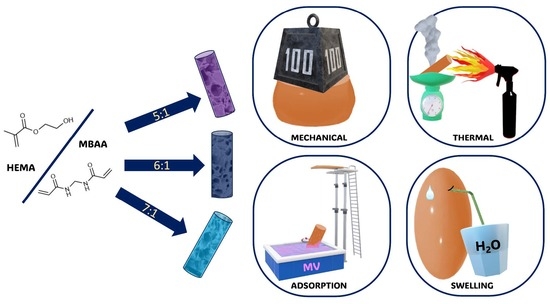

How the Crosslinker Amount Influences the Final Properties of Hydroxyethyl Methacrylate Cryogels

Abstract

:1. Introduction

2. Results and Discussion

2.1. Cryogels Synthesis

2.2. Infrared Analysis

2.3. Thermogravimetric Analysis

2.4. Morphological Analysis

2.5. Mechanical Analysis

2.6. Swelling

2.7. Adsorption Test

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Synthesis of Cryogels

4.3. Thermogravimetric Analysis

4.4. Morphological Analysis

4.5. Infrared Analysis

4.6. Mechanical Analysis

4.7. Swelling Test

4.8. Adsorption Capacity

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fuchs, S.; Shariati, K.; Ma, M. Specialty Tough Hydrogels and Their Biomedical Applications. Adv. Healthc. Mater. 2020, 9, 1901396. [Google Scholar] [CrossRef]

- Sajjadi, S.; Gholizadeh-Hashjin, A.; Shafizadeh, F.; Marefat, S.; Hamidi, S.; Farjami, A. Advancing Biomedicine with Gel-based Materials and Composites: A Comprehensive Review. J. Appl. Polym. Sci. 2023, 140, e54641. [Google Scholar] [CrossRef]

- Haleem, A.; Pan, J.-M.; Shah, A.; Hussain, H.; He, W. A Systematic Review on New Advancement and Assessment of Emerging Polymeric Cryogels for Environmental Sustainability and Energy Production. Sep. Purif. Technol. 2023, 316, 123678. [Google Scholar] [CrossRef]

- Zagni, C.; Dattilo, S.; Mecca, T.; Gugliuzzo, C.; Scamporrino, A.A.; Privitera, V.; Puglisi, R.; Carola Carroccio, S. Single and Dual Polymeric Sponges for Emerging Pollutants Removal. Eur. Polym. J. 2022, 179, 111556. [Google Scholar] [CrossRef]

- Baimenov, A.; Berillo, D.A.; Poulopoulos, S.G.; Inglezakis, V.J. A Review of Cryogels Synthesis, Characterization and Applications on the Removal of Heavy Metals from Aqueous Solutions. Adv. Colloid Interface Sci. 2020, 276, 102088. [Google Scholar] [CrossRef]

- Haleem, A.; Chen, S.-Q.; Ullah, M.; Siddiq, M.; He, W.-D. Highly Porous Cryogels Loaded with Bimetallic Nanoparticles as an Efficient Antimicrobial Agent and Catalyst for Rapid Reduction of Water-Soluble Organic Contaminants. J. Environ. Chem. Eng. 2021, 9, 106510. [Google Scholar] [CrossRef]

- Cantarella, M.; Impellizzeri, G.; Di Mauro, A.; Privitera, V.; Carroccio, S.C. Innovative Polymeric Hybrid Nanocomposites for Application in Photocatalysis. Polymers 2021, 13, 1184. [Google Scholar] [CrossRef] [PubMed]

- Akbayeva, D.N.; Smagulova, I.A.; Maksotova, K.S.; Bakirova, B.S.; Tatykhanova, G.S.; Kudaibergenov, S.E. In Situ Entrapment of Catalase within Macroporous Cryogel Matrix for Ethanol Oxidation: Flow-through Mode versus Batch Reactor. Catalysts 2023, 13, 1075. [Google Scholar] [CrossRef]

- Zagni, C.; Coco, A.; Mecca, T.; Curcuruto, G.; Patamia, V.; Mangano, K.; Rescifina, A.; Carroccio, S.C. Sponge-like Macroporous Cyclodextrin-Based Cryogels for Controlled Drug Delivery. Mater. Chem. Front. 2023, 7, 2693–2705. [Google Scholar] [CrossRef]

- Pacelli, S.; Di Muzio, L.; Paolicelli, P.; Fortunati, V.; Petralito, S.; Trilli, J.; Casadei, M.A. Dextran-Polyethylene Glycol Cryogels as Spongy Scaffolds for Drug Delivery. Int. J. Biol. Macromol. 2021, 166, 1292–1300. [Google Scholar] [CrossRef]

- Babić Radić, M.M.; Filipović, V.V.; Vukomanović, M.; Nikodinović Runić, J.; Tomić, S.L. Degradable 2-Hydroxyethyl Methacrylate/Gelatin/Alginate Hydrogels Infused by Nanocolloidal Graphene Oxide as Promising Drug Delivery and Scaffolding Biomaterials. Gels 2021, 8, 22. [Google Scholar] [CrossRef]

- Kutlusoy, T.; Oktay, B.; Apohan, N.K.; Süleymanoğlu, M.; Kuruca, S.E. Chitosan-Co-Hyaluronic Acid Porous Cryogels and Their Application in Tissue Engineering. Int. J. Biol. Macromol. 2017, 103, 366–378. [Google Scholar] [CrossRef]

- Inci, I.; Kirsebom, H.; Galaev, I.Y.; Mattiasson, B.; Piskin, E. Gelatin Cryogels Crosslinked with Oxidized Dextran and Containing Freshly Formed Hydroxyapatite as Potential Bone Tissue-Engineering Scaffolds: Potential Gelatin-Dextran-Hydroxyapatite Bone TE Scaffold. J. Tissue Eng. Regen. Med. 2013, 7, 584–588. [Google Scholar] [CrossRef]

- Bölgen, N.; Vargel, I.; Korkusuz, P.; Güzel, E.; Plieva, F.; Galaev, I.; Matiasson, B.; Pişkin, E. Tissue Responses to Novel Tissue Engineering Biodegradable Cryogel Scaffolds: An Animal Model. J. Biomed. Mater. Res. 2009, 91A, 60–68. [Google Scholar] [CrossRef] [PubMed]

- Bölgen, N.; Yang, Y.; Korkusuz, P.; Güzel, E.; El Haj, A.J.; Pişkin, E. Three-Dimensional Ingrowth of Bone Cells Within Biodegradable Cryogel Scaffolds in Bioreactors at Different Regimes. Tissue Eng. Part A 2008, 14, 1743–1750. [Google Scholar] [CrossRef] [PubMed]

- Tatykhanova, G.S.; Klivenko, A.N.; Kudaibergenova, G.M.; Kudaibergenov, S.E. Flow–Through Catalytic Rector Based on Macroporous Amphoteric Cryogels and Gold Nanoparticles. Macromol. Symp. 2016, 363, 49–56. [Google Scholar] [CrossRef]

- Abed, N.; Mohammed, A.; Musa, A. Effect of Crosslinker Amount on Properties of Poly Phenylacrylamide Gels. Egypt. J. Chem. 2021, 64, 1981–1987. [Google Scholar] [CrossRef]

- Su, X.; Zhang, Q.; Zhong, Q.; Liu, L.; Gao, H.; Meng, R.; Yao, J. Macroporous Cellulose-Based Cryogels with Tunable Porous Structure and Surface Functional Groups. Fibers Polym. 2016, 17, 712–720. [Google Scholar] [CrossRef]

- Wan, T.; Cheng, W.; Zhou, Z.; Xu, M.; Zou, C.; Li, R. Influence of Crosslinker Amount on Swelling and Gel Properties of Hectorite/Poly(Acrylamide/Itaconic Acid) Nanocomposite Hydrogels. Korean J. Chem. Eng. 2015, 32, 1434–1439. [Google Scholar] [CrossRef]

- Okay, O. (Ed.) Polymeric Cryogels: Macroporous Gels with Remarkable Properties; Advances in Polymer Science; Springer International Publishing: Cham, Switzerland, 2014; Volume 263, ISBN 978-3-319-05845-0. [Google Scholar]

- Bakhshpour, M.; Idil, N.; Perçin, I.; Denizli, A. Biomedical Applications of Polymeric Cryogels. Appl. Sci. 2019, 9, 553. [Google Scholar] [CrossRef]

- Zagni, C.; Coco, A.; Dattilo, S.; Patamia, V.; Floresta, G.; Fiorenza, R.; Curcuruto, G.; Mecca, T.; Rescifina, A. HEMA-Based Macro and Microporous Materials for CO2 Capture. Mater. Today Chem. 2023, 33, 101715. [Google Scholar] [CrossRef]

- Zagni, C.; Scamporrino, A.A.; Riccobene, P.M.; Floresta, G.; Patamia, V.; Rescifina, A.; Carroccio, S.C. Portable Nanocomposite System for Wound Healing in Space. Nanomaterials 2023, 13, 741. [Google Scholar] [CrossRef] [PubMed]

- Erol, I.; Aksu, M.; Gürler, Z. Preparation of Poly(AAm-Co-HEMA)/ZnO Nanocomposites via in Situ Polymerization/Hydrothermal Method and Determination of Their Properties. Polym. Bull. 2023, 80, 5675–5703. [Google Scholar] [CrossRef]

- Baydemir, G.; Bereli, N.; Andaç, M.; Say, R.; Galaev, I.Y.; Denizli, A. Bilirubin Recognition via Molecularly Imprinted Supermacroporous Cryogels. Colloids Surf. B Biointerfaces 2009, 68, 33–38. [Google Scholar] [CrossRef]

- Bereli, N.; Andaç, M.; Baydemir, G.; Say, R.; Galaev, I.Y.; Denizli, A. Protein Recognition via Ion-Coordinated Molecularly Imprinted Supermacroporous Cryogels. J. Chromatogr. A 2008, 1190, 18–26. [Google Scholar] [CrossRef]

- Derazshamshir, A.; Ergün, B.; Peşint, G.; Odabaşı, M. Preparation of Zn2+-chelated Poly(HEMA-MAH) Cryogel for Affinity Purification of Chicken Egg Lysozyme. J. Appl. Polym. Sci. 2008, 109, 2905–2913. [Google Scholar] [CrossRef]

- Avcibaşi, N.; Uygun, M.; Çorman, M.E.; Akgöl, S.; Denizli, A. Application of Supermacroporous Monolithic Hydrophobic Cryogel in Capturing of Albumin. Appl. Biochem. Biotechnol. 2010, 162, 2232–2243. [Google Scholar] [CrossRef]

- Rahmatpour, A.; Goodarzi, N.; Moazzez, M. A Novel Route for Synthesis of Cross-Linked Polystyrene Copolymer Beads with Tunable Porosity Using Guar and Xanthan Gums from Bioresources as Alternative Synthetic Suspension Stabilizers. Des. Monomers Polym. 2018, 21, 116–129. [Google Scholar] [CrossRef]

- Demirelli, K.; Coşkun, M.; Kaya, E. A Detailed Study of Thermal Degradation of Poly(2-Hydroxyethyl Methacrylate). Polym. Degrad. Stab. 2001, 72, 75–80. [Google Scholar] [CrossRef]

- Passos, M.F.; Dias, D.R.C.; Bastos, G.N.T.; Jardini, A.L.; Benatti, A.C.B.; Dias, C.G.B.T.; Maciel Filho, R. pHEMA Hydrogels: Synthesis, Kinetics and in Vitro Tests. J. Therm. Anal. Calorim. 2016, 125, 361–368. [Google Scholar] [CrossRef]

- Rottreau, T.J.; Parkes, G.E.; Schirru, M.; Harries, J.L.; Granollers Mesa, M.; Topham, P.D.; Evans, R. NMR Cryoporometry of Polymers: Cross-Linking, Porosity and the Importance of Probe Liquid. Colloids Surf. A Physicochem. Eng. Asp. 2019, 575, 256–263. [Google Scholar] [CrossRef]

- Salzano De Luna, M.; Ascione, C.; Santillo, C.; Verdolotti, L.; Lavorgna, M.; Buonocore, G.G.; Castaldo, R.; Filippone, G.; Xia, H.; Ambrosio, L. Optimization of Dye Adsorption Capacity and Mechanical Strength of Chitosan Aerogels through Crosslinking Strategy and Graphene Oxide Addition. Carbohydr. Polym. 2019, 211, 195–203. [Google Scholar] [CrossRef] [PubMed]

- Doğan, M.; Özdemir, Y.; Alkan, M. Adsorption Kinetics and Mechanism of Cationic Methyl Violet and Methylene Blue Dyes onto Sepiolite. Dye. Pigment. 2007, 75, 701–713. [Google Scholar] [CrossRef]

- Wan, B.; Li, J.; Ma, F.; Yu, N.; Zhang, W.; Jiang, L.; Wei, H. Preparation and Properties of Cryogel Based on Poly(2-Hydroxyethyl Methacrylate-Co-Glycidyl Methacrylate). Langmuir 2019, 35, 3284–3294. [Google Scholar] [CrossRef]

- Mashkoor, F. Exploring the Reusability of Synthetically Contaminated Wastewater Containing Crystal Violet Dye Using Tectona Grandis Sawdust as a Very Low-Cost Adsorbent. Sci. Rep. 2018, 8, 8314. [Google Scholar] [CrossRef]

| Sample | HEMA:MBAA | HEMA (μL) | MBAA (μg) | APS (μL) | TEMED (μL) | Vol H2O (μL) | Vol tot (μL) | Y% 1 |

|---|---|---|---|---|---|---|---|---|

| A | 5:1 | 234 | 59.5 | 45 | 45 | 2633 | 3000 | 93 |

| B | 6:1 | 234 | 49.6 | 45 | 45 | 2640 | 3000 | 90 |

| C | 7:1 | 234 | 42.5 | 45 | 45 | 2645 | 3000 | 85 |

| Sample | HEMA: MBAA | ρ [g·cm−3] 3 | Ec [kPa] 1 | εf [%] 2 | Ec/ρ [kPa·cm3·g−1] 4 | |

|---|---|---|---|---|---|---|

| A | 5:1 | 0.145 ± 0.005 | dry | 17.57 ± 6.31 | 30.14 ± 3.19 | 120.19 ± 39.70 |

| swollen | 0.053 ± 0.016 | 7.090 ± 1.430 | 0.369 ± 0.107 | |||

| B | 6:1 | 0.145 ± 0.009 | dry | 12.15 ± 1.64 | 32.97 ± 1.31 | 83.20 ± 6.12 |

| swollen | 0.048 ± 0.006 | 6.645 ± 0.265 | 0.331 ± 0.041 | |||

| C | 7:1 | 0.152 ± 0.012 | dry | 8.86 ± 2.78 | 27.22 ± 0.22 | 57.33 ± 13.74 |

| swollen | 0.036 ± 0.005 | 5.950 ± 0.860 | 0.234 ± 0.030 |

| Sample | TMAX 1 (°C) | P % 2 | Davg 3 (μm) | S% 4 | Qe 5 (mg/g) | R% 6 | Ec/ρ [kPa·cm3·g−1] 7 |

|---|---|---|---|---|---|---|---|

| A | 424 ± 1 | 30.2 | 10.8 | 871.1 ± 2% | 94.1 | 17% | 120.19 ± 39.70 |

| B | 421 ± 1 | 34.1 | 14.5 | 907.1 ± 2% | 109.9 | 20% | 83.20 ± 6.12 |

| C | 420 ± 1 | 46.1 | 17.4 | 931.5 ± 2% | 113.7 | 21% | 57.33 ± 13.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Proietto Salanitri, G.; Luzzi, E.; Caretti, D.; Mecca, T.; Carroccio, S.C.; Scamporrino, A.A. How the Crosslinker Amount Influences the Final Properties of Hydroxyethyl Methacrylate Cryogels. Gels 2024, 10, 163. https://doi.org/10.3390/gels10030163

Proietto Salanitri G, Luzzi E, Caretti D, Mecca T, Carroccio SC, Scamporrino AA. How the Crosslinker Amount Influences the Final Properties of Hydroxyethyl Methacrylate Cryogels. Gels. 2024; 10(3):163. https://doi.org/10.3390/gels10030163

Chicago/Turabian StyleProietto Salanitri, Giuseppe, Enrica Luzzi, Daniele Caretti, Tommaso Mecca, Sabrina C. Carroccio, and Andrea A. Scamporrino. 2024. "How the Crosslinker Amount Influences the Final Properties of Hydroxyethyl Methacrylate Cryogels" Gels 10, no. 3: 163. https://doi.org/10.3390/gels10030163