A Method for Efficiency Determination of Permanent Magnet Synchronous Motor

Abstract

:1. Introduction

2. Materials and Methods

3. Results

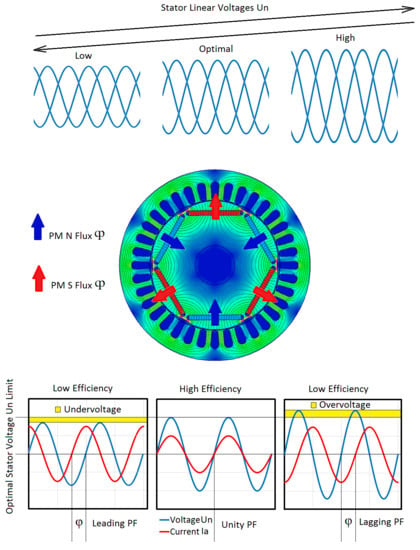

3.1. PMSM Nominal Voltage Determination Experiment

3.2. PMSM Efficiency Determination Experimets

3.2.1. PMSM Efficiency Determination Experiment with 302-V Voltage

3.2.2. PMSM Efficiency Determination Experiment with Reduced 240 V

3.2.3. PMSM Efficiency Determination Experiment with Increased Voltage of 360 V

3.3. PMSM Stator’s Current and Voltage Singnals Simulation

4. Conclusions

- During the nominal voltage determination of the permanent magnet synchronous motor (PMSM) experiment, a 302-V electromotive force was measured, which is equal to PMSM nominal voltage.

- During the efficiency determination experiment of permanent magnet synchronous motor (PMSM), the highest efficiency of 98.7% was reached with 302-V nominal voltage. The PMSM nominal voltage and current curve coincidence in Figure 7 was proved to be an active load with nominal voltage.

- As PMSM was tested with reduced voltage and the efficiency decreased to 88.39%, it was seen from the voltage and current oscillogram (Figure 9) that the current overcame the voltage and the motor acted as a reactive load with capacitive character.

- The PMSM increased above the nominal voltage, which reached 85.7% efficiency, and current stayed behind from the voltage in the oscillogram (Figure 11), which occurred because the motor acted as an inductive reactive load.

- The increase of active power of the PMSM was noticed as the input voltage was increased, but the value of torque reached its peak of 7.2 N·m when nominal 302-V voltage was applied, which influenced the peak efficiency result.

- Simulation model results in the National Instruments environment corresponded to the experimental results and PMSM input oscillograms. This simulation model is applicable for further PMSM research.

- From the experimental results, it can be concluded that rotor’s permanent magnets did not produce enough magnetic field and that is why they were not able to create a nominal 400-V electro motive force.

Author Contributions

Funding

Conflicts of Interest

References

- Rassolkin, A.; Heidari, H.; Kallaste, A.; Vaimann, T.; Acedo, J.P.; Romero-Cadaval, E. Efficiency Map Comparison of Induction and Synchronous Reluctance Motors. In Proceedings of the 26th International Workshop on Electric Drives: Improvement in Efficiency of Electric Drives (IWED), Moscow, Russia, 30 January–2 February 2019. [Google Scholar]

- De Almeida, A.T.; Ferreira, F.J.; Baoming, G. Beyond Induction Motors—Technology Trends to Move Up Efficiency. IEEE Trans. Ind. Appl. 2013, 50, 2103–2114. [Google Scholar] [CrossRef]

- Ferreira, F.J.; Baoming, G.; de Almeida, A.T. Reliability and Operation of High-Efficiency Induction Motors. In Proceedings of the IEEE Transactions on Industry Applications, Calgary, AB, Canada, 5–8 May 2015; Volume 52, pp. 4628–4637. [Google Scholar]

- Zhang, S.; Zhou, X.; Gao, D. Strategy of efficiency optimization of PMSM-DTC system used for EVs. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Bejing, China, 31 August–3 September 2014. [Google Scholar]

- Sakunthala, S.; Kiranmayi, R.; Mandadi, P.N. A study on industrial motor drives: Comparison and applications of PMSM and BLDC motor drives. In Proceedings of the 2017 International Conference on Energy, Communication, Data Analytics and Soft Computing (ICECDS), Chennai, India, 1–2 August 2017. [Google Scholar]

- Staszak, J.; Ludwinek, K.; Gawęcki, Z.; Kurkiewicz, J.; Bekier, T.; Jaśkiewicz, M. Utilization of permanent magnet synchronous motors in industrial robots. In Proceedings of the 2015 International Conference on Information and Digital Technologies, Zilina, Slovakia, 7–9 July 2015. [Google Scholar]

- Daut, I.; Abdullah, M.; Gomesh, N.; Yanawati, Y.; Shafiqin, S.N.; Pungut, I. The impacts of stator materials on induction motor nameplate parameters for high performance. In Proceedings of the 2010 IEEE Student Conference on Research and Development (SCOReD), Putrajaya, Malaysia, 13–14 December 2010. [Google Scholar]

- Lee, K.; Frank, S.; Sen, P.K.; Polese, L.G.; Alahmad, M.; Waters, C. Estimation of induction motor equivalent circuit parameters from nameplate data. In Proceedings of the 2012 North American Power Symposium (NAPS), Champaign, IL, USA, 9–11 September 2012. [Google Scholar]

- Ukil, A.; Bloch, R.; Andenna, A. Estimation of Induction Motor Operating Power Factor from Measured Current and Manufacturer Data. IEEE Trans. Energy 2011, 26, 699–706. [Google Scholar] [CrossRef]

- Deda, S.; De Kock, J.A. Induction Motor Efficiency Test Methods: A Comparison of Standards. In Proceedings of the 2017 International Conference on the Industrial and Commercial Use of Energy (ICUE), Cape Town, South Africa, 15–16 August 2017. [Google Scholar]

- Guo, F.; Liu, M.; Jia, P.; Liu, J.H.; Dong, P.; Shen, Y. Application Research of Small and Medium-sized Three-phase Asynchronous Motor Energy Efficiency Testing System. In Proceedings of the 2018 2nd IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 20–22 October 2018. [Google Scholar]

- Karanayil, B.; Rahman, M.F.; Grantham, C. Induction motor parameter determination technique using artificial neural networks. In Proceedings of the 2008 International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008. [Google Scholar]

- Wlas, M.; Krzeminski, Z.; Toliyat, H.A. Toliyat. Neural-Network-Based Parameter Estimations of Induction Motors. IEEE Trans. Ind. Electron. 2008, 55, 1783–1794. [Google Scholar] [CrossRef]

- Lee, H.K.; Shin, K.H.; Bang, T.K.; Choi, J.Y.; Cho, S.K. Characteristic Analysis of a V-Shape Interior Permanent Magnet Synchronous Motor According to Design Parameter. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, South Korea, 7–10 October 2018. [Google Scholar]

- Zhao, W.; Zhao, F.; Lipo, T.A.; Kwon, B.I. Optimal Design of a Novel V-Type Interior Permanent Magnet Motor with Assisted Barriers for the Improvement of Torque Characteristics. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Zhou, W.; Dou, R. The study of influence on the performance of PMSM with space between permanent magnet pieces. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 20–23 August 2011. [Google Scholar]

- Sorgdrager, A.J.; Grobler, A.J. Influence of magnet size and rotor topology on the air-gap flux density of a radial flux PMSM. In Proceedings of the 2013 IEEE International Conference on Industrial Technology (ICIT), Cape Town, South Africa, 25–28 February 2013. [Google Scholar]

- He, C.; Wu, T. Analysis and design of surface permanent magnet synchronous motor and generator. CES Trans. Electr. Mach. Syst. 2019, 3, 94–100. [Google Scholar] [CrossRef]

- Nur, T.; Haroen, Y. Investigation the influence of magnet slots with fixed slot opening width on the cogging torque of Inset-PMSM. In Proceedings of the 2nd IEEE Conference on Power Engineering and Renewable Energy (ICPERE) 2014, Bali, Indonesia, 9–11 December 2014. [Google Scholar]

- Feng, G.; Qi, W.; Zhang, B.; Li, C. Analysis and comparison of three-phase variable frequency PMSM with single-phase induction motor in household appliances. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 20–23 August 2011. [Google Scholar]

- Spina, I.; del Pizzo, A.; Beneduce, L.; Cascone, B.; Fratelli, L. Comparative analysis of performance and energy losses in light railways vehicles equipped with IM or PMSM drive. In Proceedings of the 2014 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 18–20 June 2014. [Google Scholar]

- Kim, K.; Bae, J.; Kim, W.H.; Ham, S.H.; Cho, S.; Lee, J. Design and comparison between IM and PMSM for hybrid electrical vehicles. In Proceedings of the 2010 14th Biennial IEEE Conference on Electromagnetic Field Computation, Chicago, IL, USA, 9–12 May 2010. [Google Scholar]

- Petrov, I.; Niemelä, M.; Ponomarev, P.; Pyrhönen, J. Rotor Surface Ferrite Permanent Magnets in Electrical Machines: Advantages and Limitations. IEEE Trans. Ind. Electron. 2017, 64, 5314–5322. [Google Scholar] [CrossRef]

- De Almeida, A.T.; Ferreira, F.J.; Quintino, A. Technical and Economical Considerations on Super High-Efficiency Three-Phase Motors. In Proceedings of the IEEE Transactions on Industry Applications, Louisville, KY, USA, 20–24 May 2012; Volume 50, pp. 1274–1285. [Google Scholar] [CrossRef]

- Popescu, M.; Dorrell, D. A method for determining ipm motor parameters from simple torque test data. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013. [Google Scholar]

- Puron, L.D.; Neto, J.E.; Fernández, I.A. Neural networks based estimator for efficiency in VSI to PWM of induction motors drives. In Proceedings of the 2016 IEEE International Conference on Automatica (ICA-ACCA), Curico, Chile, 19–21 October 2016. [Google Scholar]

- Al-Taee, M.A.; Al-Din, M.S.; AlZu’bi, H.S. Real-time efficiency optimisation of open-loop controlled synchronous PM motor drive using Adaptive Neural Networks. In Proceedings of the 2011 IEEE EUROCON-International Conference on Computer as a Tool, Lisbon, Portugal, 27–29 April 2011. [Google Scholar]

- Mosaad, M.I.; Banakher, F.A. Direct Torque Control of Synchronous Motors Using Artificial Neural Network. In Proceedings of the 2019 IEEE International Conference on Electro Information Technology (EIT), Brookings, SD, USA, 20–22 May 2019. [Google Scholar]

| Experiment | T [N·m] | V [rpm] | P [W] | Pmech [W] | I [A] | cos ф | η [%] |

|---|---|---|---|---|---|---|---|

| 240 V input | 6.2 | 1500 | 1101.8 | 973.9 | 3.66 | 0.853 | 88.39 |

| 260 V input | 6.7 | 1500 | 1163.4 | 1052.5 | 2.96 | 0.879 | 90.5 |

| 280 V input | 6.7 | 1500 | 1156.9 | 1052.5 | 2.64 | 0.929 | 91.0 |

| 302 V input | 7.2 | 1500 | 1156.3 | 1142.8 | 2.81 | 0.997 | 98.7 |

| 320 V input | 6.2 | 1500 | 1067.4 | 983.2 | 1.89 | 0.949 | 92.1 |

| 340 V input | 6.0 | 1500 | 1060.2 | 951.5 | 1.80 | 0.887 | 89.7 |

| 360 V input | 6.3 | 1500 | 1165.6 | 999.1 | 2.20 | 0.763 | 85.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dambrauskas, K.; Vanagas, J.; Zimnickas, T.; Kalvaitis, A.; Ažubalis, M. A Method for Efficiency Determination of Permanent Magnet Synchronous Motor. Energies 2020, 13, 1004. https://doi.org/10.3390/en13041004

Dambrauskas K, Vanagas J, Zimnickas T, Kalvaitis A, Ažubalis M. A Method for Efficiency Determination of Permanent Magnet Synchronous Motor. Energies. 2020; 13(4):1004. https://doi.org/10.3390/en13041004

Chicago/Turabian StyleDambrauskas, Karolis, Jonas Vanagas, Tomas Zimnickas, Artūras Kalvaitis, and Mindaugas Ažubalis. 2020. "A Method for Efficiency Determination of Permanent Magnet Synchronous Motor" Energies 13, no. 4: 1004. https://doi.org/10.3390/en13041004