Characterization of Agricultural Residues of Zea mays for Their Application as Solid Biofuel: Case Study in San Francisco Pichátaro, Michoacán, Mexico

Abstract

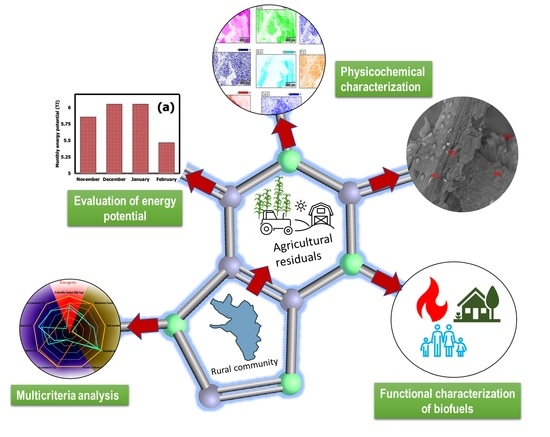

:1. Introduction

2. Materials and Methods

2.1. Availability of the Biomass Residue of Corn Stubble

2.2. Physico-Chemical Characterization

2.3. Proximate Analysis and Calorific Value

2.4. Elemental Analysis and Basic Chemical Analysis

2.5. Multicriteria Analysis

2.6. Evaluation of the Energetic Potential

- 𝑃𝐸: Energy potential [TJ/year]

- 𝑀𝑟𝑠: Mass of dry residue [t/year]

- 𝐸: Energy of the residue per unit mass [TJ/t]

- CV: Calorific value (MJ/kg)

2.7. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Charactarization

3.2. Proximate Analysis and Calorific Value

3.3. Elemental Analysis and Basic Chemical Analysis

3.4. Multicriteria Analysis

3.5. Evaluation of the Energy Potential

3.6. Final Remarks

- The change of land use, for the production of exogenous crops that generate negative impacts of an environmental and socioeconomic nature. This, coupled with the low economic profitability that this crop has experienced in recent years, promotes the abandonment of corn production practices. However, if it is reactivated, the evaluation of waste could be encouraged to satisfy the demand for local energy, which mainly depends on forest biomass, so there is a little explored area of opportunity. Reactivating the planting of corn at this time would generate double benefits; on the one hand, recovering an ancestral production system that is necessary and that provides food sovereignty in addition to low environmental impacts to the ecosystem, and on the other hand, because the community does not have a significant livestock vocation, the use of corn residues would contribute to the generation of clean, economic and local energy.

- Coordination with government programs. Currently, the Government of Mexico has programs to reactivate local production systems; one of them, “Sembrado Vida”, generates economic incentives to promote the cultivation of corn. If this type of program were spread even more, the active cultivation area would be larger, which would generate a possible and representative use of residues that have high energy potential, as previously mentioned.

- Previous studies have already been carried out that show the feasibility of using forest biomass residues for the production of solid biofuels (Briquettes), which can be manufactured locally and that, in efficient end-use technologies, would generate benefits for this locality study. Therefore, it is suggested to explore the technical feasibility of Z. mays residues as biofuels, with the aim of diversifying the matrix of energy production from these local resources. In addition, unlike the forest, the production of agricultural residues has a faster and more periodic generation capacity, which by exploiting large areas of cultivation could significantly satisfy, in a complementary way, the demand for thermal energy at the local level.

- This locality (Pichátaro) is governed by the indigenous self-government scheme, which is economically and legally managed locally, with subsidies from the Mexican government to meet their basic needs. Therefore, the generation of energy locally is a way to strengthen their processes of self-sufficiency and self-determination. They also have local programs that can disseminate efficient energy consumption practices regulated from their community decisions, which makes the energy transition based on energy production through their local energy resources attractive.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheba, K.; Bak, I. Environmental Production Efficiency in the European Union Countries as a Tool for the Implementation of Goal 7 of the 2030 Agenda. Energies 2021, 14, 4593. [Google Scholar] [CrossRef]

- Morales-Máximo, M.; Rutiaga-Quiñones, J.G.; Masera, O.; Ruiz-García, V.M. Briquettes from Pinus Spp. Residues: Energy Savings and Emissions Mitigation in the Rural Sector. Energies 2022, 15, 3419. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, W.; Rosentrater, K.A. Anhydrous Ammonia Pretreatment of Corn Stover and Enzymatic Hydrolysis of Glucan from Pretreated Corn Stover. Fermentation 2017, 3, 9. [Google Scholar] [CrossRef]

- Ramírez-Ramírez, M.A.; Carrillo-Parra, A.; Ruíz-Aquino, F.; Hernández-Solís, J.J.; Pintor-Ibarra, L.F.; González-Ortega, N.; Orihuela-Equihua, R.; Carrillo-Ávila, N.; Rutiaga-Quiñones, J.G. Evaluation of Selected Physical and Thermal Properties of Briquette Hardwood Biomass Biofuel. BioEnergy Res. 2022, 15, 1407–1414. [Google Scholar] [CrossRef]

- Van Fan, Y.; Romanenko, S.; Gai, L.; Kupressova, E.; Varbanov, P.S.; Klemeš, J.J. Biomass Integration for Energy Recovery and Efficient Use of Resources: Tomsk Region. Energy 2021, 235, 121378. [Google Scholar] [CrossRef]

- Nska, M.D.; Nski, S.O.; Piekut, J.; Yildiz, G. The Utilization of Plum Stones for Pellet Production and Investigation of Post-Combustion Flue Gas Emissions. Energies 2020, 13, 5107. [Google Scholar] [CrossRef]

- Carrillo-parra, A.; Contreras-trejo, J.C.; Pompa-García, M.; Pulgarín-Gámiz, M.Á.; Rutiaga-Quiñones, J.G.; Pámanes-Carrasco, G.; Ngangyo-Heya, M. Agro-Pellets from Oil Palm Residues/ Pine Sawdust Mixtures: Relationships of Their Physical, Mechanical and Energetic Properties, with the Raw Material Chemical Structure. Appl. Sci. 2020, 10, 6383. [Google Scholar] [CrossRef]

- Rutiaga-Quiñones, J.G.; Pintor-Ibarra, L.F.; Orihuela-Equihua, R.; González-Ortega, N.; Ramírez-Ramírez, A.; Carrillo-Parra, A.; Carrillo-Ávila, N.; Navarrete-García, M.A.; Ruíz-Aquino, F.; Rangel-Mendez, J.R.; et al. Characterization of Mexican Waste Biomass Relative to Energy Generation. BioResources 2020, 15, 8529–8553. [Google Scholar] [CrossRef]

- Morales Máximo, C.N. Impacto Socio-Ambiental Del Cultivo Convencional de Papa, En La Comunidad de San Francisco Pichátaro, Michoacán; Universidad Intercultural Indígena de Michoacán: Pátzcuaro, Michoacán, México, 2017; Available online: https://repositoriouiim.mx/xmlui/handle/123456789/120 (accessed on 12 July 2022).

- de México, A.C.C. Comisión Nacional Para El Conocimiento y Uso de La Biodiversidad (CONABIO). Available online: http://www.conabio.gob.mx/informacion/gis/ (accessed on 25 June 2022).

- UNE-EN 14774-1 Biocombustibles Sólidos. Determinación Del Contenido de Humedad. In Parte 1: Humedad Total; Asociación Española de Normalización y Certificación: Madrid, Spain, 2010; p. 10.

- UNE-EN 14775 Biocombustibles Sólidos. In Método para la Determinación del Contenido de Cenizas; Asociación Española de Normalización y Certificación: Madrid, Spain, 2010; p. 10.

- ASTM E872-82; Standard Test Method for Volatile Matter in the Analysis of Particulate Wood Fuels. ASTM International: West Conshohocken, PA, USA, 2013.

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Bioresource Technology Characterization of Spanish Biomass Wastes for Energy Use. Bioresourse Technol. 2012, 103, 249–258. [Google Scholar] [CrossRef]

- Asociación Española de Normalización y Certificación. Determinación del Poder Calorífico; UNE-EN 14918:2011; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2016. [Google Scholar]

- U-C. 15104 E; Determinación Del Contenido de Carbono, Hidrógeno y Nitrógeno. Métodos Instrumentales [Determination of the Content of Carbon, Hydrogen and Nitrogen. Instrumental Methods]. Métodos Instrumentales: Madrid, Spain, 2008.

- Goering HK, V.S.P. Forage Fiber Analyses (Appa-Ratus, Reagents, Procedures and Some Applications); US Government Printing Office, Ed.; Agricultural Handbook; USDA-ARS: Washington, DC, USA, 1970. [Google Scholar]

- Morales-Máximo, M.; García, C.A.; Pintor-Ibarra, L.F.; Alvarado-Flores, J.J.; Velázquez-Martí, B.; Rutiaga-Quiñones, J.G. Evaluation and Characterization of Timber Residues of Pinus Spp. as an Energy Resource for the Production of Solid Biofuels in an Indigenous Community in Mexico. Forests 2021, 12, 977. [Google Scholar] [CrossRef]

- Goering, H.K.; Van Soest, P.J. Forage Fiber Analyses: Apparatus, Reagents, Procedures, and Some Applications; US Agricultural Research Service Location: Washington, DC, USA, 1970; Volume 379. [Google Scholar]

- E11-20; A Standard Specification for Women Wire Test Sieve Cloth and Test Sieves. ASTM International: West Conshohocken, PA, USA, 2020.

- TAPPI T264 cm-97. In Preparation of Wood for Chemical Analysis; TAPPI Press: Atlanta, GA, USA, 2000.

- López-Sosa, L.B.; Morales-Máximo, M. Manual de Principios Sobre Vinculación, Innovación y Diseño Para El Desarrollo de Proyectos Ecotecnológicos; Millán-Ramírez, A., Ed.; Universidad Intercultural Indígena de Michoacán: Pátzcuaro, Michoacán, Mexico, 2022; ISBN 9786079386016. [Google Scholar]

- Serrato Monroy, C.C.; Lesmes Cepeda, V. Metodología Para El Cálculo De Energía Extraída a Partir De La Biomasa En El Departamento De Cundinamarca; Universidad Distrital Francisco José de Caldas: Bogotá, Colombia, 2016. [Google Scholar]

- Valdez-Vazquez, I.; Acevedo-Benítez, J.A.; Hernández-Santiago, C. Distribution and Potential of Bioenergy Resources from Agricultural Activities in Mexico. Renew. Sustain. Energy Rev. 2010, 14, 2147–2153. [Google Scholar] [CrossRef]

- Gutiérrez-Pulido, H.; de la Vara-Salazar, R. Análisis y Diseño de Experimentos [Analysis and Design of Experiments]; McGrawHill: Mexico City, Mexico, 2004. [Google Scholar]

- Abderrahim, B.; Abderrahman, E.; Mohamed, A.; Fatima, T.; Abdesselam, T.; Krim, O. Kinetic Thermal Degradation of Cellulose, Polybutylene Succinate and a Green Composite: Comparative Study. World J. Environ. Eng. 2015, 3, 95–110. [Google Scholar] [CrossRef]

- López-Sosa, L.B.; Alvarado-Flores, J.J.; Corral-Huacuz, J.C.; Aguilera-Mandujano, A.; Rodríguez-Martínez, R.E.; Guevara-Martínez, S.J.; Alcaraz-Vera, J.V.; Rutiaga-Quiñones, J.G.; Zárate-Medina, J.; Ávalos-Rodríguez, M.L.; et al. A Prospective Study of the Exploitation of Pelagic Sargassum Spp. As a Solid Biofuel Energy Source. Appl. Sci. 2020, 10, 8706. [Google Scholar] [CrossRef]

- Lupoi, J.S.; Singh, S.; Parthasarathi, R.; Simmons, B.A.; Henry, R.J. Recent Innovations in Analytical Methods for the Qualitative and Quantitative Assessment of Lignin. Renew. Sustain. Energy Rev. 2015, 49, 871–906. [Google Scholar] [CrossRef]

- Pandey, K.K.; Pitman, A.J. FTIR Studies of the Changes in Wood Chemistry Following Decay by Brown-Rot and White-Rot Fungi. Int. Biodeterior. Biodegrad. 2003, 52, 151–160. [Google Scholar] [CrossRef]

- Faix, O. Fourier Transform Infrared Spectroscopy. In Methods in Lignin Chemistry; Lin, S.Y., Dence, C.W., Eds.; Springer: Berlin/Heidelberg, Germany, 1992; ISBN 978-3-642-74067-1. [Google Scholar]

- Orea Igarza, U.; Carballo Abreu, L.R.; Cordero Machado, E. Composición Química de Tres Maderas En La Provincia de Pinar Del Río, Cuba a Tres Alturas Del Fuste Comercial. Parte No 2: Eucalyptus Pellita F. Muell Revista. Rev. Chapingo. Ser. Cienc. For. Y Del Ambiente 2004, 10, 51–55. [Google Scholar]

- Decou, R.; Serk, H.; Ménard, D.; Pesquet, E. Analysis of Lignin Composition and Distribution Using Fluorescence Laser Confocal Microspectroscopy; de Lucas, M., Etchells, J.P., Eds.; Xylem. Met.; Humana Press: New York, NY, USA, 2017; ISBN 9781493967209. [Google Scholar]

- Spectroscopy, R. Infrared and Raman Spectroscopy of Cellulose. Cellul. Chem. Technol. 1977, 48, 206–218. [Google Scholar]

- Li, Z.; Zhai, H.; Zhang, Y.; Yu, L. Cell Morphology and Chemical Characteristics of Corn Stover Fractions. Ind. Crops Prod. 2012, 37, 130–136. [Google Scholar] [CrossRef]

- Nyakuma, B.B.; Ajibade, S.S.M.; Adebayo, V.B.; Alkali, H.; Otitolaiye, V.O.; Audu, J.O.; Bashir, F.M.; Dodo, Y.A.; Mahmoud, A.S.; Oladokun, O. Carbon Dioxide-Assisted Torrefaction of Maize Cobs by Thermogravimetry: Product Yield and Energy Recovery Potentials. Phys. Chem. Solid State 2022, 23, 16–24. [Google Scholar] [CrossRef]

- López Villacis, I.C. Evaluación de la biomasa residual agrícola de los cultivos de papa (Solanum tuberosum), maíz (Zea mays) y tomate de árbol (Solanum betaceum) como recurso energético renovable en la provincia de tungurahua. Repositorio Institucional de la Universidad Técnica de Ambato 2021, 593, 131. [Google Scholar]

- dos Santos, A.C.F.; Overton, J.C.; Szeto, R.; Patel, M.H.; Gutierrez, D.M.R.; Eby, C.; Martínez Moreno, A.M.; Erk, K.A.; Aston, J.E.; Thompson, D.N.; et al. New Strategy for Liquefying Corn Stover Pellets. Bioresour. Technol. 2021, 341, 125773. [Google Scholar] [CrossRef] [PubMed]

- Núñez Camargo, D.W. Uso de Residuos Agrícolas Para La Producción de Biocombustibles En El Departamento Del Meta. Rev. Tecnura 2012, 16, 142. [Google Scholar] [CrossRef]

- Pintor-Ibarra, L.F.; Jesús Rivera-Prado, J.; Ngangyo-Heya, M.; Rutiaga-Quiñones, J.G. Evaluation of the Chemical Components of Eichhornia Crassipes as an Alternative Raw Material for Pulp and Paper. BioResources 2018, 13, 2800–2813. [Google Scholar] [CrossRef]

- Castro, B.; Rodríguez, J.; Hernández, W.; Camargo, G.; Agudelo, N. Coco en Atmósfera de CO2 Evaluation of the Pyrolysis Process with Corn and Coconut Wastes in CO2. Atmosphere 2021, 12, 33–46. [Google Scholar]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding Performance and Physical Properties of Wheat and Barley Straws, Corn Stover and Switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Lizotte, P.L.; Savoie, P.; De Champlain, A. Ash Content and Calorific Energy of Corn Stover Components in Eastern Canada. Energies 2015, 8, 4827–4838. [Google Scholar] [CrossRef]

- Ngangyo-Heya, M.; Foroughbahchk-Pournavab, R.; Carrillo-Parra, A.; Rutiaga-Quiñones, J.G.; Zelinski, V.; Pintor-Ibarra, L.F. Calorific Value and Chemical Composition of Five Semi-Arid Mexican Tree Species. Forests 2016, 7, 58. [Google Scholar] [CrossRef]

- Núñez-Retana, V.D.; Rosales-Serna, R.; Prieto-Ruíz, J.Á.; Wehenkel, C.; Carrillo-Parra, A. Improving the Physical, Mechanical and Energetic Properties of Quercus Spp. Wood Pellets by Adding Pine Sawdust. PeerJ 2020, 8, 1–20. [Google Scholar] [CrossRef]

- Morales-Máximo, M.; Ruíz-García, V.M.; López-Sosa, L.B.; Rutiaga-Quiñones, J.G. Exploitation of Wood Waste of Pinus Spp for Briquette Production: A Case Study in the Community of San Francisco Pichátaro, Michoacán, Mexico. Appl. Sci. 2020, 10, 2933. [Google Scholar] [CrossRef]

- Medic, D.; Darr, M.; Shah, A.; Rahn, S. The Effects of Particle Size, Different Corn Stover Components, and Gas Residence Time on Torrefaction of Corn Stover. Energies 2012, 5, 1199–1214. [Google Scholar] [CrossRef]

- Curto, P.; Pena, G.; Mantero, C.; Siri, G.; Tancredi, N.; Amaya, A.; Durante, A.; Ibañez, A.; Ernst, F.; Flores, M. Cuantificación y Evaluación Del Potencial Energético de Residuos Agrarios y Agroindustriales No Tradicionales; Montevideo: Udelar. FI. IIMPI 2017. Available online: https://www.colibri.udelar.edu.uy/jspui/handle/20.500.12008/31287 (accessed on 12 July 2022).

- Wang, Z.; He, X.; Yan, L.; Wang, J.; Hu, X.; Sun, Q.; Zhang, H. Enhancing Enzymatic Hydrolysis of Corn Stover by Twin-Screw Extrusion Pretreatment. Ind. Crops Prod. 2020, 143, 111960. [Google Scholar] [CrossRef]

- Fírvida, I.; Del Río, P.G.; Gullón, P.; Gullón, B.; Garrote, G.; Romaní, A. Alternative Lime Pretreatment of Corn Stover for Second-Generation Bioethanol Production. Agronomy 2021, 11, 155. [Google Scholar] [CrossRef]

- Zhong, X.; Yuan, R.; Zhang, B.; Wang, B.; Chu, Y.; Wang, Z. Full Fractionation of Cellulose, Hemicellulose, and Lignin in Pith-Leaf Containing Corn Stover by One-Step Treatment Using Aqueous Formic Acid. Ind. Crops Prod. 2021, 172, 113962. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Zhang, J.; Peng, N.; Liang, Y.; Zhao, S. High-Titer Lactic Acid Production by Pediococcus Acidilactici Pa204 from Corn Stover through Fed-Batch Simultaneous Saccharification and Fermentation. Microorganisms 2020, 8, 1491. [Google Scholar] [CrossRef] [PubMed]

- Sosa, L.B.L.; Avilés, M.G.; Pérez, D.G.; Gutiérrez, Y.S. Rural Solar Cookers, an Alternative to Reduce the Timber Resource Extraction through the Use of Renewable Energy Sources: Technology Transfer and Monitoring Project. Energy Procedia 2014, 57, 1593–1602. [Google Scholar] [CrossRef]

- Berrueta, V.M.; Serrano-Medrano, M.; García-Bustamante, C.; Astier, M.; Masera, O.R. Promoting Sustainable Local Development of Rural Communities and Mitigating Climate Change: The Case of Mexico’s Patsari Improved Cookstove Project. Clim. Change 2017, 140, 63–77. [Google Scholar] [CrossRef]

| Sample | C-K | O-K | Mg-K | Al-K | Si-K | P-K | Cl-K | K-K | Ca-K | Mo-L |

|---|---|---|---|---|---|---|---|---|---|---|

| P1 | 66.34 | 25.01 | 0.67 | 2.45 | 5.53 | |||||

| P2 | 62.99 | 20.39 | 0.19 | 8.78 | 1.74 | 4.28 | 1.63 | |||

| P3 | 53.52 | 36.83 | 0.27 | 0.53 | 0.34 | 8.13 | 0.39 | |||

| P4 | 70.90 | 22.14 | 0.09 | 0.27 | 5.76 | 0.10 | 0.45 | 0.30 |

| Analysis | Corn Stover Samples | |||

|---|---|---|---|---|

| CS1 | CS2 | CS3 | CS4 | |

| Moisture | 8.30 (±0.26) | 8.O7 (±0.02) | 7.04 (±0.62) | 8.11 (±0.48) |

| Ash | 9.52 (±0.22) | 7.38 (±0.31) | 7.45 (±0.06) | 14.57 (±0.33) |

| Volatile matter | 76.37 (±0.30) | 82.65 (±0.51) | 82.07 (±0.37) | 72.69 (±0.06) |

| Fixed carbon | 14.10 (±0.51) | 9.96 (±0.81) | 10.46 (±0.35) | 12.77 (±0.27) |

| Parameter | Indicator |

|---|---|

| Energetic | Calorific value (MJ/kg) |

| Proximate analysis | Moisture (%) |

| Ash (%) | |

| Volatile matter (%) Fixed carbon (%) | |

| Chemical composition | Lignin (%) |

| Cellulose (%) Hemicellulose (%) | |

| Extractives (%) |

| Indicator | Maximum Value | Minimum Value |

|---|---|---|

| Calorific value (MJ/kg) | 26.03 | 0 |

| Moisture (%) | 15 | 0 |

| Ash (%) | 10.7 | 0 |

| Volatile matter (%) | 80.40 | 0 |

| Fixed carbon (%) | 31.79 | 0 |

| Lignin (%) | 21.7 | 0 |

| Cellulose (%) | 57.4 | 0 |

| Hemicellulose (%) | 31.11 | 0 |

| Extractives (%) | 53 | 0 |

| Indicator | Corn Residue (Zea mays) | Pinus spp. Residue | Quercus spp. Residue |

|---|---|---|---|

| Calorific value (MJ/kg) | 17.6 | 20.92 | 19.5 |

| Moisture (%) | 7.99 | 15 | 25 |

| Ash (%) | 7.3 | 0.64 | 0.95 |

| Volatile matter (%) | 72.57 | 82.9 | 87.33 |

| Fixed carbon (%) | 9.19 | 8.9 | 8.88 |

| Lignin (%) | 5.07 | 22.5 | 4.9 |

| Cellulose (%) | 26.87 | 54.73 | 38.4 |

| Hemicellulose (%) | 26.96 | 13.14 | 24 |

| Extractives (%) | 41.09 | 20.55 | 6.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales-Máximo, C.N.; López-Sosa, L.B.; Rutiaga-Quiñones, J.G.; Corral-Huacuz, J.C.; Aguilera-Mandujano, A.; Pintor-Ibarra, L.F.; López-Miranda, A.; Delgado-Domínguez, S.N.; Rodríguez-Magallón, M.d.C.; Morales-Máximo, M. Characterization of Agricultural Residues of Zea mays for Their Application as Solid Biofuel: Case Study in San Francisco Pichátaro, Michoacán, Mexico. Energies 2022, 15, 6870. https://doi.org/10.3390/en15196870

Morales-Máximo CN, López-Sosa LB, Rutiaga-Quiñones JG, Corral-Huacuz JC, Aguilera-Mandujano A, Pintor-Ibarra LF, López-Miranda A, Delgado-Domínguez SN, Rodríguez-Magallón MdC, Morales-Máximo M. Characterization of Agricultural Residues of Zea mays for Their Application as Solid Biofuel: Case Study in San Francisco Pichátaro, Michoacán, Mexico. Energies. 2022; 15(19):6870. https://doi.org/10.3390/en15196870

Chicago/Turabian StyleMorales-Máximo, Cindy Nereida, Luis Bernardo López-Sosa, José Guadalupe Rutiaga-Quiñones, Juan Carlos Corral-Huacuz, Arturo Aguilera-Mandujano, Luis Fernando Pintor-Ibarra, Armando López-Miranda, Sharbaal Nicolás Delgado-Domínguez, María del Carmen Rodríguez-Magallón, and Mario Morales-Máximo. 2022. "Characterization of Agricultural Residues of Zea mays for Their Application as Solid Biofuel: Case Study in San Francisco Pichátaro, Michoacán, Mexico" Energies 15, no. 19: 6870. https://doi.org/10.3390/en15196870