The Resilience of Rendang Industries During and After Covid 19 Pandemic: A Marketing Collaboration and Supply Chain Management Approach

Research Article

The Resilience of Rendang Industries During and After Covid 19 Pandemic: A Marketing Collaboration and Supply Chain Management Approach

Winda Sartika1*, Budi Hartono2, Hari Dwi Utami2, Lilik Eka Radiati2

1Department of Social Economics, Faculty of Animal Husbandry, Andalas University Limau Manis Campus, Padang, West Sumatra, Indonesia 25164; 2Faculty of Animal Science, Brawijaya University, Malang, East Java, Indonesia 65145.

Abstract | This research was carried out to analyze the resilience of the rendang industry during and after the Covid-19 pandemic through collaboration marketing and supply chain management approaches. Research using the survey method, snowball sampling in the rendang industry with raw beef, and purposive and accidental sampling on the supply chain institutions involved in rendang production. The research respondents comprised 61 respondents from the rendang industry, including suppliers of raw materials, distributors, and consumers of rendang with qualitative and quantitative descriptive data analysis. The results of the study show that the resilience of the beef rendang industry during and after the Covid-19 pandemic caused good collaboration and cooperation between the institution chain involved; supply begins with the provision of beef raw materials in terms of information flow, financial flow, and product flow. Vertical collaboration from rendang raw material suppliers strengthens the supply chain network to distribute rendang products to the end consumers. The supply of rendang raw materials starts from breeders, collectors, wholesalers, and retailers to the rendang processing industry. The rendang industry’s beef price is IDR 115,000.00-IDR 120,000.00 per kilogram, about 7.5% lower than the price for household consumers, IDR 130,000.00 per kilogram. The most efficient marketing channel comprises farmers, collectors, and final consumers, with a marketing efficiency value of 0.94 %. Marketing collaboration and active supply chain institutions involved in the supply of raw materials for the rendang industry can make the rendang industry in Payakumbuh survive in the pandemic Covid19 situation and up this point.

Keywords | Resilience, Rendang Suir, Rendang Tumbuk, Efficiency

Received | March 01, 2023; Accepted | March 25, 2023; Published | May 10, 2023

*Correspondence | Winda Sartika, Department of Social Economics, Faculty of Animal Husbandry, Andalas University Limau Manis Campus, Padang, West Sumatra, Indonesia 25164; Email: winda.sartika@gmail.com

Citation | Sartika W, Hartono B, Utami HD, Radiati LE (2023). The resilience of rendang industries during and after covid 19 pandemic: a marketing collaboration and supply chain management approach. Adv. Anim. Vet. Sci. 11(6): 998-1005.

DOI | https://doi.org/10.17582/journal.aavs/2023/11.6.998.1005

ISSN (Online) | 2307-8316

Copyright: 2023 by the authors. Licensee ResearchersLinks Ltd, England, UK.

This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Introduction

The Covid-19 pandemic, which started at the end of 2019 until 2022, has less impacted the small and medium industries’ development efforts. Erokhin and Gao (2020) suggest various segments affected by the Covid 19 pandemic, such as production agriculture, processing food, transportation, logistics, and product request. Besides that, capital constraints and limitations on raw materials, because of the supply, could make it easier to participate in and influence an existing industry. However, the condition, on the contrary, occurred in the rendang industry in Payakumbuh City when the covid19 pandemic for small and medium industries (SMIs) continued to rendang struggling to grow their business because of sufficient rendang request ok. SMIs are evidenced by the increase in the number of Rendang SMIs by 33%, from 43 SMIs in 2019 to 57 SMIs in 2022 (Disnakperin, 2021). Ramanathan et al. (2022) stated that the Covid19 pandemic situation had made global supply chains and businesses, including local small and medium enterprises, struggle to meet consumer demand, which has never happened before.

The resilience of the rendang industry is inseparable from the availability of raw beef, an essential element in the rendang industry. Beef production in Payakumbuh City in 2016 was 921,565 kg, decreasing to 910,244 kg in 2020. The opposite condition occurred in beef consumption, where beef consumption in Payakumbuh City increased from 2.16 kg/cap/year in 2016 to 2.60 kg/cap/year in 2021 (BPS, 2021). The increase in consumption in Payakumbuh City was also not followed by an increase in the number of slaughtered cattle; from 2015 to 2020, there was an average reduction in the slaughtering of cattle by 0.14% per year. In 2021, the average number of beef cattle at the Payakumbuh City Modern Slaughterhouse (RPH) was nine cows per day. The decrease in the number of cuts impacts the availability of beef in the market where the availability of beef is insufficient, so it affects the production process of the rendang industry when demand increases. If this uncertainty continues, it will impact the marketing of rendang products. Oyeagu (2021) also stated that during the Covid-19 pandemic, there was a disturbance in the livestock supply chain. Supply of cattle and quantity cutting experienced a decline during the covid 19 pandemic in Payakumbuh City, which caused a limited amount of availability of meat cows for the beef industry.

Rendang products with beef as the raw material have now been innovated into three types of rendang variants: 1) sliced beef rendang, square in shape with relatively wet spices; 2) shredded rendang (suir/runtiah), in the form of elongated meat fibers and seasoned with dry rendang like shredded meat; and 3) rendang tumbuk, shaped like meatballs with a unique rendang spice blend (Figure 1). Rendang product innovation also increases the amount of beef used as the primary raw material of rendang products. The Covid-19 pandemic has positively impacted requests for rendang products in Payakumbuh City. Rendang products that have more power save longer compared to other processed food product, making rendang one solution to fulfilling the need of the food family when social distancing rules are implemented by the government.

It is suspected that the resilience of the rendang industry amid the Covid-19 pandemic is inseparable from the support of all institutions involved in the supply chain of the raw material industry. The supply chain includes all activities related to the flow and transformation of goods from the stage of raw materials to goods for end users and information on the flow of materials to and from the supply chain (Seuring & Muller, 2008). Knowledge and understanding of supply chain structures, physical and informational, are important elements of supply chain resilience (Hong & Choi, 2002). Frederico (2020) suggests that supply chain maturity and technology can collaborate to create a more resilient supply chain in situations of uncertainty. like the Covid19 pandemic. Michel-Villarreal (2022) explains the concept of supply chain resilience and how it can have a positive impact if implemented effectively with management chain supply. Prihatmanto (2018) explains that supply chain management (SCM) can analyze problems of imbalances between supply and demand due to differences in time, distance, and uncertainty of existing resources. The research aims to analyze the resilience of the rendang industry during and after the Covid 19 pandemic with a collaborative approach to marketing and supply chain management so that the rendang industry can continue to grow in the next century.

Materials and methods

Time and Place of Research

The research was conducted from September 2021 to February 2022 in Payakumbuh City, West Sumatra, Indonesia. The location selection was conducted using a purposive sampling technique because the City of Payakumbuh is a production center for the rendang industry in West Sumatra Province, known as the Payakumbuh Rendang City icon.

Research Methods

The survey method was used for the research. The snowball sampling technique selected respondents from the rendang industry with raw meat materials. The purposive sampling technique was for the respondent’s retailer respondents and collectors, and the accidental sampling technique was for beef cattle breeders’ respondents. Supply chain data collection begins with critical informants, namely beef rendang industry owners, through observation techniques, interviews, and questionnaire assistance. There were 61 respondents in the study, consisting of 12 SMIs rendang made from beef, 12 collectors, six beef retailers, 30 livestock, and one butcher at the Payakumbuh City Slaughterhouse (RPH).

Data Analysis Method

Data analysis begins by reviewing all available data from various research sources, such as observations, interviews, and documents related to the beef supply chain. The analysis of supply chain management data was carried out descriptively based on material flow, financial flow, and information flow. Analysis Supply chain management is studied through the marketing margin value of beef as the primary raw material for the rendang industry.

Where:

MP: marketing margin (Rp/kg)

Pr: price at consumer level (Rp/kg)

Pf: price at farm level (Rp/kg)

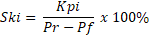

Sudiyono (2002); Sikone et al. (2022) put forward the profit share of the marketing agency and the total marketing costs, and the formula can be used:

Where:

Kpi: profit of marketing agent the- i (Rp/kg)

Kbi: marketing costs the- i (Rp/kg)

Skis: advantages of marketing agency the- i (Rp/kg)

Sbi: share marketing costs the- i (Rp/kg)

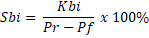

The part that the producer receives for the selling price to the consumer is called the producer’s share, where the formula can calculate the value: (Dinesh and Sharma, 2019)

Results and Discussion

Rendang Industry Resilience

The resilience concept is considered an approach with superiority operation to reach excellence in competitive in a dynamic environment (Mishra et al., 2022). The situation is not unexpected, and with unforeseen pandemic conditions, once good, the industry of food and drink and other industries in this world prepare themselves to face existing disturbances. Before the pandemic hit, the rendang industry in Payakumbuh City was already known nationally, so it owned its rendang product’s market share. The covid pandemic that hit from 2020-2022 also influenced the production of rendang because of disturbances in the provision of the raw materials for rendang, like beef. The decline in the amount of meat sold on the market, combined with restrictions on interaction outside of space (social distancing) creates a constraint in the provision of raw material. Great relationships between the institutions involved in the supply chain and the rendang industry have become a support system in producing rendang during the current pandemic. According to DuPont (2014), the most important component of a resilience supply chain is communication infrastructure, with affects the fulfillment of human and material assets. The industry is expected to survive disturbances with various alternatives, such as designing resilience systems utilizing diversity, efficiency, adaptability, and cohesion. Good coordination and cooperation in supply chain management can maintain the supply of raw materials so that the production process continues and the marketing of rendang products to consumers continues. DuPont (2014) describes resilience supply chain is also primarily determined by the process used by the company to obtain superior operational and capability capabilities in the supply chain in maintaining performance during pandemic hit.

Supply Chain Management of Rendang Industry

Supply chain management helps manage and provide raw materials for Rendang SMIs to produce quality rendang. The actors supplying raw materials to the rendang distribution process in the beef rendang supply chain in Payakumbuh consist of farmers, collectors, wholesalers, and beef retailers. Meanwhile, products in the beef rendang industry start from upstream to downstream, and financial flows will flow from downstream to upstream. Information flow, will flow from upstream to downstream and vice versa from downstream to upstream (Figure 2). Warella et al. (2021) argued that supply chain management would be successful if the institutions involved cooperated and shared information. Emhar et al. (2014) regulation of the flow of products (goods), finance, and information in the supply chain is essential in livestock and beef commodities because of the perishable characteristics of beef products and fluctuating prices.

Information Flow

The flow of information starts from suppliers (upstream) to end users (downstream) and vice versa. Information from upstream to downstream regarding the availability of beef raw materials, the required quality and quantity of beef, the price of raw materials, and the selling price of rendang to consumers. Information on the availability of rendang products and the selling price of rendang products from rendang SMIs is also very much needed by distributors for their needs during rendang sales transactions. Information that is quite important in the flow of information is the status of the delivery of raw materials or rendang products to consumers because this can affect the velocity of capital turnover for SMIs rendang. Ismareni (2019) states that the flow of information is a flow from upstream to downstream and vice versa, from downstream to upstream. Information flow related to live beef stock, beef demand, live cattle prices, beef prices, and information related to slaughter rules. Information on sales of rendang products for end consumers without intermediary distributors varies widely; any information regarding product availability, methods of payment, and the selling price of each variant of beef rendang (sliced rendang, shredded rendang, and mashed rendang) can also be seen on social media or e-commerce that has become a rendang SMIs partner. Munizu (2017) suggests that information technology plays a role in strengthening cooperation and coordination in the supply chain.

Products Flow

The flow of ingredients for beef rendang starts from buying beef to slaughtering and selling beef to consumers, including SMIs rendang as raw material for production. The flow of rendang products is preceded by the purchase of raw beef materials from retailers. The availability of beef at retailers starts with the purchase of cattle by collectors and wholesalers from beef cattle breeders. The cows that have been purchased will then be slaughtered at the Slaughterhouse (RPH), and the resulting carcasses will be directly distributed to retailers in Payakumbuh’s traditional markets. Beef is then distributed to SMIs rendang as raw material for beef rendang production. The rendang produced will be distributed to end consumers both online and offline. Offline sales of rendang products are carried out at every rendang SMIs outlet or at partner SMIs with outlets. At the same time, online sales are carried out through social media networks and e-commerce. Ghofar et al. (2020) stated that companies increasingly need supply chain integrators who can work closely with different suppliers and customers to integrate and coordinate interdependent supply chain activities to minimize costs and improve customer service.

Financial Flows

Financial flows from downstream to upstream are the opposite of material flows. The financial flow from consumers to distributors to SMIs Rendang can be done in cash or non-cash according to the agreement made during the transaction. Cash payments for rendang products can be made at the shop where the beef rendang was purchased, while non-cash payments can be made via transfer. Meanwhile, payments for rendang products and shipping costs for products made on social media or e-commerce can be made by transfer. The price for the sliced beef rendang product is IDR 60,000-82,000 per 250 grams. Whereas the price of rendang suir is IDR 59,000-82,000 per 120-250 grams, and meatballs rendang is IDR 60,000-75,000 per 200-250 grams. Each SMIs has a different price and packaging variant, which makes the selling price of its products different. Financial flows from distributors or consumers significantly affect production activities as a form of capital turnover for raw materials or materials that have been produced. Sikone et al. (2022) argue that financial flows aim to expedite the movement of transaction flows. Keban et al. (2020) said that payment for buying and selling cattle is made in cash (cash and carry). The financial flow of beef used as raw material for the rendang industry begins when breeders bring the cattle to the livestock market to be sold. The cost of transporting livestock per head is IDR 100,000.00-IDR 150,000.00, with an additional fee of IDR 10,000 per head paid in cash when entering the cattle market. The sale of cattle by breeders to takers is carried out using a price estimation system agreed upon by both parties, with an estimated selling price per live weight of IDR 50,000-55,000 per kilograms. Keban et al. (2020) said that payment for buying and selling cattle is made in cash (cash and carry).

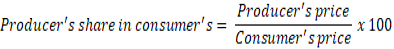

Marketing Collaboration

The scope of supply chain collaboration can be divided into two categories: vertical and horizontal. Barratt (2004) identified SC collaboration in the vertical category as the internal collaboration of SC members, such as with customers, across internal functions in the supply chain and with suppliers, while the horizontal category is SC collaboration, including competitors (internal and non-competitors) such as the sharing of production capacity (Figure 3). Hidayat et al. (2015); Mamad and Chahdi (2013) suggested that trust significantly influences supply chain performance and is an essential actor in the collaboration of supply chain members. Complete internal collaboration of the enterprise supply chain must integrate purchasing, manufacturing, logistics, and marketing activities, especially in sharing information, sharing resources, setting common goals, and having a common vision for each department. For effective results in a collaborative supply chain, internal collaboration must be linked to external collaboration (supplier and customer collaboration) regarding relationships, information sharing, and processing integration (Angerhofer & Angelides, 2006).

A. Suppliers

Suppliers to the beef rendang industry in Payakumbuh consist of farmers, wholesalers, and retailers. Breeders sell cattle to collectors or wholesalers at the farmer’s house or the Payakumbuh City livestock market, which operates every Sunday from 08.00 to 15.00 WIB. Collector traders are suppliers for wholesalers. Collector traders are often encountered when buying and selling livestock at the Payakumbuh City livestock market. Collector traders can immediately sell the livestock obtained during livestock market transactions if the selling price of the livestock has provided a small profit for the collector traders. In one transaction at the livestock market, collectors can sell 1-3 cows per day. The amount of cattle sold during the pandemic was relatively lower than before or after the pandemic, reaching 5-10 tails per day. Pricing from farmers to collectors and wholesalers uses the “marosok” system, namely, standard pricing typical of the people of West Sumatra based on estimates of body weight and the amount of beef to be obtained in one sarong or piece of cloth. Closing the hand is a code to estimate the selling price of the cow. On average, suppliers of cattle to wholesalers who become suppliers of beef retailers to traditional markets in Payakumbuh City have a cooperative relationship in supplying cattle. Most wholesalers are partner breeders who have worked together to ensure the availability of cattle during the slaughtering process. The cattle selected for the slaughter process are bulls with a body weight between 300 until 500 kilograms. Bulls have more beef than cows. The cattle available for slaughter are then taken to the Slaughterhouse (RPH), with the transportation costs borne by the wholesalers or collectors who buy the cattle from the farmers’ farms.

B. Consumers

Consumers are the spearhead in the production of a product. Consumer demand will affect the productivity and sustainability of the rendang industry. The demand for rendang raw materials increased during the Covid-19 pandemic because rendang products can be stored for a relatively long time. Besides that, many scales in the rendang industry also experienced enhanced turnover sales during the covid 19 pandemic. The beef rendang industry produced by rendang SMIs in Payakumbuh City has now produced three beef rendang variants with market segments ranging from children to adults. Beef rendang, which is commonly called cut rendang, has now come with two other innovations, namely, rendang suir (runtiah) and rendang tumbuk (meatballs). Sabahi and Parast (2020) explain that companies with a more innovative environment will be more resistant to disruption because innovation, directly and indirectly, helps companies strengthen capabilities that positively affect risk management capabilities. Rendang innovation indirectly affects and increases the production and demand for rendang in Payakumbuh. The marketing collaboration used by various Rendang SMIs in Payakumbuh City is quite varied; consumers can choose and know the types of products to buy through the Rendang SMIs’ website or through social media and e-commerce that have collaborated with Rendang SMIs. The development of constructive information technology in distributing beef rendang production to all national and international consumers. The variant of rendang slice still becomes a favorite product among consumers, both local and foreign with the condition moment or after the covid19 pandemic, while variants of suir rendang and meatballs rendang are newly consumed by local consumers.

C. Organization

Supply chain support organizations such as banking institutions and government agencies have also influenced the development of the rendang industry in Payakumbuh City to date. Payakumbuh Municipal Government actively promotes the results of the rendang industry through various media and official events. In addition, the Payakumbuh Municipal Government also helps every rendang SMIs with a distribution permit to continue improving the quality of its industry with various training and outreach activities. Banking institutions also help increase business scale by providing capital support through loans to SMIs in need. Support and collaboration between these institutions can support Rendang SMI’s survival amidst the Covid19 pandemic. Irawan (2020) explains that collaboration, acc-

Table 1: Farmer’s Share, Distribution Margin, Marketing Efficiency

| Marketing Institutions | Share (%) | Distribution Margin (%) | Efficiency Marketing (Ep) | ||

| Ski | Sbi | Ski | Sbi | (%) | |

| Channel I | |||||

|

Farmers Collecting traders Wholesalers Meat Retailer |

86,37 3,06 6,93 2,28 |

0,54 0,54 1,37 |

22,44 50,83 16,70 |

3,96 3,96 2,11 |

1,37 |

| Channel II | |||||

|

Farmers Wholesalers Meat Retailer |

86,37 10,03 2,28 |

1,03 0,29 |

73,60 16,70 |

7,59 2,11 |

1,32 |

| Channel III | |||||

|

Farmers Collecting traders Meat Retailer |

86,37 2,95 9,74 |

0,65 0,29 |

21,62 71,49 |

4,79 2,11 |

0,94 |

| Channel IV | |||||

|

Farmers Meat Retailer |

86,37 12,35 |

1,28 |

90,63 |

9,37 |

1,28 |

-ess, and relationships with third parties, such as financial institutions, are needed to run a business efficiently and increase productivity and competitiveness

D. Competitors

The number of rendang SMIs in Payakumbuh City, which are competitors in each existing industry, increases the productivity level of rendang SMIs to keep trying. It was stated that each rendang SMIs has a distinctive rendang taste and a different marketing strategy so that it can continue to maintain its existence in the rendang industry.

Marketing Efficiency

Supply chain resilience can also be seen in the efficient supply of raw materials for the rendang industry and the active role of marketing agencies in distributing raw materials for rendang. Dinesh and Sharma (2019) state that the costs incurred in marketing livestock products include transportation, handling, market levies, loading and unloading, and labor costs for the packing process. Channel marketing in the material raw used rendang industry before the covid 19 pandemic to this time consists of four channels. The first marketing channel is the longest and involves many marketing agencies, such as breeders, collectors, wholesalers, retailers, and end consumers. Simona et al. (2016) stated that the shorter the marketing chain, the greater the profit for farmers, and the longer the marketing chain, the fewer profits farmers get. The profit share of farmers in the first channel is 86.37%, with a marketing efficiency value of 1.37%. Wholesalers in the second channel directly distribute livestock products obtained from breeders to retailers in the form of carcasses. The cattle to be marketed have a live weight of 400 kilograms, a selling price at the wholesale level of IDR 21,660,000.00/head, and a carcass weight percentage of 57%. The marketing efficiency of the second marketing channel is 1.32 %, with a margin distribution share for wholesalers of 73.60% and a share for retailers of 16.70%.

The third channel is the most efficient marketing channel at 0.94 %. The third channel is more efficient because the costs incurred in marketing beef cattle are less than channels one, two, and four (Table 1). In channel three, collectors sell beef directly to retailers without intermediary wholesalers. Widaningsih et al. (2022) state that the shorter the marketing chain, the greater the profit farmers get, and vice versa. The high selling price of the product makes the collectors enjoy a marketing profit of IDR 2,166,000.00 per animal. The fourth channel is the shortest in the beef supply chain, consisting of farmers, retailers, and consumers. Retailers buy the cows directly from the farmer’s barn by bearing transportation costs, slaughtering fees, and feed. The fourth channel is the shortest but less efficient than the third channel because the costs incurred are higher than IDR 284,000.00 per animal. The fourth channel of existing marketing in the provision of raw material in the rendang industry is efficiently based on the results calculation of mark efficiency marketing; however, the most efficient channel for application is the third channel of marketing with mark efficiency marketing by 0.94%.

Conclusion

The resilience of the rendang industry during and after the Covid-19 pandemic is supported by marketing collaboration and good coordination between supply chain actors so that information flow, finance, and beef rendang products can arrive at the end of the consumer journey. Marketing and collaboration in supply chain management with excellent capability to maintain the rendang industry to survive in the situation of the covid 19 pandemic crisis. Vertical collaboration between suppliers and end consumers can sustain the current small and medium-scale rendang industry. Livestock marketing is the most efficient cow, are channel marketing is the third, namely: breeders, collectors, retailers, and consumers. The efficiency of the beef marketing channel can minimize the costs incurred in beef distribution and increase beef marketing margins as a raw material for the rendang industry.

Acknowledgments

Thank you to the Faculty of Animal Husbandry, Andalas University, Faculty of Animal Husbandry, Universitas Brawijaya. This research finally received financial support from the Ministry of Education and Culture of the Republic of Indonesia through the BPPDN funding contract number 2350/UN10.F40/PP/2019. Thanks also to the Provincial Government of West Sumatra, especially the City Government of Payakumbuh, for providing permission and the opportunity to research the site.

Conflict of interest

All authors have no conflict of interest.

novelty statement

The novelty of this research is the resilience of the small and medium industries (SMIs) Rendang made from beef in Payakumbuh City during and after the COVID-19 pandemic. This research can be an example and motivation for other SMIs to maintain their business amidst unexpected disturbances.

Author Contributions

WS analyzes data, designs research, and writes manuscripts. BH, HDU, and LER designed the study and prepared the manuscript.

References

Angerhofer BJ, Angelides MC (2006). A model and a performance measurement system for collaborative supply chains. Decision Support Syst. 42: 283-301. https://doi.org/10.1016/j.dss.2004.12.005

Barratt M (2004). Understanding the meaning of collaboration in the supply chain. Supply Chain Manag. 9: 30-42. https://doi.org/10.1108/13598540410517566

BPS (2021). Payakumbuh dalam Angka 2021. Badan Pusat Statistik (BPS). Sumatera Barat

Dinesh V, Sharma A (2019). Marketing Margin, Price Spread and Marketing Efficiency Analysis on Different Poultry Farms. Int. J. Curr. Microbiol. Appl. Sci. 8(6): 1039-1046. DOI: https://doi.org/10.20546/ijcmas.2019.806.127

Disnakperin (2021). Daftar Industri Kecil dan Menengah (IKM) Rendang Kota Payakumbuh tahun 2021. Dinas Tenaga Kerja dan Perindustrian Kota Payakumbuh. Sumatera Barat.

DuPont (2014). Managing for operational excellence: supply chain thought leadership at DuPont case study integrated operations. US Resilience Project: 1-5, available at: https://usresilienceproject.org/wp-content/uploads/2014/09/pdf-USRP_DuPont_CS_022912.pdf (accessed 5 April 2023)

Emhar A, Aji JMM, Agustin T (2014). Analisis rantai pasok daging sapi di Kabupaten Jember. Berkala Ilmiah Pertanian. 1(3): 53-61.

Erokhin V, Gao T (2020). Impacts of COVID-19 on trade and economic aspects of food security: evidence from 45 developing countries”, Int. J. Environ. Res. Pub. Health. 17 (6): 5775, https://doi.org/10.3390/ijerph17165775.

Frederico GF (2021). Towards a Supply Chain 4.0 on the post-COVID-19 pandemic: a conceptual and strategic discussion for more resilient supply chains. Emerald Publishing Limited. 15(2): 94-104. https://doi.org/10.1108/RAMJ-08-2020-0047

Ghofar A, Kundarto M, Sugandini D, Ekawati T, Amallia BA (2020). Perspektif manajemen rantai pasokan: Kapabilitas strategis. Yogyakarta.

Hong Y, Choi TY (2002). Unveiling the structure of supply networks: case studies in Honda, Acura and Daimler Chrysler. J. Operations Manag. (20): 469-93. https://doi.org/10.1016/S0272-6963(02)00025-6

Irawan D (2020). Peningkatan Daya Saing Usaha Mikro Kecil Dan Menengah Melalui Jaringan Usaha. Coopetition: J. Ilmiah Manajemen. 11(2): 103–116. https://doi.org/10.32670/coopetition.v11i2.82

Ismareni AM (2019). Kajian Rantai Pasok dan Pemasaran Daging Sapi Di Kabupaten Mempawah. Jurnal Social Economic of Agriculture, 7(1). http://dx.doi.org/10.26418/j.sea.v7i1.30758

Keban A, Niron SS, Lole UR (2020). Struktur dan peran aneka lembaga dalam rantai pasok ternak dan daging sapi potong di Provinsi Nusa Tenggara Timur (structure and role of of various institutions in supply chain of cattle and beef comodities in East Nusa Tenggara Province). J. Nukleus Peternakan. 7(2): 139-146. https://doi.org/10.35508/nukleus.v7i2.3097

Hidayat R, Hudha K, Akhmad S (2015). Effects of Supplier-Manufacturer Relationships on Supply-Chain Performance of Manufacturing Industries in Indonesia. Makara J. Technol., 19 (2): 2. https://doi.org/10.7454/mst. v19i2.3034

Mamad M, Chahdi FO (2013). The factors of the collaboration between the upstream supply chain actors: case of the automotive sector in Morocco Int. Business Res. 6(11): 15–28. https://doi.org/10.5539/ibr.v6n11p15.

Michel-Villarreal R (2022). Towards sustainable and resilient short food supply chains: a focus on sustainability practices and resilience capabilities using case studies. Brit. FoodJournal. https://doi.org/10.1108/BFJ-09-2021-1060

Mishra R, Singh RK, Subramanian N (2022). Impact of disruptions in agri-food supply chain due to COVID-19 pandemic: contextualized resilience framework to achieve operational excellence. Int. J. Logistics Manag., 33 (3): 926-954. https://doi.org/10.1108/IJLM-01-2021-0043

Munizu M (2017). Pengaruh kepercayaan, komitmen, dan teknologi informasi terhadap kinerja rantai pasokan (Studi kasus SMIS pengolah buah markisa di Kota Makassar). J. Manajemen Agribisnis, 14(1): 32-32. https://doi.org/10.17358/jma.14.1.32

Oyeagu CE, Ezeuko AS, Lewu FB, Akuru EA, Ogwuegbu MC, Osita CO, Ani AO, Mlambo V (2021). The impact of Covid-19 on the livestock industry and the way forward: A review. Adv. Anim. Vet. sci. 9(6): 941-955. http://dx.doi.org/10.17582/journal.aavs/2021/9.6.941.955

Prihatmanto BH (2018). Supply Chain Management, Ilmu Pengetahuan, Strategi dan Praktik. PT Elex Media Komputindo. Jakarta.

Ramanathan U, Aluko O, Ramanathan R. (2022). Supply chain resilience and business responses to disruptions of the COVID-19 pandemic. Benchmarking: An Int. J., 29 (7): 2275-2290. https://doi.org/10.1108/BIJ-01-2021-0023

Sabahi S, Parast MM (2020). Firm innovation and supply chain resilience: a dynamic capability perspective. Int. J. Logist. Res. Applicat. Taylor and Francis. 23(3):254-269. http://doi.org/10.1080/13675567.2019.1683522

Seuring S, Müller M (2008). From a literature review to a conceptual framework for sustainable supply chain management. J. Cleaner Prod. 16 (15): 1699-1710. https://doi.org/10.1016/j.jclepro.2008.04.020

Sikone HY, Hartono B, Suyadi, Nughroho BA (2022). Supply chain analysis of cattle market participants in north central Timor regency. Adv. Anim. Vet. sci. 10(4): 811-820. http://dx.doi.org/10.17582/journal.aavs/2022/10.4.811.820

Simona LF, Kakisiana LO, Johana M, Luhukay (2016). Sistem pemasaran daun sayur di pasar modern (hypermart) dan pasar tradisional. Agrillan. 4(1): 46-56

Sudiyono A (2002). Agricultural Marketing. University of Muhammadiyah Malang, Malang.

Warella SY, Hasibuan A, Yudha HS, Sisca S, Mardia M, Kuswandi S, Prasetio A (2021). Manajemen Rantai Pasok. Yayasan Kita Menulis

Widaningsih N, Hartono B, Utami HD, and Rohaeni ES (2022). Swamp buffalo marketing transformation (Bubalus bubalis carabauesis) digital-based marketing: cases in Hulu Sungai Utara regency, South Kalimantan province. Adv. Anim. Vet. Sci. 10(12): 2546-2554. http://dx.doi.org/10.17582/journal.aavs/2022/10.12.2546.2554

To share on other social networks, click on any share button. What are these?