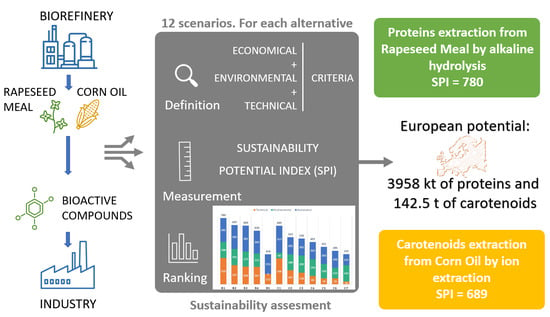

Valorizing Biodiesel and Bioethanol Side-Streams: Sustainability Potential Assessment through a Multicriteria Decision Analysis Framework and Appraisal of Valuable Compound Recovery Prospects

Abstract

:1. Introduction

- RQ1. How can a methodology for side-streams valorization scale-up selection be developed from the sustainability perspective that is easy to use and that does not require extensive knowledge or specific software deployment?

- RQ2. What is the most suitable approach to support a holistic assessment?

- RQ3. Which aspects from a technological process are linked to sustainability (from the environmental, technical, and economic fields)?

- RQ4. Which is the most suitable approach for valorizing rapeseed meal and corn oil as biorefinery side-streams?

- RQ5. What is the maximum quantity of valuable compounds that Europe could produce if the selected side-streams would be fully valorized?

2. Materials and Methods

2.1. Sustainability Potential Assessment Framework Development

- Goal and scope definition: the MCDA will use, for the environmental and technical aspects assessment, the same system boundaries and functional unit, focusing on the process itself, i.e., the same system boundaries and functional unit as the LCA will be considered, as this will be the methodology used for environmental impact assessment. As for the economic aspects, the equipment costs and maintenance are considered as well. It is important to notice that, while the LCA does not consider local conditions, organizational issues or local regulatory issues, the MCDA could consider these aspects in the decision making at a later stage.

- Selection of systems for comparison: scenarios to be assessed and compared need to be fully defined. It is very important that, for each scenario, the following aspects are clearly identified: feedstock, main technology and expected final products.

- Definition of criteria and sub-criteria: here is where the application of BM principles starts to be considered. BM names the main criteria as categories and the sub-criteria as components. Therefore, for each of the selected categories (environmental, technical, and economic), components need to be defined.

- Rating: to be able to rank the different systems, and to capture local interests and conditions, each set of categories and components (criteria and sub-criteria in the developed framework) need to be rated in accordance with their relative importance. Hence, a total of 1000 sustainability potential units are allocated to each component (similar to BM where 1000 units of measurement are distributed among the different components).

- Definition of the transformation functions: for each component, a transformation function is defined, making it possible to conduct the assessment process unequivocally and objectively.

- Technical Performance: Process yield, Final product purity, Selectivity; Is it possible to reuse process effluents? and Does the process allow for producing an active compound useful in different markets?

- Environmental Impact: Global warming potential, Photochemical oxidation potential, Acidification potential, and Eutrophication potential.

- Economic Aspects: Profitability; Does the process use commercial equipment? Might the process, at a theoretical commercial side, require any high maintenance? and Input–Output balance.

2.2. Literature Review and Data Gathering for Recovery Prospects Appraisal

3. Results

3.1. Sustainability Potential Assessment Framework Development and Validation

- Process yield, final product purity, and selectivity: the value is linearly extrapolated according to the corresponding ratio where 0 is for 50% and 1 for 100%.

- Effluents reutilization: the value is extrapolated according to the corresponding reuse ratio where 0 is for 0% reuse and 1 is for 100% reuse.

- For Products useful in different markets, 4 target markets: food (elders), food (toddlers), cosmetics and chemicals were identified, and a discrete function was defined as follows: for 1 market, factor = 0.25; for 2 markets, factor = 0.5; for 3 markets, factor = 0.75; and for 4 markets, factor = 1.

- Global warming potential, Photochemical oxidation potential, Acidification potential, Eutrophication potential rate from 0 to 1 according to the results of the LCA carried out to the different scenarios. The rating will be 0 for the highest amount (kg CO2 eq/kg–kg C2H4 eq/kg–kg SO2 eq/kg–kg PO4−3 eq/kg, respectively), and 1 to the lowest amount, and rates for the intermediate values will be extrapolated.

- Profitability: Prices from final products per kg or per L were considered. The lower price would be equivalent to 0.2 and the higher price would be equivalent to 1, extrapolating for the rest of scenarios values. In case of a scenario providing several final products, the price of the different products would be summed up;

- Kind of equipment: Since ad-hoc equipment could affect process economics by increasing the CAPEX, the following rating considerations could be used (having in mind a full commercial scale): All the process equipment needs to be tailor-made: 0; Only one piece of equipment (the one related to the core of the proposed process) and one piece of auxiliary equipment need to be tailor-made: 0.2; Only one piece of equipment (the one related to the core of the proposed process) needs to be tailor-made: 0.4; Several auxiliary equipment need to be tailor-made: 0.6; Only one piece of auxiliary equipment needs to be tailor-made: 0.8; Both main and auxiliary equipment can be acquired from commercial catalogues: 1;

- Scale-up potential: Rating was defined after the answer of the following two main questions: (1) is the business easy to scale up: is the possibility to multiply incomes based on sustainable investments?, and (2) Does the scalability of production mean an optimization of costs production?

- Maintenance of the process: High maintenance (e.g., replacement of at least one main equipment, all auxiliaries, membranes, sensors, etc. once per year) ~0; High-medium maintenance (e.g., replacement of all auxiliaries, membranes, sensors, etc. once per year) ~0.25; Medium maintenance (e.g., replacement of all auxiliaries, membranes, sensors, etc. every two years) ~0.5; Medium-low maintenance (e.g., replacement of membranes every two years) ~0.75; Low maintenance (no major replacement of main equipment, nor auxiliaries, etc. is expected within 3 years of operation) ~1;

- Input–Output balance: This component is related to OPEX and the income from selling process of produced bioactive compounds. The input-output balance needs to be calculated per each scenario and then a rating allocation and extrapolation would need to be done as in the case of profitability.

3.2. Appraisal of Recovery Prospects

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tan, S.; Mailer, R.; Blanchard, C.; Agboola, S.O. Canola Proteins for Human Consumption: Extraction, Profile, and Functional Properties. J. Food Sci. 2011, 76, 16–28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mirpoor, S.F.; Valeria, C.; Giosafatto, L.; Porta, R. Biorefining of seed oil cakes as industrial co-streams for production of innovative bioplastics. A review. Trends Food Sci. Technol. 2021, 109, 259–270. [Google Scholar] [CrossRef]

- Rivera, D. Biocompounds from rapeseed oil industry co-stream as active ingredients for skin care. Int. J. Cosmet. Sci. 2015, 37, 496–505. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Konkol, D.; Szmigiel, I.; Domzal-Kedzia, M.; Kulazynsky, M.; Krasowska, A.; Opalinski, S.; Korczynski, M.; Lukaszewicz, M. Biotransformation of rapeseed meal leading to production of polymers, biosurfactants, and fodder. Bioorganic Chem. 2019, 93, 102865. [Google Scholar] [CrossRef] [PubMed]

- Moestedt, J.; Påledal, S.; Schnürer, A.; Nordell, E. Biogas Production from Thin Stillage on an Industrial Scale—Experience and Optimisation. Energies 2013, 6, 5642–5655. [Google Scholar] [CrossRef]

- Poveda, C.; Lipsett, M.G. A Review of Sustainability Assessment and Sustainability/Environmental Rating Systems and Credit Weighting Tools. J. Sustain. Dev. 2011, 4, 36. [Google Scholar] [CrossRef]

- Chang, F.; Zhang, X.; Zhan, G.; Duan, Y.; Zhang, S. Review of Methods for Sustainability Assessment of Chemical Engineering Processes. Ind. Eng. Chem. Res. 2021, 60, 52–66. [Google Scholar] [CrossRef]

- Visentin, C.; da Silva Trentin, A.W.; Braun, A.B.; Thomé, A. Life cycle sustainability assessment: A systematic literature review through the application perspective, indicators, and methodologies. J. Clean. Prod. 2020, 270, 122509. [Google Scholar] [CrossRef]

- Wulf, C.; Werker, J.; Ball, C.; Zapp, P.; Kuckshinrichs, W. Review of Sustainability Assessment Approaches Based on Life Cycles. Sustainability 2019, 11, 5717. [Google Scholar] [CrossRef] [Green Version]

- Walzberg, J.; Lonca, G.; Hanes, R. Do We Need a New Sustainability Asessment Method for the Circular Economy? A Critical Literature Review. Front. Sustain. 2021, 1, 620047. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From laboratory to industrial scale: A scale-up framework for chemical processes in life cycle assessment studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Sala, S.; Ciuffo, B.; Nijkamp, P. A systemic framework for sustainability assessment. Ecol. Econ. 2015, 119, 314–325. [Google Scholar] [CrossRef]

- Dee, N.; Baker, J.; Drobny, N.; Duke, K.; Whitman, I.; Fahringer, D. An environmental evaluation system for water resource planning. Water Resour. Res. 1973, 9, 523–535. [Google Scholar] [CrossRef]

- Vaidya, O.S.; Kumar, S. Analytic hierarchy process: An overview of applications. Eur. J. Oper. Res. 2006, 169, 1–29. [Google Scholar] [CrossRef]

- Macias Aragones, M.; Girón Domínguez, C.; Ondrejíčková, P.; Arroyo Torralvo, F. Bioenergy production side-streams availability assessment as decision making driver for sustainable valorisation technologies development. Case study: Bioethanol and biodiesel industries. Energy Rep. 2022, 8, 6856–6865. [Google Scholar] [CrossRef]

- Martínez-Lage, I.; Vázquez-Burgo, P.; Velay-Lizancos, M. Sustainability evaluation of concretes with mixed recycled aggregate based on holistic approach: Technical, economic and environmental analysis. Waste Manag. 2020, 104, 9–19. [Google Scholar] [CrossRef]

- Kamali, M.; Costa, M.E.; Aminabhavi, T.M. Sustainability of treatment technologies for industrial biowastes effluents. Chem. Eng. J. 2019, 370, 1511–1521. [Google Scholar] [CrossRef]

- Dalkey, N.; Helmer, O. An Experimental Application of the Delphi Method to the use of experts. Manag. Sci. 1963, 9, 458–467. [Google Scholar] [CrossRef]

- Caulley, D. Conducting research literature reviews: From the internet to paper [book review]. Qual. Res. J. 2007, 7, 103–104. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.; Hultink, E. The circular economy—A new sustainability paradigm? J. Cleaner Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Di Lena, G.; Sanchez del Pulgar, J.; Lucarini, M.; Durazzo, A.; Ondrejíčková, P.; Oancea, F.; Frincu, R.-M.; Aguzzi, I.; Ferrari Nicoli, S.; Casini, I.; et al. Valorization Potentials of Rapeseed Meal in a Biorefinery Perspective: Focus on Nutritional and Bioactive Components. Molecules 2021, 26, 6787. [Google Scholar] [CrossRef] [PubMed]

- Di Lena, G.; Sanchez del Pulgar, J.; Lombardi Boccia, G.; Casini, I.; Ferrari Nicoli, S. Corn Bioethanol Side Streams: A Potential Sustainable Source of Fat-Soluble Bioactive Molecules for High-Value Applications. Foods 2020, 9, 1788. [Google Scholar] [CrossRef] [PubMed]

- Eurostat. Eurostat Data Browser—Liquid Biofuels Production Capacities. Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_inf_lbpc/default/table?lang=en (accessed on 15 April 2022).

- ePURE. European Renewable Ethanol—Key Figures 2020; ACW: London, UK, 2020. [Google Scholar]

- Van Duren, I.; Voinov, A.; Arodudu, O.; Firrisa, M.T. Where to produce rapeseed biodiesel and why? Mapping European rapeseed energy efficiency. Renew. Energy 2015, 74, 49–59. [Google Scholar] [CrossRef] [Green Version]

- Union Zur Förderung von Oel und Proteinplfanzen E.V. Rapeseed—Opportunity or Risk for the Future; Union Zur Förderung von Oel und Proteinplfanzen E.V.: Berlin, Germany, 2014. [Google Scholar]

- Beaubier, S.; Defaix, C.; Albe-Slabi, S.; Aymes, A.; Galet, O.; Fournier, F.; Kapel, R. Multiobjective decision making strategy for selective albumin extraction from a rapeseed cold-pressed meal based on Rough Set approach. Food Bioprod. Process. 2022, 133, 34–44. [Google Scholar] [CrossRef]

- Rodrigues, I.M.; Coelho, J.F.J.; Graça, M.; Carvalho, V. Isolation and valorisation of vegetable proteins from oilseed plants: Methods, limitations and potential. J. Food Eng. 2012, 109, 337–346. [Google Scholar] [CrossRef]

- Baker, P.W.; Charlton, A. A comparison in protein extraction from four major crop residues in Europe using chemical and enzymatic processes-a review. Innov. Food Sci. Emerg. Technol. 2020, 59, 102239. [Google Scholar] [CrossRef]

- Engel, B. Technical corn oil review. In Proceedings of the ISCC Stakeholder Meeting for Canada and the USA, Las Vegas, NV, USA, 5 December 2017. [Google Scholar]

- 3BCAR. “Phenolic Acids: From Research to Market,” CARNOT 3BCAR’s Workshop. Available online: https://3bcar.fr/en/phenolic-acids-from-research-to-market/ (accessed on 13 September 2022).

- Röös, E.; Bajželj, B.; Smith, P.; Patel, M.; Little, D.; Garnett, T. Protein futures for Western Europe: Potential land use and climate impacts in 2050. Reg. Environ. Chang. 2017, 17, 367–377. [Google Scholar] [CrossRef]

- Plant-Based FOODS in Europe: How Big Is the Market? The Smart Protein Plant-Based Food Sector Report. Smart Protein Project (2021). European Union’s Horizon 2020 Research and Innovation Programme (No 862957). Available online: https://smartproteinproject.eu/market-research/ (accessed on 25 May 2022).

- Yaqoob, S.; Riaz, M.; Shabbir, A.; Zia-Ul-Haq, M.; Alwakeel, S.; Bin-Jumah, M. Commercialization and Marketing Potential of Carotenoids. In Carotenoids: Structure and Function in the Human Body; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- European Commission. Waste Framework Directive. Available online: https://ec.europa.eu/environment/topics/waste-and-recycling/waste-framework-directive_en (accessed on 20 April 2022).

- Purvis, B.; Mao, Y.; Robinson, D. Three pillars of sustainability: In search of conceptual origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

| Scenario | Feed | Product | Technology |

|---|---|---|---|

| R1 | RSM | Proteins | Alkaline hydrolysis (NaOH) |

| R2 | RSM | Polyphenols | Ion extraction |

| R3 | RSM | Polyphenols | Enzymatic extraction |

| R4 | RSM | Proteins | Enzymatic extraction |

| R5 | RSM | Proteins | Alkaline hydrolysis (Na2CO3) |

| C1 | CO | Carotenoids | Ion extraction |

| C2 | CO | Triglycerides | Liquid-liquid extraction |

| C3 | CO | Bioactives (mix) | Supercritical extraction with alumina |

| C4 | CO | Bioactives (mix) | Supercritical extraction with silica gel |

| C5 | CO | Triglycerides | Ionic liquid extraction |

| C6 | CO | Bioactives (mix) | Solid extraction (bind and elute) |

| C7 | CO | Triglycerides | Solid extraction (fractioning) |

| Component | R1 | R2 | R3 | R4 | R5 |

|---|---|---|---|---|---|

| Process yield | 0.30 | 0.00 | 0.00 | 0.00 | 0.00 |

| Product purity | 0.82 | 0.60 | 0.00 | 0.85 | 0.00 |

| Selectivity | 0.90 | 0.40 | 0.80 | 0.70 | 0.60 |

| Effluents reutilization | 0.00 | 0.00 | 1.00 | 0.00 | 0.00 |

| Multi-marketed products | 1.00 | 1.00 | 0.50 | 0.50 | 0.50 |

| Global warming potential | 0.95 | 0.96 | 0.90 | 0.81 | 0.00 |

| POP * | 0.95 | 0.96 | 0.83 | 0.72 | 0.00 |

| Acidification potential | 0.94 | 0.96 | 0.91 | 0.82 | 0.00 |

| Eutrophication potential | 0.91 | 0.93 | 0.87 | 0.71 | 0.00 |

| Profitability | 0.80 | 0.80 | 0.80 | 1.00 | 0.60 |

| Kind of equipment | 1.00 | 1.00 | 1.00 | 0.80 | 0.80 |

| Maintenance required | 0.75 | 0.75 | 1.00 | 0.50 | 0.75 |

| Input-Output balance | 0.70 | 0.70 | 0.80 | 0.60 | 0.60 |

| Component | C1 | C2 | C3 | C4 | C5 | C6 | C7 |

|---|---|---|---|---|---|---|---|

| Process yield | 0.40 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Product purity | 0.80 | 0.05 | 0.05 | 0.10 | 0.05 | 0.05 | 0.00 |

| Selectivity | 0.80 | 0.35 | 0.35 | 0.10 | 0.05 | 0.05 | 0.00 |

| Effluents reutilization | 0.00 | 0.90 | 0.50 | 0.90 | 0.90 | 0.90 | 0.00 |

| Multi-marketed products | 1.00 | 0.50 | 0.50 | 0.15 | 0.00 | 0.00 | 0.25 |

| Global warming potential | 0.34 | 0.94 | 1.00 | 0.98 | 0.85 | 0.63 | 0.96 |

| POP * | 0.41 | 0.95 | 1.00 | 0.97 | 0.90 | 0.74 | 0.96 |

| Acidification potential | 0.29 | 0.95 | 1.00 | 0.98 | 0.85 | 0.64 | 0.96 |

| Eutrophication potential | 0.28 | 0.92 | 1.00 | 0.99 | 0.77 | 0.43 | 0.93 |

| Profitability | 1.00 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.00 |

| Kind of equipment | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Maintenance required | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| Input-Output balance | 0.80 | 0.70 | 0.70 | 0.70 | 0.70 | 0.70 | 0.20 |

| Country | Rapeseed Meal * (kt) | Proteins (kt) | Corn Oil * (kt) | Carotenoids (t) |

|---|---|---|---|---|

| Austria | 335 | 121 | 8.8 | 3.9 |

| Belgium | 234 | 84 | 19.2 | 8.4 |

| Bulgaria | 52 | 19 | 3.5 | 1.5 |

| Czech Republic | 218 | 79 | 8.2 | 3.6 |

| Finland | 260 | 94 | 6.0 | 2.4 |

| France | 1198 | 432 | 73.5 | 32.2 |

| Germany | 1971 | 711 | 40.5 | 17.7 |

| Hungary | 52 | 19 | 28.2 | 12.3 |

| Ireland | 30 | 11 | 0.3 | 0.1 |

| Italy | 1150 | 415 | 14.4 | 6.3 |

| Latvia | 90 | 32 | 0.8 | 0.4 |

| Lithuania | 101 | 37 | 1.0 | 0.4 |

| Netherlands | 1113 | 401 | 20.8 | 9.1 |

| Poland | 813 | 295 | 35.1 | 15.4 |

| Portugal | 375 | 135 | 0.1 | 0.0 |

| Romania | 156 | 56 | 0.4 | 0.2 |

| Slovakia | 70 | 25 | 6.4 | 2.8 |

| Spain | 2020 | 794 | 20.3 | 8.9 |

| Sweden | 234 | 84 | 14.0 | 8.9 |

| United Kingdom | 319 | 115 | 18.1 | 7.9 |

| Total | 10,978 | 3958 | 320.5 | 142.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Macias Aragonés, M.; Ondrejíčková, P.; Ugarte Lodeiro, R.; Arroyo Torralvo, F. Valorizing Biodiesel and Bioethanol Side-Streams: Sustainability Potential Assessment through a Multicriteria Decision Analysis Framework and Appraisal of Valuable Compound Recovery Prospects. Energies 2023, 16, 176. https://doi.org/10.3390/en16010176

Macias Aragonés M, Ondrejíčková P, Ugarte Lodeiro R, Arroyo Torralvo F. Valorizing Biodiesel and Bioethanol Side-Streams: Sustainability Potential Assessment through a Multicriteria Decision Analysis Framework and Appraisal of Valuable Compound Recovery Prospects. Energies. 2023; 16(1):176. https://doi.org/10.3390/en16010176

Chicago/Turabian StyleMacias Aragonés, Marta, Petra Ondrejíčková, Raul Ugarte Lodeiro, and Fátima Arroyo Torralvo. 2023. "Valorizing Biodiesel and Bioethanol Side-Streams: Sustainability Potential Assessment through a Multicriteria Decision Analysis Framework and Appraisal of Valuable Compound Recovery Prospects" Energies 16, no. 1: 176. https://doi.org/10.3390/en16010176