Study of Mechanical Properties, Microstructure, and Residual Stresses of AISI 304/304L Stainless Steel Submerged Arc Weld for Spent Fuel Dry Storage Systems

Abstract

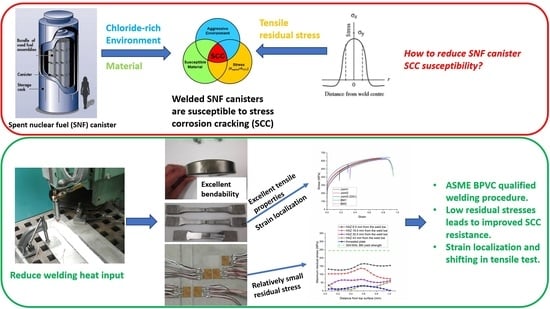

:1. Introduction

2. Materials and Experiments

2.1. Materials and Welding Equipment

2.2. Submerged Arc Welding

2.3. Welded Joint Microstructure Characterization and Mechanical Property Tests

2.3.1. Microstructure Characterization

2.3.2. Mechanical Property Testing

2.3.3. Residual Stress Measurement

3. Results

3.1. Microstructure

3.2. Mechanical Properties

3.2.1. Microhardness Distribution

3.2.2. Tensile Properties

3.3. Bend Tests

3.4. Residual Stress Measurements

4. Discussions

4.1. Local Deformation Behavior in Weld Transverse Tensile Test

4.2. Residual Stress Distribution

5. Summary and Conclusions

6. Acknowledgments

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kadak, A.C.; Yost, K. Key Issues Associated with Interim Storage of Used Nuclear Fuel; Massachusetts Institute of Technology: Cambridge, MA, USA, 2010. [Google Scholar]

- Blue Ribbon Committee. Blue Ribbon Commission on America’s Nuclear Future; Report to the Secretary of Energy; Blue Ribbon Committee: Washington, DC, USA, 2012. [Google Scholar]

- United States Nuclear Waste Technical Review Board. Evaluation of the Technical Basis for Extended Dry Storage and Transportation of Used Nuclear Fuel; United States Nuclear Waste Technical Review Board: Arlington, VA, USA, 2010. [Google Scholar]

- Chopra, O.K.; Diercks, D.R.; Fabian, R.R.; Han, Z.H.; Liu, Y.Y. Managing Aging Effects on Dry Cask Storage Systems for Extended Long-Term Storage and Transportation of Used Fuel; ANL-13/15 rev. 2; Argonne National Laboratory: Lemont, IL, USA, 2014. [Google Scholar]

- Nuclear Energy Institute. Format, Content and Implementation Guidance for Dry Cask Storage Operations-Based Aging Management; NEI 14-03 rev. 2; Nuclear Energy Institute: Washington, DC, USA, 2016. [Google Scholar]

- Electric Power Research Institute. Aging Management Guidance to Address Potential Chloride-Induced Stress Corrosion Cracking of Welded Stainless Steel Canisters; 300200819; Electric Power Research Institute: Palo Alto, CA, USA, 2017. [Google Scholar]

- US Nuclear Regulatory Commission. Managing Aging Processes in Storage (MAPS) Report; Draft Report for Comment. NUREG-2214; US Nuclear Regulatory Commission: Rockville, MD, USA, 2017. [Google Scholar]

- Jones, R.H., Jr. Dry Storage Cask Inventory Assessment; FCRD-NFST-2014-000602; Savannah River National Laboratory: Jackson, SC, USA, 2017. [Google Scholar]

- Werner, J.D.U.S. Spent Nuclear Fuel Storage; Congressional Research Service: Washington, DC, USA, 2012. [Google Scholar]

- US Nuclear Regulatory Commission. Identification and Prioritization of the Technical Information Needs Affecting Potential Regulation of Extended Storage and Transportation of Spent Nuclear Fuel; US Nuclear Regulatory Commission: Rockville, MD, USA, 2014. [Google Scholar]

- Hanson, B.; Alsaed, H.; Stockman, C.; Enos, D.; Meyer, R.; Sorenson, K. Gap Analysis to Support Extended Storage of Used Nuclear Fuel; FCRD-USED-2011-000136 rev. 0, PNNL-20509; Pacific Northwest National Laboratory: Richland, WA, USA, 2012. [Google Scholar]

- Dong, P.; Scatigno, G.G.; Wenman, M.R. Effect of Salt Composition and Microstructure on Stress Corrosion Cracking of 316L Austenitic Stainless Steel for Dry Storage Canisters. J. Nucl. Mater. 2021, 545, 152572. [Google Scholar] [CrossRef]

- Davis, J.R. Corrosion of Weldments; ASM International: Materials Park, OH, USA, 2006. [Google Scholar]

- Connor, L.P. Residual Stress and Distortion. Welding Handbook: Welding Technology; American Welding Society: Doral, FL, USA, 1989; pp. 217–264. [Google Scholar]

- Chandra, U. Control of residual stresses. In ASM Handbook: Materials Selection and Design; ASM International: Materials Park, OH, USA, 1997; pp. 811–819. [Google Scholar]

- Kim, S.; Ahn, K.; Kim, G.; Song, S.-W. Synchrotron X-ray fluorescence imaging study on chloride-induced stress corrosion cracking behavior of austenitic stainless steel welds via selective corrosion of δ-ferrite. Corros. Sci. 2023, 218, 111176. [Google Scholar] [CrossRef]

- Lee, D.; Kim, Y.; Cho, S. Evaluation of Residual Stress on Welds of Spent Fuel Dry Storage Canisters by Peening Technology. In Proceedings of the Transactions of the Korean Nuclear Society, Virtual spring Meeting, 13–14 May 2021. [Google Scholar]

- John, M.; Ralls, A.M.; Misra, M.; Menezes, P.L. Effect of ultrasonic impact peening on stress corrosion cracking resistance of austenitic stainless-steel welds for nuclear canister applications. J. Nucl. Mater. 2023, 584, 154590. [Google Scholar] [CrossRef]

- John, M.; Ralls, A.M.; Misra, M.; Menezes, P.L. Understanding the Mechanism of Stress Corrosion Cracking Resistance in Stainless Steel Welds Subjected to Laser Shock Peening without Coating for Nuclear Canister Applications. J. Mater. Eng. Perform. 2024, 21. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Stress Corrosion Cracking in Light Water Reactors: Good Practices and Lessons Learned; IAEA Nuclear Energy Series, No. NP-T-3.13; International Atomic Energy Agency: Vienna, Austria, 2011. [Google Scholar]

- US Nuclear Regulatory Commission. Potential Chloride-Induced Stress Corrosion Cracking of Austenitic Stainless Steel and Maintenance of Dry Cask Storage System Canisters; US Nuclear Regulatory Commission: Rockville, MD, USA, 2012. [Google Scholar]

- Okamura, Y.; Sakashita, A.; Fukuda, T.; Yamashita, H.; Futami, T. Latest SCC issues of core shroud and recirculation piping in Japanese BWRs. In Proceedings of the 17th International Conference on Structural Mechanics in Reactor Technology, Prague, Czech Republic, 17–22 August 2003. [Google Scholar]

- Saukkonen, T.; Aalto, M.; Virkkunen, I.; Ehrnstén, U.; Hänninen, H. Plastic strain and residual stress distributions in an AISI 304 stainless steel BWR pipe weld. In Proceedings of the 15th International Conference on Environmental Degradation of Materials in Nuclear Power Systems—Water Reactors; Springer: Cham, Switzerland, 2011; pp. 2351–2367. [Google Scholar]

- Chatzidakis, S.; Giuliano, D.; Slade, J.; Tang, W.; Miller, R.; Reeves, S.; Scaglione, J.; Howard, R. A Versatile Remediation Module for Remote Repair of Spent Nuclear Fuel and High-Level Waste Storage Containers. Nucl. Technol. 2021, 207, 750–760. [Google Scholar] [CrossRef]

- Enos, D.G.; Bryan, C.R. Final Report: Characterization of Canister Mockup Weld Residual Stress; FCRD-UFD-2016-000064; Sandia National Laboratories: Albuquerque, NM, USA, 2016. [Google Scholar]

- ASME Boiler and Pressure Vessel Code IX, Qualification Standard for Welding, Brazing, and Fusing Procedures; Welders; Brazers; and Welding, Brazing, and Fusing Operators; American Society of Mechanical Engineers: New York, NY, USA, 2013.

- SA-240/SA-240M; Specification for Chromium and Chromiumnickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications. ASTM: West Conshohocken, PA, USA, 2007.

- North American Stainless, Inspection Certificate #377084 01, 2018.

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E837-13a; Standard Test Method for Determining Residual Stress by the Hole-Drilling Strain-Gage Method. ASTM International: West Conshohocken, PA, USA, 2013.

- Sridhar, P.V.S.S.; Biswas, P.; Mahanta, P. Effect of process parameters on bead geometry, tensile and microstructural properties of double-sided butt submerged arc welding of SS 304 austenitic stainless steel. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 551. [Google Scholar] [CrossRef]

- Nam, T.-H.; An, E.; Kim, B.J.; Shin, S.; Ko, W.-S.; Park, N.; Kang, N.; Jeon, J.B. Effect of Post Weld Heat Treatment on the Microstructure and Mechanical Properties of a Submerged-Arc-Welded 304 Stainless Steel. Metals 2018, 8, 26. [Google Scholar] [CrossRef]

- Saha, S.; Mukherjee, M.; Pal, T.K. Microstructure, Texture, and Mechanical Property Analysis of Gas Metal Arc Welded AISI 304 Austenitic Stainless Steel. J. Mater. Eng. Perform. 2015, 24, 1125–1139. [Google Scholar] [CrossRef]

- Kumar, S.; Shahi, A.S. On the Influence of Welding Stainless Steel on Microstructural Development and Mechanical Performance. Mater. Manuf. Process. 2014, 29, 894–902. [Google Scholar] [CrossRef]

- Boyce, B.L.; Reu, P.L.; Robino, C.V. The Constitutive Behavior of Laser Welds in 304L Stainless Steel Determined by Digital Image Correlation. Metall. Mater. Trans. A 2006, 37A, 2481–2492. [Google Scholar] [CrossRef]

- Switzner, N.; Yu, Z.; Eff, M.; Lienert, T.; Fonseca, A. Microstructure and mechanical property variations within inertia friction-welded joints of stainless steel to steel. Int. J. Adv. Manuf. Technol. 2018, 95, 4327–4340. [Google Scholar] [CrossRef]

- Gowrisankar, I.; Bhaduri, A.K.; Seetharaman, V.; Verma, D.D.N.; Achar, D.D.G. Effect of the number of passes on the structure and properties of submerged arc welds of AISI type 316l stainless steel. Weld. Res. Suppl. 1987, 66, 147-s–154-s. [Google Scholar]

- Nam, J.Y.; Seo, D.H.; Lee, S.Y.; Hwang, W.K.; Lee, B.Y. The effect of residual stress on the SCC using ANSYS. Procedia Eng. 2011, 10, 2609–2614. [Google Scholar] [CrossRef]

- Lincoln Electric. Lincolnweld® 308/308L. Available online: https://www.lincolnelectric.com/en/products/lincolnweld308308l_saw (accessed on 18 January 2024).

| C | Cr | Mn | Ni | P | S | N | Si | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.0271 | 18.0525 | 1.7950 | 8.0270 | 0.0320 | 0.0010 | 0.0592 | 0.2395 | Balance |

| C | Cr | Mn | Ni | P | S | N | Si | Mo | Nb | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.01 | 20.0 | 1.9 | 10.1 | 0.02 | <0.01 | 0.05 | 0.31 | 0.06 | <0.01 | 0.19 | Balance |

| Welding Current (A) | Welding Voltage (V) | Welding Speed (mm/s) | Welding Wire Feed Speed (mm/s) |

|---|---|---|---|

| 450 | 30 | 8.47 | 59.3 |

| Specimen ID | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Uniform Elongation (%) | Total Elongation (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Measured | Average ± Standard Deviation | Measured | Average ± Standard Deviation | Measured | Average ± Standard Deviation | Measured | Average ± Standard Deviation | |

| Joint1 | 316 | 304 ± 12 | 635 | 638 ± 6 | 75.83 | 78.22 ± 7.97 | 78.25 | 81.52 ± 6.64 |

| Joint2 | 298 | 634 | 71.72 | 77.16 | ||||

| Joint3 (DIC) | 294 | 645 | 87.11 | 89.16 | ||||

| BM1 | 243 | 245 ± 2 | 631 | 628 ± 4 | 81.96 | 83.98 ± 2.86 | 94.28 | 94.21 ± 0.11 |

| BM2 | 246 | 625 | 86 | 94.13 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, W.; Chatzidakis, S.; Schrad, C.M.; Miller, R.G.; Howard, R. Study of Mechanical Properties, Microstructure, and Residual Stresses of AISI 304/304L Stainless Steel Submerged Arc Weld for Spent Fuel Dry Storage Systems. Metals 2024, 14, 262. https://doi.org/10.3390/met14030262

Tang W, Chatzidakis S, Schrad CM, Miller RG, Howard R. Study of Mechanical Properties, Microstructure, and Residual Stresses of AISI 304/304L Stainless Steel Submerged Arc Weld for Spent Fuel Dry Storage Systems. Metals. 2024; 14(3):262. https://doi.org/10.3390/met14030262

Chicago/Turabian StyleTang, Wei, Stylianos Chatzidakis, Caleb Matthew Schrad, Roger G. Miller, and Robert Howard. 2024. "Study of Mechanical Properties, Microstructure, and Residual Stresses of AISI 304/304L Stainless Steel Submerged Arc Weld for Spent Fuel Dry Storage Systems" Metals 14, no. 3: 262. https://doi.org/10.3390/met14030262