Analysis of intensification of zeolite drying on a vibrating conveyor dryer with infrared emitters

DOI:

https://doi.org/10.15587/2706-5448.2023.279032Keywords:

zeolite drying, dryer, heat losses, radiation drying, infrared radiation, granular materialAbstract

The object of the research is the drying process of zeolite. The work is dedicated to analyzing an effective method for intensifying the drying process of zeolite while preserving its structural integrity. For the given task, it was necessary to choose a promising drying method with minimized heat loss and preservation of the quality indicators of zeolite. Zeolite has a wide range of applications, including soil improvement, mineral fertilizer for plant growth, dietary supplement for animal feed, air, and water purification. The crucial process for obtaining high-quality natural zeolite is the drying process. In its natural state, zeolite contains moisture, and an excess of it can deteriorate its consumer properties. Therefore, considering the best and most efficient method of zeolite drying is a promising task today.

There is no available data on drying zeolite using radiation methods in the literature. Typically, this material is dried in rotary dryers. However, this drying method often results in a significant percentage of zeolite being crushed into dust. Many industries require a granular structure for zeolite. With radiation drying, this drawback is absent or the percentage of crushed zeolite into dust is minimal.

The main methods of drying zeolite have been examined, revealing a fact that indicates an incorrect approach to the drying process. Factors influencing the deterioration of zeolite's quality during drying have been analyzed. These factors have several drawbacks that affect the final product, namely: crushing zeolite into powder, over-drying, which affects its quality and poses a general scientific problem. The drawbacks of drying zeolite using the main methods have been identified.

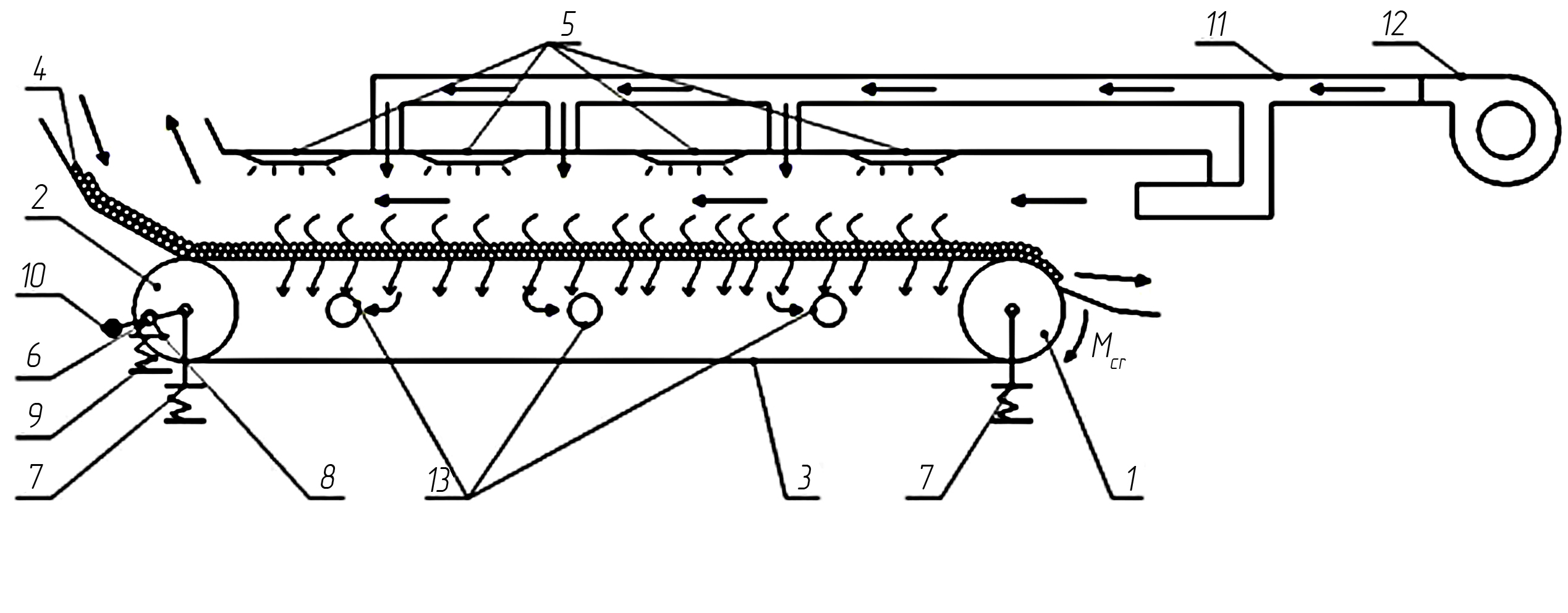

The authors have developed a dryer design that minimizes the deterioration of the mentioned qualitative characteristics of zeolite, addressing an important scientific and technical challenge of creating an efficient and environmentally friendly method of zeolite drying using infrared radiation energy and the development of appropriate equipment. The proposed dryer has suggested applications in various fields.

References

- Shevchenko, O. V. (2010). Vykorystannia enerhozberihaiuchykh tekhnolohii v krainakh YeS: dosvid dlia Ukrainy. Analitychna zapyska. Natsionalnyi instytut stratehichnykh doslidzhen.

- Eroglu, N., Emekci, M., Athanassiou, C. G. (2017). Applications of natural zeolites on agriculture and food production. Journal of the Science of Food and Agriculture, 97 (11), 3487–3499. doi: https://doi.org/10.1002/jsfa.8312

- Huang, D., Yang, P., Tang, X., Luo, L., Sunden, B. (2021). Application of infrared radiation in the drying of food products. Trends in Food Science & Technology, 110, 765–777. doi: https://doi.org/10.1016/j.tifs.2021.02.039

- Kudra, T., Mujumdar, A. S. (2009). Advanced Drying Technologies. CRC Press.

- Nawaz, Z., Xiaoping, T., Wei, X., Wei, F. (2010). Attrition behavior of fine particles in a fluidized bed with bimodal particles: Influence of particle density and size ratio. Korean Journal of Chemical Engineering, 27 (5), 1606–1612. doi: https://doi.org/10.1007/s11814-010-0240-5

- Oleskiv, N. B., Myrovych, O. V., Oleskiv, B. S. (2008). Pat. No. 41811. Ustanovka dlia sushinnia sypkykh materialiv. MKP F26B 3/30 (2006.01). No. u200815192; declareted: 29.12.2008; published: 10.06.2009, Bul. No. 11.

- Oleskiv, N. B., Myrovych, O. V., Oleskiv, B. S. (2019). Pat. No. 137307. Prystrii dlia sushinnia materialiv. MKP F26B 3/30 (2006.01). No. u201904290; declareted: 22.04.2019; published: 10.10.2019, Bul. No. 19.

- Palamarchuk, I. P., Bandura, V. M., Palamarchuk, V. I. (2014). Pat. No. 87767. Vibratsiina konveierna susharka z infrachervonymy vyprominiuvachamy. Derzhavna sluzhba intelektualnoi vlasnosti Ukrainy. MKP F26B 17/00, B01J 2/26 (2006.01). No. u201302520; declareted: 28.02.2013; published: 25.02.2014, Bul. No. 4.

- Khomchuk, A. F., Tsurkan, O. V., Herasymov, O. O., Hrabiuk, Ye. O. (2010). Pat. No. 55923. Ustanovka dlia sushinnia sypuchykh materialiv. MKP F26B 17/00. No. u201008536; declareted: 08.07.2010; published: 27.12.2010, Bul. No. 24.

- Lu, C., Tian, X., Guorui, H., Yuyuan, Q. (2022). Pat. No. 210180009. Nano material radiation drying equipment. Jiangsu Jinchuang atomic cluster tech institute.

- Novokhat, O. A., Marchevskyi, V. M. (2018). Protses sushinnia fliutynhu iz zastosuvanniam enerhii infrachervonoho vyprominiuvannia. Kyiv: KPI im. Ihoria Sikorskoho, 201. Available at: https://core.ac.uk/reader/323534229

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Vitalii Kushniruk, Oleh Novokhat

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.