Enhanced Fouling Resistance and Antimicrobial Property of Ultrafiltration Membranes Via Polyelectrolyte-Assisted Silver Phosphate Nanoparticle Immobilization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

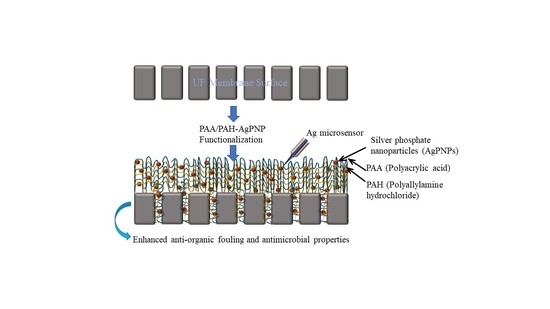

2.2. Membrane Functionalization

2.3. Membrane Surface Characterization

2.4. Silver Phosphate Nanoparticle (AgPNP) Stability Tests

2.5. Membrane Filtration Experiment

2.6. Fouling Protocol and Antifouling Performance Evaluation

3. Results and Discussion

3.1. UF Membrane Surface Properties Following PE-Assisted AgPNP Functionalization

3.2. AgPNP Stability Within PAH/PAA Layers

3.3. Effect of PAH/PAA BL Functionalization on UF Membrane Flux

3.4. Effect of PAH/PAA BLs on Organic Fouling Resistance and Flux Recovery

3.5. Effect of AgPNP-Immobilized PAH/PAA BLs on UF Membrane Antimicrobial Property

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rana, D.; Matsuura, T. Surface modifications for antifouling membranes. Chem. Rev. 2010, 110, 2448–2471. [Google Scholar] [CrossRef]

- Saqib, J.; Aljundi, I.H. Membrane fouling and modification using surface treatment and layer-by-layer assembly of polyelectrolytes: State-of-the-art review. J. Water Process Eng. 2016, 11, 68–87. [Google Scholar] [CrossRef]

- Zhou, M.; Liu, H.; Kilduff, J.E.; Langer, R.; Anderson, D.G.; Belfort, G. High-throughput membrane surface modification to control NOM fouling. Environ. Sci. Techn. 2009, 43, 3865–3871. [Google Scholar] [CrossRef]

- Razmjou, A.; Mansouri, J.; Chen, V. The effects of mechanical and chemical modification of TiO2 nanoparticles on the surface chemistry, structure and fouling performance of PES ultrafiltration membranes. J. Membr. Sci. 2011, 378, 73–84. [Google Scholar] [CrossRef]

- Reddy, A.; Mohan, D.J.; Bhattacharya, A.; Shah, V.; Ghosh, P. Surface modification of ultrafiltration membranes by preadsorption of a negatively charged polymer: I. Permeation of water soluble polymers and inorganic salt solutions and fouling resistance properties. J. Membr. Sci. 2003, 214, 211–221. [Google Scholar] [CrossRef]

- Lv, Y.; Yang, H.-C.; Liang, H.-Q.; Wan, L.-S.; Xu, Z.-K. Nanofiltration membranes via co-deposition of polydopamine/polyethylenimine followed by cross-linking. J. Membr. Sci. 2015, 476, 50–58. [Google Scholar] [CrossRef]

- Kochkodan, V.; Hilal, N. A comprehensive review on surface modified polymer membranes for biofouling mitigation. Desalination 2015, 356, 187–207. [Google Scholar] [CrossRef]

- Chung, J.; Chun, J.; Lee, J.; Lee, S.H.; Lee, Y.J.; Hong, S.W. Sorption of Pb(II) and Cu(II) onto multi-amine grafted mesoporous silica embedded with nano-magnetite: Effects of steric factors. J. Hazard. Mater. 2012, 239–240, 183–191. [Google Scholar] [CrossRef]

- Huang, M.; Chen, Y.; Huang, C.-H.; Sun, P.; Crittenden, J. Rejection and adsorption of trace pharmaceuticals by coating a forward osmosis membrane with TiO2. Chem. Eng. J. 2015, 279, 904–911. [Google Scholar] [CrossRef]

- Tian, Y.; Gao, B.; Morales, V.L.; Wang, Y.; Wu, L. Effect of surface modification on single-walled carbon nanotube retention and transport in saturated and unsaturated porous media. J. Hazard. Mater. 2012, 239–240, 333–339. [Google Scholar] [CrossRef]

- Ji, C.; Hou, J.; Chen, V. Cross-linked carbon nanotubes-based biocatalytic membranes for micro-pollutants degradation: Performance, stability, and regeneration. J. Membr. Sci. 2016, 520, 869–880. [Google Scholar] [CrossRef]

- Lee, J.; Chae, H.-R.; Won, Y.J.; Lee, K.; Lee, C.-H.; Lee, H.H.; Kim, I.-C.; Lee, J.-M. Graphene oxide nanoplatelets composite membrane with hydrophilic and antifouling properties for wastewater treatment. J. Membr. Sci. 2013, 448, 223–230. [Google Scholar] [CrossRef]

- Dong, L.-X.; Huang, X.-C.; Wang, Z.; Yang, Z.; Wang, X.-M.; Tang, C.Y. A thin-film nanocomposite nanofiltration membrane prepared on a support with in situ embedded zeolite nanoparticles. Sep. Purif. Technol. 2016, 166, 230–239. [Google Scholar] [CrossRef]

- Safarpour, M.; Khataee, A.; Vatanpour, V. Thin film nanocomposite reverse osmosis membrane modified by reduced graphene oxide/TiO2 with improved desalination performance. J. Membr. Sci. 2015, 489, 43–54. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Z.; Wang, X.; Wang, S.; Ding, W.; Gao, C. Layer-by-layer assembly of aquaporin Z-incorporated biomimetic membranes for water purification. Env. Sci. Technol. 2015, 49, 3761–3768. [Google Scholar] [CrossRef]

- Yin, J.; Zhu, G.; Deng, B. Graphene oxide (GO) enhanced polyamide (PA) thin-film nanocomposite (TFN) membrane for water purification. Desalination 2016, 379, 93–101. [Google Scholar] [CrossRef]

- Yin, J.; Kim, E.-S.; Yang, J.; Deng, B. Fabrication of a novel thin-film nanocomposite (TFN) membrane containing MCM-41 silica nanoparticles (NPs) for water purification. J. Membr. Sci. 2012, 423–424, 238–246. [Google Scholar] [CrossRef]

- Shi, X.; Shen, M.; Moehwald, H. Polyelectrolyte multilayer nanoreactors toward the synthesis of diverse nanostructured materials. Prog. Polym. Sci. 2004, 29, 987–1019. [Google Scholar] [CrossRef]

- Lichter, A.J.; van Vliet, K.J.; Rubner, M.F. Design of Antibacterial Surfaces and Interfaces: Polyelectrolyte Multilayers as a Multifunctional Platform. Macromolecules 2009, 42, 8573–8586. [Google Scholar] [CrossRef]

- DeRocher, J.P.; Mao, P.; Han, J.; Rubner, M.F.; Cohen, R.E. Layer-by-Layer assembly of polyelectrolytes in nanofluidic devices. Macromolecules 2010, 43, 2430–2437. [Google Scholar] [CrossRef]

- Zhai, L. Stimuli-responsive polymer films. Chem. Soc. Rev. 2013, 42, 7148–7160. [Google Scholar] [CrossRef] [PubMed]

- Joseph, N.; Ahmadiannamini, P.; Hoogenboom, R.; Vankelecom, I.F.J. Layer-by-layer preparation of polyelectrolyte multilayer membranes for separation. Polym. Chem. 2014, 5, 1817–1831. [Google Scholar] [CrossRef]

- Bruening, M.L.; Dotzauer, D.M.; Jain, P.; Lu, O.; Baker, G.L. Creation of functional membranes using polyelectrolyte multilayers and polymer brushes. Langmuir 2008, 24, 7663–7673. [Google Scholar] [CrossRef] [PubMed]

- Gribova, V.; Auzely-Velty, R.; Picart, C. Polyelectrolyte multilayer assemblies on materials surfaces: from cell adhesion to tissue engineering. Chem. Mater. 2012, 24, 854–869. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Decher, G. Fuzzy nanoassemblies: toward layered polymeric multicomposites. Science 1997, 277, 1232–1237. [Google Scholar] [CrossRef]

- Zhai, L.; Berg, M.C.; Cebeci, F.Ç.; Kim, Y.; Milwid, J.M.; Rubner, M.F.; Cohen, R.E. Patterned superhydrophobic surfaces: toward a synthetic mimic of the Namib desert beetle. Nano Lett. 2006, 6, 1213–1217. [Google Scholar] [CrossRef]

- Bravo, J.; Zhai, L.; Wu, Z.; Cohen, R.E.; Rubner, M.F. Transparent superhydrophobic films based on silica nanoparticles. Langmuir 2007, 23, 7293–7298. [Google Scholar] [CrossRef]

- Kharlampieva, E.; Sukhishvili, S.A. Competition of hydrogen-bonding and electrostatic interactions within hybrid polymer multilayers. Langmuir 2004, 20, 10712–10717. [Google Scholar] [CrossRef]

- Beaman, K.D.; Robertson, E.J.; Richmond, G.L. Metal ions: driving the orderly assembly of polyelectrolytes at a hydrophobic surface. Langmuir 2012, 28, 14245–14253. [Google Scholar] [CrossRef]

- Cho, C.; Xiang, F.; Wallace, K.L.; Grunlan, J.C. Combined ionic and hydrogen bonding in polymer multilayer thin film for high gas barrier and stretchiness. Macromolecules 2015, 48, 5723–5729. [Google Scholar] [CrossRef]

- Lee, H. Effects of temperature, salt concentration, and the protonation state on the dynamics and hydrogen-bond interactions of polyelectrolyte multilayers on lipid membranes. Phys. Chem. Chem. Phys. 2016, 18, 6691–6700. [Google Scholar] [CrossRef]

- Rahim, M.A.; Islam, M.S.; Bae, T.S.; Choi, W.S.; Noh, Y.-Y.; Lee, H.-J. Metal ion-enriched polyelectrolyte complexes and their utilization in multilayer assembly and catalytic nanocomposite films. Langmuir 2012, 28, 8486–8495. [Google Scholar] [CrossRef] [PubMed]

- Mentbayeva, A.; Ospanova, A.; Tashmuhambetova, Z.; Sokolova, V.; Sukhishvili, S. Polymer-metal complexes in polyelectrolyte multilayer films as catalysts for oxidation of toluene. Langmuir 2012, 28, 11948–11955. [Google Scholar] [CrossRef]

- Huang, X.; Schubert, A.B.; Chrisman, J.D.; Zacharia, N.S. Formation and tunable disassembly of polyelectrolyte-Cu2+ layer-by-layer complex film. Langmuir 2013, 29, 12959–12968. [Google Scholar] [CrossRef] [PubMed]

- Adusumilli, M. Polyelectrolyte Multilayer Films for Ion Separation and Water Purification. Ph.D. Thesis, Michigan State University, East Lansing, MI, USA, 2010. [Google Scholar]

- Mallwitz, F.; Laschewsky, A. Direct access to stable, freestanding polymer membranes by layer-by-layer assembly of polyelectrolytes. Adv. Mater. 2005, 17, 1296–1299. [Google Scholar] [CrossRef]

- Zhai, L.; Cebeci, F.C.; Cohen, R.E.; Rubner, M.F. Stable superhydrophobic coatings from polyelectrolyte multilayers. Nano Lett. 2004, 4, 1349–1353. [Google Scholar] [CrossRef]

- Chunder, A.; Etcheverry, K.; Londe, G.; Cho, H.J.; Zhai, L. Conformal switchable superhydrophobic/hydrophilic surfaces for microscale flow control. Colloids Surf. A Physicochem. Eng. Asp. 2009, 333, 187–193. [Google Scholar] [CrossRef]

- Alpatova, A.; Kim, E.-S.; Sun, X.; Hwang, G.; Liu, Y.; Gamal El-Din, M. Fabrication of porous polymeric nanocomposite membranes with enhanced anti-fouling properties: Effect of casting composition. J. Membr. Sci. 2013, 444, 449–460. [Google Scholar] [CrossRef]

- Daraei, P.; Madaeni, S.S.; Ghaemi, N.; Salehi, E.; Khadivi, M.A.; Moradian, R.; Astinchap, B. Novel polyethersulfone nanocomposite membrane prepared by PANI/Fe3O4 nanoparticles with enhanced performance for Cu(II) removal from water. J. Membr. Sci. 2012, 415–416, 250–259. [Google Scholar] [CrossRef]

- Hoek, E.M.V.; Ghosh, A.K.; Huang, X.; Liong, M.; Zink, J.I. Physical–chemical properties, separation performance, and fouling resistance of mixed-matrix ultrafiltration membranes. Desalination 2011, 283, 89–99. [Google Scholar] [CrossRef]

- Liu, Y.; Rosenfield, E.; Hu, M.; Mi, B. Direct observation of bacterial deposition on and detachment from nanocomposite membranes embedded with silver nanoparticles. Water Res. 2013, 47, 2949–2958. [Google Scholar] [CrossRef]

- Wu, H.; Tang, B.; Wu, P. Development of novel SiO2–GO nanohybrid/polysulfone membrane with enhanced performance. J. Membr. Sci. 2014, 451, 94–102. [Google Scholar] [CrossRef]

- Liu, X.; Qi, S.; Li, Y.; Yang, L.; Cao, B.; Tang, C.Y. Synthesis and characterization of novel antibacterial silver nanocomposite nanofiltration and forward osmosis membranes based on layer-by-layer assembly. Water Res. 2013, 47, 3081–3092. [Google Scholar] [CrossRef] [PubMed]

- Zodrow, K.; Brunet, L.; Mahendra, S.; Li, D.; Zhang, A.; Li, Q.; Alvarez, P.J. Polysulfone ultrafiltration membranes impregnated with silver nanoparticles show improved biofouling resistance and virus removal. Water Res. 2009, 43, 715–723. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, X.; Bai, R.; Wee, K.-H.; Liu, C.; Tang, S.-L. Membrane surfaces immobilized with ionic or reduced silver and their anti-biofouling performances. J. Membr. Sci. 2010, 363, 278–286. [Google Scholar] [CrossRef]

- Mohmood, I.; Lopes, C.B.; Lopes, I.; Ahmad, I.; Duarte, A.C.; Pereira, E. Nanoscale materials and their use in water contaminants removal—A review. Environ. Sci. Pollut. Res. 2013, 20, 1239–1260. [Google Scholar] [CrossRef]

- Pendergast, M.M.; Hoek, E.M. A review of water treatment membrane nanotechnologies. Energy Environ. Sci. 2011, 4, 1946–1971. [Google Scholar] [CrossRef] [Green Version]

- Bera, A.; Trivedi, J.S.; Kumar, S.B.; Chandel, A.K.S.; Haldar, S.; Jewrajka, S.K. Anti-organic fouling and anti-biofouling poly(piperazineamide) thin film nanocomposite membranes for low pressure removal of heavy metal ions. J. Hazard. Mater. 2018, 343, 86–97. [Google Scholar] [CrossRef]

- Firouzjaei, M.D.; Shamsabadi, A.A.; Aktij, S.A.; Seyedpour, S.F.; Sharifian Gh, M.; Rahimpour, A.; Esfahani, M.R.; Ulbricht, M.; Soroush, M. Exploiting synergetic effects of graphene oxide and a silver-based metal–rganic framework to enhance antifouling and anti-biofouling properties of thin-film nanocomposite membranes. ACS Appl. Mater. Interfaces 2018, 10, 42967–42978. [Google Scholar] [CrossRef]

- Lin, C.-F.; Huang, Y.-J.; Hao, O.J. Ultrafiltration processes for removing humic substances: Effect of molecular weight fractions and PAC treatment. Water Res. 1999, 33, 1252–1264. [Google Scholar] [CrossRef]

- Hilal, N.; Ismail, A.F.; Wright, C. Membrane Fabrication; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Richardson, J.J.; Cui, J.; Björnmalm, M.; Braunger, J.A.; Ejima, H.; Caruso, F. Innovation in layer-by-layer assembly. Chem. Rev. 2016, 116, 14828–14867. [Google Scholar] [CrossRef] [Green Version]

- Prisciandaro, M.; di Celso, G.M. On the removal of natural organic matter from superficial water by using UF and MF membranes. Desalin. Water Treat. 2016, 57, 2481–2488. [Google Scholar] [CrossRef]

- MICRODYN-NADIR. Trisep UA60 Product Specification; M.-N. GmbH, Ed.; M.-N. GmbH: Wiesbaden, Germany, 2019. [Google Scholar]

- Wang, C.T.; Rubner, M.F.; Cohen, R.E. Polyelectrolyte multilayer nanoreactors for preparing silver nanoparticle composites: Controlling metal concentration and nanoparticle size. Langmuir 2002, 18, 3370–3375. [Google Scholar] [CrossRef]

- Schuetz, P.; Caruso, F. Copper-assisted weak polyelectrolyte multilayer formation on microspheres and subsequent film crosslinking. Adv. Funct. Mater. 2003, 13, 929–937. [Google Scholar] [CrossRef]

- Sharma, M.; Ojha, K.; Ganguly, A.; Ganguli, A.K. Ag3PO4 nanoparticle decorated on SiO2 spheres for efficient visible light photocatalysis. New J. Chem. 2015, 39, 9242–9248. [Google Scholar] [CrossRef]

- Luxbacher, T. Electrokinetic characterization of flat sheet membranes by streaming current measurement. Desalination 2006, 199, 376–377. [Google Scholar] [CrossRef]

- Church, J. Electrochemical Microsensors for In Situ Monitoring of Chemical Compounds in Engineered and Natural Aquatic Systems. Ph.D. Thesis, University of Central Florida, Orlando, Fl, USA, 2018. [Google Scholar]

- Ma, X.; Armas, S.M.; Soliman, M.; Lytle, D.A.; Chumbimuni-Torres, K.; Tetard, L.; Lee, W.H. In situ monitoring of Pb2+ leaching from the galvanic joint surface in a prepared chlorinated drinking water. Environ. Sci. Technol. 2018, 52, 2126–2133. [Google Scholar] [CrossRef]

- Ma, X.; Lee, W.H.; Lytle, D.A. In-situ 2D maps of pH shifts across brass-lead galvanic joints using microelectrodes. Meas. Sci. Technol. 2016, 28, 025101. [Google Scholar] [CrossRef]

- Mensah, S.T.; Gonzalez, Y.; Calvo-Marzal, P.; Chumbimuni-Torres, K.Y. Nanomolar detection limits of Cd2+, Ag+, and K+ using paper-strip ion-selective electrodes. Anal. Chem. 2014, 86, 7269–7273. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; APHA: Washington, DC, USA; AWWA: Denver, CO, USA; WEF: Geneva, Switzerland, 2017. [Google Scholar]

- Nguyen, N.T.X. Detection of Molecular Changes Induced by Different Classes of Antibiotics against Escherichia Coli and Vibrio Parahaemolyticus Using Raman and Infra-Red Spectroscopies. Ph.D. Thesis, Université du Maine, Le Mans, France, 2017. [Google Scholar]

- Goodwin, J.R. Vibrational Microspectroscopy of Bacterial Colonies. Master’s Thesis, Queensland University of Technology, Brisbane, Australia, 2006. [Google Scholar]

- Pryshchepa, O.; Sagandykova, G.N.; Pomastowski, P.; Railean-Plugaru, V.; Król, A.; Rogowska, A.; Rodzik, A.; Sprynskyy, M.; Buszewski, B. A new approach for spontaneous silver ions immobilization onto casein. Int. J. Mol. Sci. 2019, 20, 3864. [Google Scholar] [CrossRef] [Green Version]

- Clay, R.; Cohen, R. Synthesis of metal nanoclusters within microphase-separated diblock copolymers: ICP-AES analysis of metal ion uptake. Supramol. Sci. 1997, 4, 113–119. [Google Scholar] [CrossRef]

- Machado, G.; Beppu, M.M.; Feil, A.F.; Figueroa, C.A.; Correia, R.R.B.; Teixeira, S.R. Silver nanoparticles obtained in PAH/PAA-based multilayers by photochemical reaction. J. Phys. Chem. C 2009, 113, 19005–19010. [Google Scholar] [CrossRef]

- Joly, S.; Kane, R.; Radzilowski, L.; Wang, T.; Wu, A.; Cohen, R.; Thomas, E.; Rubner, M. Multilayer nanoreactors for metallic and semiconducting particles. Langmuir 2000, 16, 1354–1359. [Google Scholar] [CrossRef]

- Jose, J.A.; Alagar, M. Preparation and Characterization of Polysulfone-Based Nanocomposites. In Manufacturing of Nanocomposites with Engineering Plastics; Mittal, V., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 31–59. [Google Scholar]

- Wagner, J. Membrane Filtration Handbook: Practical Tips and Hints; Osmonics: Cambrige, UK, 2001; Volume 129. [Google Scholar]

- STERLITECH. Trisep Flat Sheet Membrane UA60 PPA UF 1016 × 305 mm 1/Pk; STERLITECH: Kent, WA, USA, 2020. [Google Scholar]

- Guerra, K.; Pellegrino, J. Investigation of Low-Pressure Membrane Performance, Cleaning, and Economics Using a Techno-Economic Modeling Approach. In Science and Technology Program Report; USBR: Washington, DC, USA, 2012. [Google Scholar]

- Park, J.; Park, J.; Kim, S.H.; Cho, J.; Bang, J. Desalination membranes from pH-controlled and thermally-crosslinked layer-by-layer assembled multilayers. J. Mater. Chem. 2010, 20, 2085–2091. [Google Scholar] [CrossRef]

- Dakal, T.C.; Kumar, A.; Majumdar, R.S.; Yadav, V. Mechanistic basis of antimicrobial actions of silver nanoparticles. Front. Microbiol. 2016, 7, 1831. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmad, J.; Wen, X.; Li, F.; Wang, B. Novel triangular silver nanoparticle modified membranes for enhanced antifouling performance. RSC Adv. 2019, 9, 6733–6744. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Zhang, D.; He, Y.; Zhao, X.; Bai, R. Modification of membrane surface for anti-biofouling performance: Effect of anti-adhesion and anti-bacteria approaches. J. Membr. Sci. 2010, 346, 121–130. [Google Scholar] [CrossRef]

| Membrane Tested/Functionalized | Membrane Description | No. of PAH/PAA Bilayers (BL) Deposited | AgPNP Immobilized? |

|---|---|---|---|

| Virgin UF | Commercial unmodified UF membrane | 0 | No |

| PAH/PAA-UF | UF membrane conformally coated with bilayers (BL) of PAH and PAA | 1, 3, 5, 7, 10 | No |

| AgPNP-BL | UF membrane functionalized by embedding AgPNPs within PAH/PAA BLs | 5 | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olimattel, K.; Church, J.; Lee, W.H.; Chumbimuni-Torres, K.Y.; Zhai, L.; Sadmani, A.H.M.A. Enhanced Fouling Resistance and Antimicrobial Property of Ultrafiltration Membranes Via Polyelectrolyte-Assisted Silver Phosphate Nanoparticle Immobilization. Membranes 2020, 10, 293. https://doi.org/10.3390/membranes10100293

Olimattel K, Church J, Lee WH, Chumbimuni-Torres KY, Zhai L, Sadmani AHMA. Enhanced Fouling Resistance and Antimicrobial Property of Ultrafiltration Membranes Via Polyelectrolyte-Assisted Silver Phosphate Nanoparticle Immobilization. Membranes. 2020; 10(10):293. https://doi.org/10.3390/membranes10100293

Chicago/Turabian StyleOlimattel, Kunal, Jared Church, Woo Hyoung Lee, Karin Y. Chumbimuni-Torres, Lei Zhai, and A H M Anwar Sadmani. 2020. "Enhanced Fouling Resistance and Antimicrobial Property of Ultrafiltration Membranes Via Polyelectrolyte-Assisted Silver Phosphate Nanoparticle Immobilization" Membranes 10, no. 10: 293. https://doi.org/10.3390/membranes10100293