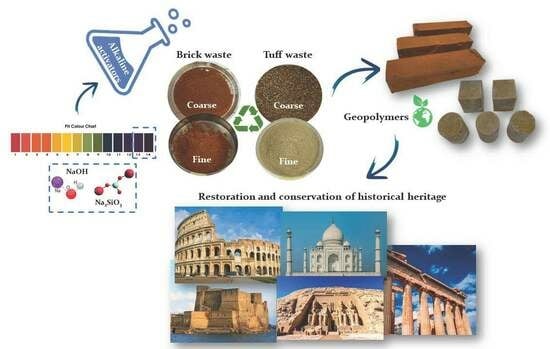

Valorisation of Tuff and Brick Wastes by Alkali Activation for Historical Building Remediation

Abstract

:1. Introduction

2. Experimental

2.1. Raw Materials and Preparation of the Geocomposites

- (1)

- Waste from red clay bricks (BW): a commercial product supplied by CTS s.r.l. (Altavilla Vicentina, Italy) and recovered from construction and demolition activities, properly sieved and divided it into two particle-size fractions of less than 0.3 mm and between 0.3 and 4 mm.

- (2)

- Waste of tuff sawing (TW): a mixture of two typical Italian tuffs, such as Neapolitan Yellow Tuff (NYT) and Viterbo red tuff (VT), was used. TW was crushed and sieved to select two particle-sized fractions of less than 0.3 mm and between 0.3 and 4 mm.

- (3)

- Fly ashes (FA): derived from combustion in coal-fired power plants for the production of electricity; they were also added as partial replacement of the waste (10 or 20%).

- -

- cylindrical (diameter 45 mm; height 50 mm),

- -

- cubic (side 50 mm),

- -

- prismatic (40 × 40 × 160 mm3).

2.2. Mineralogical and Chemical Characterization of Raw Materials

2.3. Physical and Chemical Characterization of the Geopolymeric Mortars

2.4. Mechanical Characterization of the Geopolymeric Mortars

3. Results and Discussion

3.1. Characterization of the Raw Materials

3.2. Physical and Chemical Characterization of the Geopolymeric Mortars

3.3. Mechanical Characterization of the Geopolymeric Mortars

3.4. Comparison with Typical Materials Used in Cultural Heritage

| Sample | Open Porosity (%) | CA (mg/cm2 s−1/2) | Qmax (mg/cm2) | Compressive Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|---|---|---|

| Aerial lime mortar CL-90 [59,60] | 25.90 | 13.90 | 2870 | 0.48 | 0.24 |

| Hydraulic lime mortar NHL 5 [59,60] | 23.50 | 9.40 | 3970 | 3.70 | 1.00 |

| OPC mortar (CEM II B/L 32.5) [60] | 18.80 | 3.40 | 2030 | 24.80 | 4.70 |

| Repair mortar NHL-Z 3.5 with crushed bricks and silica sand [56] | 26.23 * | 24.16 * | n. d. | 3.48 | n. d. |

| Historical magnesian mortar [56] | 30–40 | 28.51 | n. d. | n. d. | n. d. |

| Natural Bioclastic Limestone [56] | 24–30 | 31.32 | n. d. | 10.09 | n. d. |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Istituto Superiore per la Protezione e la Ricerca Ambientale (ISPRA). Rapporto Rifiuti Speciali; ISPRA: Rome, Italy, 2020.

- Agostini, I. La cultura della città storica in Italia. Sci. Territ. 2015, 3, 97–103. Available online: https://www.torrossa.com/gs/resourceProxy?an=3132843&publisher=FF3888#page=97 (accessed on 8 May 2023).

- Mancini, R. Il Recupero dei Materiali nella Costruzione e nella Riparazione delle Mura Aureliane di Roma; École Française de Rome: Rome, Italy, 2008; pp. 1000–1011. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Valencia-Saavedra, W.; de Gutiérrez, R.M. Construction and demolition waste (Cdw) recycling—As both binder and aggregates—In alkali-activated materials: A novel re-use concept. Sustainability 2020, 12, 5775. [Google Scholar] [CrossRef]

- Koda, E.; Podlasek, A. Sustainable use of construction and demolition wastes in a circular economy perspective. In Sustainable and Circular Management of Resources and Waste towards a Green Deal; Elsevier: Amsterdam, The Netherlands, 2023; pp. 137–147. [Google Scholar]

- Adams, M.; Burrows, V.; Richardson, S. Bringing Embodied Carbon Upfront; World Green Building Council: London, UK, 2019. [Google Scholar]

- Sánchez-Garrido, A.J.; Navarro, I.J.; Yepes, V. Multi-criteria decision-making applied to the sustainability of building structures based on Modern Methods of Construction. J. Clean. Prod. 2022, 330, 129724. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer cement to minimize carbon-dioxde greenhouse-warming. Ceram. Trans. 1993, 37, 165–182. Available online: https://www.researchgate.net/publication/284682578_Geopolymer_cement_to_minimize_carbon-dioxde_greenhouse-warming (accessed on 15 May 2023).

- Davidovits, J. Global Warming Impact on the Cement and Aggregates Industries. World Resour. Rev. 1994, 6, 263–278. [Google Scholar]

- Palomo, A.; Maltseva, O.; Garcia-Lodeiro, I.; Fernández-Jiménez, A. Portland versus Alkaline Cement: Continuity or Clean Break: “A Key Decision for Global Sustainability”. Front. Chem. 2021, 9, 705475. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.B.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. Geopolymerisation of multiple minerals. Miner. Eng. 2002, 15, 1131–1139. [Google Scholar] [CrossRef]

- Capasso, I.; Liguori, B.; Verdolotti, L.; Caputo, D.; Lavorgna, M.; Tervoort, E. Process strategy to fabricate a hierarchical porosity gradient in diatomite-based foams by 3D printing. Sci. Rep. 2020, 10, 612. [Google Scholar] [CrossRef] [PubMed]

- Capasso, I.; Lirer, S.; Flora, A.; Ferone, C.; Cioffi, R.; Caputo, D.; Liguori, B. Reuse of mining waste as aggregates in fly ash-based geopolymers. J. Clean. Prod. 2019, 220, 65–73. [Google Scholar] [CrossRef]

- Ferone, C.; Capasso, I.; Bonati, A.; Roviello, G.; Montagnaro, F.; Santoro, L.; Turco, R.; Cioffi, R. Sustainable management of water potabilization sludge by means of geopolymers production. J. Clean. Prod. 2019, 229, 1–9. [Google Scholar] [CrossRef]

- Lirer, S.; Liguori, B.; Capasso, I.; Flora, A.; Caputo, D. Mechanical and chemical properties of composite materials made of dredged sediments in a fly-ash based geopolymer. J. Environ. Manag. 2017, 191, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Capasso, I.; Liguori, B.; Ferone, C.; Caputo, D.; Cioffi, R. Strategies for the valorization of soil waste by geopolymer production: An overview. J. Clean. Prod. 2021, 288, 125646. [Google Scholar] [CrossRef]

- Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste. A review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Ling, Y.; Wang, K.; Li, W.; Shi, G.; Lu, P. Effect of slag on the mechanical properties and bond strength of fly ash-based engineered geopolymer composites. Compos. Part B Eng. 2019, 164, 747–757. [Google Scholar] [CrossRef]

- Liguori, B.; Capasso, I.; De Pertis, M.; Ferone, C.; Cioffi, R. Geopolymerization Ability of Natural and Secondary Raw Materials by Solubility Test in Alkaline Media. Environments 2017, 4, 56. [Google Scholar] [CrossRef]

- Si, R.; Dai, Q.; Guo, S.; Wang, J. Mechanical property, nanopore structure and drying shrinkage of metakaolin-based geopolymer with waste glass powder. J. Clean. Prod. 2020, 242, 118502. [Google Scholar] [CrossRef]

- Matalkah, F.; Soroushian, P.; Ul Abideen, S.; Peyvandi, A. Use of non-wood biomass combustion ash in development of alkali-activated concrete. Constr. Build. Mater. 2016, 121, 491–500. [Google Scholar] [CrossRef]

- Maleki, A.; Mohammad, M.; Emdadi, Z.; Asim, N.; Azizi, M.; Safaei, J. Adsorbent materials based on a geopolymer paste for dye removal from aqueous solutions. Arab. J. Chem. 2020, 13, 3017–3025. [Google Scholar] [CrossRef]

- Abdelmonem, A.; El-Feky, M.S.; Nasr, E.S.A.R.; Kohail, M. Performance of high strength concrete containing recycled rubber. Constr. Build. Mater. 2019, 227, 116660. [Google Scholar] [CrossRef]

- Liang, G.; Zhu, H.; Zhang, Z.; Wu, Q. Effect of rice husk ash addition on the compressive strength and thermal stability of metakaolin based geopolymer. Constr. Build. Mater. 2019, 222, 872–881. [Google Scholar] [CrossRef]

- D’Angelo, G.; Fumo, M.; Del Rio Merino, M.; Capasso, I.; Campanile, A.; Iucolano, F.; Caputo, D.; Liguori, B. Crushed Bricks: Demolition Waste as a Sustainable Raw Material for Geopolymers. Sustainabilty 2021, 13, 7572. [Google Scholar] [CrossRef]

- Panizza, M.; Natali, M.; Garbin, E.; Tamburini, S.; Secco, M. Assessment of geopolymers with Construction and Demolition Waste (CDW) aggregates as a building material. Constr. Build. Mater. 2018, 181, 119–133. [Google Scholar] [CrossRef]

- Dadsetan, S.; Siad, H.; Lachemi, M.; Sahmaran, M. Construction and demolition waste in geopolymer concrete technology: A review. Mag. Concr. Res. 2019, 71, 1232–1252. [Google Scholar] [CrossRef]

- Allahverdi, A.; Najafi Kani, E. Construction wastes as raw materials for geopolymer binders. Int. J. Civ. Eng. 2009, 7, 154–160. [Google Scholar]

- Clausi, M.; Tarantino, S.C.; Magnani, L.L.; Riccardi, M.P.; Tedeschi, C.; Zema, M. Metakaolin as a precursor of materials for applications in Cultural Heritage: Geopolymer-based mortars with ornamental stone aggregates. Appl. Clay Sci. 2016, 132–133, 589–599. [Google Scholar] [CrossRef]

- Giacobello, F.; Ielo, I.; Belhamdi, H.; Plutino, M.R. Geopolymers and Functionalization Strategies for the Development of Sustainable Materials in Construction Industry and Cultural Heritage Applications: A Review. Materials 2022, 15, 1725. [Google Scholar] [CrossRef]

- Kutlusoy, E.; Maras, M.M.; Ekinci, E.; Rihawi, B. Production parameters of novel geopolymer masonry mortar in heritage buildings: Application in masonry building elements. J. Build. Eng. 2023, 76, 107038. [Google Scholar] [CrossRef]

- Occhipinti, R.; Stroscio, A.; Finocchiaro, C.; Fugazzotto, M.; Leonelli, C.; José Lo Faro, M.; Megna, B.; Barone, G.; Mazzoleni, P. Alkali activated materials using pumice from the Aeolian Islands (Sicily, Italy) and their potentiality for cultural heritage applications: Preliminary study. Constr. Build. Mater. 2020, 259, 120391. [Google Scholar] [CrossRef]

- Moutinho, S.; Costa, C.; Andrejkovičová, S.; Mariz, L.; Sequeira, C.; Terroso, D.; Rocha, F.; Velosa, A. Assessment of properties of metakaolin-based geopolymers applied in the conservation of tile facades. Constr. Build. Mater. 2020, 259, 119759. [Google Scholar] [CrossRef]

- Kürklü, G.; Görhan, G. Investigation of usability of quarry dust waste in fly ash-based geopolymer adhesive mortar production. Constr. Build. Mater. 2019, 217, 498–506. [Google Scholar] [CrossRef]

- Moutinho, S.; Costa, C.; Cerqueira, Â.; Rocha, F.; Velosa, A. Geopolymers and polymers in the conservation of tile facades. Constr. Build. Mater. 2019, 197, 175–184. [Google Scholar] [CrossRef]

- Pagnotta, S.; Tenorio, A.L.; Tinè, M.R.; Lezzerini, M. Geopolymers as a potential material for preservation and restoration of Urban Build Heritage: An overview. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Prague, Czech Republic, 7–11 September 2020; IOP Publishing: Bristol, UK, 2020; Volume 609, p. 012057. [Google Scholar]

- Lăzărescu, A.V.; Ionescu, B.A.; Hegyi, A.; Florean, C. Alkali-Activated Fly Ash Based Geopolymer Paving Blocks: Green Materials for Future Conservation of Resources. Int. J. Conserv. Sci. 2022, 13, 175–186. [Google Scholar]

- Clausi, M.; Magnani, L.L.; Occhipinti, R.; Riccardi, M.P.; Zema, M.; Tarantino, S.C. Interaction of metakaolin-based geopolymers with natural and artificial stones and implications on their use in cultural heritage. Int. J. Conserv. Sci. 2016, 7, 871–884. [Google Scholar]

- UNI 11060:2003; Beni Culturali—Materiali Lapidei Naturali ed Artificiali—Determinazione della Massa Volumica e della Percentuale di Vuoti. UNI: Milano, Italy, 2003. Available online: http://store.uni.com/catalogo/uni-11060-2003?josso_back_to=http://store.uni.com/josso-security-check.php&josso_cmd=login_optional&josso_partnerapp_host=store.uni.com (accessed on 10 October 2022).

- UNI EN 15801:2010; Conservation of Cultural Property—Test Methods—Determination of Water Absorption by Capillarity. UNI: Milano, Italy, 2010.

- UNI EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. UNI: Milano, Italy, 2016.

- UNI EN 13279-2: 2014; Gypsum Binders and Gypsum Plasters—Part 2: Test Methods. UNI: Milano, Italy, 2014.

- Liguori, B.; Iucolano, F.; De Gennaro, B.; Marroccoli, M.; Caputo, D. Zeolitized tuff in environmental friendly production of cementitious material: Chemical and mechanical characterization. Constr. Build. Mater. 2015, 99, 272–278. [Google Scholar] [CrossRef]

- Novembre, D.; Gimeno, D.; Cappelletti, P.; Graziano, S.F. A case study of zeolitization process: “Tufo Rosso a Scorie Nere” (Vico volcano, Italy): Inferences for a general model. Eur. J. Mineral. 2021, 33, 315–328. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Dick, W.A. Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem. Concr. Compos. 2010, 32, 142–147. [Google Scholar] [CrossRef]

- Alexandre Bogas, J.; Gomes, M.G.; Real, S. Capillary absorption of structural lightweight aggregate concrete. Mater. Struct. Constr. 2015, 48, 2869–2883. [Google Scholar] [CrossRef]

- Verdolotti, L.; Iannace, S.; Lavorgna, M.; Lamanna, R. Geopolymerization reaction to consolidate incoherent pozzolanic soil. J. Mater. Sci. 2008, 43, 865–873. [Google Scholar] [CrossRef]

- Van Jaarsveld, J.G.S.; Van Deventer, J.S.J.; Lukey, G.C. The characterisation of source materials in fly ash-based geopolymers. Mater. Lett. 2003, 57, 1272–1280. [Google Scholar] [CrossRef]

- Shahraki, B.K.; Mehrabi, B.; Gholizadeh, K.; Mohammadinasab, M. Thermal behavior of calcite as an expansive agent. J. Min. Metall. Sect. B Metall. 2011, 47, 89–97. [Google Scholar] [CrossRef]

- Osacký, M.; Pálková, H.; Hudec, P.; Czímerová, A.; Galusková, D.; Vítková, M. Effect of alkaline synthesis conditions on mineralogy, chemistry and surface properties of phillipsite, P and X zeolitic materials prepared from fine powdered perlite by-product. Microporous Mesoporous Mater. 2020, 294, 109852. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 5th ed.; Geopolymer Institute: Saint-Quentin, France, 2020. [Google Scholar]

- Wong, C.L.; Mo, K.H.; Alengaram, U.J.; Yap, S.P. Mechanical strength and permeation properties of high calcium fly ash-based geopolymer containing recycled brick powder. J. Build. Eng. 2020, 32, 101655. [Google Scholar] [CrossRef]

- Maravelaki-Kalaitzaki, P.; Bakolas, A.; Karatasios, I.; Kilikoglou, V. Hydraulic lime mortars for the restoration of historic masonry in Crete. Cem. Concr. Res. 2005, 35, 1577–1586. [Google Scholar] [CrossRef]

- Kramar, S.; Zalar, V.; Urosevic, M.; Körner, W.; Mauko, A.; Mirtič, B.; Lux, J.; Mladenović, A. Mineralogical and microstructural studies of mortars from the bath complex of the Roman villa rustica near Mošnje (Slovenia). Mater. Charact. 2011, 62, 1042–1057. [Google Scholar] [CrossRef]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A. Influence of natural hydraulic lime content on the properties of aerial lime-based mortars. Constr. Build. Mater. 2014, 72, 208–218. [Google Scholar] [CrossRef]

- Garijo, L.; Zhang, X.; Ruiz, G.; Ortega, J.J. Age effect on the mechanical properties of natural hydraulic and aerial lime mortars. Constr. Build. Mater. 2020, 236, 117573. [Google Scholar] [CrossRef]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A. Natural hydraulic lime versus cement for blended lime mortars for restoration works. Constr. Build. Mater. 2015, 94, 346–360. [Google Scholar] [CrossRef]

| Sample | Binder (Fine Fraction, %wt) | Ag./Bin. Ratio | Act. Sol. | NaOH | Liquid/Powder | Curing Time | Curing Temperature | ||

|---|---|---|---|---|---|---|---|---|---|

| FA | BW | TW | |||||||

| BW80 | 20 | 80 | / | 0.5 | NaOH + SS | 10 M | 0.6 | 72 h | 60 °C |

| BW90 | 10 | 90 | / | ||||||

| BW100 | / | 100 | / | ||||||

| TW80 | 20 | / | 80 | ||||||

| TW90 | 10 | / | 90 | ||||||

| TW100 | / | / | 100 | ||||||

| Sample | Major Elements (wt%) | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | CaO | TiO2 | |

| BW [28] | 47.90 | 31.82 | 2.99 | 4.14 | 3.75 | 3.59 | 4.52 | / |

| NYT [46] | 58.82 | 19.10 | 4.60 | 1.11 | 3.44 | 9.39 | 3.10 | 0.53 |

| VT [47] | 53.75 | 16.86 | 4.00 | 1.55 | 1.60 | 8.15 | 5.21 | 0.51 |

| FA | 58.13 | 23.28 | 5.98 | 2.04 | 0.97 | 2.80 | 4.22 | 1.02 |

| Sample | Apparent Density (g/cm3) | Open Porosity (%) | Water Absorption (%) | CA (mg/cm2 s−1/2) | Qmax (mg/cm2) |

|---|---|---|---|---|---|

| TW80 | 1.35 ± 0.08 | 39.44 ± 1.03 | 26.70 ± 0.97 | 20.97 ± 0.34 | 1518 |

| TW90 | 1.40 ± 0.01 | 41.92 ± 0.96 | 29.89 ± 0.87 | 23.93 ± 1.19 | 1770 |

| TW100 | 1.37 ± 0.01 | 42.32 ± 0.54 | 30.97 ± 0.48 | 33.36 ± 0.11 | 1907 |

| BW80 | 1.76 ± 0.01 | 27.68 ± 0.50 | 15.71 ± 0.38 | 19.53 ± 0.82 | 1137 |

| BW90 | 1.75 ± 0.01 | 26.24 ± 0.01 | 15.02 ± 0.04 | 21.89 ± 0.24 | 1236 |

| BW100 | 1.73 ± 0.01 | 34.16 ± 0.21 | 19.75 ± 0.02 | 26.67 ± 1.89 | 1333 |

| Sample | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|

| TW80 | 1.23 ± 0.05 | 1.34 ± 0.18 |

| TW90 | 0.62 ± 0.04 | 1.48 ± 0.08 |

| TW100 | 0.39 ± 0.01 | 0.81 ± 0.06 |

| BW80 | 4.58 ± 0.06 | 13.44 ± 0.36 |

| BW90 | 3.60 ± 0.30 | 13.39 ± 0.47 |

| BW100 * | 2.85 ± 0.73 | 5.34 ± 0.66 |

| Sample | Surface Hardness |

|---|---|

| TW80 | 53.73 ± 2.20 |

| TW90 | 32.56 ± 2.32 |

| TW100 | 26.50 ± 0.82 |

| BW80 | 74.55 ± 1.17 |

| BW90 | 75.80 ± 3.02 |

| BW100 | 31.17 ± 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Capasso, I.; D’Angelo, G.; Fumo, M.; del Rio Merino, M.; Caputo, D.; Liguori, B. Valorisation of Tuff and Brick Wastes by Alkali Activation for Historical Building Remediation. Materials 2023, 16, 6619. https://doi.org/10.3390/ma16206619

Capasso I, D’Angelo G, Fumo M, del Rio Merino M, Caputo D, Liguori B. Valorisation of Tuff and Brick Wastes by Alkali Activation for Historical Building Remediation. Materials. 2023; 16(20):6619. https://doi.org/10.3390/ma16206619

Chicago/Turabian StyleCapasso, Ilaria, Gigliola D’Angelo, Marina Fumo, Mercedes del Rio Merino, Domenico Caputo, and Barbara Liguori. 2023. "Valorisation of Tuff and Brick Wastes by Alkali Activation for Historical Building Remediation" Materials 16, no. 20: 6619. https://doi.org/10.3390/ma16206619