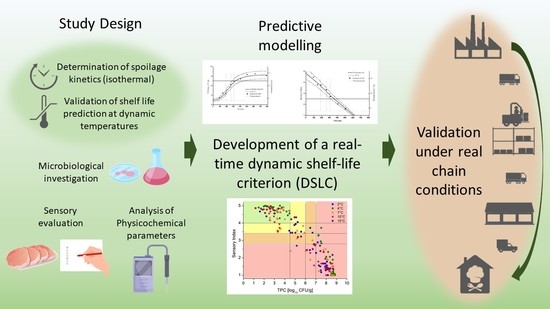

A Multi-Model Approach to Implement a Dynamic Shelf Life Criterion in Meat Supply Chains

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples and Experimental Design

2.2. Physicochemical Quality Parameters

2.3. Microbiological Parameters

2.4. Sensory Analysis

2.5. Data Analysis and Modeling

2.5.1. Modeling of Microbial and Sensory Data

2.5.2. Dynamic Modeling

2.5.3. Model Validation

3. Results and Discussion

3.1. Characterization of the Spoilage of Ma-Packed Pork Loin and Selection of the Shelf-Life Criterion

| Texture | Color | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Temperature [°C] | Hardness | Elasticity | Cohesion | L* | a* | b* | pH | Oxygen | SI |

| 2 | 0.341 * | −0.318 * | 0.474 ** | −0.712 ** | −0.705 ** | −0.951 ** | |||

| 4 | −0.253 * | 0.408 ** | −0.671 ** | −0.602 ** | −0.526 ** | −0.903 ** | −0.949 ** | ||

| 7 | 0.549 ** | −0.693 ** | −0.622 ** | 0.663 ** | −0.645 ** | −0.724 ** | −0.657 ** | −0.881 ** | −0.971 ** |

| 10 | 0.551 ** | −0.692 ** | −0.554 ** | −0.558 ** | −0.986 ** | ||||

| 15 | 0.302 * | −0.605 ** | −0.648 ** | 0.726 ** | −0.571 ** | −0.404 ** | −0.948 ** | −0.977 ** | |

| 25 | −0.700 ** | −0.403 ** | 0.763 ** | 0.296 * | −0.964 ** | −0.988 ** | |||

| Microbial Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Temperature [°C] | TPC | TVC | PSE | B. thermosphacta | Enterobacteriaceae | LAB | Yeasts/Molds |

| 2 | 0.923 ** | 0.828 ** | 0.541 ** | 0.866 ** | 0.659 ** | ||

| 4 | 0.926 ** | 0.816 ** | 0.727 ** | 0.771 ** | 0.789 ** | ||

| 7 | 0.894 ** | 0.892 ** | 0.916 ** | 0.883 ** | 0.674 ** | 0.891 ** | 0.925 ** |

| 10 | 0.913 ** | 0.900 ** | 0.666 ** | 0.485 ** | 0.868 ** | 0.766 ** | |

| 15 | 0.930 ** | 0.912 ** | 0.931 ** | 0.895 ** | 0.869 ** | 0.910 ** | 0.922 ** |

| 25 | 0.929 ** | 0.944 ** | 0.872 ** | 0.831 ** | 0.905 ** | 0.938 ** | 0.922 ** |

3.2. Shelf-Life Modeling

3.3. Validation of the Shelf-Life Models under Laboratory and Practical Conditions

| Scenario | RMSE | Bf | Af | R2 |

|---|---|---|---|---|

| Microbial development | ||||

| B1 | 0.47 | 0.99 | 1.09 | 0.95 |

| C1 | 0.30 | 0.99 | 1.04 | 0.98 |

| D1 | 0.40 | 1.00 | 1.07 | 0.96 |

| Sensory development | ||||

| B1 | 0.51 | 0.91 | 1.18 | 0.83 |

| C1 | 0.15 | 1.01 | 1.05 | 0.98 |

| D1 | 0.51 | 0.80 | 1.25 | 0.87 |

3.4. Development of the DSLC

3.5. Pilot Study and Implementation of the DSLC

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Temperature [°C] | A [log10 CFU/g] | B [1/h] | M [h] | C [log10 CFU/g] | R² |

|---|---|---|---|---|---|

| 2 | 2.1 (±0.6) | 0.0056 (±0.001) | 278 (±50) | 5.9 (±0.6) | 0.977 |

| 4 | 3.0 (±0.4) | 0.0075 (±0.001) | 186 (±24) | 5.7 (±0.5) | 0.985 |

| 7 | 3.4 (±0.3) | 0.014 (±0.003) | 150 (±13) | 5.0 (±0.3) | 0.985 |

| 10 | 2.6 (±0.1) | 0.022 (±0.002) | 106 (±3) | 5.6 (±0.1) | 0.998 |

| 15 | 3.6 (±0.4) | 0.034 (±0.010) | 49 (±6) | 4.6 (±0.5) | 0.975 |

| 25 | 2.2 (±0.4) | 0.086 (±0.030) | 21 (±4) | 6.2 (±0.5) | 0.976 |

| Temperature [°C] | Slope | Intercept | R2 |

|---|---|---|---|

| 2 | −0.00378 (±0.00023) | 4.93 (±0.14) | 0.985 |

| 4 | −0.00527 (±0.00026) | 4.95 (±0.03) | 0.990 |

| 7 | −0.00747 (±0.00046) | 4.75 (±0.05) | 0.982 |

| 10 | −0.00992 (±0.00048) | 4.64 (±0.10) | 0.988 |

| 15 | −0.02254 (±0.00138) | 4.74 (±0.10) | 0.982 |

| 25 | −0.05122 (±0.00220) | 4.61 (±0.10) | 0.991 |

References

- Corradini, M.G. Shelf Life of Food Products: From Open Labeling to Real-Time Measurements. Annu. Rev. Food Sci. Technol. 2018, 9, 251–269. [Google Scholar] [CrossRef]

- Tamplin, M.L. Integrating predictive models and sensors to manage food stability in supply chains. Food Microbiol. 2018, 75, 90–94. [Google Scholar] [CrossRef] [PubMed]

- Buisman, M.E.; Haijema, R.; Bloemhof-Ruwaard, J.M. Discounting and dynamic shelf life to reduce fresh food waste at retailers. Int. J. Prod. Econ. 2019, 209, 274–284. [Google Scholar] [CrossRef]

- Moraes, N.V.; Lermen, F.H.; Echeveste, M.E.S. A systematic literature review on food waste/loss prevention and minimization methods. J. Environ. Manag. 2021, 286, 112268. [Google Scholar] [CrossRef]

- Albrecht, A.; Ibald, R.; Raab, V.; Reichstein, W.; Haarer, D.; Kreyenschmidt, J. Implementation of Time Temperature Indicators to Improve Temperature Monitoring and Support Dynamic Shelf Life in Meat Supply Chains. J. Packag. Technol. Res. 2020, 4, 23–32. [Google Scholar] [CrossRef] [Green Version]

- Caldeira, C.; de Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef] [PubMed]

- Nychas, G.-J.E.; Skandamis, P.N.; Tassou, C.C.; Koutsoumanis, K.P. Meat spoilage during distribution. Meat Sci. 2008, 78, 77–89. [Google Scholar] [CrossRef]

- Rossaint, S.; Kreyenschmidt, J. Intelligent label—A new way to support food waste reduction. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2015, 168, 63–71. [Google Scholar] [CrossRef]

- Tukker, A.; Jansen, B. Environmental Impacts of Products: A Detailed Review of Studies. J. Ind. Ecol. 2006, 10, 159–182. [Google Scholar] [CrossRef]

- Revell, B.J. One Man’s Meat … 2050? Ruminations on Future Meat Demand in the Context of Global Warming. J Agric Econ. 2015, 66, 573–614. [Google Scholar] [CrossRef]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time-Temperature Management Along the Food Cold Chain: A Review of Recent Developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef] [PubMed]

- McMeekin, T.; Bowman, J.; McQuestin, O.; Mellefont, L.; Ross, T.; Tamplin, M. The future of predictive microbiology: Strategic research, innovative applications and great expectations. Int. J. Food Microbiol. 2008, 128, 2–9. [Google Scholar] [CrossRef] [PubMed]

- Tenenhaus-Aziza, F.; Ellouze, M. Software for predictive microbiology and risk assessment: A description and comparison of tools presented at the ICPMF8 Software Fair. Food Microbiol. 2015, 45, 290–299. [Google Scholar] [CrossRef] [PubMed]

- Bruckner, S.; Albrecht, A.; Petersen, B.; Kreyenschmidt, J. A predictive shelf life model as a tool for the improvement of quality management in pork and poultry chains. Food Control 2013, 29, 451–460. [Google Scholar] [CrossRef]

- Borch, E.; Kant-Muermans, M.-L.; Blixt, Y. Bacterial spoilage of meat and cured meat products. Int. J. Food Microbiol. 1996, 33, 103–120. [Google Scholar] [CrossRef]

- Stavropoulou, E.; Bezirtzoglou, E. Predictive Modeling of Microbial Behavior in Food. Foods 2019, 8, 654. [Google Scholar] [CrossRef] [Green Version]

- Raab, V.; Bruckner, S.; Beierle, E.; Kampmann, Y.; Petersen, B.; Kreyenschmidt, J. Generic model for the prediction of remaining shelf life in support of cold chain management in pork and poultry supply chains. J. Chain Netw. Sci. 2008, 8, 59–73. [Google Scholar] [CrossRef]

- Herbert, U.; Albrecht, A.; Kreyenschmidt, J. Definition of predictor variables for MAP poultry filets stored under different temperature conditions. Poult. Sci. 2015, 94, 424–432. [Google Scholar] [CrossRef]

- Mack, M.; Dittmer, P.; Veigt, M.; Kus, M.; Nehmiz, U.; Kreyenschmidt, J. Quality tracing in meat supply chains. Philos. Trans. A Math. Phys. Eng. Sci. 2014, 372, 20130308. [Google Scholar] [CrossRef] [Green Version]

- Zhu, S.; Luo, Y.; Feng, L.; Bao, Y. Establishment of Kinetic Models Based on Electrical Conductivity and Global Stability Index for Predicting the Quality of Allogynogenetic Crucian Carps (Carassius auratus gibelio) during Chilling Storage. J. Food Process. Preserv. 2015, 39, 167–174. [Google Scholar] [CrossRef]

- Peleg, M.; Normand, M.D. Simulating shelf life determination by two simultaneous criteria. Food Res. Int. 2015, 78, 388–395. [Google Scholar] [CrossRef]

- Ansorena, M.R.; Goñi, M.G.; Aguëro, M.V.; Roura, S.I.; Di Scala, K.C. Application of the General Stability Index method to assess the quality of butter lettuce during postharvest storage using a multi-quality indices analysis. J. Food Eng. 2009, 92, 317–323. [Google Scholar] [CrossRef]

- Gibson, A.M.; Bratchell, N.; Roberts, T.A. The effect of sodium chloride and temperature on the rate and extent of growth of Clostridium botulinum type A in pasteurized pork slurry. J. Appl. Bacteriol. 1987, 62, 479–490. [Google Scholar] [CrossRef]

- Kreyenschmidt, J.; Hübner, A.; Beierle, E.; Chonsch, L.; Scherer, A.; Petersen, B. Determination of the shelf life of sliced cooked ham based on the growth of lactic acid bacteria in different steps of the chain. J. Appl. Microbiol. 2010, 108, 510–520. [Google Scholar] [CrossRef]

- Ross, T. Indices for performance evaluation of predictive models in food microbiology. J. Appl. Bacteriol. 1996, 81, 501–508. [Google Scholar] [CrossRef] [PubMed]

- Bruckner, S.; Albrecht, A.; Petersen, B.; Kreyenschmidt, J. Characterization and Comparison of Spoilage Processes in Fresh Pork and Poultry. J Food Qual. 2012, 35, 372–382. [Google Scholar] [CrossRef]

- Gill, C.O. Meat Spoilage and Evaluation of the Potential Storage Life of Fresh Meat. J. Food Prot. 1983, 46, 444–452. [Google Scholar] [CrossRef] [PubMed]

- Mossel, D.A. Symposium on microbial changes in foods. Physiological and metabolic attributes of microbial groups associated with foods. J. Appl. Bacteriol. 1971, 34, 95–118. [Google Scholar] [CrossRef]

- Dainty, R.H.; Mackey, B.M. The relationship between the phenotypic properties of bacteria from chill-stored meat and spoilage processes. Soc. Appl. Bacteriol. Symp. Ser. 1992, 21, 103S–114S. [Google Scholar] [CrossRef]

- Limbo, S.; Torri, L.; Sinelli, N.; Franzetti, L.; Casiraghi, E. Evaluation and predictive modeling of shelf life of minced beef stored in high-oxygen modified atmosphere packaging at different temperatures. Meat Sci. 2010, 84, 129–136. [Google Scholar] [CrossRef]

- Labuza, T.P.; Fu, B. Growth kinetics for shelf-life prediction: Theory and practice. J. Ind. Microbiol. 1993, 12, 309–323. [Google Scholar] [CrossRef]

- Pothakos, V.; Samapundo, S.; Devlieghere, F. Total mesophilic counts underestimate in many cases the contamination levels of psychrotrophic lactic acid bacteria (LAB) in chilled-stored food products at the end of their shelf life. Food Microbiol. 2012, 32, 437–443. [Google Scholar] [CrossRef]

- Yimenu, S.M.; Koo, J.; Kim, B.S.; Kim, J.H.; Kim, J.Y. Freshness-based real-time shelf-life estimation of packaged chicken meat under dynamic storage conditions. Poult. Sci. 2019, 98, 6921–6930. [Google Scholar] [CrossRef]

- Giannakourou, M.C.; Koutsoumanis, K.; Nychas, G.J.; Taoukis, P.S. Development and assessment of an intelligent shelf life decision system for quality optimization of the food chill chain. J. Food Prot. 2001, 64, 1051–1057. [Google Scholar] [CrossRef]

- Koutsoumanis, K.; Giannakourou, M.; Taoukis, P.; Nychas, G. Application of shelf life decision system (SLDS) to marine cultured fish quality. Int. J. Food Microbiol. 2002, 73, 375–382. [Google Scholar] [CrossRef]

- Eriksson, M.; Strid, I.; Hansson, P.-A. Food waste reduction in supermarkets—Net costs and benefits of reduced storage temperature. Resour. Conserv. Recycl. 2016, 107, 73–81. [Google Scholar] [CrossRef]

- Stiles, M.E.; Hastings, J.W. Bacteriocin production by lactic acid bacteria: Potential for use in meat preservation. Trends Food Sci. Technol. 1991, 2, 247–251. [Google Scholar] [CrossRef]

| Trial | Scenario | Description of Storage Conditions |

|---|---|---|

| Trial A (n = 262) | A1 | A constant storage temperature at 2 °C |

| A2 | A constant storage temperature at 4 °C | |

| A3 | A constant storage temperature at 7 °C | |

| A4 | A constant storage temperature at 10 °C | |

| A5 | A constant storage temperature at 15 °C | |

| A6 | A constant storage temperature at 25 °C | |

| Trial B (n = 90) | B0 | A constant storage temperature at 4 °C |

| B1 | 4 shifts for 4 h from 4 to 15 °C at the beginning of storage | |

| Trial C (n = 95) | C0 | A constant storage temperature at 4 °C |

| C1 | 4 shifts for 4 h from 4 to 15 °C during the exponential phase | |

| Trial D (n = 120) | D1 | A constant storage temperature at 4 °C |

| D2 | 3 shifts to 15 °C after 4, 24 and 48 h and an increase to 7 °C after 120 h till the end of the storage | |

| Trial E (n = 80) | E1 | Validation study under practical conditions with a basic storage temperature of 4 °C |

| E2 | Validation study under practical conditions with a basic storage temperature of 10 °C |

| DSLC Acceptance Level | 4 | 3 | 2 | 1 |

|---|---|---|---|---|

| TPC log10 CFU/g | <4.5 | 4.5–6 | 6–7 | >7 |

| SI | >4 | 4–3.4 | 3.4–2.8 | <2.8 |

| Scenario | RMSE | Bf | Af | R2 |

|---|---|---|---|---|

| Microbial development | ||||

| E1 | 0.60 | 0.94 | 1.09 | 0.92 |

| E2 | 0.28 | 1.02 | 1.05 | 0.98 |

| Sensory development | ||||

| E1 | 0.24 | 0.97 | 1.07 | 0.97 |

| E2 | 0.27 | 0.92 | 1.09 | 0.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albrecht, A.; Mittler, M.; Hebel, M.; Waldhans, C.; Herbert, U.; Kreyenschmidt, J. A Multi-Model Approach to Implement a Dynamic Shelf Life Criterion in Meat Supply Chains. Foods 2021, 10, 2740. https://doi.org/10.3390/foods10112740

Albrecht A, Mittler M, Hebel M, Waldhans C, Herbert U, Kreyenschmidt J. A Multi-Model Approach to Implement a Dynamic Shelf Life Criterion in Meat Supply Chains. Foods. 2021; 10(11):2740. https://doi.org/10.3390/foods10112740

Chicago/Turabian StyleAlbrecht, Antonia, Maureen Mittler, Martin Hebel, Claudia Waldhans, Ulrike Herbert, and Judith Kreyenschmidt. 2021. "A Multi-Model Approach to Implement a Dynamic Shelf Life Criterion in Meat Supply Chains" Foods 10, no. 11: 2740. https://doi.org/10.3390/foods10112740