Mesophase Pitch-Based Carbon Fibers: Accelerated Stabilization of Pitch Fibers under Effective Plasma Irradiation-Assisted Modification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

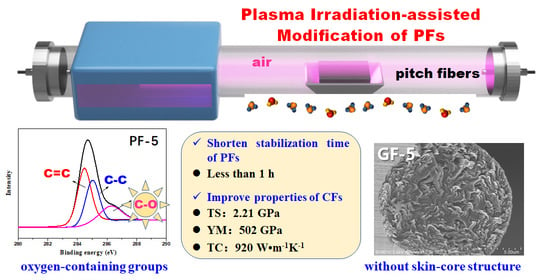

2.2. Plasma Irradiation-Assisted Modification of Pitch Fibers and Preparation of Carbon Fibers

2.3. Characterization of Pitch and Fibers

3. Results and Discussion

3.1. Surface Chemistry of PIM-Derived Pitch Fibers

3.2. Thermal Behavior of PIM-Derived Pitch Fibers and Stabilized Fibers

3.3. Microstructure and Properties of PIM-Derived Carbonized Fibers and Graphitized Fibers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mora, E.; Blanco, C.; Prada, V.; Santamaría, R.; Granda, M.; Menéndez, R. A study of pitch-based precursors for general purpose carbon fibres. Carbon 2002, 40, 2719–2725. [Google Scholar] [CrossRef]

- Park, S.J. Precursors and Manufacturing of Carbon Fibers; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Liu, Y.D.; Kumar, S. Recent progress in fabrication, structure, and properties of carbon fibers. Polym. Rev. 2012, 52, 234–258. [Google Scholar] [CrossRef]

- Yoon, S.H.; Korai, Y.; Mochida, I. Assessment and optimization of the stabilization process of mesophase pitch fibers by thermal analyses. Carbon 1994, 32, 281–287. [Google Scholar] [CrossRef]

- Matsumoto, T.; Mochida, I. Oxygen distribution in oxidatively stabilized mesophase pitch fiber. Carbon 1993, 31, 143–147. [Google Scholar] [CrossRef]

- Drbohlav, J.; Stevenson, W.T.K. The oxidative stabilization and carbonization of a synthetic mesophase pitch, part I: The oxidative stabilization process. Carbon 1995, 33, 693–711. [Google Scholar] [CrossRef]

- Zhu, J.; Park, S.W.; Joh, H.-I.; Kim, H.C.; Lee, S. Preparation and characterization of isotropic pitch-based carbon fiber. Carbon Lett. 2013, 14, 94–98. [Google Scholar] [CrossRef] [Green Version]

- Lim, T.H.; Yeo, S.Y. Investigation of the degradation of pitch-based carbon fibers properties upon insufficient or excess thermal treatment. Sci. Rep. 2017, 7, 4733. [Google Scholar] [CrossRef] [Green Version]

- Peng, Y.-S.; Yang, J.-X.; Shi, K.; Guo, J.-G.; Zhu, H.; Li, X.-K. Effects of the degree of oxidation of pitch fibers on their stabilization and carbonization behaviors. New Carbon Mater. 2020, 35, 722–730. [Google Scholar] [CrossRef]

- Park, M.S.; Jung, M.J.; Lee, Y.S. Significant reduction in stabilization temperature and improved mechanical/electrical properties of pitch-based carbon fibers by electron beam irradiation. J. Ind. Eng. Chem. 2016, 37, 277–287. [Google Scholar] [CrossRef]

- Morales, M.S.; Ogale, A.A. Carbon fibers derived from UV-assisted stabilization of wet-spun polyacrylonitrile fibers. J. Appl. Polym. Sci. 2014, 131, 318–323. [Google Scholar] [CrossRef]

- Zhao, W.; Lu, Y.; Wang, J.; Chen, Q.; Zhou, L.; Jiang, J.; Chen, L. Improving crosslinking of stabilized polyacrylonitrile fibers and mechanical properties of carbon fibers by irradiating with γ-ray. Polym. Degrad. Stab. 2016, 133, 16–26. [Google Scholar] [CrossRef]

- Šimončicová, J.; Krystofova, S.; Medvecká, V.; Ďurišová, K.; Kaliňáková, B. Technical applications of plasma treatments: Current state and perspectives. Appl. Microbiol. Biotechnol. 2019, 103, 5117–5129. [Google Scholar] [CrossRef]

- Wang, D.; He, N.; Xiao, L.; Dong, F.; Chen, W.; Zhou, Y.; Chen, C.; Wang, S. Coupling electrocatalytic NO oxidation over carbon cloth with hydrogen evolution reaction for nitrate synthesis. Angew. Chem. 2021. [Google Scholar] [CrossRef]

- Sim, K.-B.; Baek, D.; Shin, J.-H.; Shim, G.-S.; Jang, S.-W.; Kim, H.-J.; Hwang, J.-W.; Roh, J.U. Enhanced Surface Properties of Carbon Fiber Reinforced Plastic by Epoxy Modified Primer with Plasma for Automotive Applications. Polymers 2020, 12, 556. [Google Scholar] [CrossRef] [Green Version]

- Fukunaga, A.; Komami, T.; Ueda, S.; Nagumo, M. Plasma treatment of pitch-based ultra high modulus carbon fibers. Carbon 1999, 37, 1087–1091. [Google Scholar] [CrossRef]

- Dilsiz, N. Plasma surface modification of carbon fibers: A review. J. Adhes. Sci. Technol. 2000, 14, 975–987. [Google Scholar] [CrossRef]

- Xie, Y.; Sherwood, P.M.A. X-Ray Photoelectron-Spectroscopic Studies of Carbon Fiber Surfaces. Part IX: The Effect of Microwave Plasma Treatment on Carbon Fiber Surfaces. Appl. Spectrosc. 1989, 43, 1153–1158. [Google Scholar] [CrossRef]

- Liston, E.M. Plasma Treatment for Improved Bonding: A Review. J. Adhes. 1989, 30, 199–218. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J.L. Raman Spectrum of Graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Fujiwara, S.; Fujii, M. Measurements of Thermal Conductivity and Electrical Conductivity of a Single Carbon Fiber. Int. J. Thermophys. 2000, 21, 965–980. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, Z.; Wang, Y.; Dou, S.; Yan, D.; Liu, D.; Xia, Z.; Wang, S. In Situ Exfoliated, Edge-Rich, Oxygen-Functionalized Graphene from Carbon Fibers for Oxygen Electrocatalysis. Adv. Mater. 2017, 29, 1606207. [Google Scholar] [CrossRef]

- Zhu, J.; Park, S.W.; Joh, H.-I.; Kim, H.C.; Lee, S. Study on the stabilization of isotropic pitch based fibers. Macromol. Res. 2014, 23, 79–85. [Google Scholar] [CrossRef]

- Miura, K.; Nakagawa, H.; Hashimoto, K. Examination of the oxidative stabilization reaction of the pitch-based carbon fiber through continuous measurement of oxygen chemisorption and gas formation rate. Carbon 1995, 33, 275–282. [Google Scholar] [CrossRef]

- Lavin, J.G. Chemical reactions in the stabilization of mesophase pitch-based carbon fiber. Carbon 1992, 30, 351–357. [Google Scholar] [CrossRef]

- Shi, K.; Zhang, X.-X.; Wu, W.; Yang, J.-X.; Liu, H.-B.; Li, X.-K. Effect of the oxygen content and the functionality of spinnable pitches derived from ethylene tar by distillation on the mechanical properties of carbon fibers. New Carbon Mater. 2019, 34, 84–94. [Google Scholar] [CrossRef]

- Kil, H.-S.; Oh, K.; Kim, Y.-J.; Ko, S.; Jeon, Y.P.; Joh, H.-I.; Lee, S. Structural evolution of pitch fibers during low temperature carbonization. J. Anal. Appl. Pyrolysis 2018, 136, 153–159. [Google Scholar] [CrossRef]

- Fitzer, E.; Rozploch, F. Laser Ramam spectroscopy for determination of the C-C bonding length in carbon. Carbon 1988, 26, 594–595. [Google Scholar] [CrossRef]

- Lee, S.; Eom, Y.; Kim, B.-J.; Mochida, I.; Yoon, S.-H.; Kim, B.C. The thermotropic liquid crystalline behavior of mesophase pitches with different chemical structures. Carbon 2015, 81, 694–701. [Google Scholar] [CrossRef]

| Samples | C 1s Functional Group (%) | XPS Analysis (at.%) | |||

|---|---|---|---|---|---|

| C=C | C–C | C–O | C | O | |

| PF-0 | 67.8 | 32.2 | - | 96.65 | 3.35 |

| PF-1 | 60.2 | 35.0 | 4.8 | 94.27 | 5.73 |

| PF-5 | 45.4 | 39.2 | 15.4 | 83.33 | 16.67 |

| PF-10 | 53.2 | 39.8 | 7.0 | 91.73 | 8.27 |

| Samples | C (%) | H (%) | N (%) | O (%) a | C/O |

|---|---|---|---|---|---|

| PF-0 | 94.57 | 4.39 | 0.26 | 0.78 | 161.6 |

| PF-1 | 94.41 | 4.26 | 0.25 | 1.08 | 116.5 |

| PF-5 | 92.03 | 3.77 | 0.25 | 2.95 | 41.6 |

| PF-10 | 94.26 | 3.27 | 0.25 | 2.22 | 56.7 |

| SF-0 | 87.24 | 2.87 | 0.25 | 9.64 | 12.1 |

| SF-1 | 85.36 | 3.41 | 0.39 | 10.84 | 10.5 |

| SF-5 | 83.60 | 3.55 | 0.33 | 12.52 | 8.9 |

| SF-10 | 87.09 | 2.79 | 0.13 | 9.99 | 11.6 |

| Samples | Elongation (%) | TS (GPa) | TM (GPa) | ρ (μΩ·m) | λ a (W m−1 K−1) |

|---|---|---|---|---|---|

| CF-0 | 0.86 | 0.49 | 57 | - | - |

| CF-1 | 0.89 | 0.72 | 81 | - | - |

| CF-5 | 1.11 | 1.34 | 121 | - | - |

| CF-10 | 0.94 | 0.88 | 94 | - | - |

| GF-0 | 0.43 | 0.89 | 207 | 3.02 | 418 |

| GF-1 | 0.45 | 1.37 | 304 | 2.73 | 462 |

| GF-5 | 0.44 | 2.21 | 502 | 1.37 | 920 |

| GF-10 | 0.47 | 1.76 | 374 | 1.82 | 693 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Y.; Tan, R.; Liu, Y.; Yang, J.; Li, Y.; Li, J.; Fan, Z.; Shi, K. Mesophase Pitch-Based Carbon Fibers: Accelerated Stabilization of Pitch Fibers under Effective Plasma Irradiation-Assisted Modification. Materials 2021, 14, 6382. https://doi.org/10.3390/ma14216382

Peng Y, Tan R, Liu Y, Yang J, Li Y, Li J, Fan Z, Shi K. Mesophase Pitch-Based Carbon Fibers: Accelerated Stabilization of Pitch Fibers under Effective Plasma Irradiation-Assisted Modification. Materials. 2021; 14(21):6382. https://doi.org/10.3390/ma14216382

Chicago/Turabian StylePeng, Yuanshuo, Ruixuan Tan, Yue Liu, Jianxiao Yang, Yanfeng Li, Jun Li, Zheqiong Fan, and Kui Shi. 2021. "Mesophase Pitch-Based Carbon Fibers: Accelerated Stabilization of Pitch Fibers under Effective Plasma Irradiation-Assisted Modification" Materials 14, no. 21: 6382. https://doi.org/10.3390/ma14216382