Data-Driven Studies of Li-Ion-Battery Materials

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

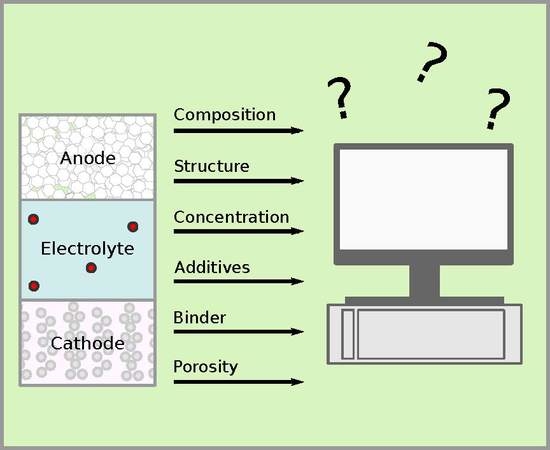

- There are many cell architectures.

- Each part of the cell is typically a composite, where the volume fraction, distribution, etc. are not always reported.

- Standardized description of the crystal structure of the cathode material should be reported.

- A uniform set of protocols for testing cells is not adhered to, and as a result reported data lack compatibility.

- The complexity associated with battery systems results in a large number of diverse descriptors. Even if the data were reported in a uniform way, this large number of descriptors might require large amounts of data for the accurate training of ML models.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ML | Machine learning |

| HHI | Herfindahl–Hirschman index |

| KRR | Kernel ridge regression |

| RF | Random forests |

| SVR | Support vector regression |

Appendix A. Descriptor and Model Details

| Element-Based Descriptor | Element-Based Descriptor | From Battery Data |

|---|---|---|

| Atomic Rad: Average | Ion: Average | Structure Type: Li3PO4 |

| Atomic Rad: Difference | Boiling Point: Average | Structure: LiCdBO3 |

| Atomic Vol: Average | Boiling Point: Difference | Structure: LiV3O8 |

| Atomic Vol: Difference | Density: Average | Structure: Na2FePO4F |

| Covalent Rad: Average | Density: Difference | Structure: Nasicon |

| Covalent Rad: Difference | Evaporation Heat: Average | Structure: Fluorophosphate |

| Dipole: Average | Evaporation Heat: Difference | Structure: Layered |

| Dipole: Difference | Fusion Heat: Average | Structure: Multiple |

| Num Electron: Average | Fusion Heat: Difference | Structure: Olivine |

| Num Electron: Difference | Gas Basicity: Average | Structure: Spinel |

| Van der Waals Radius: Average | Gas Basicity: Difference | Anode: Li |

| Van der Waals Radius: Difference | Heat of Formation: Average | Anode: Li4Ti5O12 |

| Electronegativity: Average | Heat of Formation: Difference | Anode: MCMB |

| Electronegativity: Difference | Melting Point: Average | Anode: Na |

| # Valence: Average | Melting Point: Difference | Anode: Graphite |

| # Valence: Difference | Thermal Conductivity: Average | |

| Ion: Average | Thermal Conductivity: Difference |

| Rank | Descriptor | Rank | Descriptor |

|---|---|---|---|

| 1 | Dipole: Average | 14 | Atomic Vol: Average |

| 2 | Gas Basicity: Average | 15 | Anode: Graphite |

| 3 | Gas Basicity: Difference | 16 | Electronegativity: Difference |

| 4 | Fusion Heat: Average | 17 | Melting Point: Average |

| 5 | Heat Of Formation: Average | 18 | Thermal Conductivity: Difference |

| 6 | # Electron: Average | 19 | Heat Of Formation: Difference |

| 7 | Anode: Li | 20 | Atomic Rad: Average |

| 8 | Boiling Point: Average | 21 | Van der Waals Radius: Average |

| 9 | Covalent Rad: Average | 22 | Melting Point: Difference |

| 10 | # Electron: Difference | 23 | Atomic Rad: Difference |

| 11 | Electronegativity: Average | 24 | Num Valence: Average |

| 12 | Thermal Conductivity: Average | 25 | Num Valence: Difference |

| 13 | Atomic Vol: Difference |

| Model | Parameters |

|---|---|

| Lasso | |

| Kernel Ridge Regression | , |

| Support Vector Regression | , |

| Random Forest | , |

References

- Finn, B. Origin of Electrical Power. Essay from the National Museum of American History. 2001. Available online: http://americanhistory.si.edu/powering/past/prehist.htm (accessed on 21 November 2018).

- Mizushima, K.; Jones, P.; Wiseman, P.; Goodenough, J.B. LixCoO2 (0 < x < − 1): A new cathode material for batteries of high energy density. Mater. Res. Bull. 1980, 15, 783–789. [Google Scholar]

- Frost, S. Technical Insights Report: Energy Storage and Generation for Portable Power; Technical Report; Frost & Sullivan: London, UK, 2009. [Google Scholar]

- Sparks, T.D.; Gaultois, M.W.; Oliynyk, A.; Brgoch, J.; Meredig, B. Data mining our way to the next generation of thermoelectrics. Scr. Mater. 2016, 111, 10–15. [Google Scholar] [CrossRef] [Green Version]

- Gaultois, M.W.; Oliynyk, A.O.; Mar, A.; Sparks, T.D.; Mulholland, G.J.; Meredig, B. Perspective: Web-based machine learning models for real-time screening of thermoelectric materials properties. APL Mater. 2016, 4, 053213. [Google Scholar] [CrossRef]

- Oliynyk, A.O.; Sparks, T.D.; Gaultois, M.W.; Ghadbeigi, L.; Mar, A. Gd12Co5. 3Bi and Gd12Co5Bi, Crystalline Doppelganger with Low Thermal Conductivities. Inorg. Chem. 2016, 55, 6625–6633. [Google Scholar] [CrossRef]

- Mansouri Tehrani, A.; Oliynyk, A.O.; Parry, M.; Rizvi, Z.; Couper, S.; Lin, F.; Miyagi, L.; Sparks, T.D.; Brgoch, J. Machine learning directed search for ultraincompressible, superhard materials. J. Am. Chem. Soc. 2018, 140, 9844–9853. [Google Scholar] [CrossRef]

- Kauwe, S.K.; Graser, J.; Vazquez, A.; Sparks, T.D. Machine Learning Prediction of Heat Capacity for Solid Inorganics. Integr. Mater. Manuf. Innov. 2018, 7, 43–51. [Google Scholar] [CrossRef]

- Carrasquilla, J.; Melko, R.G. Machine learning phases of matter. Nat. Phys. 2017, 13, 431. [Google Scholar] [CrossRef]

- Balachandran, P.V.; Kowalski, B.; Sehirlioglu, A.; Lookman, T. Experimental search for high-temperature ferroelectric perovskites guided by two-step machine learning. Nat. Commun. 2018, 9, 1668. [Google Scholar] [CrossRef] [PubMed]

- Zhuo, Y.; Mansouri Tehrani, A.; Brgoch, J. Predicting the Band Gaps of Inorganic Solids by Machine Learning. J. Phys. Chem. Lett. 2018, 9, 1668–1673. [Google Scholar] [CrossRef] [PubMed]

- Kauwe, S.K.; Welker, T.; Sparks, T.D. Extracting Knowledge from DFT: Experimental Band Gap Predictions Through Ensemble Learning. MRS Commun. 2018. submitted. [Google Scholar]

- Zhuo, Y.; Tehrani, A.M.; Oliynyk, A.O.; Duke, A.C.; Brgoch, J. Identifying an efficient, thermally robust inorganic phosphor host via machine learning. Nat. Commun. 2018, 9, 4377. [Google Scholar] [CrossRef] [PubMed]

- Hutchinson, M.L.; Antono, E.; Gibbons, B.M.; Paradiso, S.; Ling, J.; Meredig, B. Overcoming data scarcity with transfer learning. arXiv, 2017; arXiv:1711.05099. [Google Scholar]

- Meredig, B.; Agrawal, A.; Kirklin, S.; Saal, J.E.; Doak, J.; Thompson, A.; Zhang, K.; Choudhary, A.; Wolverton, C. Combinatorial screening for new materials in unconstrained composition space with machine learning. Phys. Rev. B 2014, 89, 094104. [Google Scholar] [CrossRef]

- Cao, B.; Adutwum, L.A.; Oliynyk, A.O.; Luber, E.J.; Olsen, B.C.; Mar, A.; Buriak, J.M. How to optimize materials and devices via design of experiments and machine learning: Demonstration using organic photovoltaics. ACS Nano 2018, 12, 7434–7444. [Google Scholar] [CrossRef] [PubMed]

- Kusne, A.G.; Gao, T.; Mehta, A.; Ke, L.; Nguyen, M.C.; Ho, K.M.; Antropov, V.; Wang, C.Z.; Kramer, M.J.; Long, C.; et al. On-the-fly machine-learning for high-throughput experiments: Search for rare-earth-free permanent magnets. Sci. Rep. 2014, 4, 6367. [Google Scholar] [CrossRef] [PubMed]

- Landrum, G.A.; Penzotti, J.E.; Putta, S. Machine-learning models for combinatorial catalyst discovery. Meas. Sci. Technol. 2004, 16, 270. [Google Scholar] [CrossRef]

- Oliynyk, A.O.; Mar, A. Discovery of intermetallic compounds from traditional to machine-learning approaches. Acc. Chem. Res. 2017, 51, 59–68. [Google Scholar] [CrossRef] [PubMed]

- Graser, J.; Kauwe, S.K.; Sparks, T.D. Machine learning and energy minimization approaches for crystal structure predictions: A review and new horizons. Chem. Mater. 2018, 30, 3601–3612. [Google Scholar] [CrossRef]

- Oliynyk, A.O.; Gaultois, M.W.; Hermus, M.; Morris, A.J.; Mar, A.; Brgoch, J. Searching for Missing Binary Equiatomic Phases: Complex Crystal Chemistry in the Hf- In System. Inorg. Chem. 2018, 57, 7966–7974. [Google Scholar] [CrossRef]

- Oliynyk, A.O.; Antono, E.; Sparks, T.D.; Ghadbeigi, L.; Gaultois, M.W.; Meredig, B.; Mar, A. High-throughput machine-learning-driven synthesis of full-Heusler compounds. Chem. Mater. 2016, 28, 7324–7331. [Google Scholar] [CrossRef]

- Oliynyk, A.O.; Adutwum, L.A.; Harynuk, J.J.; Mar, A. Classifying crystal structures of binary compounds AB through cluster resolution feature selection and support vector machine analysis. Chem. Mater. 2016, 28, 6672–6681. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.E.; Yang, Y. Advanced Machine Learning Approach for Lithium-Ion Battery State Estimation in Electric Vehicles. IEEE Trans. Transp. Electrif. 2016, 2, 140–149. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, J.; Pan, D.; Peng, Y.; Peng, X. Lithium-ion battery remaining useful life estimation with an optimized Relevance Vector Machine algorithm with incremental learning. Measurement 2015, 63, 143–151. [Google Scholar] [CrossRef]

- Ahmad, Z.; Xie, T.; Maheshwari, C.; Grossman, J.C.; Viswanathan, V. Machine Learning Enabled Computational Screening of Inorganic Solid Electrolytes for Suppression of Dendrite Formation in Lithium Metal Anodes. ACS Central Sci. 2018, 4, 996–1006. [Google Scholar] [CrossRef]

- Sendek, A.D.; Yang, Q.; Cubuk, E.D.; Duerloo, K.A.N.; Cui, Y.; Reed, E.J. Holistic computational structure screening of more than 12000 candidates for solid lithium-ion conductor materials. Energy Environ. Sci. 2017, 10, 306–320. [Google Scholar] [CrossRef]

- Wu, B.; Han, S.; Shin, K.G.; Lu, W. Application of artificial neural networks in design of lithium-ion batteries. J. Power Sources 2018, 395, 128–136. [Google Scholar] [CrossRef]

- Ghadbeigi, L.; Harada, J.K.; Lettiere, B.R.; Sparks, T.D. Performance and resource considerations of Li-ion battery electrode materials. Energy Environ. Sci. 2015, 8, 1640–1650. [Google Scholar] [CrossRef]

- Ghiringhelli, L.M.; Vybiral, J.; Levchenko, S.V.; Draxl, C.; Scheffler, M. Big Data of Materials Science: Critical Role of the Descriptor. Phys. Rev. Lett. 2015, 114, 105503. [Google Scholar] [CrossRef] [PubMed]

- Seko, A.; Hayashi, H.; Nakayama, K.; Takahashi, A.; Tanaka, I. Representation of compounds for machine-learning prediction of physical properties. Phys. Rev. B 2017, 95, 144110. [Google Scholar] [CrossRef]

- Rhone, T.D.; Chen, W.; Desai, S.; Yacoby, A.; Kaxiras, E. Data-Driven Studies of Magnetic Two-Dimensional Materials. arXiv, 2018; arXiv:1806.07989. [Google Scholar]

- Ghiringhelli, L.M.; Carbogno, C.; Levchenko, S.; Mohamed, F.; Huhs, G.; Lüders, M.; Oliveira, M.; Scheffler, M. Towards efficient data exchange and sharing for big-data driven materials science: Metadata and data formats. NPJ Comput. Mater. 2017, 3, 46. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Hastie, T.; Tibshirani, R.; Friedman, J.H. The Elements of Statistical Learning: Data Mining, Inference, and Prediction, 2nd ed.; Springer Series in Statistics; Springer: New York, NY, USA, 2009. [Google Scholar]

- Reshef, D.N.; Reshef, Y.A.; Finucane, H.K.; Grossman, S.R.; McVean, G.; Turnbaugh, P.J.; Lander, E.S.; Mitzenmacher, M.; Sabeti, P.C. Detecting novel associations in large data sets. Science 2011, 334, 1518–1524. [Google Scholar] [CrossRef] [PubMed]

- Rupp, M.; Tkatchenko, A.; Müller, K.R.; von Lilienfeld, O.A. Fast and Accurate Modeling of Molecular Atomization Energies with Machine Learning. Phys. Rev. Lett. 2012, 108, 58301. [Google Scholar] [CrossRef] [PubMed]

- Hansen, K.; Biegler, F.; Ramakrishnan, R.; Pronobis, W.; von Lilienfeld, O.A.; Müller, K.R.; Tkatchenko, A. Machine Learning Predictions of Molecular Properties: Accurate Many-Body Potentials and Nonlocality in Chemical Space. J. Phys. Chem. Lett. 2015, 6, 2326–2331. [Google Scholar] [CrossRef] [PubMed]

- Thomas, N.; Smidt, T.; Kearnes, S.; Yang, L.; Li, L.; Kohlhoff, K.; Riley, P. Tensor field networks: Rotation- and translation-equivariant neural networks for 3D point clouds. arXiv, 2018; arXiv:1802.08219. [Google Scholar]

- Al Khateeb, S.; Sparks, T.D. Spray pyrolysis of conductor-and binder-free porous FeS 2 films for high-performance lithium ion batteries. J. Mater. Sci. 2019, 54, 4089–4104. [Google Scholar] [CrossRef]

- Liu, L.; Guan, P.; Liu, C. Experimental and Simulation Investigations of Porosity Graded Cathodes in Mitigating Battery Degradation of High Voltage Lithium-Ion Batteries. J. Electrochem. Soc. 2017, 164, A3163–A3173. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Leng, X.; Han, S.; Shao, Y.; Wei, S.; Liu, Y.; Lian, J.; Jiang, Q. How to improve the stability and rate performance of lithium-ion batteries with transition metal oxide anodes. J. Mater. Res. 2017, 32, 16–36. [Google Scholar] [CrossRef]

- Mendeleev—A Python Resource for Properties of Chemical Elements, Ions and Isotopes, Ver. 0.4.3. 2014. Available online: https://bitbucket.org/lukaszmentel/mendeleev (accessed on 15 January 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kauwe, S.K.; Rhone, T.D.; Sparks, T.D. Data-Driven Studies of Li-Ion-Battery Materials. Crystals 2019, 9, 54. https://doi.org/10.3390/cryst9010054

Kauwe SK, Rhone TD, Sparks TD. Data-Driven Studies of Li-Ion-Battery Materials. Crystals. 2019; 9(1):54. https://doi.org/10.3390/cryst9010054

Chicago/Turabian StyleKauwe, Steven K., Trevor David Rhone, and Taylor D. Sparks. 2019. "Data-Driven Studies of Li-Ion-Battery Materials" Crystals 9, no. 1: 54. https://doi.org/10.3390/cryst9010054