- Patil, S.R.; Chaudhary, A.S. Synthesis and optical properties of Near-Infrared (NIR) absorbing azo dyes. In Chemistry and Technology of Natural and Synthetic Dyes and Pigments; IntechOpen: London, UK, 2020. [Google Scholar]

- Luo, X.; Li, J.; Zhao, J.; Gu, L.; Qian, X.; Yang, Y. A general approach to the design of high-performance near-infrared (NIR) D-π-A type fluorescent dyes. Chin. Chem. Lett. 2019, 30, 839–846. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, L.; Chen, J.; Zhang, J. New insights into solar UV-protective properties of natural dye. J. Clean. Prod. 2007, 15, 366–372. [Google Scholar] [CrossRef]

- Angelini, L.G.; Tozzi, S.; Bracci, S.; Quercioli, F.; Radicati, B.; Picollo, M. Characterization of traditional dyes of the Mediterranean area by non-invasive UV-vis-NIR reflectance spectroscopy. Stud. Conserv. 2010, 55, 184–189. [Google Scholar] [CrossRef]

| Fabric Code | Type of Material | Type of Weave | Warp Density (Ends/cm) | Weft Density (Pick/cm) | Level of Relative Fabric Density | Relative Fabric Density (%) |

|---|---|---|---|---|---|---|

| 1 | Raw | Plain | 29.8 | 13.2 | I | 62 |

| 2 | Raw | Plain | 30.2 | 17.9 | II | 73 |

| 3 | Raw | Plain | 29.4 | 24.1 | III | 83 |

| 4 | Raw | Twill | 38.7 | 18.2 | I | 63 |

| 5 | Raw | Twill | 38.6 | 24.6 | II | 73 |

| 6 | Raw | Twill | 38.2 | 32.8 | III | 84 |

| 7 | Raw | Satin | 43.7 | 19.5 | I | 60 |

| 8 | Raw | Satin | 43.0 | 27.1 | II | 74 |

| 9 | Raw | Satin | 42.8 | 36.9 | III | 81 |

| 10 | Beet-dyed | Plain | 29.9 | 13.7 | I | 63 |

| 11 | Beet-dyed | Plain | 29.2 | 19.4 | II | 74 |

| 12 | Beet-dyed | Plain | 29.1 | 25.5 | III | 85 |

| 13 | Beet-dyed | Twill | 36.2 | 19.6 | I | 63 |

| 14 | Beet-dyed | Twill | 38.8 | 25.7 | II | 75 |

| 15 | Beet-dyed | Twill | 39.1 | 33.1 | III | 85 |

| 16 | Beet-dyed | Satin | 43.0 | 19.9 | I | 60 |

| 17 | Beet-dyed | Satin | 44.4 | 27.4 | II | 71 |

| 18 | Beet-dyed | Satin | 42.0 | 37.1 | III | 81 |

| 19 | Walnut-dyed | Plain | 29.6 | 13.6 | I | 63 |

| 20 | Walnut-dyed | Plain | 28.4 | 18.8 | II | 72 |

| 21 | Walnut-dyed | Plain | 29.0 | 26.1 | III | 86 |

| 22 | Walnut-dyed | Twill | 39.4 | 18.2 | I | 64 |

| 23 | Walnut-dyed | Twill | 39.0 | 25.7 | II | 75 |

| 24 | Walnut-dyed | Twill | 39.2 | 32.6 | III | 85 |

| 25 | Walnut-dyed | Satin | 45.2 | 19.8 | I | 61 |

| 26 | Walnut-dyed | Satin | 44.7 | 29.2 | II | 74 |

| 27 | Walnut-dyed | Satin | 41.6 | 37.1 | III | 80 |

| Fabric Type | Transmittance (%) | |||||

|---|---|---|---|---|---|---|

| UV (390 nm) | VIS (770 nm) | IRA (950 nm) | ||||

| BCF 1 | WCF 2 | BCF | WCF | BCF | WCF | |

| Twill I | 5.0 | 4.7 | 34.7 | 22.8 | 36.8 | 35.7 |

| Twill II | 2.2 | 2.9 | 31.6 | 21.4 | 34.8 | 34.1 |

| Twill III | 2.1 | 1.3 | 30.2 | 16.7 | 33.1 | 30.5 |

| Satin I | 3.4 | 3.1 | 30.8 | 17.9 | 33.3 | 31.0 |

| Satin II | 1.0 | 1.8 | 28.2 | 17.6 | 31.1 | 29.5 |

| Satin III | 0.8 | 0.3 | 25.1 | 10.4 | 28.8 | 25.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dubrovski, P.D.; Fakin, D.; Ojstršek, A. Cotton Woven Fabrics as Protective Polymer Materials against Solar Radiation in the Range of 210–1200 nm. Polymers 2023, 15, 1310. https://doi.org/10.3390/polym15051310

Dubrovski PD, Fakin D, Ojstršek A. Cotton Woven Fabrics as Protective Polymer Materials against Solar Radiation in the Range of 210–1200 nm. Polymers. 2023; 15(5):1310. https://doi.org/10.3390/polym15051310

Chicago/Turabian StyleDubrovski, Polona Dobnik, Darinka Fakin, and Alenka Ojstršek. 2023. "Cotton Woven Fabrics as Protective Polymer Materials against Solar Radiation in the Range of 210–1200 nm" Polymers 15, no. 5: 1310. https://doi.org/10.3390/polym15051310