The Impact of Thermal Treatment on Light-Induced Degradation of Multicrystalline Silicon PERC Solar Cell

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Lifetime Sample

3.2. mc-Si PERC Solar Cell

4. Prospect

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fischer, H.; Pschunder, W. Investigation of Photon and Thermal Changes in Silicon Solar Cells. In Proceedings of the 10th IEEE Photovoltaic Specialists Conference, Palo Alto, CA, USA, 13–15 November 1973. [Google Scholar]

- Lindroos, J.; Savin, H. Review of Light-induced Degradation in Crystalline Silicon Solar Cells. Sol. Energy Mater. Sol. Cells 2016, 147, 115–126. [Google Scholar] [CrossRef]

- Kersten, F.; Engelhart, P.; Ploigt, H.-C.; Stekolnikov, A.; Lindner, T.; Stenzel, F.; Bartzsch, M.; Szpeth, A.; Petter, K.; Heitmann, J.; et al. A New mc-Si Degradation Effect Called LeTID. In Proceedings of the 42nd Photovoltaic Specialist Conference, New Orleans, LA, USA, 14–19 June 2015. [Google Scholar]

- Fung, T.H.; Kim, M.; Chen, D.; Chan, C.E.; Hallam, B.J.; Chen, R.; Payne, D.N.R.; Ciesla, A.; Wenham, S.R.; Abbott, M.D. A Four-state Kinetic Model for the Carrier-induced Degradation in Multicrystalline Silicon: Introducing the Reservoir State. Sol. Energy Mater. Sol. Cells 2018, 184, 48–56. [Google Scholar] [CrossRef]

- Luka, T.; Großer, S.; Hagendorf, C.; Ramspeck, K.; Turek, M. Intra-grain Versus Grain Boundary Degradation due to Illumination and Annealing Behavior of Multi-crystalline Solar Cells. Sol. Energy Mater. Sol. Cells 2016, 158, 43–49. [Google Scholar] [CrossRef]

- Payne, D.N.R.; Chan, C.E.; Hallam, B.J.; Hoex, B.; Abbott, M.D.; Wenham, S.R.; Bagnall, D.M. Rapid Passivation of Carrier-induced Defects in P-type Multi-crystalline Silicon. Sol. Energy Mater. Sol. Cells 2016, 158, 102–106. [Google Scholar] [CrossRef]

- Jensen, M.A.; Morishige, A.E.; Hofstetter, J.; Needleman, D.B.; Buonassisi, T. Evolution of LeTID Defects in P-type Multicrystalline Silicon During Degradation and Regeneration. IEEE J. Photovolt. 2017, 7, 980–987. [Google Scholar] [CrossRef]

- Eberle, R.; Kwapil, W.; Schindler, F.; Glunz, S.W.; Schubert, M.C. Firing Temperature Profile Impact on Light Induced Degradation in Multicrystalline Silicon. Energy Procedia 2017, 124, 712–717. [Google Scholar] [CrossRef]

- Chen, D.; Kim, M.; Stefani, B.V.; Hallam, B.J.; Abbott, M.D.; Chan, C.E.; Chen, R.; Payne, D.N.R.; Nampalli, N.; Ciesla, A.; et al. Evidence of an Identical Firing-activated Carrier-induced Defect in Monocrystalline and Multicrystalline Silicon. Sol. Energy Mater. Sol. Cells 2017, 172, 293–300. [Google Scholar] [CrossRef]

- Jensen, M.A.; Morishige, A.E.; Chakraborty, S.; Sharma, R.; Laine, H.S.; Lai, B.; Rose, V.; Youssef, A.; Looney, E.E.; Wieghold, S.; et al. Solubility and Diffusivity: Important Metrics in the Search for the Root Cause of Light- and Elevated Temperature-induced Degradation. IEEE J. Photovolt. 2018, 8, 448–455. [Google Scholar] [CrossRef]

- Chan, C.E.; Payne, D.N.R.; Hallam, B.J.; Abbott, M.D.; Fung, F.H.; Wenham, A.M.; Tjahjono, B.S.; Wenham, S.R. Rapid Stabilization of High-performance Multicrystalline P-type Silicon PERC Cells. IEEE J. Photovolt. 2016, 6, 1473–1479. [Google Scholar] [CrossRef]

- Herguth, A.; Derricks, C.; Keller, P.; Terheiden, B. Recovery of LeTID by Low Intensity Illumination: Reaction Kinetics, Completeness and Threshold Temperature. Energy Procedia 2017, 124, 740–744. [Google Scholar] [CrossRef]

- Nicolai, M.; Zanuccoli, M.; Galiazzo, M.; Bertazzo, M.; Sangiorgi, E.; Fiegna, C. Simulation Study of Light-induced, Current-induced Degradation and Recovery on PERC Solar Cells. Energy Procedia 2016, 92, 153–159. [Google Scholar] [CrossRef] [Green Version]

- Fritz, J.M.; Zuschlag, A.; Skorka, D.; Schmid, A.; Hahn, G. Temperature Dependent Degradation and Regeneration of Differently Doped mc-Si Materials. Energy Procedia 2017, 124, 718–725. [Google Scholar] [CrossRef]

- Bredemeier, D.; Walter, D.; Herlufsen, S.; Schmidt, J. Lifetime Degradation and Regeneration in Multicrystalline Silicon under Illumination at Elevated Temperature. AIP Adv. 2016, 6, 035119. [Google Scholar] [CrossRef]

- Sinton, R.A.; Cuevas, A. Contactless Determination of Current–voltage Characteristics and Minority-carrier Lifetimes in Semiconductors from Quasi-steady-state Photoconductance Data. Appl. Phys. Lett. 1996, 69, 2510–2512. [Google Scholar] [CrossRef]

- Bredemeier, D.; Walter, D.; Schmidt, J. Light-induced Lifetime Degradation in High-performance Multicrystalline Silicon: Detailed Kinetics of the Defect Activation. Sol. Energy Mater. Sol. Cells 2017, 173, 2–5. [Google Scholar] [CrossRef]

- Vahlman, H. Light-induced Degradation due to Cu Precipitation in Crystalline Silicon: Modeling and Impact on PERC Solar Cells. Ph.D. Dissertation, Aalto University, Helsinki, Finland, 2018. [Google Scholar]

- Peral, A.; Dastgheib-Shirazi, A.; Fano, V.; Jimeno, J.C.; Hahn, G.; del Cañizo, C. Impact of Extended Contact Cofiring on Multicrystalline Silicon Solar Cell Parameters. IEEE J. Photovolt. 2017, 7, 91–96. [Google Scholar] [CrossRef] [Green Version]

- Bredemeier, D.; Walter, D.; Herlufsen, S.; Schmidt, J. Understanding the Light-induced Lifetime Degradation and Regeneration in Multicrystalline Silicon. Energy Procedia 2016, 92, 773–778. [Google Scholar] [CrossRef] [Green Version]

- Padmanabhan, M.; Jhaveri, K.; Sharma, R.; Basu, P.K.; Raj, S.; Wong, J.; Li, J. Light-induced Degradation and Regeneration of Multicrystalline Silicon Al-BSF and PERC Solar Cells. Phys. Status Solidi RRL 2016, 10, 874–881. [Google Scholar] [CrossRef]

- Luka, T.; Turek, M.; Großer, S.; Hagendorf, C. Microstructural Identification of Cu in Solar Cells Sensitive to Light-induced Degradation. Phys. Status Solidi RRL 2017, 11, 1600426. [Google Scholar] [CrossRef]

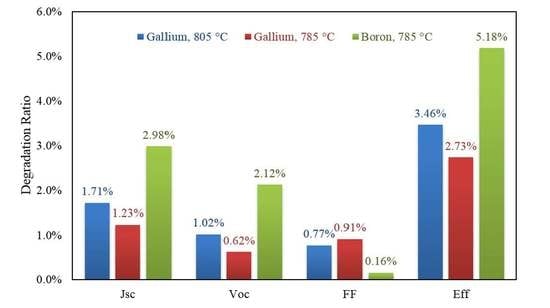

| Wafer Type | Sintering Peak Temperature (°C) | ΔJsc (%rel) | ΔVoc (%rel) | ΔFF (%rel) | ΔEff (%rel) |

|---|---|---|---|---|---|

| Ga-doped | 785 | −1.23 | −0.62 | −0.91 | −2.73 |

| Ga-doped | 805 | −1.71 | −1.02 | −0.77 | −3.46 |

| B-doped | 785 | −2.98 | −2.12 | −0.16 | −5.18 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Peng, J.; Qian, H.; Shen, H.; Wei, Q.; Lian, W.; Ni, Z.; Jie, J.; Zhang, X.; Xie, L. The Impact of Thermal Treatment on Light-Induced Degradation of Multicrystalline Silicon PERC Solar Cell. Energies 2019, 12, 416. https://doi.org/10.3390/en12030416

Zhang S, Peng J, Qian H, Shen H, Wei Q, Lian W, Ni Z, Jie J, Zhang X, Xie L. The Impact of Thermal Treatment on Light-Induced Degradation of Multicrystalline Silicon PERC Solar Cell. Energies. 2019; 12(3):416. https://doi.org/10.3390/en12030416

Chicago/Turabian StyleZhang, Shude, Jiaqi Peng, Hongqiang Qian, Honglie Shen, Qingzhu Wei, Weifei Lian, Zhichun Ni, Jiansheng Jie, Xiaohong Zhang, and Lingzhi Xie. 2019. "The Impact of Thermal Treatment on Light-Induced Degradation of Multicrystalline Silicon PERC Solar Cell" Energies 12, no. 3: 416. https://doi.org/10.3390/en12030416