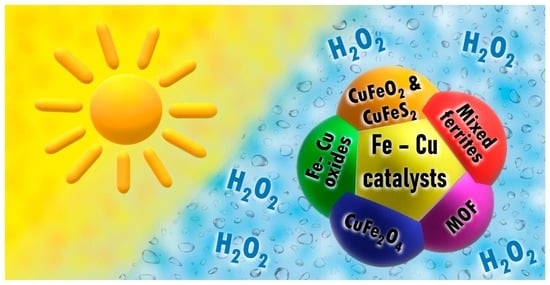

Recent Advances in the Development of Novel Iron–Copper Bimetallic Photo Fenton Catalysts

Abstract

:1. Introduction

2. CuFe2O4

3. Mixed Ferrites Containing Fe and Cu

4. CuFeO2 and CuFeS2 Materials

5. Fe–Cu Oxide Composites

6. Metal–Organic Frameworks Based on Fe and Cu

7. Conclusions and Future Perspective

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Afrad, M.S.I.; Monir, M.B.; Haque, M.E.; Barau, A.A.; Haque, M.M. Impact of Industrial Effluent on Water, Soil and Rice Production in Bangladesh: A Case of Turag River Bank. J. Environ. Health Sci. Eng. 2020, 18, 825–834. [Google Scholar] [CrossRef] [PubMed]

- Amor, C.; Marchão, L.; Lucas, M.S.; Peres, J.A. Application of Advanced Oxidation Processes for the Treatment of Recalcitrant Agro–Industrial Wastewater: A Review. Water 2019, 11, 205. [Google Scholar] [CrossRef] [Green Version]

- Lama, G.; Meijide, J.; Sanromán, A.; Pazos, M. Heterogeneous Advanced Oxidation Processes: Current Approaches for Wastewater Treatment. Catalysts 2022, 12, 344. [Google Scholar] [CrossRef]

- Shokri, A.; Fard, M.S. A Critical Review in Fenton–like Approach for the Removal of Pollutants in the Aqueous Environment. Environ. Chall. 2022, 7, 100534. [Google Scholar] [CrossRef]

- Aparicio, F.; Escalada, J.P.; De Gerónimo, E.; Aparicio, V.C.; Einschlag, F.S.G.; Magnacca, G.; Carlos, L.; Mártire, D.O. Carbamazepine Degradation Mediated by Light in the Presence of Humic Substances–Coated Magnetite Nanoparticles. Nanomaterials 2019, 9, 1379. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Litter, M.I.; Slodowicz, M. An Overview on Heterogeneous Fenton and PhotoFenton Reactions Using Zerovalent Iron Materials. J. Adv. Oxid. Technol. 2017, 20, 20160164. [Google Scholar] [CrossRef]

- Babuponnusami, A.; Muthukumar, K. A Review on Fenton and Improvements to the Fenton Process for Wastewater Treatment. J. Environ. Chem. Eng. 2014, 2, 557–572. [Google Scholar] [CrossRef]

- Bokare, A.D.; Choi, W. Review of Iron–Free Fenton–like Systems for Activating H2O2 in Advanced Oxidation Processes. J. Hazard. Mater. 2014, 275, 121–135. [Google Scholar] [CrossRef]

- Hussain, S.; Aneggi, E.; Goi, D. Catalytic Activity of Metals in Heterogeneous Fenton–like Oxidation of Wastewater Contaminants: A Review. Environ. Chem. Lett. 2021, 19, 2405–2424. [Google Scholar] [CrossRef]

- Nichela, D.A.; Berkovic, A.M.; Costante, M.R.; Juliarena, M.P.; García Einschlag, F.S. Nitrobenzene Degradation in Fenton–like Systems Using Cu(II) as Catalyst. Comparison between Cu(II)– and Fe(III)–Based Systems. Chem. Eng. J. 2013, 228, 1148–1157. [Google Scholar] [CrossRef]

- Berkovic, A.M.; Costante, M.R.; García Einschlag, F.S. Combining Multivariate Curve Resolution and Lumped Kinetic Modelling for the Analysis of Lignin Degradation by Copper–Catalyzed Fenton–like Systems. React. Chem. Eng. 2022, 7, 1954–1967. [Google Scholar] [CrossRef]

- Bali, U.; Karagözoǧlu, B. Performance Comparison of Fenton Process, Ferric Coagulation and H2O2/Pyridine/Cu(II) System for Decolorization of Remazol Turquoise Blue G–133. Dye Pigment. 2007, 74, 73–80. [Google Scholar] [CrossRef]

- Tian, X.; Jin, H.; Nie, Y.; Zhou, Z.; Yang, C.; Li, Y.; Wang, Y. Heterogeneous Fenton–like Degradation of Ofloxacin over a Wide PH Range of 3.6–10.0 over Modified Mesoporous Iron Oxide. Chem. Eng. J. 2017, 328, 397–405. [Google Scholar] [CrossRef]

- Do, Q.C.; Kim, D.G.; Ko, S.O. Catalytic Activity Enhancement of a Fe3O4@SiO2 Yolk–Shell Structure for Oxidative Degradation of Acetaminophen by Decoration with Copper. J. Clean. Prod. 2018, 172, 1243–1253. [Google Scholar] [CrossRef]

- Salem, I.A. Kinetics of the Oxidative Color Removal and Degradation of Bromophenol Blue with Hydrogen Peroxide Catalyzed by Copper(II)–Supported Alumina and Zirconia. Appl. Catal. B Environ. 2000, 28, 153–162. [Google Scholar] [CrossRef]

- Pignatello, J.; Oliveros, E.; MacKay, A. Advanced oxidation processes for organic contaminant destruction based on the fenton reaction and related chemistry. Crit. Rev. Environ. Sci. Technol. 2006, 36, 1–84. [Google Scholar] [CrossRef]

- Zhang, M.H.; Dong, H.; Zhao, L.; Wang, D.-X.; Meng, D. A Review on Fenton Process for Organic Wastewater Treatment Based on Optimization Perspective. Sci. Total Environ. 2019, 670, 110–121. [Google Scholar] [CrossRef]

- McNaught, A.D.; Wilkinson, A. The IUPAC Compendium of Chemical Terminology; International Union of Pure and Applied Chemistry (IUPAC): Durham, NC, USA, 2019; ISBN 0-9678550-9-8. [Google Scholar]

- Sun, C.; Chen, C.; Ma, W.; Zhao, J. Photodegradation of Organic Pollutants Catalyzed by Iron Species under Visible Light Irradiation. Phys. Chem. Chem. Phys. 2011, 13, 1957–1969. [Google Scholar] [CrossRef] [PubMed]

- Kalal, S.; Singh Chauhan, N.P.; Ameta, N.; Ameta, R.; Kumar, S.; Punjabi, P.B. Role of Copper Pyrovanadate as Heterogeneous Photo–Fenton like Catalyst for the Degradation of Neutral Red and Azure–B: An Eco–Friendly Approach. Korean J. Chem. Eng. 2014, 31, 2183–2191. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, H.; Lee, C. Degradation of Diclofenac and Carbamazepine by the Copper(II)–Catalyzed Dark and Photo–Assisted Fenton–like Systems. Chem. Eng. J. 2014, 245, 258–264. [Google Scholar] [CrossRef]

- Faust, B.C.; Hoigné, J. Photolysis of Fe (III)–Hydroxy Complexes as Sources of OH Radicals in Clouds, Fog and Rain. Atmos. Environ. Part A Gen. Top. 1990, 24, 79–89. [Google Scholar] [CrossRef]

- Malato, S.; Fernández–Ibáñez, P.; Maldonado, M.I.; Blanco, J.; Gernjak, W. Decontamination and Disinfection of Water by Solar Photocatalysis: Recent Overview and Trends. Catal. Today 2009, 147, 1–59. [Google Scholar] [CrossRef]

- García Einschlag, F.S.; Braun, A.M.; Oliveros, E. Fundamentals and Applications of the Photo–Fenton Process to Water Treatment. In Handbook of Environmental Chemistry; Springer: Berlin/Heidelberg, Germany, 2015; Volume 35, pp. 301–342. [Google Scholar]

- Bauer, R.; Fallmann, H. The Photo–Fenton Oxidation—A Cheap and Efficient Wastewater Treatment Method. Res. Chem. Intermed. 1997, 23, 341–354. [Google Scholar] [CrossRef]

- Pliego, G.; Zazo, J.A.; Garcia–Muñoz, P.; Munoz, M.; Casas, J.A.; Rodriguez, J.J. Trends in the Intensification of the Fenton Process for Wastewater Treatment: An Overview. Crit. Rev. Environ. Sci. Technol. 2015, 45, 2611–2692. [Google Scholar] [CrossRef]

- Rahim Pouran, S.; Abdul Aziz, A.R.; Wan Daud, W.M.A. Review on the Main Advances in Photo–Fenton Oxidation System for Recalcitrant Wastewaters. J. Ind. Eng. Chem. 2015, 21, 53–69. [Google Scholar] [CrossRef]

- Miralles–Cuevas, S.; Oller, I.; Pérez, J.A.S.; Malato, S. Application of Solar Photo–Fenton at Circumneutral PH to Nanofiltration Concentrates for Removal of Pharmaceuticals in MWTP Effluents. Environ. Sci. Pollut. Res. 2015, 22, 846–855. [Google Scholar] [CrossRef]

- Maniakova, G.; Salmerón, I.; Aliste, M.; Inmaculada Polo–López, M.; Oller, I.; Malato, S.; Rizzo, L. Solar Photo–Fenton at Circumneutral PH Using Fe(III)–EDDS Compared to Ozonation for Tertiary Treatment of Urban Wastewater: Contaminants of Emerging Concern Removal and Toxicity Assessment. Chem. Eng. J. 2022, 431, 133474. [Google Scholar] [CrossRef]

- López–Vinent, N.; Cruz–Alcalde, A.; Lai, C.; Giménez, J.; Esplugas, S.; Sans, C. Role of Sunlight and Oxygen on the Performance of Photo–Fenton Process at near Neutral PH Using Organic Fertilizers as Iron Chelates. Sci. Total Environ. 2022, 803, 149873. [Google Scholar] [CrossRef]

- Ahile, U.J.; Wuana, R.A.; Itodo, A.U.; Sha’Ato, R.; Dantas, R.F. A Review on the Use of Chelating Agents as an Alternative to Promote Photo–Fenton at Neutral PH: Current Trends, Knowledge Gap and Future Studies. Sci. Total Environ. 2020, 710, 134872. [Google Scholar] [CrossRef]

- Sanabria, P.; Wilde, M.L.; Ruiz–Padillo, A.; Sirtori, C. Trends in Fenton and Photo–Fenton Processes for Degradation of Antineoplastic Agents in Water Matrices: Current Knowledge and Future Challenges Evaluation Using a Bibliometric and Systematic Analysis. Environ. Sci. Pollut. Res. 2022, 29, 42168–42184. [Google Scholar] [CrossRef]

- Matta, R.; Hanna, K.; Kone, T.; Chiron, S. Oxidation of 2,4,6-trinitrotoluene in the presence of different iron-bearing minerals at neutral pH. Chem. Eng. J. 2008, 144, 453–458. [Google Scholar] [CrossRef]

- He, J.; Yang, X.; Men, B.; Wang, D. Interfacial Mechanisms of Heterogeneous Fenton Reactions Catalyzed by Iron–Based Materials: A Review. J. Environ. Sci. 2016, 39, 97–109. [Google Scholar] [CrossRef] [PubMed]

- Zuo, S.; Jin, X.; Wang, X.; Lu, Y.; Zhu, Q.; Wang, J.; Liu, W.; Du, Y.; Wang, J. Sandwich Structure Stabilized Atomic Fe Catalyst for Highly Efficient Fenton–like Reaction at All PH Values. Appl. Catal. B Environ. 2021, 282, 119551. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J. Degradation of 2,4,6–Trichlorophenol Using Magnetic Nanoscaled Fe3O4/CeO2 Composite as a Heterogeneous Fenton–like Catalyst. Sep. Purif. Technol. 2015, 149, 255–264. [Google Scholar] [CrossRef]

- Wang, J.; Tang, J. Fe–Based Fenton–like Catalysts for Water Treatment: Catalytic Mechanisms and Applications. J. Mol. Liq. 2021, 332, 115755. [Google Scholar] [CrossRef]

- Xin, S.; Ma, B.; Liu, G.; Ma, X.; Zhang, C.; Ma, X.; Gao, M.; Xin, Y. Enhanced Heterogeneous Photo–Fenton–like Degradation of Tetracycline over CuFeO2/Biochar Catalyst through Accelerating Electron Transfer under Visible Light. J. Environ. Manag. 2021, 285, 112093. [Google Scholar] [CrossRef]

- Wei, Y.; Wang, C.; Liu, D.; Jiang, L.; Chen, X.; Li, H.; Zhang, F. Photo–Catalytic Oxidation for Pyridine in Circumneutral Aqueous Solution by Magnetic Fe–Cu Materials Activated H2O2. Chem. Eng. Res. Des. 2020, 163, 1–11. [Google Scholar] [CrossRef]

- Guo, X.; Xu, Y.; Wang, K.; Zha, F.; Tang, X.; Tian, H. Synthesis of Magnetic CuFe2O4 Self–Assembled Hollow Nanospheres and Its Application for Degrading Methylene Blue. Res. Chem. Intermed. 2020, 46, 853–869. [Google Scholar] [CrossRef]

- Tang, J.; Wang, J. Iron–Copper Bimetallic Metal–Organic Frameworks for Efficient Fenton–like Degradation of Sulfamethoxazole under Mild Conditions. Chemosphere 2020, 241, 125002. [Google Scholar] [CrossRef]

- Han, Z.; Dong, Y.; Dong, S. Copper–Iron Bimetal Modified PAN Fiber Complexes as Novel Heterogeneous Fenton Catalysts for Degradation of Organic Dye under Visible Light Irradiation. J. Hazard. Mater. 2011, 189, 241–248. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, Z.; Tian, P.; Sheng, Y.; Xu, J.; Han, Y.F. Oxidative Degradation of Nitrobenzene by a Fenton–like Reaction with Fe–Cu Bimetallic Catalysts. Appl. Catal. B Environ. 2019, 244, 1–10. [Google Scholar] [CrossRef]

- Diodati, S.; Walton, R.I.; Mascotto, S.; Gross, S. Low–Temperature Wet Chemistry Synthetic Approaches towards Ferrites. Inorg. Chem. Front. 2020, 7, 3282–3314. [Google Scholar] [CrossRef]

- Bastianello, M.; Gross, S.; Elm, M.T. Thermal Stability, Electrochemical and Structural Characterization of Hydrothermally Synthesised Cobalt Ferrite (CoFe2O4). RSC Adv. 2019, 9, 33282–33289. [Google Scholar] [CrossRef] [Green Version]

- Ranga, R.; Kumar, A.; Kumari, P.; Singh, P.; Madaan, V.; Kumar, K. Ferrite Application as an Electrochemical Sensor: A Review. Mater. Charact. 2021, 178, 111269. [Google Scholar] [CrossRef]

- Rana, G.; Dhiman, P.; Kumar, A.; Vo, D.V.N.; Sharma, G.; Sharma, S.; Naushad, M. Recent Advances on Nickel Nano–Ferrite: A Review on Processing Techniques, Properties and Diverse Applications. Chem. Eng. Res. Des. 2021, 175, 182–208. [Google Scholar] [CrossRef]

- Kaur, B.; Kaushal, G.; Rana, S.; Kumar, P.; Khanra, P.; Dhiman, M. Magnetic Ferrites: A Brief Review About Substation on Electric and Magnetic Properties. ECS Trans. 2022, 107, 9093–9101. [Google Scholar] [CrossRef]

- Almessiere, M.A.; Slimani, Y.; Trukhanov, A.V.; Sadaqat, A.; Korkmaz, A.D.; Algarou, N.A.; Aydın, H.; Baykal, A.; Toprak, M.S. Review on Functional Bi–Component Nanocomposites Based on Hard/Soft Ferrites: Structural, Magnetic, Electrical and Microwave Absorption Properties. Nano-Struct. Nano-Objects 2021, 26, 100728. [Google Scholar] [CrossRef]

- Chand, P.; Vaish, S.; Kumar, P. Structural, Optical and Dielectric Properties of Transition Metal (MFe2O4; M = Co, Ni and Zn) Nanoferrites. Phys. B Condens. Matter 2017, 524, 53–63. [Google Scholar] [CrossRef]

- Kefeni, K.K.; Mamba, B.B. Photocatalytic Application of Spinel Ferrite Nanoparticles and Nanocomposites in Wastewater Treatment: Review. Sustain. Mater. Technol. 2020, 23, e00140. [Google Scholar] [CrossRef]

- Shobana, M.K. Nanoferrites in Biosensors—A Review. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2021, 272, 115344. [Google Scholar] [CrossRef]

- Amiri, M.; Salavati–Niasari, M.; Akbari, A. Magnetic Nanocarriers: Evolution of Spinel Ferrites for Medical Applications. Adv. Colloid Interface Sci. 2019, 265, 29–44. [Google Scholar] [CrossRef] [PubMed]

- Alao, A.O.; Popoola, A.P.; Sanni, O. The Influence of Nanoparticle Inhibitors on the Corrosion Protection of Some Industrial Metals: A Review. J. Bio- Tribo-Corrosion 2022, 8, 68. [Google Scholar] [CrossRef]

- Mmelesi, O.K.; Masunga, N.; Kuvarega, A.; Nkambule, T.T.; Mamba, B.B.; Kefeni, K.K. Cobalt Ferrite Nanoparticles and Nanocomposites: Photocatalytic, Antimicrobial Activity and Toxicity in Water Treatment. Mater. Sci. Semicond. Process. 2021, 123, 105523. [Google Scholar] [CrossRef]

- Dippong, T.; Levei, E.A.; Cadar, O. Recent Advances in Synthesis and Applications of MFe2O4 (M = Co, Cu, Mn, Ni, Zn) Nanoparticles. Nanomaterials 2021, 11, 1560. [Google Scholar] [CrossRef]

- Iqbal, M.J.; Yaqub, N.; Sepiol, B.; Ismail, B. A Study of the Influence of Crystallite Size on the Electrical and Magnetic Properties of CuFe2O4. Mater. Res. Bull. 2011, 46, 1837–1842. [Google Scholar] [CrossRef]

- Bagade, A.; Nagwade, P.; Nagawade, A.; Thopate, S.; Pandit, V.; Pund, S. Impact of Mg2+ Substitution on Structural, Magnetic and Optical Properties of Cu–Cd Ferrites. Mater. Today Proc. 2022, 53, 144–152. [Google Scholar] [CrossRef]

- Holinsworth, B.S.; Mazumdar, D.; Sims, H.; Sun, Q.C.; Yurtisigi, M.K.; Sarker, S.K.; Gupta, A.; Butler, W.H.; Musfeldt, J.L. Chemical Tuning of the Optical Band Gap in Spinel Ferrites: CoFe2O4 vs. NiFe2O4. Appl. Phys. Lett. 2013, 103, 082406. [Google Scholar] [CrossRef]

- Lai, Y.J.; Lee, D.J. Solid Mediator Z–Scheme Heterojunction Photocatalysis for Pollutant Oxidation in Water: Principles and Synthesis Perspectives. J. Taiwan Inst. Chem. Eng. 2021, 125, 88–114. [Google Scholar] [CrossRef]

- Feng, Y.; Lee, P.H.; Wu, D.; Zhou, Z.; Li, H.; Shih, K. Degradation of Contaminants by Cu+–Activated Molecular Oxygen in Aqueous Solutions: Evidence for Cupryl Species (Cu3+). J. Hazard. Mater. 2017, 331, 81–87. [Google Scholar] [CrossRef]

- Silva, E.D.N.; Brasileiro, I.L.O.; Madeira, V.S.; De Farias, B.A.; Ramalho, M.L.A.; Rodríguez–Aguado, E.; Rodríguez–Castellón, E. Reusable CuFe2O4–Fe2O3 catalyst Synthesis and Application for the Heterogeneous Photo–Fenton Degradation of Methylene Blue in Visible Light. J. Environ. Chem. Eng. 2020, 8, 104132. [Google Scholar] [CrossRef]

- Cao, Z.; Zuo, C.; Wu, H. One Step for Synthesis of Magnetic CuFe2O4 Composites as Photo–Fenton Catalyst for Degradation Organics. Mater. Chem. Phys. 2019, 237, 121842. [Google Scholar] [CrossRef]

- Leichtweis, J.; Silvestri, S.; Welter, N.; Vieira, Y.; Zaragoza–Sánchez, P.I.; Chávez–Mejía, A.C.; Carissimi, E. Wastewater Containing Emerging Contaminants Treated by Residues from the Brewing Industry Based on Biochar as a New CuFe2O4/Biochar Photocatalyst. Process Saf. Environ. Prot. 2021, 150, 497–509. [Google Scholar] [CrossRef]

- Jiang, J.; Gao, J.; Niu, S.; Wang, X.; Li, T.; Liu, S.; Lin, Y.; Xie, T.; Dong, S. Comparing Dark– and Photo–Fenton–like Degradation of Emerging Pollutant over Photo–Switchable Bi2WO6/CuFe2O4: Investigation on Dominant Reactive Oxidation Species. J. Environ. Sci. 2021, 106, 147–160. [Google Scholar] [CrossRef]

- Clarizia, L.; Russo, D.; Di Somma, I.; Marotta, R.; Andreozzi, R. Homogeneous Photo–Fenton Processes at near Neutral PH: A Review. Appl. Catal. B Environ. 2017, 209, 358–371. [Google Scholar] [CrossRef]

- Guo, X.; Wang, K.; Xu, Y. Tartaric Acid Enhanced CuFe2O4–Catalyzed Heterogeneous Photo–Fenton–like Degradation of Methylene Blue. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2019, 245, 75–84. [Google Scholar] [CrossRef]

- Li, Y.; Qin, C.; Zhang, J.; Lan, Y.; Zhou, L. Cu(II) Catalytic Reduction of Cr(VI) by Tartaric Acid under the Irradiation of Simulated Solar Light. Environ. Eng. Sci. 2014, 31, 447–452. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rocha, A.K.S.; Magnago, L.B.; Santos, J.J.; Leal, V.M.; Marins, A.A.L.; Pegoretti, V.C.B.; Ferreira, S.A.D.; Lelis, M.F.F.; Freitas, M.B.J.G. Copper Ferrite Synthesis from Spent Li–Ion Batteries for Multifunctional Application as Catalyst in Photo Fenton Process and as Electrochemical Pseudocapacitor. Mater. Res. Bull. 2019, 113, 231–240. [Google Scholar] [CrossRef]

- Lin, Y.Y.; Lu, S.Y. Selective and Efficient Cleavage of Lignin Model Compound into Value–Added Aromatic Chemicals with CuFe2O4 Nanoparticles Decorated on Partially Reduced Graphene Oxides via Sunlight–Assisted Heterogeneous Fenton Processes. J. Taiwan Inst. Chem. Eng. 2019, 97, 264–271. [Google Scholar] [CrossRef]

- Ayala, L.I.M.; Paquet, M.; Janowska, K.; Jamard, P.; Quist–Jensen, C.A.; Bosio, G.N.; Mártire, D.O.; Fabbri, D.; Boffa, V. Water Defluoridation: Nanofiltration vs. Membrane Distillation. Ind. Eng. Chem. Res. 2018, 57, 14740–14748. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Wang, Z.; Wang, P.; Tang, Y. An Integration of Photo–Fenton and Membrane Process for Water Treatment by a PVDF@CuFe2O4 Catalytic Membrane. J. Membr. Sci. 2019, 572, 419–427. [Google Scholar] [CrossRef]

- Guin, D.; Baruwati, B.; Manorama, S.V. A Simple Chemical Synthesis of Nanocrystalline AFe2O4 (A = Fe, Ni, Zn): An Efficient Catalyst for Selective Oxidation of Styrene. J. Mol. Catal. A Chem. 2005, 242, 26–31. [Google Scholar] [CrossRef]

- Zhenmin, L.; Xiaoyong, L.; Hong, W.; Dan, M.; Chaojian, X.; Dan, W. General Synthesis of Homogeneous Hollow Core–Shell Ferrite Microspheres. J. Phys. Chem. C 2009, 113, 2792–2797. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, S.; Singhal, S. Tailoring the Photo–Fenton Activity of Spinel Ferrites (MFe2O4) by Incorporating Different Cations (M = Cu, Zn, Ni and Co) in the Structure. RSC Adv. 2015, 5, 6006–6018. [Google Scholar] [CrossRef]

- Li, N.; Fu, F.; Lu, J.; Ding, Z.; Tang, B.; Pang, J. Facile Preparation of Magnetic Mesoporous MnFe2O4@SiO2−CTAB Composites for Cr(VI) Adsorption and Reduction. Environ. Pollut. 2017, 220, 1376–1385. [Google Scholar] [CrossRef]

- Deng, J.; Xu, M.; Qiu, C.; Chen, Y.; Ma, X.; Gao, N.; Li, X. Magnetic MnFe2O4 Activated Peroxymonosulfate Processes for Degradation of Bisphenol A: Performance, Mechanism and Application Feasibility. Appl. Surf. Sci. 2018, 459, 138–147. [Google Scholar] [CrossRef]

- Velinov, N.; Petrova, T.; Genova, I.; Ivanov, I.; Tsoncheva, T.; Idakiev, V.; Kunev, B.; Mitov, I. Synthesis and Mössbauer Spectroscopic Investigation of Copper–Manganese Ferrite Catalysts for Water–Gas Shift Reaction and Methanol Decomposition. Mater. Res. Bull. 2017, 95, 556–562. [Google Scholar] [CrossRef]

- Fu, W.; Yi, J.; Cheng, M.; Liu, Y.; Zhang, G.; Li, L.; Du, L.; Li, B.; Wang, G.; Yang, X. When Bimetallic Oxides and Their Complexes Meet Fenton–like Process. J. Hazard. Mater. 2022, 424, 127419. [Google Scholar] [CrossRef] [PubMed]

- Meena, S.; Anantharaju, K.S.; Vidya, Y.S.; Renuka, L.; Uma, B.; Sharma, S.C.; Prasad, B.D.; More, S.S. Enhanced Sunlight Driven Photocatalytic Activity and Electrochemical Sensing Properties of Ce–Doped MnFe2O4 Nano Magnetic Ferrites. Ceram. Int. 2021, 47, 14760–14774. [Google Scholar] [CrossRef]

- Niu, J.; Qian, H.; Liu, J.; Liu, H.; Zhang, P.; Duan, E. Process and Mechanism of Toluene Oxidation Using Cu1–YMn2CeyOx/Sepiolite Prepared by the Co–Precipitation Method. J. Hazard. Mater. 2018, 357, 332–340. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Zhou, J.; Liu, D.; Li, X.; Liang, H. Enhanced Catalytic Performance of Cu–Doped MnFe2O4 Magnetic Ferrites: Tetracycline Hydrochloride Attacked by Superoxide Radicals Efficiently in a Strong Alkaline Environment. Chemosphere 2022, 297, 134154. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Zeng, D.; Zhang, B.; Hassan, M.; Li, P.; Qi, C.; He, Y. Enhanced Catalytic Activation of Photo–Fenton Process by Cu0·5Mn0·5Fe2O4 for Effective Removal of Organic Contaminants. Chemosphere 2020, 247, 125780. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.T.; Li, Y.; Zhang, X.Q.; Li, J.F.; Luo, Y.N.; Wang, C.W. Fabrication of a Magnetically Separable Cu2ZnSnS4/ZnFe2O4 p–n Heterostructured Nano–Photocatalyst for Synergistic Enhancement of Photocatalytic Activity Combining with Photo–Fenton Reaction. Appl. Surf. Sci. 2019, 479, 86–95. [Google Scholar] [CrossRef]

- Shi, L.; Shi, Y.; Zhuo, S.; Zhang, C.; Aldrees, Y.; Aleid, S.; Wang, P. Multi–Functional 3D Honeycomb Ceramic Plate for Clean Water Production by Heterogeneous Photo–Fenton Reaction and Solar–Driven Water Evaporation. Nano Energy 2019, 60, 222–230. [Google Scholar] [CrossRef]

- Schmachtenberg, N.; Silvestri, S.; Da Silveira Salla, J.; Dotto, G.L.; Hotza, D.; Jahn, S.L.; Foletto, E.L. Preparation of Delafossite–Type CuFeO2 Powders by Conventional and Microwave–Assisted Hydrothermal Routes for Use as Photo–Fenton Catalysts. J. Environ. Chem. Eng. 2019, 7, 102954. [Google Scholar] [CrossRef]

- Liu, Q.L.; Zhao, Z.Y.; Zhao, R.D.; Yi, J.H. Fundamental Properties of Delafossite CuFeO2 as Photocatalyst for Solar Energy Conversion. J. Alloys Compd. 2020, 819, 153032. [Google Scholar] [CrossRef]

- da Silveira Salla, J.; da Boit Martinello, K.; Dotto, G.L.; García–Díaz, E.; Javed, H.; Alvarez, P.J.J.; Foletto, E.L. Synthesis of Citrate–Modified CuFeS2 Catalyst with Significant Effect on the Photo–Fenton Degradation Efficiency of Bisphenol a under Visible Light and near–Neutral PH. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 595, 124679. [Google Scholar] [CrossRef]

- Da Silveira Salla, J.; Dotto, G.L.; Hotza, D.; Landers, R.; Da Boit Martinello, K.; Foletto, E.L. Enhanced Catalytic Performance of CuFeS2 chalcogenide Prepared by Microwave–Assisted Route for Photo–Fenton Oxidation of Emerging Pollutant in Water. J. Environ. Chem. Eng. 2020, 8, 104077. [Google Scholar] [CrossRef]

- Cai, X.; Huang, Q.; Hong, Z.; Zhang, Y.; Hu, H.; Huang, Z.; Liang, J.; Qin, Y. Cu Anchored on Manganese Residue through Mechanical Activation to Prepare a Fe–Cu@SiO2/Starch–Derived Carbon Composites with Highly Stable and Active Visible Light Photocatalytic Performance. J. Environ. Chem. Eng. 2021, 9, 104710. [Google Scholar] [CrossRef]

- Xin, S.; Huo, S.; Zhang, C.; Ma, X.; Liu, W.; Xin, Y.; Gao, M. Coupling Nitrogen/Oxygen Self–Doped Biomass Porous Carbon Cathode Catalyst with CuFeO2/Biochar Particle Catalyst for the Heterogeneous Visible–Light Driven Photo–Electro–Fenton Degradation of Tetracycline. Appl. Catal. B Environ. 2022, 305, 121024. [Google Scholar] [CrossRef]

- Xin, S.; Huo, S.; Xin, Y.; Gao, M.; Wang, Y.; Liu, W.; Zhang, C.; Ma, X. Heterogeneous Photo–Electro–Fenton Degradation of Tetracycline through Nitrogen/Oxygen Self–Doped Porous Biochar Supported CuFeO2 Multifunctional Cathode Catalyst under Visible Light. Appl. Catal. B Environ. 2022, 312, 121442. [Google Scholar] [CrossRef]

- Aparicio, F.; Mizrahi, M.; Ramallo–López, J.M.; Laurenti, E.; Magnacca, G.; Carlos, L.; Mártire, D.O. Novel Bimetallic Magnetic Nanocomposites Obtained from Waste–Sourced Bio–Based Substances as Sustainable Photocatalysts. Mater. Res. Bull. 2022, 152, 111846. [Google Scholar] [CrossRef]

- Ayala, L.I.M.; Aparicio, F.; Boffa, V.; Magnacca, G.; Carlos, L.; Bosio, G.N.; Mártire, D.O. Removal of As(III) via Adsorption and Photocatalytic Oxidation with Magnetic Fe–Cu Nanocomposites. Photochem. Photobiol. Sci. 2022, 1, 1–10. [Google Scholar] [CrossRef]

- Mansoori, S.; Davarnejad, R.; Ozumchelouei, E.J.; Ismail, A.F. Activated Biochar Supported Iron–Copper Oxide Bimetallic Catalyst for Degradation of Ciprofloxacin via Photo–Assisted Electro–Fenton Process: A Mild PH Condition. J. Water Process Eng. 2021, 39, 101888. [Google Scholar] [CrossRef]

- Espinosa, J.C.; Catalá, C.; Navalón, S.; Ferrer, B.; Álvaro, M.; García, H. Iron Oxide Nanoparticles Supported on Diamond Nanoparticles as Efficient and Stable Catalyst for the Visible Light Assisted Fenton Reaction. Appl. Catal. B Environ. 2018, 226, 242–251. [Google Scholar] [CrossRef]

- Manickam–Periyaraman, P.; Espinosa, J.C.; Ferrer, B.; Subramanian, S.; Álvaro, M.; García, H.; Navalón, S. Bimetallic Iron–Copper Oxide Nanoparticles Supported on Nanometric Diamond as Efficient and Stable Sunlight–Assisted Fenton Photocatalyst. Chem. Eng. J. 2020, 393, 124770. [Google Scholar] [CrossRef]

- Khan, A.; Valicsek, Z.; Horváth, O. Comparing the Degradation Potential of Copper(II), Iron(II), Iron(III) Oxides, and Their Composite Nanoparticles in a Heterogeneous Photo–Fenton System. Nanomaterials 2021, 11, 225. [Google Scholar] [CrossRef]

- Asenath–Smith, E.; Ambrogi, E.K.; Barnes, E.; Brame, J.A. CuO Enhances the Photocatalytic Activity of Fe2O3 through Synergistic Reactive Oxygen Species Interactions. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 603, 125179. [Google Scholar] [CrossRef]

- Lu, M.; Wang, J.; Wang, Y.; He, Z. Heterogeneous Photo–Fenton Catalytic Degradation of Practical Pharmaceutical Wastewater by Modified Attapulgite Supported Multi–Metal Oxides. Water 2021, 13, 156. [Google Scholar] [CrossRef]

- Davarnejad, R.; Hassanvand, Z.R.; Mansoori, S.; Kennedy, J.F. Metronidazole Elimination from Wastewater through Photo–Fenton Process Using Green–Synthesized Alginate–Based Hydrogel Coated Bimetallic Iron-copper Nanocomposite Beads as a Reusable Heterogeneous Catalyst. Bioresour. Technol. Rep. 2022, 18, 101068. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, P.; Jin, M.; Gao, G.; Xi, Q.; Zhou, H.; Xu, G.; Xu, J. Promoting the Photo–Fenton Catalytic Activity with Carbon Dots: Broadening Light Absorption, Higher Applicable PH and Better Reuse Performance. Mol. Catal. 2020, 481, 110254. [Google Scholar] [CrossRef]

- Zhang, B.; Hou, Y.; Yu, Z.; Liu, Y.; Huang, J.; Qian, L.; Xiong, J. Three–Dimensional Electro–Fenton Degradation of Rhodamine B with Efficient Fe–Cu/Kaolin Particle Electrodes: Electrodes Optimization, Kinetics, Influencing Factors and Mechanism. Sep. Purif. Technol. 2019, 210, 60–68. [Google Scholar] [CrossRef]

- Joseph, J.; Iftekhar, S.; Srivastava, V.; Fallah, Z.; Zare, E.N.; Sillanpää, M. Iron–Based Metal–Organic Framework: Synthesis, Structure and Current Technologies for Water Reclamation with Deep Insight into Framework Integrity. Chemosphere 2021, 284, 131171. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Wang, M.; Li, Z. Fe–Based Metal–Organic Frameworks for Highly Selective Photocatalytic Benzene Hydroxylation to Phenol. ACS Catal. 2015, 5, 6852–6857. [Google Scholar] [CrossRef]

- Ahmad, M.; Chen, S.; Ye, F.; Quan, X.; Afzal, S.; Yu, H.; Zhao, X. Efficient Photo–Fenton Activity in Mesoporous MIL–100(Fe) Decorated with ZnO Nanosphere for Pollutants Degradation. Appl. Catal. B Environ. 2019, 245, 428–438. [Google Scholar] [CrossRef]

- He, X.; Fang, H.; Gosztola, D.J.; Jiang, Z.; Jena, P.; Wang, W.N. Mechanistic Insight into Photocatalytic Pathways of MIL–100(Fe)/TiO2 Composites. ACS Appl. Mater. Interfaces 2019, 11, 12516–12524. [Google Scholar] [CrossRef] [PubMed]

- Oladipo, A.A. MIL–53 (Fe)–Based Photo–Sensitive Composite for Degradation of Organochlorinated Herbicide and Enhanced Reduction of Cr(VI). Process Saf. Environ. Prot. 2018, 116, 413–423. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, Q.; Al–Enizi, A.M.; Nafady, A.; Ma, S. Recent Advances in MOF–Based Photocatalysis: Environmental Remediation under Visible Light. Inorg. Chem. Front. 2020, 7, 300–339. [Google Scholar] [CrossRef]

- Do, T.L.; Ho, T.M.T.; Doan, V.D.; Le, V.T.; Hoai Thuong, N. Iron–Doped Copper 1,4–Benzenedicarboxylate as Photo–Fenton Catalyst for Degradation of Methylene Blue. Toxicol. Environ. Chem. 2019, 101, 13–25. [Google Scholar] [CrossRef]

- Shi, S.; Han, X.; Liu, J.; Lan, X.; Feng, J.; Li, Y.; Zhang, W.; Wang, J. Photothermal–Boosted Effect of Binary Cu—Fe Bimetallic Magnetic MOF Heterojunction for High–Performance Photo–Fenton Degradation of Organic Pollutants. Sci. Total Environ. 2021, 795, 148883. [Google Scholar] [CrossRef]

- Zhong, Z.; Li, M.; Fu, J.; Wang, Y.; Muhammad, Y.; Li, S.; Wang, J.; Zhao, Z.; Zhao, Z. Construction of Cu–Bridged Cu2O/MIL(Fe/Cu) Catalyst with Enhanced Interfacial Contact for the Synergistic Photo–Fenton Degradation of Thiacloprid. Chem. Eng. J. 2020, 395, 125184. [Google Scholar] [CrossRef]

- Wu, Q.; Siddique, M.S.; Guo, Y.; Wu, M.; Yang, Y.; Yang, H. Low–Crystalline Bimetallic Metal–Organic Frameworks as an Excellent Platform for Photo–Fenton Degradation of Organic Contaminants: Intensified Synergism between Hetero–Metal Nodes. Appl. Catal. B Environ. 2021, 286, 119950. [Google Scholar] [CrossRef]

| Material (a) | Conditions | Contaminant | Degradation Efficiency | Reference |

|---|---|---|---|---|

| Fe2O3/CuFe2O4(b) | UV light, pH 7, [H2O2] = 832.50 mg L−1 | Pyridine (100 mg L−1) | >99% within 30 min; TOC removal of 97% within 50 min | [39] |

| α–Fe2O3/CuFe2O4 (c) | Natural solar light, pH 7, [H2O2] = 300 mg L−1 | MB (MB, 100 mg L−1) | 100% removal of the dye in 180 min | [62] |

| CuFe2O4/CuO (d) | Halogen lamp, pH not indicated, [H2O2] not indicated | MB (40 mg L−1), Rhodamine B (20 mg L−1), Methyl Orange (20 mg L−1) | 100% dye degradation within 50 min | [63] |

| Hollow CuFe2O4 nanospheres (e) | 300–W UV curing lamp (λ > 400 nm), pH not indicated, [H2O2] = 0.02 M | MB (30 mg L−1) | 96.4% in 60 min | [40] |

| CuFe2O4/biochar nanocomposites (f) | Fluorescent lamp (395−580 nm)/Sunlight, pH 3–7, [H2O2] from 2.5 to 10 μM | Rhodamine B | 100% color removal was obtained at 10 and 20 min of reaction for 10 and 50 mg L−1 of dye with solar radiation | [64] |

| Bi2WO6/CuFe2O4 (e) | Visible light, pH 2.6–6.3, [H2O2] = 10 mM | Tetracycline hydrochloride (TCH) | After 30 min, 92.1% TCH (20 mg L−1) degradation (pH 2.6) efficiency and 50.7% and 35.1% mineralization performance. | [65] |

| CuFe2O4/tartaric acid (TA) (b) | UV–curing lamp (365–450 nm), pH 5.0, [H2O2] = 0.02 M | MB (50 mg L−1) | Introducing TA enhanced MB decolorization rate from 52.0% to 92.1% within 80 min. | [67] |

| CuFe2O4 (f) | Sunlight, pH 7.0, [H2O2] = 0.3 M | MB (10 mg L−1) | Decolorization efficiency was 96.1% in 45 min of reaction. | [69] |

| CuFe2O4@rGO (g) | Simulated sunlight, pH not indicated | Guaiacylglycerol–β–guaiacyl ether (lignin model compound) | Yields of 72.6% and 52.5% were achieved for guaiacol and 2–methoxy–4–propylpheno, respectively, in 60 min. | [70] |

| CuFe2O4 nanoparticles doped in polyvinylidene fluoride (PVDF) membranes (h) | Xe arc lamp, pH 3.0–11.0. The H2O2 (30 wt.%) dosage was in the range 50–1200 μL in 50 mL MB solution | MB (100 mg L−1) | MB was thoroughly degraded in 30 min when the pH is 3.0, while there is still 15.6% of the MB left at solution pH of 11.0. | [72] |

| Cu0.5Mn0.5Fe2O4 (i) | Cu0.5Mn0.5Fe2O4 0.08 g L−1 pH: 4.2 [H2O2] = 10 mM | BPA (10 mg L−1) | 100% degradation and 47.6% mineralization 5 min | [83] |

| Cu0.8Mn0.2Fe2O4 (e) | Catalyst 0.100 g L−1 pH 3 and 11 300 W Xe lamp with a 420 nm UV–cut off filter | TC–HCL 100 mL 80 mg L−1 | 99% 30 min | [82] |

| CZTS/ZFO p–n heterostructures (e) | Catalyst 0.5 g L−1 pH 3 to 9 [H2O2] = 10 mM. 500 W Xe high intensity discharge lamp > 450 nm | MO 10 mg L−1 | 91% 120 min At optimum pH: 6 | [84] |

| CuFeMnO4 on the surface of a honeycomb ceramic substrate (j) | 0.05g of catalyst pH = 6.71. [H2O2] from 0 to 0.1 M Solar light | Phenol as a VOC model 10, 20,50 and 100 mg L−1 MB 10 mg L−1 | ∼99.18% COD and MB was removed 20 min | [85] |

| Material (a) | Conditions | Contaminant | Degradation Efficiency | Reference |

|---|---|---|---|---|

| Delafossite–type CuFeO2 (b,c) | visible light, pH from 2.4 to 3.6, H2O2 from 3 to 13 mM, catalyst from 0.13 to 0.33 gL−1 | Reactive Red 141 dye, 50 mg L−1 | about 98% at 30 min | [86] |

| 3R–delafossite CuFeO2 microcrystals (b) | 200 mL reactor, 20 mM of H2O2, 1 g L−1 catalyst, initial pH 8 | Tetracycline hydrochloride 20 mg L−1 | 96.1% in 180 min | [87] |

| CuFeS2(c) | visible light, 20 mM of H2O2, 0.2 g L−1 catalyst, pH 6 | bisphenol A (BPA) 20 mg L−1 | 97% in 60 min | [88] |

| CuFeS2 chalcogenide powders (b,c) | visible light, pH 3.0, 8.33 mM of H2O2, 0.2 g L−1 of catalyst | tartrazine, 100 mg L−1 | 99.1% of tartrazine decolorization after 40 min and 87.3% of mineralization after 150 min | [89] |

| MAMR–Fe–Cu@SiO2/SC, a core–shell structure of CuFeO2@SiO2/starch–derived carbon anchored on a Manganese Residue (d) | Xe–lamp with UV cut–off, pH from 2.5 to 9.5, 15 mM of H2O2, 0.7 g L−1 of catalyst | Tetracycline 50 mg L−1 | 100% in 40 min | [90] |

| CuFeO2/biochar (b) | Xe Lamp with UV cutoff, pH 4 to 8, 20 mM of H2O2, 0.2 g L−1 of catalyst | Tetracycline 20 mg L−1 | 97.6% in 120 min | [38] |

| CuFeO2/biochar (b) | photo–electro–Fenton, Xe–Lamp with UV cutoff, pH from 3 to 11, H2O2 generated by a NO–doped/porous carbon cathode | Tetracycline (20 to 200 mg L−1) | 100% in 60–70 min | [91] |

| Nitrogen/oxygen self–doped porous biochar (NO/PBC) and NO/PBC–supported CuFeO2 (CuFeO2–NO/PBC) (b) | undivided quartz reactor, visible light, pH from 3 to 11, H2O2 by a gas diffusion electrode | Tetracycline 20 mg L−1 | 98% at 30 min | [92] |

| Material (a) | Conditions | Contaminant | Degradation Efficiency | Reference |

|---|---|---|---|---|

| Iron–copper oxide impregnated NaOH–activated biochar (FeCu/ABC catalyst) (b) | Heterogeneous PEF process, pH = 5.8 catalyst dosage of 1 g L−1, electrical current of 200 mA | CIP (45 mg L−1) | 100% removal 2 h | [95] |

| Fe20Cu80(0.2 wt.%)/D3 (c) | catalyst ~200 mg L−1, [H2O2] (200 mg L−1; 5.88 mM), 20 °C, simulated sunlight. pH = 4 | Phenol (100 mg L−1) | 90% removal 2 h | [103] |

| NP–3 (CuII0.4FeII0.6FeIII2O4) (d) | NP–3 = 400 mg L−1, [H2O2] = 1.76 × 10−1 mol L−1, pH = 7.5 Optonica SP1275 LED lamp (GU10, 7 W, 400 Lm, 6000 K, Optonica LED, Sofia, Bulgaria) | MB (1.5 × 10−5 mol L−1) RhB (1.75 × 10−5 mol L−1) | 100% 140 min | [98] |

| Iron oxide (α–Fe2O3, hematite) colloids combined with other transition–metal oxide (TMO) colloids (e.g., CuO and ZnO) (e) | 750 mg L−1 catalyst, [H2O2] = 0.025 mol L−1. Tungsten halogen lamps | MO (25 µM) | 7 to 78% 60 min | [99] |

| Fe–Mn–Cu@ATP (f) | 500 mL of Fe–Mn–Cu@ATP dosage (1–12 g L−1), pH = 3 [H2O2] (0.1–0.6 mol L−1) UV 40 W UV lamp | pharmaceutical wastewater | COD removal: 64.9% 180 min | [100] |

| Fe2O3–CuO@Ca–Alg hydrogel (g) | 4.7 mg L−1 of catalyst, pH = 3.5 [H2O2] = 33.17 mmol L−1 UV light | [MNZ]0 10 mg L−1 | Removal = 95% 85 min | [101] |

| FCCN (h) | Catalyst 1 g L−1 pH: 7–12 [H2O2] = 15 mM 500W Xe lamp 564 nm cut–off filter | MO, acid orange II and mordant yellow 10–20 mg L−1 | 100% 15 min | [102] |

| Material (a) | Conditions | Contaminant | Degradation Efficiency | Reference |

|---|---|---|---|---|

| Fe–CuBDC(b) | Simulated sunlight, pH 6, [H2O2] = 50 mM, [Catalyst] = 1 g L−1 | Methyl Blue (50 mg L−1) | 100% removal of the dye in 70 min | [110] |

| MCuFe MOF (b,c) | 300 W xenon lamp equipped with a UV cut–off filter (λ > 400 nm), pH 4–9, [H2O2] = 5 mM, [Catalyst] = 0.05 g L−1 | Methyl Blue (50 mg L−1) | 100% removal of the dye in 40 min | [111] |

| Cu2O/MIL(Fe/Cu) (b) | 500 W xenon lamp, pH 7.47, [H2O2] = 49 mM, [Catalyst] = 0.5 g L−1 | Thiacloprid (80 mg L−1) | 100% removal of TCL in 20 min; 82% TOC removal in 80 min | [112] |

| L–MIL–53 (Fe, Cu) (b) | 300 W xenon lamp equipped with a UV cut–off filter (λ > 420 nm), pH 7, [H2O2] = 5 mM, [Catalyst] = 0.1 g L−1 | Ciprofloxacin (20 mg L−1) | 60% removal of CIP in 30 min | [113] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bosio, G.N.; García Einschlag, F.S.; Carlos, L.; Mártire, D.O. Recent Advances in the Development of Novel Iron–Copper Bimetallic Photo Fenton Catalysts. Catalysts 2023, 13, 159. https://doi.org/10.3390/catal13010159

Bosio GN, García Einschlag FS, Carlos L, Mártire DO. Recent Advances in the Development of Novel Iron–Copper Bimetallic Photo Fenton Catalysts. Catalysts. 2023; 13(1):159. https://doi.org/10.3390/catal13010159

Chicago/Turabian StyleBosio, Gabriela N., Fernando S. García Einschlag, Luciano Carlos, and Daniel O. Mártire. 2023. "Recent Advances in the Development of Novel Iron–Copper Bimetallic Photo Fenton Catalysts" Catalysts 13, no. 1: 159. https://doi.org/10.3390/catal13010159