Impact of Series and Parallel Connection of Macro Fiber Composite Patches in Piezoelectric Harvester on Energy Storage

Abstract

:1. Introduction

2. Laboratory Setup

3. Results

3.1. Impact of Capacitor Leakage Current on Losses Stored Energy

3.2. Capacitor Charging by the Use of Unimorphs

- The capacitor was charged by a unimorph containing an MFC patch glued on the upper surface of the carrying substrate;

- The capacitor was charged by a unimorph containing an MFC patch glued on the bottom surface of the carrying substrate.

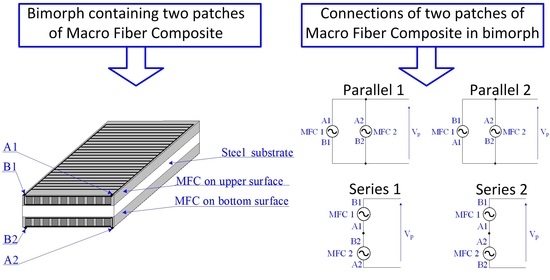

3.3. Parallel and Series Connection of MFC Patch in Bimorph

- A1 connected the conduit and upper electrode in MFC glued on the upper surface of the substrate;

- B1 connected the conduit and bottom electrode in MFC glued on the upper surface of the substrate;

- A2 connected the conduit and bottom electrode in MFC glued on the bottom surface of the substrate;

- B2 connected the conduit and upper electrode in MFC glued on the bottom surface of the steel substrate.

3.4. Capacitor Charging by Use of Bimorph with MFC Patches Parallel and Series Connected

3.5. Current for Capacitive Load and Resistive Load

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Machado, S.P.; Febbo, M.; Gatti, C.D.; Osinaga, S.M. A piezoelectric beam model with geometric, material and damping nonlinearities for energy harvesting. Smart Mater. Struct. 2020, 29, 095009. [Google Scholar] [CrossRef]

- Khazaee, M.; Rezaniakolaie, A.; Rosendahl, L.A. broadband macro-fiber-composite piezoelectric energy harvester for higher energy conversion from practical wideband vibrations. Nano Energy 2020, 76, 104978. [Google Scholar] [CrossRef]

- Zhang, J.; Fang, Z.; Shu, C.; Zhang, J.; Zhang, Q.; Li, C. A rotational piezoelectric energy harvester for efficient wind energy harvesting. Sens. Actuators A Phys. 2017, 262, 123–129. [Google Scholar] [CrossRef]

- Machado, S.P.; Febbo, M.; Ramírez, J.M.; Gatti, C.D. Rotational double-beam piezoelectric energy harvester impacting against a stop. J. Sound Vib. 2020, 469, 115141. [Google Scholar] [CrossRef]

- Zhou, M.; Chen, Q.; Xu, Z.; Wang, W. Piezoelectric wind energy harvesting device based on the inverted cantilever beam with leaf-inspired extensions. AIP Adv. 2019, 9, 035213. [Google Scholar] [CrossRef] [Green Version]

- Elahi, H.; Eugeni, M.; Fune, F.; Lampani, L.; Mastroddi, F.; Paolo Romano, G.; Gaudenzi, P. Performance evaluation of a piezoelectric energy harvester based on flag-flutter. Micromachines 2020, 11, 933. [Google Scholar] [CrossRef]

- Li, S.; Crovetto, A.; Peng, Z.; Zhang, A.; Hansen, O.; Wang, M.; Wang, F. Bi-resonant structure with piezoelectric PVDF films for energy harvesting from random vibration sources at low frequency. Sens. Actuators A Phys. 2016, 247, 547–554. [Google Scholar] [CrossRef] [Green Version]

- Dai, Q.; Ng, K. Investigation of electromechanical properties of piezoelectric structural fiber composites with micromechanics analysis and finite element modeling. Mech. Mater. 2012, 53, 29–46. [Google Scholar] [CrossRef]

- Mo, C.; Kim, S.; Clark, W.W. Theoretical analysis of energy harvesting performance for unimorph piezoelectric benders with interdigitated electrodes. Smart Mater. Struct. 2009, 18, 055017. [Google Scholar] [CrossRef]

- Wang, H.; Meng, Q. Analytical modeling and experimental verification of vibration-based piezoelectric bimorph beam with a tip-mass for power harvesting. Mech. Syst. Signal Process. 2013, 36, 193–209. [Google Scholar] [CrossRef]

- Zhao, S.; Erturk, A. Electroelastic modeling and experimental validations of piezoelectric energy harvesting from broadband random vibrations of cantilevered bimorphs. Smart Mater. Struct. 2012, 22, 015002. [Google Scholar] [CrossRef]

- Lumentut, M.F.; Howard, I.M. Analytical and experimental comparisons of electromechanical vibration response of a piezoelectric bimorph beam for power harvesting. Mech. Syst. Signal Process. 2013, 36, 66–86. [Google Scholar] [CrossRef] [Green Version]

- Kuo, C.L.; Lin, S.C.; Wu, W.J. Fabrication and performance evaluation of a metal-based bimorph piezoelectric MEMS generator for vibration energy harvesting. Smart Mater. Struct. 2016, 25, 105016. [Google Scholar] [CrossRef]

- Yang, Y.; Tang, L.; Li, H. Vibration energy harvesting using macro-fiber composites. Smart Mater. Struct. 2009, 18, 115025. [Google Scholar] [CrossRef]

- Mokhtari, F.; Spinks, G.M.; Sayyar, S.; Cheng, Z.; Ruhparwar, A.; Foroughi, J. Highly Stretchable Self-Powered Wearable Electrical Energy Generator and Sensors. Adv. Mater. Technol. 2021, 6, 2000841. [Google Scholar] [CrossRef]

- Song, H.J.; Choi, Y.T.; Wereley, N.M.; Purekar, A.S. Energy harvesting devices using macro-fiber composite materials. J. Intell. Mater. Syst. Struct. 2010, 21, 647–658. [Google Scholar] [CrossRef]

- Liao, Y.; Sodano, H.A. Modeling and comparison of bimorph power harvesters with piezoelectric elements connected in parallel and series. J. Intell. Mater. Syst. Struct. 2010, 21, 149–159. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, L.; Jiang, Z.; Luo, G.; Yang, P.; Han, X.; Li, X.; Maeda, R. High accuracy comsol simulation method of bimorph cantilever for piezoelectric vibration energy harvesting. AIP Adv. 2019, 9, 095067. [Google Scholar] [CrossRef]

- Mohammadi, S.; Cheraghi, K.; Khodayari, A. Piezoelectric vibration energy harvesting using strain energy method. Eng. Res. Express 2019, 1, 015033. [Google Scholar] [CrossRef]

- Zhu, Y.K.; Yu, Y.G.; Li, L.; Jiang, T.; Wang, X.Y.; Zheng, X.J. Modeling and characterization of multilayered d15 mode piezoelectric energy harvesters in series and parallel connections. Smart Mater. Struct. 2016, 25, 075027. [Google Scholar] [CrossRef]

- Lien, I.C.; Shu, Y.C. Array of piezoelectric energy harvesting by the equivalent impedance approach. Smart Mater. Struct. 2012, 21, 082001. [Google Scholar] [CrossRef] [Green Version]

- Al-Ashtari, W.; Hunstig, M.; Hemsel, T.; Sextro, W. Enhanced energy harvesting using multiple piezoelectric elements: Theory and experiments. Sens. Actuators A Phys. 2013, 200, 138–146. [Google Scholar] [CrossRef]

- Wu, P.H.; Lin, J.T.; Lo, Y.C.; Shu, Y.C. An SECE array of piezoelectric energy harvesting. Smart Mater. Struct. 2021, 30, 045008. [Google Scholar] [CrossRef]

- Grzybek, D. Piezoelectric generator for the Power Supply of the Monitoring System. In Proceedings of the 2014 15th International Carpathian Control Conference (ICCC), Velke Karlovice, Czech Republic, 28–30 May 2014; pp. 135–138. [Google Scholar]

- Bagheri, S.; Wu, N.; Filizadeh, S. Modeling of capacitor charging dynamics in an energy harvesting system considering accurate electromechanical coupling effects. Smart Mater. Struct. 2018, 27, 065026. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiang, H.; Tang, L. Modeling, analysis and comparison of four charging interface circuits for piezoelectric energy harvesting. Mech. Syst. Signal Process. 2021, 152, 107476. [Google Scholar] [CrossRef]

- Niu, J.; Conway, B.E.; Pell, W.G. Comparative studies of self-discharge by potential decay and float-current measurements at C double-layer capacitor and battery electrodes. J. Power Source 2004, 135, 332–343. [Google Scholar] [CrossRef]

- Prasath, S.S.; Arockiarajan, A. Influence of bonding layer on effective electromechanical properties of macro-fiber composites (MFCs). Smart Mater. Struct. 2014, 23, 095046. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, N. Optimal design of a piezoelectric coupled beam for power harvesting. Smart Mater. Struct. 2012, 21, 085013. [Google Scholar] [CrossRef]

- Dalzell, P.; Bonello, P. Analysis of an energy harvesting piezoelectric beam with energy storage circuit. Smart Mater. Struct. 2012, 21, 105029. [Google Scholar] [CrossRef]

| Parameters | Symbol | Value |

|---|---|---|

| Length of piezoelectric area inside MFC patch | lp | 85 |

| Overall length of MFC patch | lMFC | 100 |

| Width of piezoelectric area in MFC patch | wp | 14 |

| Width of steel substrate | wb | 16 |

| Thickness of MFC patch | tMFC | 0.3 |

| Thickness of steel substrate | tb | 2 |

| Distance between fixed tip and moved tip | lke | 105 |

| Quality | Unit | Value | |||

|---|---|---|---|---|---|

| Capacitor capacitance C | µF | 250 | 500 | 1000 | 1500 |

| Equivalent resistance Req | kΩ | 298 | 297 | 296 | 295 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grzybek, D.; Micek, P. Impact of Series and Parallel Connection of Macro Fiber Composite Patches in Piezoelectric Harvester on Energy Storage. Energies 2021, 14, 2379. https://doi.org/10.3390/en14092379

Grzybek D, Micek P. Impact of Series and Parallel Connection of Macro Fiber Composite Patches in Piezoelectric Harvester on Energy Storage. Energies. 2021; 14(9):2379. https://doi.org/10.3390/en14092379

Chicago/Turabian StyleGrzybek, Dariusz, and Piotr Micek. 2021. "Impact of Series and Parallel Connection of Macro Fiber Composite Patches in Piezoelectric Harvester on Energy Storage" Energies 14, no. 9: 2379. https://doi.org/10.3390/en14092379