Open-Source Flexible Material Tensile Testing Apparatus

Abstract

:1. Introduction

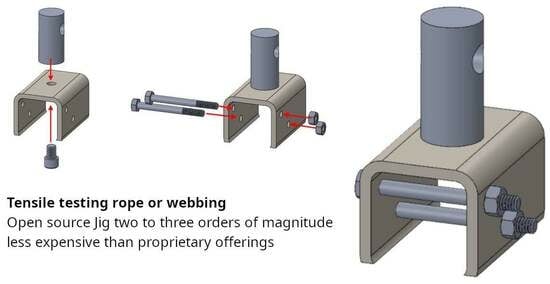

2. Design

3. Build Instructions

3.1. Manufacturing

3.2. Assembly

3.3. Open-Source Design License

4. Operating Instructions

5. Validation

5.1. Results

5.2. Assessment of Jig Performance

5.3. Assessment of Denim Performance

5.4. Future Work

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Toon, O.B.; Robock, A.; Turco, R.P. Environmental Consequences of Nuclear War. Phys. Today 2008, 61, 37–42. [Google Scholar] [CrossRef]

- Coupe, J.; Bardeen, C.G.; Robock, A.; Toon, O.B. Nuclear Winter Responses to Nuclear War Between the United States and Russia in the Whole Atmosphere Community Climate Model Version 4 and the Goddard Institute for Space Studies ModelE. J. Geophys. Res. Atmos. 2019, 124, 8522–8543. [Google Scholar] [CrossRef]

- Chapman, C.R.; Morrison, D. Impacts on the Earth by Asteroids and Comets: Assessing the Hazard. Nature 1994, 367, 33–40. [Google Scholar] [CrossRef]

- Tabor, C.R.; Bardeen, C.G.; Otto-Bliesner, B.L.; Garcia, R.R.; Toon, O.B. Causes and Climatic Consequences of the Impact Winter at the Cretaceous-Paleogene Boundary. Geophys. Res. Lett. 2020, 47, e60121. [Google Scholar] [CrossRef]

- Rampino, M.R. Supereruptions as a Threat to Civilizations on Earth-like Planets. Icarus 2002, 156, 562–569. [Google Scholar] [CrossRef]

- Rougier, J.; Sparks, R.S.J.; Cashman, K.V.; Brown, S.K. The Global Magnitude–Frequency Relationship for Large Explosive Volcanic Eruptions. Earth Planet. Sci. Lett. 2018, 482, 621–629. [Google Scholar] [CrossRef]

- Denkenberger, D.; Pearce, J.M. Feeding Everyone No Matter What: Managing Food Security after Global Catastrophe; Academic Press: London, UK, 2015. [Google Scholar]

- Denkenberger, D.C.; Pearce, J.M. Feeding Everyone: Solving the Food Crisis in Event of Global Catastrophes That Kill Crops or Obscure the Sun. Futures 2015, 72, 57–68. [Google Scholar] [CrossRef]

- Tzachor, A.; Richards, C.E.; Holt, L. Future Foods for Risk-Resilient Diets. Nat. Food 2021, 2, 326–329. [Google Scholar] [CrossRef]

- Winstead, D.J.; Jacobson, M.G. Food Resilience in a Dark Catastrophe: A New Way of Looking at Tropical Wild Edible Plants. Ambio 2022, 51, 1949–1962. [Google Scholar] [CrossRef] [PubMed]

- Denkenberger, D.C.; Cole, D.D.; Abdelkhaliq, M.; Griswold, M.; Hundley, A.B.; Pearce, J.M. Feeding Everyone If the Sun Is Obscured and Industry Is Disabled. Int. J. Disaster Risk Reduct. 2017, 21, 284–290. [Google Scholar] [CrossRef]

- Denkenberger, D.; Pearce, J.; Taylor, A.R.; Black, R. Food without Sun: Price and Life-Saving Potential. Foresight 2018, 21, 118–129. [Google Scholar] [CrossRef]

- Bjerregaard, R.; Valderrama, D.; Radulovich, R.; Diana, J.; Capron, M.; Mckinnie, C.A.; Cedric, M.; Hopkins, K.; Yarish, C.; Goudey, C.; et al. Seaweed Aquaculture for Food Security, Income Generation and Environmental Health in Tropical Developing Countries. Available online: https://documents.worldbank.org/en/publication/documents-reports/documentdetail/947831469090666344/Seaweed-aquaculture-for-food-security-income-generation-and-environmental-health-in-Tropical-Developing-Countries (accessed on 1 September 2023).

- John, R.P.; Anisha, G.S.; Nampoothiri, K.M.; Pandey, A. Micro and Macroalgal Biomass: A Renewable Source for Bioethanol. Bioresour. Technol. 2011, 102, 186–193. [Google Scholar] [CrossRef] [PubMed]

- Jehn, F.U.; Dingal, F.J.; Mill, A.; Harrison, C.S.; Ilin, E.; Roleda, M.Y.; James, S.C.; Denkenberger, D.C. Seaweed as a Resilient Food Solution after a Nuclear War. Earth’s Future 2023, 12, e2023EF003710. [Google Scholar] [CrossRef]

- Mill, A.; Harrison, C.S.; James, S.; Shah, S.; Fist, T.; Alvarado, K.A.; Taylor, A.R. Preventing Global Famine in Case of Sun-Blocking Scenarios: Seaweed as an Alternative Food Source. In Proceedings of the 2019 Effective Altruism Global, London, UK, 18–20 October 2019. [Google Scholar]

- Mouritsen, O.G.; Dawczynski, C.; Duelund, L.; Jahreis, G.; Vetter, W.; Schröder, M. On the Human Consumption of the Red Seaweed Dulse (Palmaria Palmata (L.) Weber & Mohr). J. Appl. Phycol. 2013, 25, 1777–1791. [Google Scholar] [CrossRef]

- Priyadarshini, A.; Priyadarshini, A.; Rajauria, G. Economic Status of Seaweed: Production, Consumption, Commercial Applications, Hazards, and Legislations. In Recent Advances in Micro and Macroalgal Processing; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; pp. 604–616. ISBN 978-1-119-54265-0. [Google Scholar]

- Fedoroff, N.V.; Battisti, D.S.; Beachy, R.N.; Cooper, P.J.M.; Fischhoff, D.A.; Hodges, C.N.; Knauf, V.C.; Lobell, D.; Mazur, B.J.; Molden, D.; et al. Radically Rethinking Agriculture for the 21st Century. Science 2010, 327, 833–834. [Google Scholar] [CrossRef]

- Mills, M.J.; Toon, O.B.; Turco, R.P.; Kinnison, D.E.; Garcia, R.R. Massive Global Ozone Loss Predicted Following Regional Nuclear Conflict. Proc. Natl. Acad. Sci. USA 2008, 105, 5307–5312. [Google Scholar] [CrossRef]

- Xu, L.; Wei, K.; Wu, X.; Smyshlyaev, S.P.; Chen, W.; Galin, V.Y. The Effect of Super Volcanic Eruptions on Ozone Depletion in a Chemistry-Climate Model. Adv. Atmos. Sci. 2019, 36, 823–836. [Google Scholar] [CrossRef]

- Bardeen, C.G.; Kinnison, D.E.; Toon, O.B.; Mills, M.J.; Vitt, F.; Xia, L.; Jägermeyr, J.; Lovenduski, N.S.; Scherrer, K.J.N.; Clyne, M.; et al. Extreme Ozone Loss Following Nuclear War Results in Enhanced Surface Ultraviolet Radiation. J. Geophys. Res. Atmos. 2021, 126, e2021JD035079. [Google Scholar] [CrossRef]

- Greene, C.H.; Scott-Buechler, C.M.; Hausner, A.L.P.; Johnson, Z.I.; Lei, X.G.; Huntley, M.E. Transforming the Future of Marine Aquaculture: A Circular Economy Approach. Oceanography 2022, 35, 26–34. [Google Scholar] [CrossRef]

- Froehlich, H.E.; Afflerbach, J.C.; Frazier, M.; Halpern, B.S. Blue Growth Potential to Mitigate Climate Change through Seaweed Offsetting. Curr. Biol. 2019, 29, 3087–3093.e3. [Google Scholar] [CrossRef]

- Handbook on Eucheuma Seaweed. Available online: https://www.fao.org/3/AC287E/AC287E03.htm (accessed on 1 September 2023).

- Mohamed, G. Current Trends and Prospects of Seaweed Farming in India. Available online: http://eprints.cmfri.org.in/10671/ (accessed on 1 September 2023).

- Source HDPE Seaweed Farming Nets Rope on, m. Alibaba.Com. Available online: https://m.alibaba.com/product/62537750517/HDPE-seaweed-farming-nets-rope.html (accessed on 1 September 2023).

- Deng, P. What Kind of Rope Is Used for Cultivating Seaweed? Available online: https://www.linkedin.com/pulse/what-kind-rope-used-cultivating-seaweed-%E5%B0%8F%E6%B6%9B-%E5%8D%A2 (accessed on 1 September 2023).

- Flory, J.F. International and National Standards for Large Synthetic-Fiber Ropes; OnePetro: Richardson, TX, USA, 1987. [Google Scholar]

- Goldfarb, L. Braided Rope Tensile Testing. Available online: https://www.instron.com/en/resources/blog/2020/october/braided-rope-tensile-testing (accessed on 11 May 2023).

- Pneumatic Action Tire Cord Grips. 10 kN. Available online: https://www.instron.com/en/products/testing-accessories/grips/wire-cable/2714-107 (accessed on 11 November 2023).

- Pneumatic Cord and Yarn Tensile Grips. Available online: https://www.instron.com/en/products/testing-accessories/grips/pneumatic-cord-and-yarn-tensile-grips (accessed on 11 November 2023).

- SG-1 Wire Snubbing Grips. Available online: https://www.instron.com/en/products/testing-accessories/grips/wire-cable/w-5074m (accessed on 11 November 2023).

- Webbing Capstan Tensile Grips. Available online: https://www.instron.com/en/products/testing-accessories/grips/webbing-capstan-tensile-grips (accessed on 11 November 2023).

- D6775 Standard Test Method for Breaking Strength and Elongation of Textile Webbing, Tape and Braided Material. Available online: https://www.astm.org/d6775-13r17.html (accessed on 4 February 2024).

- Adelaide. In Adelaide Testing Machines Inc Model FC-100 Low Cycle Fatigue Testing Software Operating Manual; Etobicoke: Adelaide, ON, Canada, 2016.

- Nylon Ropes-Strengths. Available online: https://www.engineeringtoolbox.com/nylon-rope-strength-d_1513.html (accessed on 11 November 2023).

- ASTM D4268-Rope Tensile Strength. Available online: https://www.universalgripco.com/astm-d4268 (accessed on 29 January 2024).

- Tensile Tester Project-YouTube. Available online: https://www.youtube.com/playlist?list=PLaeIi4Gbl1T9_tOk-mwGmbdWcfcrAMq4m (accessed on 11 November 2023).

- Fully OPEN SOURCE Universal Test Machine! 2019. Available online: https://www.youtube.com/watch?v=uvn-J8CbtzM (accessed on 11 November 2023).

- MechEngineerMike TestrBot: The $300 Universal Test Machine. Available online: https://www.instructables.com/TestrBot-The-300-Universal-Test-Machine/ (accessed on 11 November 2023).

- CrazyBlackStone Universal Tensile Testing Machine Version Two. Available online: https://www.instructables.com/Universal-Tensile-Testing-Machine-VERSION-TWO/ (accessed on 11 November 2023).

- Hoffman Tactical. A Quick Look at the New Tensile Test Machine. 2021. Available online: https://www.youtube.com/watch?v=FBKQatM8QNE (accessed on 11 November 2023).

- Amend, J.R.; Lipson, H. FreeLoader: An Open Source Universal Testing Machine for High-Throughput Experimentation; American Society of Mechanical Engineers Digital Collection; American Society of Mechanical Engineers: New York, NY, USA, 2012; pp. 685–693. [Google Scholar]

- FreeLoader. Available online: https://www.creativemachineslab.com/freeloader.html (accessed on 11 November 2023).

- Liu, X.C.; Pajovic, S.; Kei, C.Y.L.; Delaviz, Y.; Ramsay, S.D. Use of a Low-Cost, Open-Source Universal Mechanical Testing Machine in an Introductory Materials Science Course. 22 June 2020. Available online: https://peer.asee.org/use-of-a-low-cost-open-source-universal-mechanical-testing-machine-in-an-introductory-materials-science-course (accessed on 11 November 2023).

- Jose Mathew, S.; Francis, V. Development, Validation and Implementation of Universal Testing Machine. 2020. Available online: https://www.diva-portal.org/smash/get/diva2:1472019/FULLTEXT01.pdf (accessed on 11 November 2023).

- Materiom-Universal Testing Machine. Available online: https://github.com/materiom/UTM/wiki (accessed on 11 November 2023).

- Oberloier, S.; Pearce, J.M. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs 2018, 2, 2. [Google Scholar] [CrossRef]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific Publishing Company: Singapore, 2009; pp. 568–580. ISBN 978-981-4280-25-9. [Google Scholar]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

| Component | Unit Cost (CAD) | Quantity | Cost (CAD) | Supplier | Material/Description |

|---|---|---|---|---|---|

| Main body | 5.61 | 2 | 11.22 | Metal Supermarkets (London, ON, Canada) | 2” mild square steel tubing, 1/8” thick, 3” length |

| Jig mount | 3.28 | 2 | 6.56 | Metal Supermarkets (London, ON, Canada) | 1” hot-rolled mild steel round bar, 2” length |

| Jig bolt | 0.36 | 2 | 0.72 | Fastenal (Winona, MN, USA) (SKU: 23301) | Black-oxide alloy steel socket head screw, 3/8”-16 thread size, 1/2” long |

| Sample mounting bolt | 0.28 * | 4 | 1.12 | McMaster-Carr (Elmhurst, IL, USA) (91247A553) | Grade 5 steel hex head shoulder screw, 1/4” shoulder diameter, 2” shoulder length, ¾” thread length, 1/4”-20 thread |

| Sample mounting nut | 0.0476 | 4 | 0.19 | Fastenal (Winona, MN, USA) (SKU: 1137260) | 1/4”-20 zinc finish grade 5 finished hex nut |

| Required Tooling | Alternative Low Cost | Optional |

|---|---|---|

| Horizontal band saw | Hack saw, angle grinder, reciprocating saw | Purchase material precut to length to reduce cutting operations to 1 |

| Steel punch and hammer | Omit for reduced accuracy and ease | |

| Metal scribe | Marker, welder’s pencil, wax pencil | |

| Belt sander | Metal file | |

| 5/16” drill bit and coarse thread hand tap | Metal inert gas (MIG) welder (depending on accessible tooling) | |

| Drill press | Drill | Computer numeric control (CNC) and lathe for improved locating and accuracy on round bar |

| ¼” and ½” drill bits | ||

| Measuring tape | ||

| Digital caliper | Ruler, measuring tape |

| Material Thickness (in) | Number of Sample Widths | Number of Folds | Maximum Loading (N) |

|---|---|---|---|

| 1 5/8 | 1 | 0 | 332 |

| 3 1/4 | 2 | 1 | 700 |

| 4 7/8 | 3 | 2 | 862 |

| 6 1/2 | 4 | 3 | 1282 |

| 8 1/8 | 5 | 4 | 1654 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woods, M.C.; Nauta, N.; Pearce, J.M. Open-Source Flexible Material Tensile Testing Apparatus. Hardware 2024, 2, 33-49. https://doi.org/10.3390/hardware2010002

Woods MC, Nauta N, Pearce JM. Open-Source Flexible Material Tensile Testing Apparatus. Hardware. 2024; 2(1):33-49. https://doi.org/10.3390/hardware2010002

Chicago/Turabian StyleWoods, Morgan C., Nathan Nauta, and Joshua M. Pearce. 2024. "Open-Source Flexible Material Tensile Testing Apparatus" Hardware 2, no. 1: 33-49. https://doi.org/10.3390/hardware2010002