Pyrolysis Study of Different Fruit Wastes Using an Aspen Plus Model

- 1Division of Sustainable Development, College of Science and Engineering, Hamad Bin Khalifa University, Qatar Foundation, Doha, Qatar

- 2Division of Engineering Management and Decision Sciences, College of Science and Engineering, Hamad Bin Khalifa University, Qatar Foundation, Doha, Qatar

Large quantities of fruit wastes are generated during the consumption and processing of fruits. The disposal of fruit wastes in an environmentally benign way is a challenging task. The biochar production from fruit wastes by pyrolysis is receiving huge attention because it can alleviate pollution of fruit wastes and provide a supply of biochar sustainably. In this study, five fruit waste types—orange peel, banana peel, mango endocarp, apricot kernel shell, and date pits—are examined. An Aspen Plus simulation tool was employed to develop a steady-state model to predict the pyrolysis product yields of the fruit wastes. The details of the proximate and elemental analyses of the fruit wastes were applied as input parameters in the model, and the simulation was carried out at 300–600°C and 1 atm pressure. Among the fruit wastes, the date pits presented the highest char yield (50.92 wt.%), while the mango endocarp offered the highest syngas yield (54.23 wt.%). From the simulation results, it can be inferred that the date pits are best suited for biochar production, whereas the mango endocarp and orange peel are appropriate for syngas generation. The study is further analyzed by studying the optimization of biomass feedstock blend to yield the highest char relative to bio-oil and syngas. The optimization results demonstrate apricot kernel shell and date pits to dominate the feedstock blend. It is hoped that the current outcomes will be helpful in the selection of appropriate feedstocks for biochar generation through pyrolysis.

Introduction

Food waste occupies a significant proportion in municipal solid waste, and almost 1.3 billion tons of food waste is generated globally every year (Melikoglu, 2020). This figure is expected to increase further in the ensuing years. Fruit waste contributes a major share in the food waste. As fruits are richer in nutrients and vitamins and consumed readily, they have a huge demand throughout each year. Because of their high consumption, a significant amount of fruit wastes such as peels, seeds, etc. is generated, and the disposal of these wastes is problematic and is becoming a serious concern everywhere.

Currently, the fruit wastes are disposed of by methods such as landfilling, burning (open), and composting. However, these methods are unfriendly to the environment, and also they fail to recover useful energy/chemicals from the waste. As fruit wastes are from plants/trees, they are also composed of extractives, hemicellulose, cellulose, lignin, and soluble sugars, which can be used as a source from which to extract energy.

The energy extraction from the fruit wastes can be accomplished using pyrolysis, as it has been considered as one of the most effective methods of energy recovery from biomass. In addition, pyrolysis delivers products in three forms—solid (char), liquid (bio-oil), and syngas (pyrolytic gas); hence, it is commonly preferred to convert biomass waste to energy (Elkhalifa et al., 2019a). Among the pyrolysis products, the demand for char is gradually increasing due to its versatile applications. The char is applied as a fuel, soil conditioner, and adsorbent. Three modes of pyrolysis, namely, slow, fast, and flash, are in practice. Slow pyrolysis produces more char, while fast and flash favor bio-oil and syngas generation. In this study, the slow pyrolysis mode is the focus.

In this study, five different fruit wastes—orange peel, banana peel, mango endocarp, apricot kernel shell, and date pits—have been investigated. Generally, orange peels are used to synthesize D-limonene, an organic polymer, which finds its application in the food and processing industry, cosmetic industry, pharmaceutical industry, chemical industry, etc. However, in most cases, the orange peels are discarded. Banana peels are commonly fed to livestock such as cattle, goats, and others. Considering its generation potential, the consumption of peels by livestock is meager. Mostly, the peels are dumped in the garbage. A mango endocarp contributes 15–18% (wt.) of the total fruit weight (Andrade et al., 2016). The mango endocarps are commonly preserved to grow their saplings. However, the usage of seeds for the above purpose is rare. Once the fruits are consumed, the mango seeds are also generally thrown into the garbage. Apricot fruits are commonly consumed by people in temperate regions. The apricot constitutes a seed/pit that houses a kernel. The kernel is used in the production of medicines, cosmetics, and perfumes, while the pit is used as a fuel. In recent years, the kernel shell has been viewed as a potential source for the generation of char and activated carbon. Date pits are the most common agricultural waste in the Arabian Peninsula. The pits themselves contribute 8–15% (wt.) of the total fruit weight (Demirbas, 2017). They are normally consumed as an animal feed and a coffee substitute. They are also used to extract date seed oil. In spite of their consumption for the aforesaid applications, a significant quantity of date seeds remains unused and are usually dumped in landfills as waste. Hence, the generation of the above fruit wastes offers an excellent area for the current research. In spite of these fruit wastes abundant availability, the collection and sorting of the wastes is a complicated and laborious process. Hence, an appropriate waste management scheme should have to be in place to overcome the above issue.

In recent years, the application of the Aspen Plus modeling software in process engineering has become a common practice. Aspen refers to an advanced system for process engineering. It is a modeling software tool, which is used to calculate the physicochemical and biological parameters of a process. The tool is popular, as it can be used for all the phases (solid, liquid, and vapor) of the process (AlNouss et al., 2018). A few recent research works have proven that the simulation tool can also be used for analyzing pyrolysis studies to predict the yield(s) of the process (Elkhalifa et al., 2019b). The tool is also effective in optimizing the pyrolysis process operating parameters such as heating rate, temperature, solid residence time, feedstock size, etc.

Many experimental pyrolysis studies on fruit wastes such as Karanja (Pongamia pinnata) fruit hulls (Tan et al., 2019), oil palm fruit bunch (Elaeis guineensis) (Lee et al., 2020), sweet lime (Citrus limetta) empty fruit bunch (Sukumar et al., 2020), lemon peels (Citrus limon) (Adeniyi et al., 2019), pomegranate (Punica granatum L.) peel (Saadi et al., 2019), watermelon (Citrullus lanatus) peel (Lam et al., 2016), jackfruit (Artocarpus heterphyllus) peel (Adeniyi et al., 2019), pine (Pinus) fruit shell (Alves et al., 2019), casuarina (Casuarina equisetifolia) fruit waste (Parthasarathy and Sheeba, 2015), coconut (Cocos nucifera) shell (Castilla-Caballero et al., 2020), longan (Dimocarpus longan) fruit seed (Yang et al., 2015), etc. have been performed. Even a few pyrolysis experimental works on orange peel, banana peel, mango endocarp, apricot kernel shell, and data seed also can be found. Although the application of Aspen Plus in the pyrolysis studies is in practice, there are only a few such works found. Ismail et al. performed a pyrolysis study of waste tires employing Aspen Plus (Ismail et al., 2017). The Aspen Plus model was successfully implemented to predict the production of pyrolysis products and also to investigate the influence of temperature on the pyrolysis products. Dineshkumar et al. (2019) conducted a microwave pyrolysis study of four biomass wastes such as Calophyllum inophyllum seed, Acacia Nilotica, Bael shell, and rice husk using Aspen Plus. The intention of the simulation study was to identify the biomass that generates the maximum bio-oil yield. The Aspen Plus results established that the biomass C. inophyllum produced the highest bio-oil yield (48 wt.%). Kabir et al. carried out simulation and experimental investigations on the pyrolysis of municipal green waste (Kabir et al., 2015). The objective of the study was to ensure if the Aspen Plus results are consistent with the experimental results. The focus of the study was also to optimize the pyrolysis process operating conditions such as feedstock size, temperature, moisture, and air-to-fuel ratio that produces a maximum bio-oil yield. It was noted that the simulation and experimental results were in good agreement with each other, indicating that the Aspen Plus simulator can be applied to predict the pyrolysis products yield. The simulation results also confirmed that the pyrolysis operating parameters can be effectively optimized using Aspen Plus, and the outcomes can be implemented for testing experimentally.

The aim of the current study is to predict the pyrolysis product yields of five different fruit wastes—orange peel, banana peel, mango endocarp, apricot kernel shell, and date pit—using Aspen Plus. The simulation study also aims to estimate the composition of the syngas that is generated from the pyrolysis of the mentioned fruit wastes. The study will help to understand the behavior of the pyrolysis process without undertaking laborious, high-cost involved time-consuming experiments (Zhai et al., 2016). The outcomes of the study will be helpful in the selection of the most appropriate feedstock suited for the char generation.

Materials and Methods

Material

In this work, five different fruit wastes—orange (Citrus sinensis) peel, banana (Musa spp.) peel, mango (Mangifera indica) endocarp, apricot (Prunus armeniaca) kernel shell, and date (Phoenix dactylifera) seed—are investigated. The fruit wastes orange peel, banana peel, and mango endocarp are chosen, as their fruits are widely consumed globally. The apricot kernel shell is chosen because it possesses a high lignin content, which is expected to support a higher char yield. The date pits are chosen, as dates are commonly used in the Arabian Peninsula and the disposal of the seeds is a major concern in the Gulf region.

Methodology

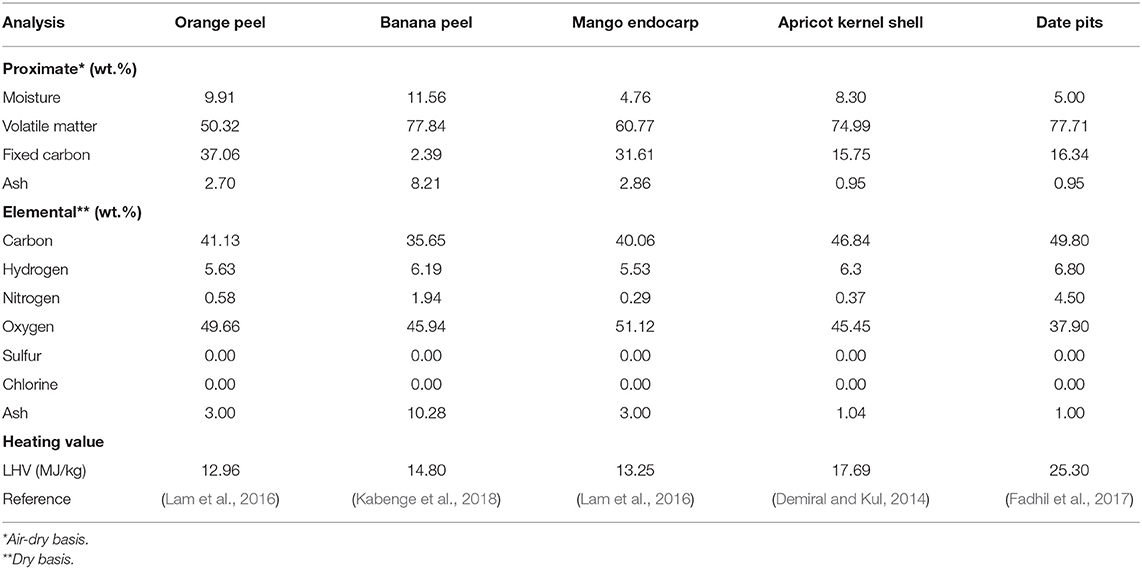

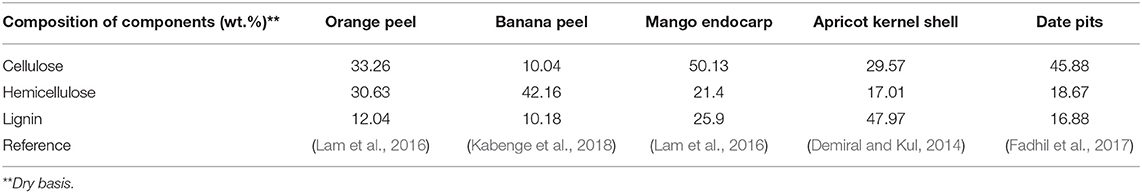

In this study, the problem is formulated based on the proximate and elemental analyses data (provided in Table 1) of the selected fruit wastes, and these data were taken from previous literature (Demiral and Kul, 2014; Lam et al., 2016; Fadhil et al., 2017; Kabenge et al., 2018).

As the composition of the biomass components (cellulose, hemicellulose, and lignin) has a significant influence on the pyrolysis products yield, the chemical composition details of the selected fruit wastes reported elsewhere have been provided in Table 2. It is believed that these particulars will be helpful in comprehending the reason for the pyrolysis product behavior of feedstocks.

Development of Model

In this work, ASPEN Plus® V9 was selected and developed to predict the pyrolysis products yield of the fruit wastes. The ASPEN tool takes care of the interactions among solid, liquid, and gas phases. The tool solves the process engineering complexities by providing integrated solutions. It comes with the large set of material property databank. The tool utilizes FORTRAN subroutines to develop even complex unit operations. The simulation model constitutes several operating blocks, which are used to describe the process which is under study. The blocks are developed based on the designated flowsheet by entering the values of the mass flow and the energy flow streams.

The current pyrolysis study is simulated based on the following assumptions (Elkhalifa et al., 2019b):

➢ The model is under a steady state.

➢ The model is in kinetic-free equilibrium.

➢ The process is operating under constant pressure (isobaric).

➢ The process has negligible pressure drop.

➢ The process has no tar formation.

The RYield reactor type was chosen to transform the feedstock into constituent elements, and the non-stoichiometric Gibb's free energy equilibrium-based splitter model was employed to describe the solid separation (AlNouss et al., 2020).

Simulation

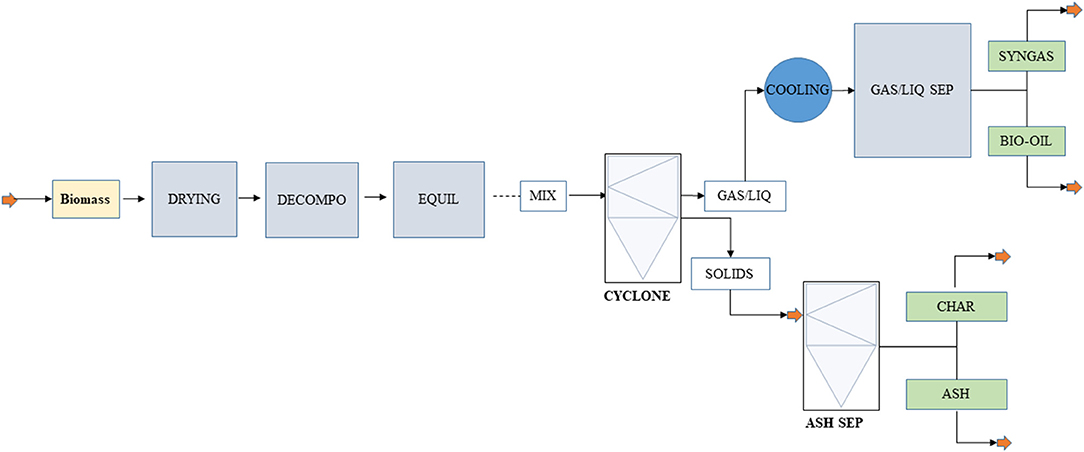

The simulation of pyrolysis process can be done using Aspen Plus software. A series of built-in-unit blocks are used to replicate the real-time process, as the simulation tool do not have an in-built pyrolysis model. The flowsheet of the pyrolysis scheme is given in Figure 1.

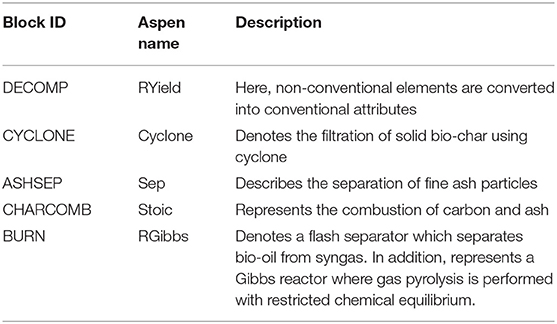

The pyrolysis flowsheet was then used to develop the Aspen Plus model. As the intention of the study is to produce char, we assumed only slow pyrolysis operating conditions for the simulation runs. Hence, the simulation was performed at 300–600°C and 1 atm pressure (Pawar et al., 2020). The description of each block used in the flowsheet is presented in Table 3.

Validation

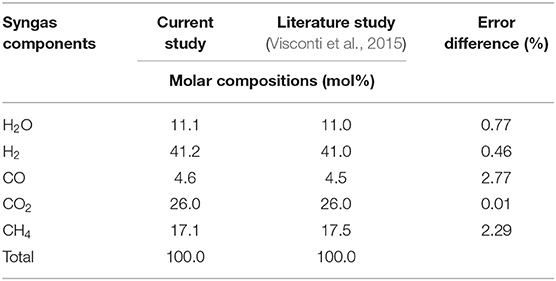

The Aspen Plus simulation model has been validated against the reported gas composition. Similar inputs as the ones presented in Visconti et al. (2015) have been fed into the simulated model in the current study. The results presented in Table 4 demonstrate a perfect agreement of the presented model (in this study) with the reported literature. The compositions of syngas produced from the pyrolysis process is showing only a <5% error difference.

Process Optimization

After the pyrolysis model development, the process was optimized so as to optimize the solid-to-gas ratio. The optimization equation can be represented by:

where solid represents the flowrate of the produced bio-char (moles), and syngas indicates the flowrate of the produced H2-rich synthesis gas.

Results and Discussion

The Pyrolysis Products Yield of the Selected Fruit Wastes

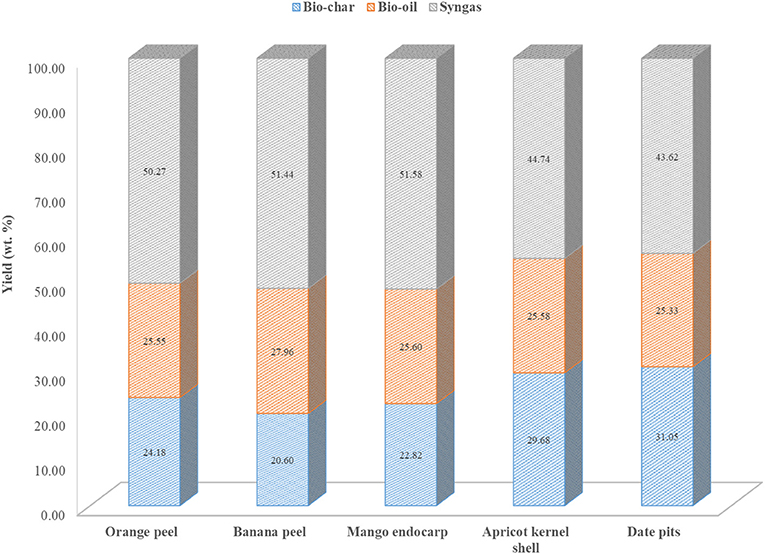

As stated earlier, the pyrolysis products yield of the five fruit wastes was predicted using the proximate and elemental analyses data presented in Table 1. The entire simulation results of the study are presented in Supplementary Tables 1–5. The product yields of the fruit wastes obtained from the simulation results are presented in Figure 2.

From the figure, it can be seen that all the fruit wastes exhibited a high syngas yield (46–55%), a high biochar yield (39–51%), and a low bio-oil yield (<11.00%). The observed high syngas yield of the fruit wastes could be due to their high volatile content, as it favors syngas generation (Parthasarathy et al., 2015). High volatile content also supports bio-oil production. The volatile content of orange peel, banana peel, mango endocarp, apricot kernel shell, and date pits are 50.32, 77.84, 60.77, 74.99, and 77.71%, respectively.

When the product yields of the selected fruit wastes were compared, it was found that the date pits had the highest char yield (50.92%), which could be because of its high elemental carbon (49.80%) (Chaiwong et al., 2012). Next to date pits, the char yield was higher (43.82%) for apricot kernel shell. The high elemental carbon (46.84%) and lignin content (47.97%) could have contributed to its high char yield (Prakash and Sheeba, 2016). Among the fruit wastes, mango endocarp displayed a high syngas yield. The high syngas yield (54.23%) of mango endocarp could have been due to its high elemental oxygen and hydrogen (56.65%) and holocellulose content (71.43%). The orange peel also displayed a high syngas yield (50.34%), which could be because of its high elemental oxygen and hydrogen (55.29%) and high holocellulose (hemicellulose and cellulose) content (63.89%) (Gupta et al., 2016).

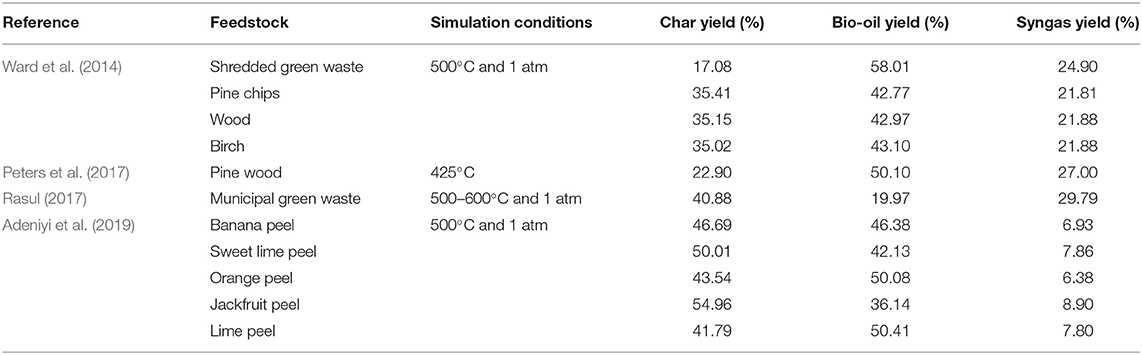

The simulation results indicated that among the fruit wastes, the date pits are more suited for biochar generation, while the mango endocarp and orange peel are more suited for syngas production. Moreover, the optimization study has indicated a feedstock of 52:48 blend of date pits and apricot kernel shell with no presence for the rest of fruit biomass. The optimization has yielded a higher char content of around 31.7%, with lower syngas and bio-oil of 43.4 and 24.9%, respectively. This demonstrates more the dominance of date pits and apricot kernel shell in yielding higher char product. The current simulation results are compared with the results of a few other similar works which are presented in Table 5. In the work of Ward et al. the bio-oil yield was greater than the char and syngas yields (Ward et al., 2014). Peters et al. also observed a high bio-oil yield in their study using pinewood (Peters et al., 2017). However, Rasul noted a high char yield with municipal green waste, while Adeniyil et al. witnessed a mixed trend in the yield of bio-oil and char for fruit peelings waste (Rasul, 2017; Adeniyi et al., 2019). These researchers reported a high char yield in the case of banana peel, sweet lime peel, and jackfruit peel. But in the case of orange peel and lime peel, a high bio-oil yield was noticed.

The variance in the product yield of feedstock is due to the difference in the properties of feedstock, dissimilarity in the assumptions (made by the researchers), variation in the methodology (followed by the researchers), and a distinction in the operating conditions. However, in most works, it has been established that the Aspen simulation results are in good agreement and of high quality with the experimental results, indicating that the simulation tool is very reliable.

Predicted Syngas Composition of the Chosen Fruit Wastes

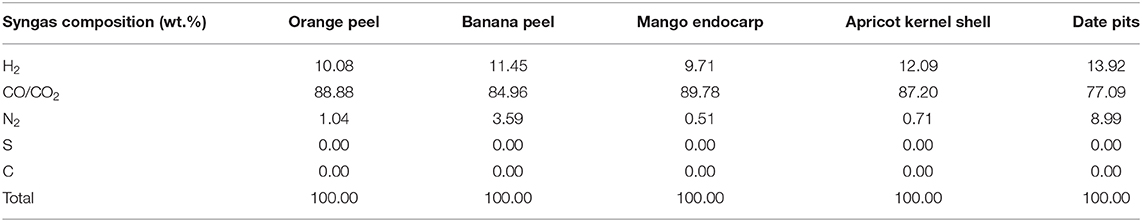

The simulation model was also used to predict the syngas composition of the chosen fruit wastes. The predicted syngas composition of the selected fruit wastes is presented in Table 6.

From the table, it can be observed that among the fruit wastes, date pits (13.92%) exhibited the highest H2 composition followed by apricot kernel shell (12.09%) and banana peel (11.45%). The H2 composition of orange peel and mango seed was 10.08 and 9.71%, respectively. As expected, the fruit wastes did not show any sulfur presence, as the elemental sulfur content of the fruit wastes feedstock was nil.

Conclusion

Generation of valuable commodities such as biochar, bio-oil, and syngas from fruit wastes through pyrolysis is a promising scheme, as it can minimize pollution and somehow alleviate the fruit wastes disposal issues. In this study, the pyrolysis product yields of five different fruit wastes—orange peel, banana peel, mango endocarp, apricot kernel shell, and date pits—was studied using an Aspen simulation model under standard pyrolysis conditions. The developed model was first validated using the data reported elsewhere and was then applied to predict the pyrolysis product yields of the selected fruit wastes.

The simulation results indicated that all the fruit wastes displayed a high syngas yield (46–55%), a high biochar yield (39–51%), however a low bio-oil yield (<11.00%). The high syngas yield of all fruit wastes is attributed to their high volatile content (50–78%). Among the fruit wastes, date pits exhibited the highest char yield (50.92 wt.%), while the mango endocarp showed the highest syngas yield (54.23 wt.%). The high char yield of date pits can be attributed to its high elemental carbon content and moderate cellulose composition. The high syngas yield of mango endocarp can be ascribed to its high elemental oxygen–hydrogen composition and very high holocellulose content. The study predicted that all the selected fruit wastes can be used as feedstocks' for pyrolysis to generate syngas. Further, the study forecasted that the date pits can serve as a potential feedstock for pyrolysis process to produce biochar.

In the future, real-time experiments need to be conducted to validate the simulation results. Future simulation works should focus on studying the influence of heating rate, temperature, residence time, feedstock size, purge gas, blending ratio of feedstock, and catalyst on the pyrolysis products so as to develop a robust pyrolysis simulation model. The current study provides some insights into the selection of suitable feedstock for the production of value-added products such as biochar, bio-oil, and syngas through pyrolysis. The study reveals that an excellent scope for the production of biochar and syngas from the selected fruit wastes through pyrolysis exist.

Data Availability Statement

The datasets presented in this study can be found in online repositories. The names of the repository/repositories and accession number(s) can be found in the article/Supplementary Material.

Author Contributions

AA: data collection, substantial data interpretation, and substantial manuscript preparation. PP: data collection, lead data interpretation, and lead manuscript preparation. HM and TA-A: project concept, project design, and manuscript revision. GM: project lead, project concept, project design, data interpretation, and manuscript revision. All authors contributed to the article and approved the submitted version.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

The authors would like to thank Qatar National Research Fund (QNRF) for their support of this research through NPRP-11S-0117-180328, the Supreme Committee for Delivery and Legacy (SCDL), to Hamad Bin Khalifa University (HBKU), and Qatar Foundation (QF).

Supplementary Material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2021.604001/full#supplementary-material

References

Adeniyi, A. G., Otoikhian, K. S., Ighalo, J. O., and Mohammed, I. A. (2019). Pyrolysis of different fruit peel waste via a thermodynamic model. Int. J. Eng. Res. Dev. 2, 16–24. doi: 10.5281/zenodo.3722809

AlNouss, A., Mckay, G., and Al-Ansari, T. (2018). Optimum utilization of biomass for the production of power and fuels using gasification. Comp. Aided Chem. Eng. 43, 1481–1486. doi: 10.1016/B978-0-444-64235-6.50258-8

AlNouss, A., Mckay, G., and Al-Ansari, T. (2020). Enhancing waste to hydrogen production through biomass feedstock blending: a techno-economic-environmental evaluation. Appl. Energy 266:114885. doi: 10.1016/j.apenergy.2020.114885

Alves, J. L. F., Da Silva, J. C. G., da Silva Filho, V. F., Alves, R. F., de Araujo Galdino, W. V., Andersen, S. L. F., et al. (2019). Determination of the bioenergy potential of Brazilian pine-fruit shell via pyrolysis kinetics, thermodynamic study, and evolved gas analysis. Bioenergy Res. 12, 168–183. doi: 10.1007/s12155-019-9964-1

Andrade, L. A., Barrozo, M. A. S., and Vieira, L. G. M. (2016). Thermo-chemical behavior and product formation during pyrolysis of mango seed shell. Ind. Crops Prod. 85, 174–180. doi: 10.1016/j.indcrop.2016.03.004

Castilla-Caballero, D., Barraza-Burgos, J., Gunasekaran, S., Roa-Espinosa, A., Colina-Márquez, J., Machuca-Martínez, F., et al. (2020). Experimental data on the production and characterization of biochars derived from coconut-shell wastes obtained from the Colombian Pacific coast at low temperature pyrolysis. Data in Brief 28:104855. doi: 10.1016/j.dib.2019.104855

Chaiwong, K., Kiatsiriroat, T., Vorayos, N., and Thararax, C. (2012). Biochar production from freshwater algae by slow pyrolysis. Maejo Int. J. Sci. Technol. 6, 186–195. doi: 10.14456/mijst.2012.13

Demiral, I., and Kul, S. Ç. (2014). Pyrolysis of apricot kernel shell in a fixed-bed reactor: characterization of bio-oil and char. J. Anal. Appl. Pyrolysis. 107, 17–24. doi: 10.1016/j.jaap.2014.01.019

Demirbas, A. (2017). Utilization of date biomass waste and date seed as bio-fuels source. Energy Sources Part A: Recovery Utilizat. Environ. Effects 39, 754–760. doi: 10.1080/15567036.2016.1261208

Dineshkumar, M., Shrikar, B., and Ramanathan, A. (2019). Development of computer aided modelling and optimization of microwave pyrolysis of biomass by using aspen plus. IOP Conf. Ser. Earth Environ. Sci. 312:12006. doi: 10.1088/1755-1315/312/1/012006

Elkhalifa, S., Al-Ansari, T., Mackey, H. R., and Mckay, G. (2019a). Food waste to biochars through pyrolysis : a review. Resour. Conserv. Recycl. 144, 310–320. doi: 10.1016/j.resconrec.2019.01.024

Elkhalifa, S., AlNouss, A., Al-Ansari, T., Mackey, H. R., Parthasarathy, P., and Mckay, G. (2019b). Simulation of food waste pyrolysis for the production of biochar: a qatar case study. Comp. Aided Chem. Eng. 46, 901–906. doi: 10.1016/B978-0-12-818634-3.50151-X

Fadhil, A. B., Alhayali, M. A., and Saeed, L. I. (2017). Date (Phoenix dactylifera L.) palm stones as a potential new feedstock for liquid bio-fuels production. Fuel. 210, 165–176. doi: 10.1016/j.fuel.2017.08.059

Gupta, N. K., Prakash, P., Kalaichelvi, P., and Sheeba, K. N. (2016). The effect of temperature and hemicellulose-lignin, cellulose-lignin, and cellulose-hemicellulose on char yield from the slow pyrolysis of rice husk. Energy Sources Part A: Rec. Utiliz. Environ. Effects 38, 1428–1434. doi: 10.1080/15567036.2014.941518

Ismail, H. Y., Abbas, A., Azizi, F., and Zeaiter, J. (2017). Pyrolysis of waste tires: a modeling and parameter estimation study using aspen plus®. Waste Manage. 60, 482–493. doi: 10.1016/j.wasman.2016.10.024

Kabenge, I., Omulo, G., Banadda, N., and Seay, J. (2018). Characterization of banana peels wastes as potential slow pyrolysis feedstock. J. Sustain. Dev. 11, 14–24. doi: 10.5539/jsd.v11n2p14

Kabir, M., Chowdhury, A., and Rasul, M. (2015). Pyrolysis of municipal green waste: A modelling, simulation and experimental analysis. Energies 8, 7522–7541. doi: 10.3390/en8087522

Lam, S. S., Liew, R. K., Lim, X. Y., Ani, F. N., and Jusoh, A. (2016). Fruit waste as feedstock for recovery by pyrolysis technique. Int. Biodeterior. Biodegradation 113, 325–333. doi: 10.1016/j.ibiod.2016.02.021

Lee, X. J., Lee, L. Y., Hiew, B. Y. Z., Gan, S. S., and Thangalazhy-Gopakumar, H. K. (2020). Valorisation of oil palm wastes into high yield and energy content biochars via slow pyrolysis: Multivariate process optimisation and combustion kinetic studies. Mater. Sci. Energy Technol. 3, 601–610. doi: 10.1016/j.mset.2020.06.006

Melikoglu, M. (2020). Reutilisation of food wastes for generating fuels and value added products: a global review. Environ. Technol. Innovat. 19:101040. doi: 10.1016/j.eti.2020.101040

Parthasarathy, P., Gupta, N. K., and Narayanan, K. S. (2015). Effect of composting on products of slow pyrolysis. Biofuels 6, 313–321. doi: 10.1080/17597269.2015.1110772

Parthasarathy, P., and Sheeba, K. N. (2015). Combined slow pyrolysis and steam gasification of biomass for hydrogen generation—a review. Int. J. Energy Res. 39, 147–164. doi: 10.1002/er.3218

Pawar, A., Panwar, N. L., and Salvi, B. L. (2020). Comprehensive review on pyrolytic oil production, upgrading and its utilization. J. Mater. Cycles Waste Manage. 22, 1712–1722. doi: 10.1007/s10163-020-01063-w

Peters, J. F., Banks, S. W., Bridgwater, A. V., and Dufour, J. (2017). A kinetic reaction model for biomass pyrolysis processes in Aspen Plus. Appl. Energy 188, 595–603. doi: 10.1016/j.apenergy.2016.12.030

Prakash, P., and Sheeba, K. N. (2016). Prediction of pyrolysis and gasification characteristics of different biomass from their physico-chemical properties. Energy Sources Part A: Recovery Utilizat. Environ. Effects 38, 1530–1536. doi: 10.1080/15567036.2014.953713

Rasul, M. G. (2017). Municipal green waste (MGW) pyrolysis. Encycl. Sustain. Technol. 8, 229–243. doi: 10.1016/B978-0-12-409548-9.10109-5

Saadi, W., Rodríguez-Sánchez, S., Rui, B., Souissi-Najar, S., Ouederni, A., and Fuente, E. (2019). Pyrolysis technologies for pomegranate (Punica granatum L.) peel wastes. Prospects bioenergy sector. Renew. Energy 136, 373–382. doi: 10.1016/j.renene.2019.01.017

Sukumar, V., Manieniyan, S., Senthilkumar, V., and Sivaprakasam, R. (2020). Production of bio oil from sweet lime empty fruit bunch by pyrolysis. Renew. Energy 146, 309–315. doi: 10.1016/j.renene.2019.06.156

Tan, Y. L., Abdullah, A. Z., and Hameed, B. H. (2019). Product distribution of the thermal and catalytic fast pyrolysis of karanja (Pongamia pinnata) fruit hulls over a reusable silica-alumina catalyst. Fuel 245, 89–95. doi: 10.1016/j.fuel.2019.02.028

Visconti, A., Miccio, M., and Juchelková, D. (2015). An Aspen Plus® tool for simulation of lignocellulosic biomass pyrolysis via equilibrium and ranking of the main process variables. Int. J. Mathematical Models Methods Appl. Sci. 9, 70–86.

Ward, J., Rasul, M. G., and Bhuiya, M. M. K. (2014). Energy recovery from biomass by fast pyrolysis. Proc. Eng. 90, 669–674. doi: 10.1016/j.proeng.2014.11.791

Yang, J., Yu, M., and Chen, W. (2015). Adsorption of hexavalent chromium from aqueous solution by activated carbon prepared from longan seed: kinetics, equilibrium and thermodynamics. J. Indust. Eng. Chem. 21, 414–422. doi: 10.1016/j.jiec.2014.02.054

Keywords: fruit waste, pyrolysis, Aspen plus, biochar, syngas

Citation: AlNouss A, Parthasarathy P, Mackey HR, Al-Ansari T and McKay G (2021) Pyrolysis Study of Different Fruit Wastes Using an Aspen Plus Model. Front. Sustain. Food Syst. 5:604001. doi: 10.3389/fsufs.2021.604001

Received: 08 September 2020; Accepted: 04 January 2021;

Published: 18 February 2021.

Edited by:

Carlos Martin-Rios, University of Applied Sciences and Arts of Western Switzerland, SwitzerlandReviewed by:

Cahyono Agus, Gadjah Mada University, IndonesiaRock Keey Liew, Universiti Malaysia Terengganu, Malaysia

Copyright © 2021 AlNouss, Parthasarathy, Mackey, Al-Ansari and McKay. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Gordon McKay, gmckay@hbku.edu.qa

Ahmed AlNouss

Ahmed AlNouss Prakash Parthasarathy

Prakash Parthasarathy Hamish R. Mackey

Hamish R. Mackey Tareq Al-Ansari

Tareq Al-Ansari Gordon McKay

Gordon McKay