Revealing the influence of ultrasonic processing on the kinetic parameters of convective and combined drying of raw apple materials

DOI:

https://doi.org/10.15587/1729-4061.2023.276748Keywords:

apple raw materials, sonication, convective drying, combined drying, direct electric heatingAbstract

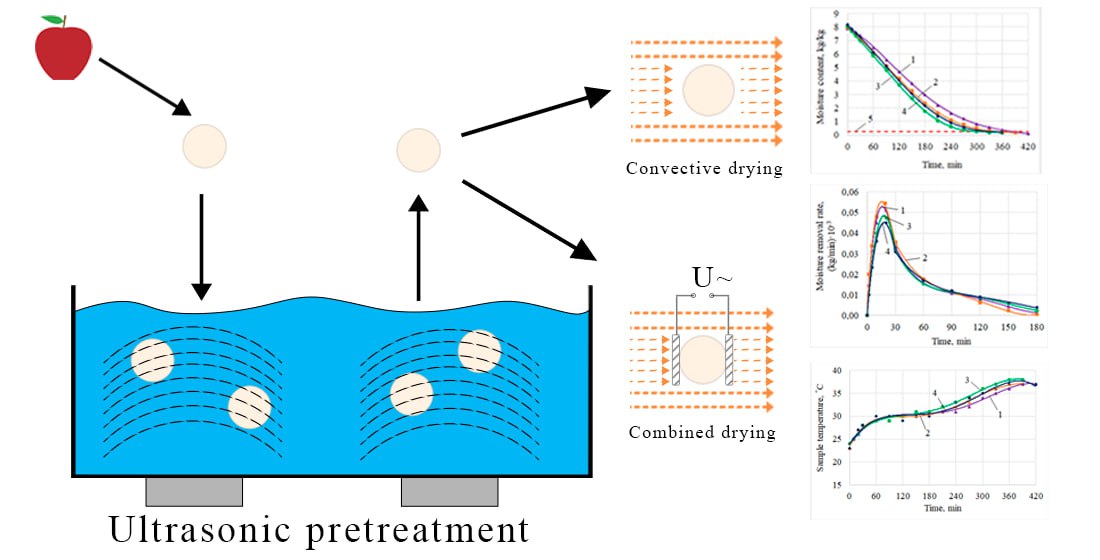

The object of research is the process of convective and combined drying of apple raw materials treated before dehydration in an ultrasonic bath. The use of pretreatment solves the issue of intensifying the dehydration process and maintaining the quality of the product.

Sonication for 5 min reduces the dehydration process by 13.7 %, and at 10 min processing – by 27.8 % compared to traditional convective drying. With increasing processing time to 20 minutes, the dehydration rate deteriorates.

Sonication of raw materials for 5 minutes under combined heating does not intensify the dehydration process, and within 10 and 20 minutes it reduces the efficiency of moisture removal. When processed for 10 minutes, the time to reach the final moisture content is increased by 17.2 %, and at 20 min – by 23.4 % compared to control samples.

Regardless of the processing time, there is a decrease in the maximum temperature of the samples in the combined drying process. When processed for 5 minutes, the maximum temperature of the samples decreased by 4.3 %, and with 10 and 20-minute processing – by 8.6 % and 12 % compared to the temperature of samples without sonication.

The results are explained by the "sponge effect" caused by ultrasonic vibrations and the phenomenon of cavitation that occurs in the liquid during the action of the ultrasonic field.

The peculiarity of the pre-sonication before drying is the possibility to intensify the convective dehydration process without increasing the heat carrier's temperature. The use of this type of processing in a combined energy supply will solve the problem of preserving the quality of the finished product by reducing the maximum temperature of the raw material.

The research reported here could be a prerequisite for practial design of an energy-efficient electrical system for drying fruit and vegetable raw materials.

References

- Chandramohan, V. (2020). Convective drying of food materials: An overview with fundamental aspect, recent developments, and summary. Heat Transfer, 49(3), 1281–1313. doi: https://doi.org/10.1002/htj.21662

- Defraeye, T., Verboven, P. (2017). Convective drying of fruit: Role and impact of moisture transport properties in modelling. Journal of Food Engineering, 193, 95–107. doi: https://doi.org/10.1016/j.jfoodeng.2016.08.013

- Bhatta, S., Stevanovic Janezic, T., Ratti, C. (2020). Freeze-Drying of Plant-Based Foods. Foods, 9 (1), 87. doi: https://doi.org/10.3390/foods9010087

- Ma, Y., Yi, J., Jin, X., Li, X., Feng, S., Bi, J. (2022). Freeze-Drying of Fruits and Vegetables in Food Industry: Effects on Phytochemicals and Bioactive Properties Attributes - A Comprehensive Review. Food Reviews International, 1–19. doi: https://doi.org/10.1080/87559129.2022.2122992

- Zhou, X., Wang, S. (2018). Recent developments in radio frequency drying of food and agricultural products: A review. Drying Technology, 37 (3), 271–286. doi: https://doi.org/10.1080/07373937.2018.1452255

- Huang, D., Yang, P., Tang, X., Luo, L., Sunden, B. (2021). Application of infrared radiation in the drying of food products. Trends in Food Science & Technology, 110, 765–777. doi: https://doi.org/10.1016/j.tifs.2021.02.039

- Fan, K., Zhang, M., Mujumdar, A. S. (2017). Application of airborne ultrasound in the convective drying of fruits and vegetables: A review. Ultrasonics Sonochemistry, 39, 47–57. doi: https://doi.org/10.1016/j.ultsonch.2017.04.001

- Savoiskyi, O., Yakovliev, V., Sirenko, V. (2021). Determining the kinetic and energy parameters for a combined technique of drying apple raw materials using direct electric heating. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 33–41. doi: https://doi.org/10.15587/1729-4061.2021.224993

- Yadav, A. K., Singh, S. V. (2012). Osmotic dehydration of fruits and vegetables: a review. Journal of Food Science and Technology, 51 (9), 1654–1673. doi: https://doi.org/10.1007/s13197-012-0659-2

- Shete, Y., Chavan, S. R., Champawat, P., Jain, S. (2018). Reviews on osmotic dehydration of fruits and vegetables. Journal of Pharmacognosy and Phytochemistry, 7 (2), 1964–1969. Available at: https://www.phytojournal.com/archives/2018/vol7issue2/PartAB/7-2-141-966.pdf

- Ciurzyńska, A., Kowalska, H., Czajkowska, K., Lenart, A. (2016). Osmotic dehydration in production of sustainable and healthy food. Trends in Food Science & Technology, 50, 186–192. doi: https://doi.org/10.1016/j.tifs.2016.01.017

- Husarova, O. (2018). Influence of different types blanching apples on drying process for crisps production. Prohresyvni tekhnika ta tekhnolohiyi kharchovykh vyrobnytstv restorannoho hospodarstva i torhivli, 1, 147–156. Available at: http://nbuv.gov.ua/UJRN/Pt_2018_1_13

- Khan, M. J., Yeasmin, F., Islam, M. N., Ahmmed, R., Das, P. C., Ali, M. H. (2019). Effect of pretreatments on drying behavior of eggplant. Journal of the Bangladesh Agricultural University, 17 (1), 105–109. doi: https://doi.org/10.3329/jbau.v17i1.40671

- García-Martínez, E., Igual, M., Martín-Esparza, M. E., Martínez-Navarrete, N. (2012). Assessment of the Bioactive Compounds, Color, and Mechanical Properties of Apricots as Affected by Drying Treatment. Food and Bioprocess Technology, 6 (11), 3247–3255. doi: https://doi.org/10.1007/s11947-012-0988-1

- Brar, H. S., Kaur, P., Subramanian, J., Nair, G. R., Singh, A. (2020). Effect of Chemical Pretreatment on Drying Kinetics and Physio-chemical Characteristics of Yellow European Plums. International Journal of Fruit Science, 20, S252–S279. doi: https://doi.org/10.1080/15538362.2020.1717403

- Doymaz, İ. (2010). Effect of citric acid and blanching pre-treatments on drying and rehydration of Amasya red apples. Food and Bioproducts Processing, 88 (2-3), 124–132. doi: https://doi.org/10.1016/j.fbp.2009.09.003

- Doymaz, İ., Demir, H., Yildirim, A. (2014). Drying of Quince Slices: Effect of Pretreatments on Drying and Rehydration Characteristics. Chemical Engineering Communications, 202 (10), 1271–1279. doi: https://doi.org/10.1080/00986445.2014.921619

- Guida, V., Ferrari, G., Pataro, G., Chambery, A., Di Maro, A., Parente, A. (2013). The effects of ohmic and conventional blanching on the nutritional, bioactive compounds and quality parameters of artichoke heads. LWT - Food Science and Technology, 53 (2), 569–579. doi: https://doi.org/10.1016/j.lwt.2013.04.006

- Sniezhkin, Yu. F., Petrova, Zh. O., Paziuk V. M. (2012). Hidrotermichna obrobka funktsionalnoi syrovyny. Naukovi pratsi ONAKhT, 41, 13–18.

- Xiao, H.-W., Pan, Z., Deng, L.-Z., El-Mashad, H. M., Yang, X.-H., Mujumdar, A. S. et al. (2017). Recent developments and trends in thermal blanching – A comprehensive review. Information Processing in Agriculture, 4 (2), 101–127. doi: https://doi.org/10.1016/j.inpa.2017.02.001

- Orikasa, T., Ono, N., Watanabe, T., Ando, Y., Shiina, T., Koide, S. (2018). Impact of blanching pretreatment on the drying rate and energy consumption during far-infrared drying of Paprika (Capsicum annuum L.). Food Quality and Safety, 2 (2), 97–103. doi: https://doi.org/10.1093/fqsafe/fyy006

- Savoiskyi, A., Yakovlev, V. (2017). Electrophysical method of intensification of the drying process of fruits. Naukovyi visnyk Tavriyskoho derzhavnoho ahrotekhnolohichnoho universytetu, 1 (7), 219–224. Available at: http://nbuv.gov.ua/UJRN/nvtdau_2017_7_1_31

- Kriaa, K., Nassar, A. F. (2022). Comparative study of pretreatment on microwave drying of Gala apples (Malus pumila): Effect of blanching, electric field and freezing. LWT, 165, 113693. doi: https://doi.org/10.1016/j.lwt.2022.113693

- Nowacka, M., Wiktor, A., Śledź, M., Jurek, N., Witrowa-Rajchert, D. (2012). Drying of ultrasound pretreated apple and its selected physical properties. Journal of Food Engineering, 113 (3), 427–433. doi: https://doi.org/10.1016/j.jfoodeng.2012.06.013

- Tüfekçi, S., Özkal, S. G. (2020). Investigation of Effect of Ultrasound Pretreatment on Drying and Rehydration Characteristics and Microstructure of Apple Slices. Yuzuncu Yıl University Journal of Agricultural Sciences, 30, 950–962. doi: https://doi.org/10.29133/yyutbd.698826

- Mieszczakowska-Frąc, M., Dyki, B., Konopacka, D. (2015). Effects of Ultrasound on Polyphenol Retention in Apples After the Application of Predrying Treatments in Liquid Medium. Food and Bioprocess Technology, 9 (3), 543–552. doi: https://doi.org/10.1007/s11947-015-1648-z

- Savoiskyi, O., Yakovliev, V., Sirenko, V. (2021). Comparative analysis of methods supplies thermal energy in high-water biological objects during drying. ScienceRise, 1, 3–10. doi: https://doi.org/10.21303/2313-8416.2021.001667

- Yakovlev, V., Savoiskyi, A. (2018). The use of direct electric heat in a technological process of combined drying. Visnyk Kharkivskoho natsionalnoho tekhnichnoho universytetu silskoho hospodarstva im. P. Vasylenka, 195, 91–96. Available at: http://repo.snau.edu.ua/handle/123456789/7343

- Savoiskyi, A., Yakovlev, V., Sirenko, V. (2019). Research of the combined drying process of apple raw material of high humidity. Naukovyi visnyk Tavriyskoho derzhavnoho ahrotekhnolohichnoho universytetu, 1 (9). Available at: http://repo.snau.edu.ua/bitstream/123456789/7971/1/3.pdf

- Savoiskyi, A., Yakovlev, V., Sirenko, V. (2019). Research of quantity of unit electrical resistance apple raw in the drying process. Visnyk Kharkivskoho natsionalnoho tekhnichnoho universytetu silskoho hospodarstva imeni Petra Vasylenka, 203, 107–110. Available at: https://repo.btu.kharkov.ua/bitstream/123456789/5714/1/39.pdf

- Savoiskyi, O. (2020). Research of electroplasmolysis of apple raw materials in the process of combined drying. Proceedings of the Tavria State Agrotechnological University, 20 (4), 247–257. doi: https://doi.org/10.31388/2078-0877-2020-20-4-247-257

- Fijalkowska, A., Nowacka, M., Witrowa-Rajchert, D. (2017). The physical, optical and reconstitution properties of apples subjected to ultrasound before drying. Italian Journal of Food Science, 29 (2). doi: https://doi.org/10.14674/1120-1770/ijfs.v642

- Witrowa-Rajchert, D., Wiktor, A., Sledz, M., Nowacka, M. (2014). Selected Emerging Technologies to Enhance the Drying Process: A Review. Drying Technology, 32 (11), 1386–1396. doi: https://doi.org/10.1080/07373937.2014.903412

- Wiktor, A., Sledz, M., Nowacka, M., Rybak, K., Witrowa-Rajchert, D. (2016). The influence of immersion and contact ultrasound treatment on selected properties of the apple tissue. Applied Acoustics, 103, 136–142. doi: https://doi.org/10.1016/j.apacoust.2015.05.001

- Režek Jambrak, A., Mason, T. J., Paniwnyk, L., Lelas, V. (2007). Ultrasonic effect on pH, electric conductivity, and tissue surface of button mushrooms, Brussels sprouts and cauliflower. Czech Journal of Food Sciences, 25 (2), 90–99. doi: https://doi.org/10.17221/757-cjfs

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Oleksandr Savoiskyi, Viktor Sirenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.