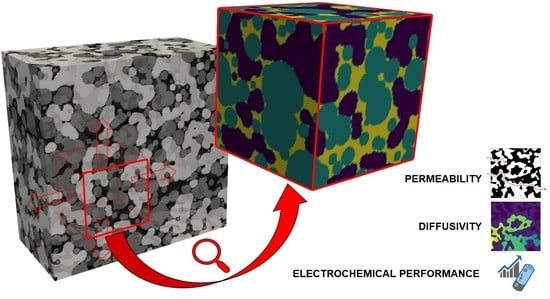

Systematic Workflow for Efficient Identification of Local Representative Elementary Volumes Demonstrated with Lithium-Ion Battery Cathode Microstructures

Abstract

:1. Introduction

2. Methods

2.1. Image Generation and Post-Processing

2.2. Application of the lREV Workflow

- (1)

- General definitions

- (2)

- Extraction of Pore Network Information

- (3)

- Estimation of lower bound REV

- (4)

- Striding Windows

- (5)

- Penalty Function

2.3. Simulation Methods

2.3.1. Diffusion

2.3.2. Hydrodynamics

2.3.3. Electrochemistry

3. Results

- Step One: Extraction of Pore Network Information

- Step Two: Estimation of the lower bound of the REV

- Step Three: Striding Windows

- Step Four: Penalty Function

3.1. Diffusion and Hydrodynamics Benchmark

3.2. Electrochemical Benchmark

4. Discussion

5. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Active material |

| CBD | Carbon-binder domain |

| CFD | Computational fluid dynamics |

| CT | Computed tomography |

| dREV | Deterministic REV |

| FIB | Focused ion beam |

| LBM | Lattice Boltzmann method |

| lREV | Local REV |

| PN | Pore network |

| PNM | Pore network modeling |

| REA | Representative elementary area |

| REV | Representative elementary volume |

| SEM | Scanning electron microscope |

| sREV | Statistical REV |

| TPC | Two-point correlation |

Appendix A. Penalty for the Pore Size Distribution

References

- Danner, T.; Eswara, S.; Schulz, V.P.; Latz, A. Characterization of gas diffusion electrodes for metal-air batteries. J. Power Sources 2016, 324, 646–656. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Bertei, A.; Finegan, D.P.; Tan, C.; Daemi, S.R.; Weaving, J.S.; O’Regan, K.B.; Heenan, T.M.M.; Hinds, G.; Kendrick, E.; et al. 3D microstructure design of lithium-ion battery electrodes assisted by X-ray nano-computed tomography and modelling. Nat. Commun. 2020, 11, 2079. [Google Scholar] [CrossRef] [PubMed]

- Lautenschlaeger, M.P.; Prifling, B.; Kellers, B.; Weinmiller, J.; Danner, T.; Schmidt, V.; Latz, A. Understanding Electrolyte Filling of Lithium-Ion Battery Electrodes on the Pore Scale Using the Lattice Boltzmann Method. Batter. Supercaps 2022, 5, e202200090. [Google Scholar] [CrossRef]

- Lautenschlaeger, M.P.; Weinmiller, J.; Kellers, B.; Danner, T.; Latz, A. Homogenized lattice Boltzmann model for simulating multi-phase flows in heterogeneous porous media. Adv. Water Resour. 2022, 170, 104320. [Google Scholar] [CrossRef]

- Kelly, S.; El-Sobky, H.; Torres-Verdín, C.; Balhoff, M.T. Assessing the utility of FIB-SEM images for shale digital rock physics. Adv. Water Resour. 2016, 95, 302–316. [Google Scholar] [CrossRef]

- Sun, H.; Vega, S.; Tao, G. Analysis of heterogeneity and permeability anisotropy in carbonate rock samples using digital rock physics. J. Pet. Sci. Eng. 2017, 156, 419–429. [Google Scholar] [CrossRef]

- Jacob, A.; Enzmann, F.; Hinz, C.; Kersten, M. Analysis of Variance of Porosity and Heterogeneity of Permeability at the Pore Scale. Transp. Porous Media 2019, 130, 867–887. [Google Scholar] [CrossRef]

- Kanit, T.; Forest, S.; Galliet, I.; Mounoury, V.; Jeulin, D. Determination of the size of the representative volume element for random composites: Statistical and numerical approach. Int. J. Solids Struct. 2003, 40, 3647–3679. [Google Scholar] [CrossRef]

- Bargmann, S.; Klusemann, B.; Markmann, J.; Schnabel, J.E.; Schneider, K.; Soyarslan, C.; Wilmers, J. Generation of 3D representative volume elements for heterogeneous materials: A review. Prog. Mater. Sci. 2018, 96, 322–384. [Google Scholar] [CrossRef]

- Flannery, B.P.; Deckman, H.W.; Roberge, W.G.; D’Amico, K.L. Three-Dimensional X-ray Microtomography. Science 1987, 237, 1439–1444. [Google Scholar] [CrossRef]

- Curtis, M.E. Structural Characterization of Gas Shales on the Micro- and Nano-Scales. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar] [CrossRef]

- Garum, M.; Glover, P.W.; Lorinczi, P.; Drummond-Brydson, R.; Hassanpour, A. Micro- and Nano-Scale Pore Structure in Gas Shale Using Xμ-CT and FIB-SEM Techniques. Energy Fuels 2020, 34, 12340–12353. [Google Scholar] [CrossRef]

- Ren, P.E.; Bakke, S. Process based reconstruction of sandstones and prediction of transport properties. Transp. Porous Media 2002, 46, 311–343. [Google Scholar] [CrossRef]

- Strebelle, S. Conditional simulation of complex geological structures using multiple-point statistics. Math. Geol. 2002, 34, 1–21. [Google Scholar] [CrossRef]

- Westhoff, D.; Manke, I.; Schmidt, V. Generation of virtual lithium-ion battery electrode microstructures based on spatial stochastic modeling. Comput. Mater. Sci. 2018, 151, 53–64. [Google Scholar] [CrossRef]

- Blunt, M.J.; Bijeljic, B.; Dong, H.; Gharbi, O.; Iglauer, S.; Mostaghimi, P.; Paluszny, A.; Pentland, C. Pore-scale imaging and modelling. Adv. Water Resour. 2013, 51, 197–216. [Google Scholar] [CrossRef] [Green Version]

- Rebai, M.; Prat, M. Scale effect and two-phase flow in a thin hydrophobic porous layer. Application to water transport in gas diffusion layers of proton exchange membrane fuel cells. J. Power Sources 2009, 192, 534–543. [Google Scholar] [CrossRef]

- Misaghian, N.; Sadeghi, M.A.; Roberts, E.; Gostick, J. Investigating the Role of the Triple-Phase Boundary in Zinc-Air Cathodes Using Pore Network Modeling. J. Electrochem. Soc. 2022, 169, 100549. [Google Scholar] [CrossRef]

- Astaneh, M.; Maggiolo, D.; Ström, H. Finite-size effects on heat and mass transfer in porous electrodes. Int. J. Therm. Sci. 2022, 179, 107610. [Google Scholar] [CrossRef]

- Santos, J.E.; Yin, Y.; Jo, H.; Pan, W.; Kang, Q.; Viswanathan, H.S.; Prodanović, M.; Pyrcz, M.J.; Lubbers, N. Computationally Efficient Multiscale Neural Networks Applied to Fluid Flow in Complex 3D Porous Media. Transp. Porous Media 2021, 140, 241–272. [Google Scholar] [CrossRef]

- Gao, Y.; Hou, Z.; Wu, X.; Xu, P. The impact of sample size on transport properties of carbon-paper and carbon-cloth GDLs: Direct simulation using the lattice Boltzmann model. Int. J. Heat Mass Transf. 2018, 118, 1325–1339. [Google Scholar] [CrossRef]

- García-Salaberri, P.A.; Zenyuk, I.V.; Shum, A.D.; Hwang, G.; Vera, M.; Weber, A.Z.; Gostick, J.T. Analysis of representative elementary volume and through-plane regional characteristics of carbon-fiber papers: Diffusivity, permeability and electrical/thermal conductivity. Int. J. Heat Mass Transf. 2018, 127, 687–703. [Google Scholar] [CrossRef]

- Singh, A.; Regenauer-Lieb, K.; Walsh, S.D.C.; Armstrong, R.T.; Griethuysen, J.J.M.; Mostaghimi, P. On Representative Elementary Volumes of Grayscale Micro-CT Images of Porous Media. Geophys. Res. Lett. 2020, 47, 1–9. [Google Scholar] [CrossRef]

- Hack, J.; García-Salaberri, P.A.; Kok, M.D.R.; Jervis, R.; Shearing, P.R.; Brandon, N.; Brett, D.J.L. X-ray Micro-Computed Tomography of Polymer Electrolyte Fuel Cells: What is the Representative Elementary Area? J. Electrochem. Soc. 2020, 167, 013545. [Google Scholar] [CrossRef]

- Kashkooli, A.G.; Amirfazli, A.; Farhad, S.; Lee, D.U.; Felicelli, S.; Park, H.W.; Feng, K.; De Andrade, V.; Chen, Z. Representative volume element model of lithium-ion battery electrodes based on X-ray nano-tomography. J. Appl. Electrochem. 2017, 47, 281–293. [Google Scholar] [CrossRef]

- Zenyuk, I.V.; Parkinson, D.Y.; Connolly, L.G.; Weber, A.Z. Gas-diffusion-layer structural properties under compression via X-ray tomography. J. Power Sources 2016, 328, 364–376. [Google Scholar] [CrossRef] [Green Version]

- GeoDict Simulation Software Release 2023. Math2Market GmbH, Germany. Available online: https://www.math2market.com/geodict-software/geodict-software-download.html (accessed on 3 April 2023).

- Gostick, J.; Aghighi, M.; Hinebaugh, J.; Tranter, T.; Hoeh, M.A.; Day, H.; Spellacy, B.; Sharqawy, M.H.; Bazylak, A.; Burns, A.; et al. OpenPNM: A Pore Network Modeling Package. Comput. Sci. Eng. 2016, 18, 60–74. [Google Scholar] [CrossRef] [Green Version]

- Gostick, J.T.; Khan, Z.A.; Tranter, T.G.; Kok, M.D.; Agnaou, M.; Sadeghi, M.; Jervis, R. PoreSpy: A Python Toolkit for Quantitative Analysis of Porous Media Images. J. Open Source Softw. 2019, 4, 1296. [Google Scholar] [CrossRef]

- Hill, R. Elastic properties of reinforced solids: Some theoretical principles. J. Mech. Phys. Solids 1963, 11, 357–372. [Google Scholar] [CrossRef]

- Bear, J. Dynamics of Fluids in Porous Media; Environmental Science Series; American Elsevier: New York, NY, USA, 1972. [Google Scholar]

- Puyguiraud, A.; Gouze, P.; Dentz, M. Is There a Representative Elementary Volume for Anomalous Dispersion? Transp. Porous Media 2020, 131, 767–778. [Google Scholar] [CrossRef]

- Vik, B.; Bastesen, E.; Skauge, A. Evaluation of representative elementary volume for a vuggy carbonate rock—Part: Porosity, permeability, and dispersivity. J. Pet. Sci. Eng. 2013, 112, 36–47. [Google Scholar] [CrossRef]

- Shearing, P.R.; Howard, L.E.; Jørgensen, P.S.; Brandon, N.P.; Harris, S.J. Characterization of the 3-dimensional microstructure of a graphite negative electrode from a Li-ion battery. Electrochem. Commun. 2010, 12, 374–377. [Google Scholar] [CrossRef]

- Yan, Z.; Hara, S.; Kim, Y.; Shikazono, N. Homogeneity and representativeness analyses of solid oxide fuel cell cathode microstructures. Int. J. Hydrog. Energy 2017, 42, 30166–30178. [Google Scholar] [CrossRef]

- Joos, J.; Ender, M.; Carraro, T.; Weber, A.; Ivers-Tiffée, E. Representative volume element size for accurate solid oxide fuel cell cathode reconstructions from focused ion beam tomography data. Electrochim. Acta 2012, 82, 268–276. [Google Scholar] [CrossRef]

- Baveye, P.; Rogasik, H.; Wendroth, O.; Onasch, I.; Crawford, J.W. Effect of sampling volume on the measurement of soil physical properties: Simulation with X-ray tomography data. Meas. Sci. Technol. 2002, 13, 775–784. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, R.; Chen, S.; Soll, W.E. Pore scale study of flow in porous media: Scale dependency, REV, and statistical REV. Geophys. Res. Lett. 2000, 27, 1195–1198. [Google Scholar] [CrossRef]

- Bachmat, Y.; Bear, J. Macroscopic Modelling of Transport Phenomena in Porous Media. 1: The Continuum Approach. Transp. Porous Media 1986, 1, 213–240. [Google Scholar] [CrossRef]

- Sandherr, J.; Kleefoot, M.J.; Nester, S.; Weisenberger, C.; DeSilva, A.K.; Michel, D.; Reeb, S.; Fingerle, M.; Riegel, H.; Knoblauch, V. Micro embossing of graphite-based anodes for lithium-ion batteries to improve cell performance. J. Energy Storage 2023, 65, 107359. [Google Scholar] [CrossRef]

- Gostick, J.T. Versatile and efficient pore network extraction method using marker-based watershed segmentation. Phys. Rev. E 2017, 96, 023307. [Google Scholar] [CrossRef] [Green Version]

- SciPy: Fundamental Algorithms for Scientific Computing in Python. Version 1.10.1. Available online: https://scipy.org/ (accessed on 3 April 2023).

- Bodla, K.K.; Garimella, S.V.; Murthy, J.Y. 3D reconstruction and design of porous media from thin sections. Int. J. Heat Mass Transf. 2014, 73, 250–264. [Google Scholar] [CrossRef] [Green Version]

- Lautenschlaeger, M.P.; Hasse, H. Shear-rate dependence of thermodynamic properties of the Lennard-Jones truncated and shifted fluid by molecular dynamics simulations. Phys. Fluids 2019, 31, 063103. [Google Scholar] [CrossRef]

- Zou, Q.; He, X. On pressure and velocity boundary conditions for the lattice Boltzmann BGK model. Phys. Fluids 1997, 9, 1591–1596. [Google Scholar] [CrossRef] [Green Version]

- Bhatnagar, P.L.; Gross, E.P.; Krook, M. A Model for Collision Processes in Gases. I. Small Amplitude Processes in Charged and Neutral One-Component Systems. Phys. Rev. 1954, 94, 511–525. [Google Scholar] [CrossRef]

- Latt, J.; Malaspinas, O.; Kontaxakis, D.; Parmigiani, A.; Lagrava, D.; Brogi, F.; Belgacem, M.B.; Thorimbert, Y.; Leclaire, S.; Li, S.; et al. Palabos: Parallel Lattice Boltzmann solver. Comput. Math. Appl. 2021, 81, 334–350. [Google Scholar] [CrossRef]

- Fraunhofer ITWM. BEST—Battery and Electrochemistry Simulation Tool. 2014. Available online: https://www.itwm.fraunhofer.de/best (accessed on 3 April 2023).

- Latz, A.; Zausch, J. Thermodynamic consistent transport theory of Li-ion batteries. J. Power Sources 2011, 196, 3296–3302. [Google Scholar] [CrossRef] [Green Version]

- Latz, A.; Zausch, J. Thermodynamic Derivation of a Butler–Volmer Model for Intercalation in Li-Ion Batteries. Electrochim. Acta 2013, 110, 358–362. [Google Scholar] [CrossRef]

- De Lauri, V.; Krumbein, L.; Hein, S.; Prifling, B.; Schmidt, V.; Danner, T.; Latz, A. Beneficial Effects of Three-Dimensional Structured Electrodes for the Fast Charging of Lithium-Ion Batteries. ACS Appl. Energy Mater. 2021, 4, 13847–13859. [Google Scholar] [CrossRef]

- Mostaghimi, P.; Blunt, M.J.; Bijeljic, B. Computations of Absolute Permeability on Micro-CT Images. Math. Geosci. 2013, 45, 103–125. [Google Scholar] [CrossRef]

- Lautenschlaeger, M.P.; Hasse, H. Thermal, caloric and transport properties of the Lennard–Jones truncated and shifted fluid in the adsorbed layers at dispersive solid walls. Mol. Phys. 2020, 118, e1669838. [Google Scholar] [CrossRef]

- Liang, Y.; Ding, W.; Yao, B.; Zheng, F.; Smirnova, A.; Gu, Z. Mediating Lithium Plating/Stripping by Constructing 3D Au@Cu Pentagonal Pyramid Array. Batteries 2023, 9, 279. [Google Scholar] [CrossRef]

| Porosity (%) | Binder Vol. Frac. (%) | Tortuosity (-) | Spec. Surf. Area S (1/m) |

|---|---|---|---|

| 21.09 | 13.02 | 1.2 | 188,209 |

| (-) | (-) | k (1/m) |

|---|---|---|

| 0.085 | 0.690 |

| Median (mAh/cm) | min|max (mAh/cm) | Mean ± Std. Deviation (mAh/cm) |

|---|---|---|

| 1.840 | 1.813|1.864 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kellers, B.; Lautenschlaeger, M.P.; Rigos, N.; Weinmiller, J.; Danner, T.; Latz, A. Systematic Workflow for Efficient Identification of Local Representative Elementary Volumes Demonstrated with Lithium-Ion Battery Cathode Microstructures. Batteries 2023, 9, 390. https://doi.org/10.3390/batteries9070390

Kellers B, Lautenschlaeger MP, Rigos N, Weinmiller J, Danner T, Latz A. Systematic Workflow for Efficient Identification of Local Representative Elementary Volumes Demonstrated with Lithium-Ion Battery Cathode Microstructures. Batteries. 2023; 9(7):390. https://doi.org/10.3390/batteries9070390

Chicago/Turabian StyleKellers, Benjamin, Martin P. Lautenschlaeger, Nireas Rigos, Julius Weinmiller, Timo Danner, and Arnulf Latz. 2023. "Systematic Workflow for Efficient Identification of Local Representative Elementary Volumes Demonstrated with Lithium-Ion Battery Cathode Microstructures" Batteries 9, no. 7: 390. https://doi.org/10.3390/batteries9070390