Recent progress in strategies for preparation of metal-organic frameworks and their hybrids with different dimensions

Abstract

As a new kind of organic-inorganic hybrid porous material, metal-organic frameworks (MOFs) exhibit a wide application prospect in gas storage and separation, catalysis and sensing due to their characteristics of large specific surface area, high porosity and coordination unsaturation. As more and more types of MOFs were reported, the synthetic strategies of MOFs-based materials have become a hot research topic. According to the morphological dimension, MOFs can be roughly divided into one-dimensional, two-dimensional and three-dimensional structures. Herein, we summarize the synthetic methods and principles of MOFs from multi-dimensional perspectives, and explore the growth mechanism of MOFs with different morphologies based on dynamic and thermodynamic tuning. Finally, based on the above summaries, the challenges and opportunities of MOFs in the future are discussed.

Keywords

INTRODUCTION

Since 1995, when Yaghi et al. reported the synthesis of coordination compounds from transition metal cobalt and rigid organic ligand, metal-organic frameworks (MOFs) have attracted much attention as a new type of organic-inorganic hybrid porous material[1-9]. Subsequently, they synthesized the three-dimensional pore structure MOF-5 with Zn (II) and the rigid organic ligand terephthalic acid[10]. This material is thermally stable and its backbone structure is maintained after the guest molecule is removed. Therefore, the researchers varied the length of the dicarboxylic acid ligand based on MOF-5 to achieve functionalization and size variation of the MOF with the same topology. As ligands continue to be expanded, so does the understanding of MOF. MOFs are inorganic nodes and organic ligands linked to form infinitely extended network structures with periodicities, also known as porous coordination polymers (PCPs)[11,12]. Compared with conventional inorganic polymers, MOFs can be rationally designed and tuned by selecting specific metal nodes and organic linkers, and exhibit characteristics of well-aligned structures, high specific surface area, large-sized porosity, unsaturated coordination sites and ligand structural diversity[13,14]. The unique structures and properties of MOFs make them promising for a wide range of applications in various fields, including gas storage and separation, catalysis, ion exchange, drug delivery, as well as bio-sensors[15-26].

Generally, up to date, MOFs-based materials have undergone a four-generation journey[1]. The stability of first-generation MOFs is low and the structures of the MOFs tend to collapse easily due to the inseparable guest anions in the pore of the frameworks. Researchers have since developed second-generation MOFs materials based on the first generation with organic ligands containing mainly carboxyl groups. The second generation of MOFs has stable porosity, which compensates for the low stability of the first generation. The third-generation MOFs show framework flexibility and dynamics when exchanging guest or external stimuli, exhibiting various intelligent properties. For example, Dybtsev et al. have synthesized materials with a two-dimensional structure using zinc nitrate and terephthalic acid, and the structure of the MOFs shows a certain dynamic behavior after exchanging the ligand, and the pore channels in the MOFs could keep changing accordingly under the influence of light or different solvent guest molecules[27]. The fourth generation of MOFs, also called post-processing MOFs, is accompanied by postsynthetic modifications of MOFs and can be applied in various fields[28]. In principle, the synthetic strategies and applications of third- and fourth-generation MOFs were extensively explored.

In recent years, with the number of reported MOFs increasing rapidly, the synthetic strategies of MOFs have been widely developed. Recently, the design and controllable synthesis of MOF nanocrystals with different phases and morphologies by tailoring thermodynamic and kinetic processes has become a hot topic[29-33]. For example, typical kinetic parameters are related to the activation energy, which reflects the effect of temperature on the reaction rate. Different reaction temperatures, solvents, time, concentrations, pH values and molar ratios of metal ions to ligands can all have an effect on the growth of MOFs. Growth factors also influence the pore size of the structure, leaving one and mostly two-dimensional structures that are not porous, and only three-dimensional and a small number of two-dimensional have porosity. So far, most of the reported MOFs are microporous (pore size < 2 nm). Micropores are necessary to ensure the interaction between substrate and MOFs, the stability of small-sized actives and size selectivity[34]. Therefore, in order to construct MOF crystals with desired sizes and thus achieve structures with the target function, understanding and controlling the crystallization process of MOFs is critical[35].

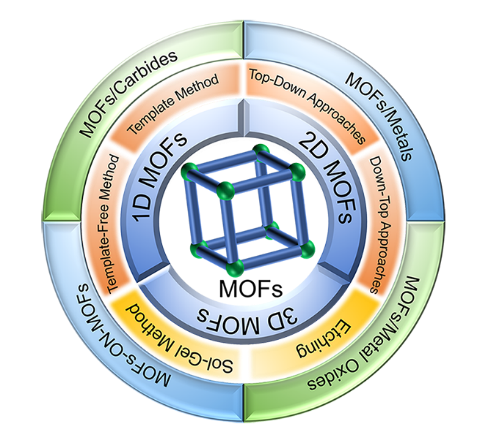

Essentially, the synthetic strategies of MOFs can be roughly divided into physical (microwave, ultrasound, ball milling, etc.) and chemical methods (electrochemistry, mechanochemistry, etching, etc.). Based on the morphology, MOFs can be classified according to their morphological structures into one-dimensional (1D) chains, two-dimensional (2D) layers and three-dimensional (3D) framework structures[36]. In view of the diversity of synthesis strategies, this article will focus on the macro-morphology of MOF crystals in terms of classification into 1D, 2D and 3D MOFs materials. Table 1 shows the advantages and limitations of each dimensional MOFs. When preparing MOFs with special morphologies or crystal facets, thermodynamical and kinetic adjustments are often adopted in the synthetic processes, which is conducive to enhancing the performances, for example, recrystallization, interface synthesis and self-assembly. The aim of this review is to promote a deeper understanding of metal-organic skeletal materials, to grasp their structural characteristics and to increase research efforts on these materials. In this review, we summarize and provide an overview of the synthesis of metal-organic framework materials from multi-dimensional perspectives by combining physical and chemical methods, introduce various widely used and relatively novel synthetic methods in the past 20 years, and describe the preparation of some typical MOF-based hybrids and their applications, as shown in Scheme 1, in which the relationship between the thermodynamical and kinetic adjustments and the structural control of MOFs will be emphasized.

Scheme 1. The main synthetic strategies for MOFs-based materials. MOFs: Metal-organic frameworks; 1D: one-dimensional; 2D: two-dimensional; 3D: three-dimensional.

Comparison of MOFs in various morphological dimensions

| Morphology | 1D MOFs | 2D MOFs | 3D MOFs |

| Strength | High aspect ratios Excellent flexibility | Large surface areas Stable mechanical properties | High porosity Frame stability |

| Limitation | Structural instability Poor regulation | Uneven sizes Uncontrollable thickness | Micronization difficulties |

The hydrothermal/solvothermal method is one of the classical synthetic strategies due to its ease of operation. Metal salts and ligands are added to water or organic solutions and then encapsulated in a reactor and heated to a certain temperature, often resulting in materials with excellent physicochemical properties[37-46]. The synergy between temperature, pressure and solvent allows the metal salts and ligands to begin to participate in the reaction. The high temperature and pressure environment in the reactor also provides a powerful aid to crystal nucleation growth. Note that various surfactants or covering agents are often introduced into the reaction to control the morphology and size of the MOFs. Table 2 summarizes some recent examples of hydrothermal/solvothermal synthesis of MOFs. In addition to hydrothermal/solvothermal methods, many synthetic strategies have been explored, but rarely generalized. Solid-state mechanochemical methods require no solvents, low temperature and only mechanized stress[55]. A common solid-state synthesis method refers to mechanical grinding, where MOFs are formed by mixing all components well and reacting directly. Katsenis et al. worked on the final synthesis of ZIF-8 from ZnO and 2-methylimidazole in 2017 using mechanochemical methods[56]. The method is cost-saving and environmentally friendly. Nevertheless, mechanochemical methods often make it difficult to isolate crystals suitable for X-ray single-crystal diffraction. This paper will focus on other typical synthetic methods as well as newer methods that have been developed in recent years. Last but not least, challenges and promising developments in the field of MOF are also discussed.

Examples of hydrothermal/solvothermal synthesis of MOFs

| MOF | Feature | Synthesis methods | Synthesis conditions | Refs. |

| MIL-47(V) | 1D Micro Rod | Solvothermal | 180 oC 20 h | [46] |

| MIL-53(Fe) | 1D Micro Rod | Solvothermal | 150 oC 6 h | [47] |

| MIL-110(Al) | 1D Nanotube | Hydrothermal reaction | 90 oC 3 h | [48] |

| Fe-MOF | 2D Nanobelt | Solvothermal | 110 oC 24 h | [45] |

| Ni-MOF | 2D Nanosheets | Solvothermal | 80 oC 18 h | [40] |

| Zr-MOF | 2D Nanosheets | Solvothermal | 120 oC 24 h | [49] |

| Cu-TCPP | 2D Nanosheets | Solvothermal | 80 oC 3 h | [50] |

| Cu-MOF | 2D Nanosheets | Hydrothermal reaction | 140 oC 72 h | [51] |

| Co-MOF | 3D Bulk | Solvothermal | 130 oC 3 d | [43] |

| MFM-303 (Al) | 3D Needle Bar | Hydrothermal reaction | 210 oC 3 d | [52] |

| MUT-4(Zn) | 3D Columnar | Solvothermal | 120 oC 24 h | [44] |

| UiO-68-TZDC | 3D Octahedron | Solvothermal | 100 oC 72 h | [41] |

| MIL-101(Cr) | 3D Octahedron | Hydrothermal reaction | 180 oC 15 h | [39] |

| NNU-29 | 3D Bulk | Hydrothermal reaction | 180 oC 72 h | [53] |

| NiCo-MOFs | 3D Bulk | Solvothermal | 140 oC 48 h | [54] |

SYNTHESIS OF MOFs WITH 1D STRUCTURES (1D MOFs)

1D MOFs can be classified into nanowires, nanotubes, nanorods and nanoribbons. In the past 20 years, 1D MOFs have shown promising applications in electronics, photonics, biology and energy storage and conversion due to their unique anisotropy[57-60]. 1D MOFs create opportunities for new applications of MOFs due to their unique combination of both nanostructured advantages and porous properties. However, research on 1D MOFs is still in its infancy and is still mainly focused on the development of new synthetic methods. As shown in Figure 1, the most common chemical synthesis methods can be classified into template and template-free strategies.

Figure 1. Schematic diagram of two illustrative strategies for the preparation of 1D MOFs. MOFs: Metal-organic frameworks; 1D: one-dimensional.

Template strategies

Assembling nanoparticles into one-dimensional nanostructures through nanoparticles is an emerging research area over the years, which not only builds a bridge between the nanoscale and the micron-scale, but also offers endless applications in optoelectronic engineering, biotechnology, magnetic components and more[61]. In contrast, for 1D MOFs, template methods are one of the effective methods for synthesizing size- and composition-controlled nanomaterials[62-64]. Template strategies can be further divided into hard template methods and sacrificial template methods.

Hard template method

The hard template method induces the nucleation and growth of MOFs nanostructures on the surface of template materials, such as graphene oxide, Te nanowires and ZnO nanorods, to form MOFs-based one-dimensional hybrid materials[65-69]. The morphology of the material and the pore size is modulated with templates. Back in 2010, Jahan et al. had successfully synthesized unusual MOFs nanowires by using benzoic acid functionalized graphene oxide (BFG) as a structurally oriented hard template to induce nucleation of MOF-5 on its surface and growth along the [220] crystallographic plane direction[70]. In order to synthesize MOF/BFG complexes, they tried adding different amounts of BFG (1,4 and 5 wt%) as the precursors and eventually found that the diameter of the nanowires closely correlated with the lateral size of the functionalized graphene. In 2012, Pachfule et al. speculated that the nano-hollow structure might have special encapsulation capabilities due to its constraint[65]. Subsequently, highly crystalline MOFs were grown in the inner cavities of one-dimensional carbon nanofibers (CNF) using pre-synthesized CNF as templates with reasonable experimental parameters. The analysis of the powder X-ray diffraction data indicated that the MOF phase was the thermodynamically unstable MOF-2 [Zn(bdc)], rather than the expected MOF-5 [Zn4O(bdc)3], and high-resolution transmission electron microscopy of the MOF-2@CNF composite also clearly showed MOF-2 nanocrystals stacked in the inner cavities of the one-dimensional carbon nanofibers. To further explore the crystal growth, they functionalized the CNF, introduced functional groups and then performed MOF synthesis, and found that the MOF-2 crystals grew on the outer surface of the CNF, indicating the importance of surface functionalization of carbon templates. Commercial trace-etched polycarbonate (PCTE) membranes have also been widely used as hard templates for the synthesis of inorganic nanowires. Caddeo et al. then used polycarbonate (PC) templates to deposit Cu nanowires, which were then converted to Cu3(BTC)2 MOF nanowires by electrochemical oxidation by injecting an organic linker solution into the template[71]. Since the MOF is formed inside the template, the shape is consistent with the host nanochannel and MOF nanowires with diameters between 80 and 260 nm can be obtained. In 2018, Arbulu et al. used PCTE to synthesize continuous 1D ZIF-8[72]. ZIF-8 nanomorphology is related to Zn metal salt concentration and PCTE membrane pore size [Figure 2A-C].

Figure 2. (A-C) TEM images of different 1D ZIF8-100 nanostructures. (D) Schematic diagram of the NFC template for the synthesis of MOF nanofibers. (E) Mechanistic scheme summarizing the principal phases of the formation of MIL-69(Al) NWs. (A-C) Adapted with permission[72]. Copyright 2018, John Wiley and Sons. (D) Adapted with permission[73]. Copyright 2022, John Wiley and Sons.

In general, the development of applications for MOFs is strongly influenced by the superstructure. With the aid of templates, MOFs can be assembled into superstructures in solvents, but templates for highly homogeneous 1D nanomaterials are not available and the synthesis of superstructures is limited as a result. Recently, Li et al. reported the synthesis of MOF materials with 1D nanofiber morphology using nanofibrillated cellulose (NFC) as a template[73]. The synthesized core-shell nanofibrous materials have the advantages of a high aspect ratio, great flexibility, good dispersion and ease of large-scale assembly. The prepared ZIF-8, UiO-66 and MIL-53 (Al) nanofibers have high aspect ratios of over 100 and can be used to assemble into a variety of macroscopic materials [Figure 2D]. NFC is considered to be a good amphiphilic material due to the presence of both hydrophilic and hydrophobic alkane fractions, and can be dispersed in both polar aprotic organic solvents and non-polar solvents alone. This unique property makes NFC an ideal template for the synthesis of 1D flexible MOF nanofibers. The synthetic strategy that uses solution treatment is expected to ensure the production of MOF nanofibers at scale and promote the industrialization of MOFs.

It is well known that low-symmetry nanocrystals (NCs) are important in areas such as catalysis, sensing and electronics[74,75]. While the majority of MOF nanoparticles (NPs) are obtained as polycrystalline powders or spherical nanocrystals (NCs), and only a very few one-dimensional anisotropic MOF nanostructures were identified. In 2020, Muschi et al. formulated an original approach to synthesize MIL-69 (Al) nanowires (NWs) grown along the [001] crystal plane direction by using graphene oxide as a template modifier[76]. Graphene oxide nanowires are one-dimensional carbon materials formed by rolling graphene oxide sheets from one side or edge into Archimedean-type helices[77]. Inspired by this, they exploited the potential rolling of graphene oxide and the following anisotropic growth of MIL-69 (Al) in the inner cavities of graphene oxide nanoscrolls to contain the formation of single-crystal MOFs [Figure 2E]. The anisotropic growth is motivated by the interaction forces between the MIL-69 (Al) NPs and the hydroxyl and carboxyl functional groups of the graphene oxide.

Sacrificial template method

The sacrificial template method is more attractive than the hard template method, which can easily remove the template but hardly triggers the collapse of the 1D MOF structures[78]. This is a process in which a number of 1D metal oxides or hydroxides are used as templates for their own in-situ dissolved metal ions properties, ultimately inducing the formation of 1D MOFs. In recent years, metal nanoparticles (MNPs) doped in MOFs have been widely used in the field of multiphase catalysis[79-81]. However, the key to the catalytic efficiency of MNPs@MOFs lies in how to shorten the distance between the reactants and the active sites to achieve this process, which means that the spatial distribution of MNPs in MOFs needs to be precisely tuned. In 2017, Yang et al. employed spherical metal oxides both as a support for MNPs and as a sacrificial template for growing MOFs to achieve precise encapsulation of controlled positioning of MNPs in 1D MOFs [Figure 3A][82]. Initially, the MNPs were first loaded onto the metal oxides, and the organic ligands in solution were coordinated with the metal ions in oxides, and the MNPs were then encapsulated into the MOF crystals [Figure 3B-E]. The concentration of the organic ligand regulates the spatial position of the MNPs in the MOFs. When the concentration of organic ligands is high, the nucleation of MOFs follows a “dissolution precipitation mechanism”[83,84]. As increasing the concentration of Zn(Hmim)42+, ZIF-8 crystals were slowly deposited on the metal oxide surface to form a polycrystalline layer, while MNPs were encapsulated between the interface of ZnO and ZIF-8 as they remained on the metal oxide surface. When the concentration of organic ligands is low, the conversion follows a “local conversion mechanism” and the MNPs are immobilized on the surface of the MOFs[85]. It was found that the method was applicable to a wide range of MNPs and MOFs, and that the synthesized MNPs@MOFs had significantly enhanced catalytic activity. In 2018, Li et al. also used metal oxides encapsulated into ZIF-8 to achieve good catalytic performance[86].

Figure 3. (A) Spatial localization of MNPs in MOF crystals regulated by template-sacrifice method. (B-E) TEM images of ZnO NRs (B), ZnO NRs@Au (C) and (D and E) ZnO NRs@Au@ZIF-8 composites with Au NPs at different locations: (D) inside and (E) near to the surface of ZIF-8. (F) Formation of the hierarchical CNT/Co3O4 microtubes. (G-I) FESEM of the synthesized ZIF-67 microtubes.

Among all nanostructured materials, nanotubes have attracted a particular attraction due to the characteristic application properties shown in adsorption, catalysis and sensing due to the fact that these fascinating tubular nanostructures provide three different contact regions, i.e., the interior, the exterior surface as well as the ends[87-90]. Nanotube-structured electrode materials are capable of enhancing electrochemical properties not possible for conventional bulk materials, thanks to higher surface areas and shorter diffusion paths that enhance the attraction for free electrons[91-95]. Among the various structural designs, hierarchical tubular structures (HTSs) have received considerable attention for their advantages such as pore volume for expanding the electrode/electrolyte contact area. In 2016, Chen et al. devised a multi-step strategy to use zeolite imidazolate framework (ZIF-67) as a single source of carbon and cobalt in the resultant composites through a controlled chemical transformation, and a two-step annealing process to obtain a layered CNT/Co3O4 hollow tubular structure, which has excellent as an anode material for Li-ion batteries[96]. They selected electrospun polyacrylonitrile (PAN)-cobalt acetate [Co(Ac)2] composite nanofibers as a bifunctional template and made use of the strong coordination of 2-methylimidazole and the cobalt source on the template, resulting in the growth of uniform ZIF-67 nanocrystal shells on the nanofibers [Figure 3F-I]. After DMF treatment, the nanofibers were removed to form tubular structures. In the final step, carbon nanotubes are retained after annealing treatment, yielding layered CNT/Co3O4 microtubes. The transformation from cobalt solid nanoparticles to Co3O4 hollow particles can be attributed to the Kirkendall effect during the annealing process[97]. In the same year, Liu et al. used Cu2O as a template and successfully converted pristine nanowires into layered HKUST-1 nanotubes by immersing Cu2O nanowires in a mixture of acetic acid, ethanol and H3BTC/DMA using the characteristics of acetic acid to dissolve Cu2O[98]. They have experimentally found that the solvent group is critical to the growth of nanomaterials and that the solvent plays an important role in the balance between the dissolution rate, nucleation rate and crystal growth of copper ions.

Electrospinning

Electrospinning has been widely used as a method for preparing nanowire fibers due to the mature synthetic technology and low cost[99,100]. A simple electrostatic spinning device consists of three main components [Figure 4A], a high-voltage power supply, a capillary/syringe with a needle and a grounded collector[101]. The choice of precursor solution is also one of the keys, with the viscosity of the precursor determining the size and morphology of the fiber materials[102,103]. The mechanism of electrospinning is predicated on the ejection and elongation of a molten viscous polymer under a high-voltage electric field, followed by solidification at the collector in the form of a stream of charged liquid. There are two main routes to forming MOF-polymer nanofiber structures via electrostatic spinning, namely “direct electrostatic spinning” and “surface modification”, both of which can be converted into MOF nanofiber derivatives by post-treatment[104]. In the direct electrostatic spinning method, a slurry containing MOF particles is mixed with polymers and directly electrospun into nanofiber complexes[105-107]. However, this direct electrostatic spinning method is not suitable for applications pursuing a material pore perspective, due to the fact that the slurry of mixed polymers can clog the pores inside the MOFs. The second method of generating complexes is reached by growing MOF particles in situ on the surface of nanofibers[108,109]. This in situ growth mode maintains the advantages of the porosity and high specific surface area of MOFs and can also have good applications in the field of adsorption. The “surface modification” method has become the preferred method for electrostatic spinning in recent years, despite its high experimental requirements. Researchers can design the composition and morphology of the material by doping it with metals or other small molecules after the electrostatic spinning process, thereby expanding the diversity of electrostatically spun nanofibers. In terms of energy materials, the high structural stability of electrostatically spin-synthesized 1D MOFs effectively prevents structural expansion and collapse of the electrode material. The 1D structure also improves the material’s distance for charge transport and ion diffusion during discharge. Electrospinning techniques effectively inhibit the aggregation of MOF particles and improve the utilization of active substances by building a network structure; therefore, they are also considered an effective way to expand the range of practical applications of MOFs[110-112].

Figure 4. (A) Schematic diagram of the electrostatic spinning unit. (B) The synthesis of hollow particle-based N-doped carbon nanofibers (HPCNFs-N). (C and D) FESEM and TEM images of the PAN/ZIF-8 composite nanofibers. (E and F) FESEM and TEM images of the HPCNFs-N sample. (G) Diagrammatic representation of the different synthetic routes for the structuring of HKUST-1 into MOF NFs. (A) Adapted with permission[101]. Copyright 2007, American Chemical Society. (B-F) Adapted with permission[113]. Copyright 2017, The Royal Society of Chemistry. (G) Adapted with permission[115]. Copyright 2021, Springer Nature. MOFs: Metal-organic frameworks; FESEM: field emission scanning electron microscopy; PAN: polyacrylonitrile; NFs: nanofibers.

In 2017, Chen et al. generated hollow particle-based nitrogen-doped carbon nanofibers (HPCNFs-N)

Template-free method

The synthesis of 1D MOF nanomaterials by a template-free method is often expected to produce single-crystalline one-dimensional MOF.

Modifiers-induced growth method

For a long time, scientists have been working on reducing the size of MOFs crystals to the nanoscale without changing the properties of the MOFs crystals themselves and investigating the correlation between the porous properties of the nanocrystals and the interfacial structure. The direct synthesis of 1D MOFs via metal precursors and organic ligands is more difficult and most are usually obtained in alcoholic solvents or ethanol/water mixtures[116,117]. Over the years, ligand-modulated synthesis of MOFs via monocarboxylic acids, organic bases, dopamine and amphiphilic copolymers as modulators has also been reported[118-124]. It is important to understand the crystal growth of metal framework materials, and the modulation method involves the use of molecules that are structurally similar to the ligand and a weaker coordination affinity to the metal clusters to compete with the ligand and thus regulate the coordination equilibrium of the crystal morphology growth of MOFs. When the coordination equilibrium between the metal ion and the organic linker is altered, the crystal size, morphology and crystallinity of the MOFs can be controlled[125-127]. The relatively weak interactions between ligand bonds dominate the assembly process of MOFs and also lead to the formation of crystals. In 2009, Tsuruoka et al. used a simple and straightforward method to modulate the coordination equilibrium by adding a modulator with the same chemical function as the linker to the reaction system to enhance the one-dimensional anisotropic fusion of nanocrystals by impeding the coordination interactions between the metal ions and the organic linker[128]. They synthesized one-dimensional [Cu2(ndc)2-(dabco)] nanorods (ndc = 1,4-naphthalene dicarboxylate; dabco = 1,4-diazabicyclo [2.2.2] octane) using acetic acid as a modifier. It was found that the increase in acetic acid concentration significantly inhibited the growth of Cu-NDC in the [100] direction, prompting eventual growth along the [001] direction to form nanorods. In 2016, Pachfule et al. successfully synthesized MOF-74-Rod at room temperature using a unique modulator-assisted approach to stabilize the active metal sites on the surface of MOF crystals by introducing salicylic acid modulators into the system to guide the growth of MOF in rod-like morphology [Figure 5A][129]. They then used KOH-assisted sonication, where K+ was inserted into the carbon nanorods in a disordered stack during solution-based sonication, and again during subsequent heat treatment, where the K+ containing nanorods were unfolded to form a nanoribbon structure. Further acoustic treatment and thermal activation of the rod-like MOF could open up new avenues for the efficient production of one- and two-dimensional carbon materials. Conventional acoustic treatment is ultrasonication, which relies primarily on the transmission of acoustic waves through a medium such as a solution, causing oscillation of the medium particles. In contrast, non-traditional surface acoustic waves (SAWs) are electromechanical waves with nano- or sub-nano-amplitudes that are accompanied by changes in the electric field along the propagation path[130]. SAWs combine acoustic and electric fields and offer advantages in controlling the thickness of stripped nanosheets. By 2019, they had also synthesized chestnut-shell spherical superstructure metal-organic framework nanorods (SS-MOFNR) by hydrothermal transformation using urea as a modulator[131]. In control experiments without the addition of urea, the coexistence of unassembled MOF nanorods and partially spherical superstructures was observed using SEM. In contrast, the addition of urea resulted in the formation of morphologically homogeneous and highly crystalline SS-MOFNRs [Figure 5B-G]. By investigating the time-dependent process, it was found that with increasing time, Zn-MOF-74 NPs were first transformed into Zn-MOF-HT nanorods, and finally, micro-sized SS-MOFNRs were slowly assembled, a process that was transformed gradually. The screening of the solvent revealed that water as a solvent was favorable to the formation of 1D MOFs. SS-MOGNR also maintained its original morphology after carbonization with argon, and its performance as a carrier for the Pd immobilization catalyst was improved.

Figure 5. (A) Synthesis scheme for MOF-74-Rod. (B-D) SEM images of SS-MOFNR composed of 1D MOF nanorods. (E) SEM image of a fractured SS-MOFNR showing its internal hollow structure. (F and G) TEM images of SS-MOFNR. (A) Adapted with permission[129]. Copyright 2016, Springer Nature. (B-G) Adapted with permission[131]. Copyright 2019, John Wiley and Sons. MOFs: Metal-organic frameworks; SS-MOFNR: spherical superstructure metal-organic framework nanorods; 1D: one-dimensional.

Phase transition method

The single-crystal-to-single-crystal (SCSC) conversion is an intriguing and essential process in chemistry and material science and is an important feature in the preparation of coordination polymers[132-139]. Over the last few decades, much research demonstrated that SCSC conversions of MOFs could be triggered by external stimuli, including physical and chemical processes, such as temperature, pressure, gas adsorption, etc.[140-145]. Through these stimuli, the number of ligands and dimensions can be changed, such as 0D to 1D/2D and 1D to 2D/3D, leading to the synthesis of MOFs[146]. In 2019, Han et al. achieved the transition from QUST-81 to QUST-82 through thermodynamically controlled crystal phase transitions in physical stimuli[147]. Synthesis of QUST-81 crystals at 100 oC, followed by high-temperature heating to 120 oC in the mother liquor again, enables the formation of new stable QUST-82 crystals [Figure 6A and B]. In contrast, there is no dissolution or recrystallization of the single crystal during this process. Single crystal X-ray diffraction (SCXRD) showed that the coordination environment of QUST-82 changed during the crystalline phase transformation, with new coordination bonds forming. The formation of new bonds is also indirectly evidenced by the color of the reactants, with QUST-81 crystals showing a color change from dark green to colorless back to green, indicating the presence of a reduction of Cu2+ to Cu+ followed by re-oxidation to Cu2+ in air. The heterometallic MOF QUST-82 serves as an excellent adsorbent for the elimination of organosulfur. However, there are not many studies on chemical stimuli with the same metal but different coordination environments causing the SCSC transition of MOFs. In particular, there are few discussions on the crystalline transformation of 1D MOFs. Chen et al. did advance research[148]. Starting with 0D Cu nanoparticles [MOP-1, Cu24(m-BDC)24(DMF)14(H2O)10], they began to explore the effect of SCSC conversions induced by different organic ligands on the structure. They first synthesized 0D rhombic MOP-1 crystals, and SXRD data showed them to be connected by a Cu2(COO-)4 paddlewheel unit and two isophthalic acids (m-BDC). Two terminal ligands are attached to each unit, pointing to the exterior and center of the crystal, respectively. Compared to oxygen atoms, nitrogen atoms are less electronegative and give more electrons, making it easier to give electrons to form coordination bonds with metal salts. They then introduced 1-methylimidazole as a second ligand in an attempt to break the original coordination structure and transform the 0D structure. SXRD confirmed that the introduction of 1-methylimidazole resulted in the coordination of a Cu atom to two oxygen atoms in two m-BDCs and three nitrogen atoms in three 1-methylimidazoles to form a 1D chain structure. In 2017, Yang et al. synthesized 1D-NCPs (nanoscale coordination polymers) containing gambogic acid (GA) through a phase transfer strategy[149]. PEGylated 1D-NCPs were constructed by mixing Mn ions and indocyanine green (ICG, a NIR dye) along with poly-l-histidine-PEG (pHis-PEG). First, metal ions and organic ligands self-assemble through coordination interactions in solution methanol to form a three-dimensional porous structure. It is then transferred into an aqueous solution, where the highly polar water molecules coordinate with the metal ions to form a one-dimensional nanofiber-like structure [Figure 6C]. An interesting phenomenon occurred when the reaction phase was transformed from an organic solvent to an aqueous solution, and the granular structure of the Mn-ICG@pHis-PEG NCPs nanoparticles slowly transformed into a fibrous one-dimensional structure over time. The authors found that the 3D porous structure becomes unstable due to the larger sulphonic acid anions of ICG. In strongly polar aqueous solutions, the Mn2+ coordination environment was changed and the hydrogen binding led to the formation of a 1D chain-like structure. For the change of the nanostructure from 3D to 1D, they performed molecular dynamics fitting computational simulations on Mn2+ according to the universal force field[150]. The research found that in methanol, Mn2+ is coordinated to six sulfonate anions of organic ligand ICG. Concurrently, Mn2+ could also coordinate with the imidazole ring of poly-histidine-PEG. Poly-histidine-PEG relying on imidazole groups can strongly bind metal ions, but poly-histidine-PEG has only one imidazole ring and can only coordinate with one Mn2+. Therefore, when Mn2+ is coordinated with poly-histidine-PEG and the growth of MOF stops, 3D porous MOFs are formed. After the introduction of highly polar water molecules, the hydroxyl group can connect with the sulfonate anion to form a hydrogen bond to form a 1D structure. This simple crystal phase transfer strategy, which can be extended to various kinds of metal ions, is expected to open up new opportunities for the synthesis of MOFs.

Figure 6. (A) SEM images of QUST-81-SC, QUST-82-SC, and QUST-82-P (SC = single crystal and P = powder). (B) The SC-SC phase transition process between QUST-81 and QUST-82. (C) Scheme to illustrate one-step synthesis of 1D PEGylated NCPs. (A and B) Adapted with permission[147]. Copyright 2019, John Wiley and Sons. (C) Adapted with permission[149]. Copyright 2017, John Wiley and Sons. NCPs: Nanoscale coordination polymers; 1D: one-dimensional.

Recrystallization

The anisotropic 1D MOF structures were prepared only by the template method and surfactant-assisted method, but the single-crystal nano MOFs or nano MOFs with high aspect ratios could not be prepared[70,151]. Taking graphene oxide templates as an example, graphene oxide flakes are thinner and more brittle. The surface is modified with functional groups such as hydroxyl groups, which are easily chelated with metal ions, while the carboxyl groups are mainly distributed on the sides and edges of the flakes. It is therefore difficult to form MOFs with high aspect ratios using it as a structural guide for molecular assembly. Surfactant-assisted methods are often used to modulate the morphology and size of MOFs and are generally used as auxiliary agents. Moreover, surfactants are often classified as anionic, cationic, amphiphilic and polymeric, and there is some skill in choosing which surfactant to use. Utilizing metal oxides as metal source precursors, the synthesis of MOFs phases by secondary crystallization has been reported previously[152-154]. However, the synthesis of 1D MOF nanostructures with both single crystal and ultra-long morphologies is still a great challenge. Commonly, the kinetic process of crystallization influences the morphology of the crystals. Different precursors have different solubilities in specific solvents. Lower crystallization rates facilitate the formation of high aspect ratio, anisotropic MOFs. By 2018, Zou et al. had successfully fabricated the first high aspect ratio single-crystal Co-MOF nanotubes via an amorphous MOF-mediated recrystallization method (AMMRA)[155]. To achieve anisotropic, ultra-long single crystals. They first prepared Co-MOF-74 nanoparticles (Co-MOF-74-NP) in the amorphous phase, exploiting the property that the amorphous Co-MOF-74-NP dissolves slightly in water and later recrystallized the Co-MOF-74-NP in aqueous solution (pH = 7.15) to produce ultra-long single crystals of Co-MOF-74 nanotubes (Co-MOF-74-NT) [Figure 7]. Compared to the low aspect ratio Co-MOF-74 micro-rod (Co-MOF-74-MR) (3-30 μm in length, 1-5 μm in diameter), the secondary crystallization method demonstrates the great advantage of nanosize control to achieve a homogeneous morphology of high aspect ratio nanotubes.

Figure 7. Synthesis protocols for Co-MOF-74-NT and Co-MOF-74-MR. Adapted with permission[155]. Copyright 2018, American Chemical Society.

SYNTHESIS OF MOFs WITH 2D MORPHOLOGIES (2D MOFs)

Since 2004, when flake graphene was first prepared, various 2D materials have been explored with rapid development[156]. The synthesis of 2D nanomaterials has gradually become a hot research topic. Studies have shown that almost all inorganic layered materials can be exfoliated into 2D materials[157]. Moreover, similar to conventional 2D materials, 2D MOFs have a large aspect ratio, fully exposed active sites and fast diffusion channels, making them attractive for applications in electronics, energy conversion and storage and gas separation[158-160]. Although there are many approaches to the synthesis of 2D MOFs materials to date, they can be broadly classified into two main categories: top-down and bottom-top strategies [Figure 8]. The first one mainly entails the delamination of bulk MOFs, and the latter is based on the direct synthesis of 2D MOFs crystals with high aspect ratios based on metal nodes and organic ligands[161,162]. Here, we focus on some classical and new synthesis strategies in recent years.

Figure 8. Schematic diagram of the synthesis strategy of 2D MOFs. MOFs: Metal-organic frameworks; 2D: two-dimensional.

Top-down approaches

As the name implies, the top-down strategy refers to the exfoliation method of the overall MOFs, which can easily overcome the weak interlayer interaction, mainly relying on the weak interaction between the layers of different 2D MOFs, e.g., van der Waals forces, - stacking, etc.[163].

Micromechanical exfoliation

In 2004, Novoselov et al. succeeded in obtaining the first graphene with a perfect hexagonal honeycomb lattice by repeatedly peeling off highly oriented pyrolytic graphite using transparent tape, inspired by the use of tape to remove impurities from the surface of graphite while working on metal field effect transistors[156]. Subsequently, this micromechanical peeling using tape was widely used in preparing 2D materials. Although 2D materials are mostly structures with weak van der Waals force interactions between layers stacked on top of each other, there are strong covalent bonds in each sheet and 2D materials have been gaining popularity in the field of covalent functionalization in recent years. Traditionally, surface modification is carried out after obtaining the ultrathin 2D material. However, due to the poor reactivity of the 2D MOFs, defects and incomplete functionalization were often performed after modification[164]. In 2018, Lopez-Cabrelles et al. designed pre-synthetic ligand functionalization followed by micromechanical exfoliation to successfully prepare defect-free functionalized 2D MOF [Figure 9A and B][165]. The crystallinity and integrity of the exfoliated flakes were confirmed by projection electron microscopy and regional electron diffraction patterns [Figure 9C]. Although micromechanical peeling is easy to handle, it is less efficient. There is also a risk of disrupting the quantum structure of the material during stripping, resulting in stripping losses and affecting large-scale stripping.

Figure 9. (A) A common strategy for the functionalization of 2D (inorganic) materials, consisting of two steps. (B) Pre-synthetic functionalization, where the functionalized block is first obtained prior to mechanical stripping, resulting in a quasi-perfect array of unaltered functional groups attached to the surface. (C) (i) Low magnification TEM image of a thin section, where the darker grey areas are associated with thicker sections; (ii-iv) The experimental SAED pattern corresponding to the [0 0 1] area axis (iii) was obtained for the selected area [surrounded by the green circle on the TEM image in (ii)] and fitted very well with the simulated SAED pattern (iv). (A-C) Adapted with permission[165]. Copyright 2018, Springer Nature. 2D: Two-dimensional.

Ultrasonic stripping

As a new member of the 2D material family, 2D MOF materials, although still in the early stages of research, have larger lateral dimensions and ultra-thin thicknesses than other inorganic nanosheet materials, giving them a larger surface area than other inorganic nanosheet materials[50,166,167]. For 2D MOF crystals, the different layers are attached by weak interactions, including hydrogen bonding and van der Waals forces. If the weak interactions are broken, monolayers of 2D-MOFs can be obtained. This idea has been implemented by a simple ultrasonic peeling method. Ultrasound waves are originated from acoustic cavitation within collapsing bubbles. After the solution has been processed by ultrasound, ultrasound energy accumulates in the oscillating bubbles and can generate high pressures and local temperatures[168]. Small bubbles in a solution periodically undergo a process of creation, expansion and bursting. As the bubbles burst, energy is applied to the stripped precursor with a shock wave and tensile stresses are generated within the components of the precursor until the nanosheets are stripped. Ultrathin MOF nanosheets (UMOF NSs) can be prepared using the ultrasonic stripping strategy. UMOF NSs are characterized by the following features: nanoscale thickness allowing fast transport, superior electron transfer, ligand-unsaturated metal sites and exposed catalytically active surfaces[169-171]. In 2016, Zhao et al. then used ultrasonic exfoliation to prepare a series of UMOF NSs with ligand-unsaturated sites and high electrocatalytic activity towards OER at room temperature[54]. It showed that the coordination-unsaturated metal atoms are the main active centers and this type of UMOF NSs is expected to be a strategy for synthesizing atomically accurate active catalysts.

At present, few systematic studies have been carried out on the exfoliation of bulk materials into ultrathin 2D nanosheets. For this reason, the discovery of new methods to facilitate the exfoliation of freestanding nanosheets is a necessary crystallographic challenge. Previously, the effect of the length of the suspended chains located in the MOF pores on the exfoliation has often been neglected. However, in 2019,

Figure 10. (A) General reaction scheme for the targeted synthesis of MOFs [Cu(n)(DMF)]n, where n = 1-5. Defines the R groups in the dicarboxylic acid ligand precursors H21 to H25. (B-D) AFM images of Cu(3), Cu(4) and Cu(5) nanosheets following ultrasonic stripping and centrifugation (1500 rpm for 1 h) in MeCN. (E-G) Scatterplot of correlation for MON dimensions. (A-G) Adapted with permission[172]. Copyright 2019, American Chemical Society. MOFs: Metal-organic frameworks; AFM: atomic force microscopy;

Figure 11. (A) Schematic diagram of exfoliation of MOF 1 blocks into UMOF NSs. (B) SEM image of MOF 1. (C) TEM image of MON 1. (D) MON 1 Tyndall effect of suspensions in i-PrOH. (E) SEM image of the Al-MOF bulk crystals. (F) TEM image of exfoliated Al-MOF nanosheets. (G) The AFM image of Al-MOF nanosheets on a silicon wafer, the inset shows the corresponding height profile.

Chemical exfoliation

As well as micro-mechanical exfoliation and ultrasonication, chemical exfoliation with the selection of organic small molecules as insertion agents is commonly used for preparing UMOF NSs. In 2017,

Figure 12. (A) Schematic diagram of the entire formation of 2D MOF nanosheets by chemical exfoliation. Adapted with permission[177]. Copyright 2017, American Chemical Society. (B) Schematic representation of the synthesizing 2D Zn-MOF nanosheets. Adapted with permission[180]. Copyright 2021, Royal Society of Chemistry. MOFs: Metal-organic frameworks; 2D: two-dimensional.

Solution stripping

With the further exploration of 2D materials, a number of chemical strategies have been developed and applied to the preparation of UMOF NSs. In 2013, Gallego et al. completely exfoliated the laminate by solvent interaction alone, before which solvent exfoliation (without the application of other external forces) of 3D laminates had almost not been reported[181]. They achieve complete separation of the crystals by immersing the layered MOF [Cu(µ-pym2S2)(µ-Cl)]n · nY (where Y can be MeOH, H2O or 1/2EtOH) in water. The interlayer cavities in the crystal structures can be filled by solvent molecules in a simplistic and repetitive manner. This solvent exchange does not affect the crystallinity of the single crystals. The structural features of the compounds show that the solvent in the interlayer cavities prohibits strong layer-to-layer interactions. This method is very soft in terms of energy due to solvent-assisted procedures, avoiding the potential complications of exfoliation in laminar crystals or solid matrices. In 2017, Wang et al. used the freeze-thaw method to exfoliate a kind of bulk MOFs, MAMS-1 [Ni8(5-bbdc)6(µ-OH)4], into large, defect-free 2D nanosheets [Figure 13A-D][182]. The hexane solution undergoes a transformation between a solid and a liquid state under the influence of temperature, which generates a shear force that leads to the exfoliation of nanosheets. These nanosheets are also used as molecular sieve membrane structures to facilitate gas separation. The Aida team used SMe-H2ip ligands to synthesize a porous kagome lattice of bulk MOF[183]. When immersed in a non-plasmonic polar solvent, employing N,N-dimethylformamide (DMF) or tetrahydrofuran (THF), kgmSMe was discovered to swell rapidly like an accordion, gradually exfoliating the monolayer nanosheets. The solvent stripping is similar to the chemical exfoliation where the solvent is used as an insert to strip the material. The disadvantages are slow peel rates, low yields and a narrow range of applications.

Figure 13. (A) MAMS-1 crystals freeze-thawed and exfoliated into dispersed nanosheets. (B) FE-SEM image of a laminated MAMS-1 crystal. (C) Crystal structure of MAMS-1. (D) AFM image of purified MAMS-1 nanosheets. (A-D) Adapted with permission[182]. Copyright 2017, Springer Nature. MOFs: Metal-organic frameworks; FE-SEM: field-emission scanning electron microscopy;

Bottom-top approaches

Although top-down methods have wide applicability in the preparation of various UMOF NSs, they often face difficulties in controlling the thickness and size of 2D materials[184,185]. In contrast, bottom-up approaches offer the advantage of being more efficient, scalable and flexible. This strategy relies heavily on the assembly between metal nodes and organic linkers and is suitable for the preparation of nanosheets that possess isotropic bonds[186]. Classical bottom-up methods for synthesizing 2D materials generally include interfacial synthesis and layer-by-layer methods, etc.

Interface synthesis

Restricting the growth of MOF crystals to the interface of two dissimilar phases is a common method for synthesizing 2D MOF nanosheets (MONs)[187,188]. Interfacial synthesis confines metal ions and organic ligands at the interface of two phases to form a thin sheet of MOFs. With the aid of non-destructive optical methods, it is possible to monitor the growth of the crystal interface and indicate the presence of a reversible transition layer at the growth interface, which provides guidance for the synthesis of MOFs[189,190]. Coordination reactions that typically occur at the interface of two phases have the advantage of large area, good size ratio and easy transfer to the device[191]. By considering the type of interface, interfacial synthesis can be divided into three categories: liquid/air interface, liquid/solid interface and liquid/liquid interface.

Liquid/air interface: accompanied by the evaporation process of the organic solvent at the interface and then the introduction of surface pressure with the Langmuir-Blodgett (LB) technique, the grown monolayer MOFs can be comfortably transferred to the substrate. In 2015, Sakamoto et al. used the liquid/air interface reaction to synthesize monolithic nanosheets with a lateral size larger than 10 µm in size[192]. They added a solution of dichloromethane containing a very small amount of three-way dipyrrin ligand molecule (L1) slowly and dropwise to an aqueous phase containing zinc (II) acetate. Along with the rapid volatilization of dichloromethane, an immediate coordination between L1 and zinc (II) ions is achieved, generating a monolayer of MOF (N1) at the interface. Ying et al. fabricated flexible Cu(dhbc)2(bpy) · H2O MONs at the air/water interface and dispersed them in an isopropanol solution with a significant Tyndall effect

Figure 14. (A) Scheme for the preparation of layered less Cu(dhbc)2(bpy) · H2O MONs at the air/water interface. (B) AFM image of Cu(dhbc)2(bpy) · H2O MONs. Inset: height profiles of MONs corresponding to the three labeled lines. (C and D) TEM and HRTEM image of Cu(dhbc)2(bpy) · H2O MONs. (E) Schematic illustration of SDA strategy for the synthesis of CoNi-MOFNA, (F) SEM image. (G) TEM image. (H) AFM image. (I) Formation of isolated, anisotropically shaped DUT-134(Cu) ·DMF microcrystals. (J) Spontaneous self-assembly of the microcrystals into face-to-face or edge-to-face arrangements in fresh DMF solution. (K and L) Freestanding carpets and spontaneous roll-ups resulting in lengths up to ca. 100 µm in diameter and up to 20 mm or longer. Bottom: (I) SEM image of a DUT-134(Cu) flake. (J) surface of the carpet. (K) macrostructure of the dried carpet. Photos: (L) Translucent DUT-134 carpet in DMF (left) and large “multi-walled” macro-tubes in DMF (right). (A-D) Adapted with permission[193]. Copyright 2021, John Wiley and Sons. (E-H) Adapted with permission[199]. Copyright 2019, Elsevier. (I-L) Adapted with permission[207]. Copyright 2022, John Wiley and Sons. MOFs: Metal-organic frameworks; MONs: MOF nanosheets; AFM: atomic force microscopy; SDA: self-dissociative assembly; DMF: dimethylformamide.

Liquid/solid interface: the reactants frequently constructed MONs by self-assembly at the two-phase interface between a metal or carbon substrate and a solution. Commonly utilized substrates are nickel foam (NF), graphite-carbon ensemble graphene, etc.[195]. In recent years, inorganic salts with cheap prices, large crystallite planes, and high stability have gradually become common substrates for the synthesis of large-area 2D materials[196,197]. Huang et al. then utilized sodium chloride templates to in-situ prepare high-quality ultrathin ZIF-67 nanosheets[198]. The limited solvent and the appropriate amount of sodium chloride were key factors in the synthetic process. The growth of ZIF-67 was confined to the narrow space of sodium chloride microcrystals, ensuring that the ZIF-67 nanoparticles extended along the microcrystalline planes. In 2020, this team proposed a self-dissociative assembly (SDA) strategy to synthesize ultrathin nanosheets that served as highly active oxidative evolution reaction (OER) catalysts[199]. Firstly, they picked a cobalt-nickel alloy as the template and mixed the template with a solvent that could dissolve the metal source and ligand. In a hydrothermal process, benzenedicarboxylic acid (BDC) oxidized the CoNi alloy template and dissociated Co2+ and Ni2+ on the template surface. Co2+ and Ni2+ were, in turn, coordinated with BDC and assembled into ultra-thin CONi-MOF nanosheet arrays (CoNi-MOFNA) on the alloy substrate surface

Liquid/liquid interface synthesis: two kinds of solutions with different densities are frequently utilized to dissolve metal salts and ligands, respectively, and the nanosheets are formed in the limited space at the interface of the two phases. Most MOFs are considered to be electrical insulators due to their poor electrical conductivity, but the emergence of new synthetic methods over the last decade or so has revealed some examples of conductive MOFs that allow them to be used as optical electronic components[200-205].

Layer-by-layer assembly

The layer-by-layer (LBL) synthesis method is a sub-method of the liquid phase epitaxy (LPE) procedure. The LBL process is defined as the cyclic immersion of functionalized substrates such as gold and silicon in a solution containing metal ions and a solution containing organic linkers, resulting in highly crystalline surface-anchored MOFs (SURMOFs)[210-213]. Between each immersion, the samples need to be washed with a pure solvent to remove excess scaffolds[214]. The thickness of the film can be regulated by the number of repeated immersions. A few years earlier, Sakaida et al. reported the first 2D tetracyanonickelate-based MOF by drawing on their previous method of synthesizing 3D MOF[215]. Since the orientation of the crystals heavily influenced the deposition process, they tried to form self-assembled monolayer (SAM) by first immersing the gold substrates in an ethanolic solution of 4-mercaptopyridine overnight. The substrates were then alternately immersed in the two ethanol solutions for 20 cycles, resulting in the synthesis of highly crystalline films [Figure 15A]. Xiao et al. constructed ultrathin TA-Zn2+ layers based on tannic acid (TA) and Zn2+ on polyethersulfone substrates using the LBL method, and subsequently converted the TA-Zn2+ layers into ZIF-8 films by immersing them in the 2-methylimidazole (Hmim) solution as a zinc source[216]. The LBL method has also been applied to heteroepitaxy and Liu et al. have reported the use of the LBL method to fabricate a photoactive MOF-on-MOF heterostructure[217]. Conductive MOF films have great applications in various fields, such as energy storage and optical field, due to their thin thickness, conductivity and large area size. In 2021, the preparation of 2D Cu3(HHTP)2 (HHTP = 2,3,6,7,10,11-hexahydroxytriphenylene) films were achieved by Zhao et al. through the layer-by-layer assembly method[218]. Controlled thickness growth was easily achieved by controlling the growth period

Figure 15. (A) Diagram of LbL film fabrication. (B) Schematic synthesis of Cu3(HHTP)2. (C) Diagram of layer-by-layer growth of

Surfactant-assisted strategy

The synthesis of 2D MOF nanosheets or nanofilms using interfacial synthesis and LBL methods usually requires specific substrates and relatively complex preparation steps, but the direct synthesis of 2D MOF nanosheets has not been reported. Common surfactants, such as polyvinylpyrrolidone (PVP) and cetyltrimethylammonium bromide (CTAB), not only limit the growth of MOFs along the stacking direction but also assist in stabilizing the MOFs precursors. In 2015, Cao et al. firstly reported a surfactant-mediated strategy for the direct production of ultrathin, homogeneous, high-quality 2D MOF nanosheets[50]. They selected PVP as a surfactant to control the various anisotropic growth of Zn-TCPP crystals to form ultrathin MOF nanosheets with a thickness of less than 10 nm [Figure 16A-D]. Later, they investigated the generality of different metals for forming 2D nanosheets and found that 2D nanosheets could be constructed when using Zn, Cu, Cd or Co salts as metal precursors. Subsequently, in 2016, they prepared 2D porphyrin paddlewheel framework-3 (PPF-3) MOF nanosheets using a surfactant-mediated method and obtained 2D composites for super electrode materials by sulfidation and carbonization[219]. It has been shown that PVP molecules can selectively attach to the surface of MOFs, reducing interlayer contact and stacking, resulting in the growth of MOFs in a two-dimensional direction and eventually forming MONs[220]. Hang et al. used PVP to prepare 2D Zn-TCPP MOF for controlled photodynamic therapy (PDT) materials for the treatment of specific cancers[221].

Figure 16. (A) Routine and surfactant-assisted synthesis of MOF. (B) STEM image of Zn-TCPP nanosheets. (C) TEM image of single Zn-TCPP nanosheets. (D) AFM images of Zn-TCPP nanosheets, Scale bar: 2 µm. (E) Scheme for the synthesis of ultrathin HHB-Cu nanosheets using a surfactant-assisted method. (F) Scheme for the synthesis of HHB-Cu. (G) SEM images of HHB-Cu NSs with lamellar morphology and layered structures. (H) AFM image and height profile along the white line marked on the HHB-Cu NSs. (A-D) Adapted with permission[50]. Copyright 2015, John Wiley and Sons. (E-H) Adapted with permission[222]. Copyright 2020, Royal Society of Chemistry. MOFs: Metal-organic frameworks; AFM: atomic force microscopy; NSs: nanosheets.

In 2020, Wang et al. employed the anionic surfactant sodium dodecyl sulfate (SDS) to prepare homogeneous 2D conjugated MOFs (2D c-MOFs)[222]. In this process, SDS molecules acted as structural modifiers, and the negatively charged hydrophilic groups in the molecule preferentially anchored on the surface of MOFs under electrostatic interactions, alleviating the buildup between layers and facilitating the formation of ultrathin nanosheets [Figure 16E]. HHB-Cu was first constructed and subsequently stripped of HHB-Cu NSs under sonication. The prepared single crystal HHB-Cu NSs are characterized by a thickness of 4-5 nm (~8-10 atomic layers) [Figure 16F-H].

Zirconium-based MOFs have received much attention compared to other metal-based MOFs due to their higher thermal stability and rich structural types[223,224]. Reports on Zr-MOF nanosheets are limited when compared to many other MOF nanosheets, due to the strong metal coordination bonds[49]. In contrast, in 2019, Zhang et al. demonstrated a simple strategy for the direct synthesis of 2D Zr-BDC MOF nanosheets[225]. Considering the defective linker in UIO-66, they chose a bio-based surfactant (SAAS-Cm) as a ligand competitor to attach to the defect in Zr-BDC MOFs, leading to anisotropic growth of MOFs. Pseudo-assembly into bulk MOFs occurs during the growth of the crystals, and the interaction forces between the layers of the bulk MOFs are weakened by the interaction of the surfactant hydrophobic chains, which in turn disintegrate into ultrathin nanosheets (3-4 nm). Furthermore, they found that changing the number of alkyl groups on the hydrophobic chains can simply modulate the thickness of 2D nanosheets

SYNTHESIS OF MOFs WITH 3D MORPHOLOGIES (3D MOFs)

3D MOFs are commonly porous MOFs structures with unique 3D morphology, assembled and stacked from simple individual MOFs building blocks[18,226-232]. Compared to low-dimensional MOFs materials, 3D MOFs materials exhibit fantastic morphologies, large specific surface areas and high porosity, making them widely used in many fields, especially in catalysis, gas storage and separation, and energy storage. In catalysis, the high porosity of MOFs facilitates the transfer of substances and provides space for the encapsulation of guest molecules. However, most 3D MOFs materials only exhibit microporous structures (< 2 nm). The problem of small pore size would limit molecular transport and diffusion, reduce efficiency, and increase the catalytic time, which is not in line with the concept of sustainability. In terms of gas storage and separation, the structural hierarchy provided by the variation of MOFs building blocks becomes a favorable option for storing/separating gases. In general, MOFs are used for selective adsorption and separation of specific gases in a gas mixture. The appropriate introduction of mesoporous or defective spaces in microporous MOFs can provide additional adsorption sites, allowing further access to molecules. MOF-based materials also play an integral role in energy storage devices such as supercapacitors and batteries. The synergy between the layered pores in the structure allows MOFs to exhibit excellent electrochemical properties. However, it is still difficult to design and fabricate well-defined 3D MOFs on the nano/micro scale, especially for architectures consisting of morphologically ordered simple building blocks; scientists continue to explore new synthetic methods for 3D MOFs materials with nano/micro-pore structures[233]. Due to their structural diversity of pores and the presence of unsaturated coordination sites, various synthetic strategies have also received extensive attention.

Etching

Compared with 1D and 2D MOFs, 3D MOFs with more complex structures generally have higher surface-to-volume ratios. Nevertheless, to date, there are poor references for the rational preparation of single-crystal MOFs with complicated open nanostructures[234,235]. However, some uncommon nanostructures, such as nanocages, nano-hollow spheres, etc., can be prepared by the etching method. For example, partial etching of prefabricated MOF crystals results in partially defective single crystalline hollow MOFs with stable and tunable active centers, facilitating the development of more efficient reaction routes[236-238]. In 2016, Han et al. reported on the use of ammonia to etch Ni-Co Prussian Blue (PBA) cubes to grow anisotropically into cubic nanocages[239]. Etching occurs preferentially at the apex of the cube and slowly along the diagonal direction, increasing the etching time. Through controlled experiments, it was found that the etching rate was dependent on the defect density in the corner regions of the cube. In the case of Ni-Co PBA crystals, the growth process is from the outside-in, with the inner core being more “loose” and defect-rich than the exterior shell, resulting in a faster etching rate, finally, a pyramid-like nanocage [Figure 17].

Figure 17. (A-D) TEM image of etched product obtained after reaction of 20 mg Ni-Co PBA cubes with 2.5 mL of ammonia at room temperature for (A) 0 h, (B) 0.5 h, (C) 2 h, and (D) 6 h. (E) The corresponding schematic illustrates the formation of a Ni-Co PBA cage. (A-E) Adapted with permission[239]. Copyright 2016, John Wiley and Sons. PBA: Prussian blue analogues.

MOFs are promising porous crystalline materials as catalyst carrier materials[80,240-244]. Etching methods tend to etch metal ions so as to achieve a defective morphology. For MOFs, numerous studies have been done on etching from the perspective of ligands. Two years ago, Luo et al. tried to etch MOFs by using strong oxidants to oxidize organic ligands, sever the C-C bond and selectively degrade the organic linker into organic small molecules, developing an oxidative linker cutting process[245]. They used 2,5-dihydroxyterephthalic acid (DOBDC) as a sacrificial connector and selected oxidants of different strengths [nitric acid and reactive oxygen species (ROS)] for comparison, UiO-66-(OH)2 could be horizontally carved from the inside out or from the outside in, resulting in single crystal hollow and yolk-shell structures

Figure 18. (A) TEM images of UiO-66-(OH)2@UiO-66-Br particles and their SAED patterns. (B) TEM images of UiO-66-(OH)2@UiO-66-Br treated with HNO3 at different times, SAED pattern and SEM image are provided on the right. (C) TEM images of UiO-66-(OH)2@UiO-66-Br after different times of ROS treatment, SAED pattern and SEM images are provided on the right. (D) Powder X-ray diffraction patterns of hollow UiO-66-Br. (E) N2 adsorption isotherms of solid UiO-66-Br and hollow UiO-66-Br obtained.

Microwave-assisted

Microwave (MW) irradiation was previously a widely used method in organic chemical synthesis, and over the years, it has been used to synthesize inorganic nanomaterials such as zeolites and MOFs[246-248]. Traditional hydrothermal synthesis involves heating the medium from the outside to the inside; however, the microwave-assisted strategy is different, using microwaves to directly heat the reactants, with heat being generated in the reaction medium from the inside to the outside[249,250]. Compared to conventional synthesis techniques, microwave-assisted methods offer advantages in terms of crystal nucleation, morphological size of the MOF, reaction yields, and reproducibility[251-253]. In many research findings, MW radiation has been found to produce smaller-sized MOFs due to enhanced heat and mass transfer capabilities, which usually accelerate the crystal nucleation[254,255]. In 2016, Babu et al. successfully synthesized highly porous 3D MOFs (MOF-205) by MW irradiation[256]. They controlled the reaction time to probe the crystal formation process and applied them for the immobilization of atmospheric CO2 due to their unique physical and structural properties. Chen et al. synthesized MOF-74 (Ni) using MW-assisted, hydrothermal and condensation reflux methods, respectively[257]. By comparison, it was found that MW could shorten the synthesis time from 32 h and 24 h to 1 h, which greatly improved the reaction efficiency. In addition, the MW route produced smaller and more stable products. Relying on the abundant metal sites, it is more conducive to the adsorption of CO2. Wang et al. synthesized robust Cu-MOF using a MW reactor under mild conditions at 60 °C [Figure 19A][258]. The Cu-MOF showed good catalytic activity as a catalyst for the direct catalysis of carboxylation of 1-ethylbenzene and carbon dioxide. Kong et al. produced MOF-303 nanocrystals with a controllable size of 50-500 nm by a MW-assisted method[259]. After doping with methanesulfonic acid (MeSA), MeSA@MOF-303 exhibited high plasmonic conductivity. Although MW-assisted synthesis of MOFs is nowadays a safe and convenient strategy, the lack of reactor engineering in the MW field still hinders the further application of MW technology in synthesizing 3D MOFs[260,261]. Under MW irradiation, the resonant power distribution is uneven and the heating in the MW field is not uniform, which can easily lead to local overheating and hot spots[262]. In 2021, Zhao et al. studied the use of numerical simulations to find out the hot spot variation pattern by exploring the MW input power, cavity size and stirring rate parameters to find out the variation pattern of hot spots [Figure 19B][263]. It was confirmed that adjusting the MW power and cavity structure could help eliminate hot spots and produce MOFs with uniform and regular dimensions. However, the reaction parameters also need to be optimized quite precisely in order to achieve the desired morphology and yields. Compared to conventional heating, microwave heating is rapid, highly concentrated in terms of instantaneous energy and requires no heat transfer. Polar solvents absorb microwave energy and heat up quickly, yet non-polar solvents hardly absorb microwave energy and warm up very slowly. Rapid heating is also a “double-edged sword” and might make it difficult to measure the actual temperature of the sample and maintain a particular temperature.

Figure 19. (A) MW-Assisted Synthesis of Cu-MOF. (B) Synthetic procedure and experimental setup for MIL-88B (Fe) synthesis in the MW field. (A) Adapted with permission[258]. Copyright 2021, John Wiley and Sons. (B) Adapted with permission[263]. Copyright 2021, Elsevier. MOFs: Metal-organic frameworks; MW: microwave.

Self-assembly

The self-assembly method is inspired by nature[264,265]. It is a process of spontaneous aggregation between atoms of a material and/or their orderly arrangements into novel structures. The assembled structures often have properties beyond imagination. Normally, the poor stability is considered to be a negative disadvantage. However, in some cases, instability may also be a positive and beneficial factor[266]. Thus in 2015, Huang et al. were inspired by the template method and prepared H-MOFs by self-assembly using unstable metal-organic assemblies (MOAs) as templates and stable MOFs as bodies[267]. The formation and disappearance of MOAs can be controlled during the self-assembly process due to the sensitivity of the template to moisture and acid [Figure 20A]. Considering that the mesopore size of the generated H-MOFs (~11 nm) is much smaller than that of the added MOAs (370~520 nm), they suggested that there was a process of decomposition or rearrangement of MOAs in the reaction and confirmed the speculation by elemental analysis (EA) and inductively coupled plasma (ICP) emission spectroscopy. The in-situ regenerated MOAs were used as templates to guide the synthesis of H-MOFs, and it was found that MOAs with different structures and complexities could be used as template precursors for the preparation of

Figure 20. (A) Schematic representation for the fabrication of H-MOF. (B) Representative FE-SEM image of a self-assembled superstructure made from TRD ZIF-8 crystals (size 210 ± 10 nm). (A) Adapted with permission[267]. Copyright 2015, Springer Nature. (B) Adapted with permission[273]. Copyright 2017, Springer Nature. MOFs: Metal-organic frameworks; TRD: truncated rhombic dodecahedral; MOA: smetal-organic assemblies.

Sol-gel method

In general, the crystallization of MOFs produces polydisperse microcrystalline powders. There are a large number of voids between the discrete crystals, which can reduce the packing density and thus affect the overall bulk adsorption capacity[274,275]. While these microcrystalline powders are suitable for scientific research, their chemical nature limits the large-scale applicability of MOFs, with a number of inherent technical problems to be solved, such as poor handling, mechanical instability and mass transfer limitations[16,276]. The advent of the sol-gel method, however, provides a new way to avoid the microcrystalline powder state and synthesize MOF monoliths[277,278]. In the case of MOFs, sol-gel methods offer potentially powerful strategies for improving the properties of the material, such as chemical functionalization of pore surfaces or crystal interfaces, hybridization of MOFs with other material types and precise spatial localization and orientation of MOF crystals[279,280]. The term “sol-gel” relates to the chemical process that generates a sol, a colloidal suspension of submicron-sized particles[281]. Although some studies have shown that the MOF gel state is formed by the aggregation of dispersed crystalline nanoparticles in the system through weak non-covalent interactions, the formation mechanism of these materials has generally been poorly investigated. Normally, the primary particles that form the gel need to be small enough to ensure that they can grow at the gel interface during drying[282]. In their study of high density HKUST-1 monomer and UiO-66 in gas absorption, Tian et al. found that the drying temperature was critical to determine whether the MOF gels eventually formed robust and dense monoliths, and that the rate for the drying step must be slow[283,284]. In 2017, Bueken et al. studied a series of Zr-based MOFs (UiO-based series, MOF-808 and NU-1000) and found that three parameters, i.e., metal source, water and concentration of reactants, play a critical role in the formation of gelation[285]. It is easier to produce gels when using ZrOCl2 · 8H2O than ZrCl4 to produce microcrystalline precipitates.

After several years of exploration, the formation mechanism of MOF gel was subsequently generalized and studied in detail by Hou et al. in 2020[286]. The precursor of MOF monoliths is the MOF gel state. The forming process of the gel state is important in relation to the aggregation of MOF nanoparticles, while the monodispersity of MOF nanoparticles is facilitated by controlling the crystallization process. It is known that the crystallization process occurs in supersaturated solutions, and once the solution is supersaturated, nucleation takes place and crystal seeds start to grow. A sufficient decrease in the concentration of reactants signals the cessation of nucleation and crystal growth. The nucleation and crystal growth rates can be determined using the Avrami and Gualtieri models[287,288]. MOF gelation starts with crystal competition between MOF nanoparticles as a result of the rapid formation of a high concentration of nanocrystals in solution [Figure 21]. In the sol-gel method, the MOFs are chemically homogeneous, with small particles and high crystallinity, as the precursors are initially dispersed in the solution to form a low-viscosity solution. The good dispersion of the precursors facilitates the smooth progress of the reaction.

Figure 21. Mechanism of the formation of MOF gels, precipitates and metal-organic gels. Adapted with permission[286]. Copyright 2020, Royal Society of Chemistry. MOFs: Metal-organic frameworks.

Innovation from traditional methods

Since the discovery of MOFs materials in the 1990s, the variety and quantity of MOFs have increased and the methods for synthesizing MOFs have been innovative. With continued exploration, the synthesis of 3D MOFs is no longer limited to a single traditional method, e.g., hydrothermal/solvothermal methods, microwave processing, ultrasonic synthesis, moderator methods, etc. The convergence between different strategies may shed new light on the structure and properties of MOFs. Colloids are microcapsules or microspheres that are consisted of closely packed particles with outer shells[289]. In 2013, Pang et al. inspired by colloids, intentionally pursued MOF colloids, reporting the use of emulsions as soft stencils, allowing the assembly of MOFs polyhedral building blocks (BBs) into hollow 3D structures on their surfaces[290]. Considering that monodisperse BBs are an innate element in the construction of superstructures, in their previous study, they selected tert-butylamines as organic structure directing agents (SDAs) and polyvinylpyrrolidone (PVP) as surfactants to obtain monodisperse BBs under solvothermal conditions[291]. When PVP was replaced by polyoxyethylene (20) sorbitan trioleate (tween-85), some interesting phenomena happened and the cubic BBs spontaneously assembled into spheres. Moreover, the size of the hollow colloid could be controlled by adjusting the amount of tween-85 [Figure 22A-D]. Under the action of the stirring drive, tween-85 can form emulsified droplets, and the prior formation of monodisperse Fe-soc-MOF cubes in the presence of SDAs then spontaneously self-assembles to form a shell structure on the surface of the emulsified droplets. As the droplet evaporates, the template disappears and eventually forms a hollow colloid [Figure 22E].

Figure 22. (A and B) SEM and TEM images of small Fe-soc-MOF hollow colloids prepared by addition of 0.05 mL tween-85. (C and D) SEM and TEM images by adding 0.03 mL of tween-85. (E) Schematic representation of the synthesis and integration of Fe-soc-MOF cubes into hollow colloids. (F) Schematic representation of the synthesis of 3DOSA-ZIF-8 and 3DOSC-ZIF-8. (G) SEM image of 3DOSA-ZIF-8, (H) SEM images of 3DOSC-ZIF-8 at different resolutions. (A-E) Adapted with permission[290]. Copyright 2013, American Chemical Society. (F-H) Adapted with permission[294]. Copyright 2022, American Chemical Society. MOFs: Metal-organic frameworks.

Zheng et al. found that 4,4'-bipyridyl can be used as a coordination modulator to modulate the morphological transformation of [Ni(Tdc)(Bpy)]n MOF from 1D nanofibers to 2D nanosheets and finally to 3D columnar nanocrystals, proposing a dual-ligand-based hard-soft acid-base strategy[292]. The MOFs prepared by this strategy are efficient electrode materials with good stability, providing a general approach for the realization of morphologically/functionally tunable MOFs in the future. In 2021, the Milko group synthesized single crystals of hollow MOFs with a unique appearance by means of acoustic-chemical-solvent thermal conditions[293]. The sonication of the solvent was the key step, and a dimethylformamide (DMF)/chloroform mixture was sonicated for 1.5 h. The resulting free radicals were able to interact with the metal salts to reduce their stability. This process exacerbates the formation of multi-domain crystals with internal structural defects by using single crystals as sacrificial templates, which suggests that sonication can alter the ratio of metal ions to ligands, leading to morphological changes in the resulting MOFs. It is often important to design the nanostructure and porosity of crystalline materials, and the synthesis of MOFs crystals in pre-designed templates often enables more precise control of structural features such as morphology, particle size, porosity and surface regularity.