Abstract

Barothermal treatment of the cast binary alloy Al–8 at % Si has been performed at 560°C/100 MPa/3 h. A microstructure with silicon particles with an average equivalent diameter of ~2.9 microns has been formed in the alloy. Barothermically treated silumin had a yield stress of 67.6 MPa, a tensile strength of 141.6 MPa, and a relative elongation of 34.1%. Cold deformation of the alloy to obtain a foil with a thickness of 16 microns has been realized. A decrease of the aluminum and silicon crystal lattice constants has been established, which is more noticeable at the maximum deformation of the alloy. When deformed, a textured alloy structure is formed with an axis of {100} along the rolling direction. The mechanical properties of the deformed alloy are determined, and the values of yield stress, tensile strength, and elongation equal to ~265 MPa, 305 MPa, and 5.5%, respectively, are obtained for a tape with a thickness of 900 microns. With a higher degree of deformation, for a tape with a thickness of 90 microns, these characteristics have values of ~146 MPa, 165 MPa and 1.4%, respectively, and for the foil with a thickness of 16 microns, ~180 MPa, 196 MPa and 0.3%, respectively.

Similar content being viewed by others

REFERENCES

U. Dahlborg, M. Besser, M. Calvo-Dahlborg, G. Cuello, C. D. Dewhurst, M. J. Kramer, J. R. Morris, and D. J. Sordelet, “Structure of molten Al–Si alloys,” J. Non-Cryst. Solids 353, 3005–3010 (2017).

I. Snigireva, K. V. Falch, D. Casari, M. Di Michiel, C. Detlefs, R. Mathiesen, and A. Snigirev, “Hard X‑ray in-situ full-field microscopy for material science applications,” Microsc. Microanal. 24 (Suppl. 2), 552–553 (2018). https://doi.org/10.1017/S1431927618014952

R. H. Mathiesen, L. Arnberg, Y. Li, V. Meier, P. L. Schaffer, I. Snigireva, A. Snigirev, and A. K. Dahle, “X-ray videomicroscopy studies of eutectic Al–Si in Al–Si–Cu,” Metall. Mater. Trans. A, 42, 170–180 (2011). https://doi.org/10.1007/s11661-019-05575-5

S. Chankitmunkong, D. G. Eskin, and C. Limmaneevichitr, “Structure modification upon processing of an AA4032 piston alloy : comparison of permanent mold and direct-chill casting,” Metall. Mater. Trans. A, 51, 818–829 (2020). https://doi.org/10.1007/s11661-015-3287-4

X. Li, A. Gagnoud, Y. Fautrellee, R. Moreau, D. Du, Z. Ren, and X. Lu, “Effect of transverse magnetic field on solidification structures in unmodified and Sr-modified Al–7 wt % Si alloys during directional solidification,” Metall. Mater. Trans. A, 47 1198–1214 (2016). https://doi.org/10.1007/s11661-015-3287-4

Z. Zhang, H.-T. Li, I. C. Stone, and Z. Fan, The 3rd Int. Conf. on Solidificaton Processes,” IOP Conf. Ser.: Mater. Sci. Eng. 27, 012042 (2011). https://doi.org/10.1088/1757-899X/27/1/012042

R. Wladysiak and A. Kozun, “Effect of water mist cooling on microstructure of hypereutectic Al–Si alloy,” Arch. Foundry Eng. 14 (3), 117–122 (2014). https://doi.org/10.2478/afe-2014-0074

T. Tanski, K. Labicz, B. Krupinska, M. Krupinski, M. Krol, R. Maniara, and W. Borek, “Analysis of crystallization kinetics of cast aluminum-silicon alloy,” J. Therm. Anal. Calorim. (2015). https://doi.org/10.1007/s10973-015-4871-y

H. Qian, C. Hu, and X. Jiang, “Effects of Zr additive on microstucture, mechanical properties, and fractography of Al–Si alloy,” Metals 8, 124 (2018). https://doi.org/10.3390/met89020124

M. Sheng, Z. Tao, P. Jia, J. Leng, and H. Geng, “Effects of Y and Y combined with Al-5Ti-1B on the microstructure and mechanical properties of hypoeutectic Al–Si alloy,” JOM 67 (2), 330–335 (2015). https://doi.org/10.1007/s11837-014-1199-1

V. Vijeesh and K. N. Prabhu, “Computer aided cooling curve analysis and microstructure of cerium added hypereutectic Al–Si (LM29) alloy,” Trans. Indian Inst. Met. 67 (4), 541–549 (2014). https://doi.org/10.1007/s12666-014-0379-6

S. A. Alkahtani, E. M. Elgallad, M. M. Tash, A. M. Samuel, and F. H. Samuel, “Effect of rear earth metals on the microstructure of Al–Si based alloys,” Materials 8 (6) (2016). https://doi.org/10.3390/ma9010045

R. Ahmad, and M. B. Asmael, “Influence of cerium on microstructure and solidification of eutectic Al–Si piston alloy,” Mater. Manuf. Processes 31 (15) 1948–1957 (2016). https://doi.org/10.1080/10426914.2015.1127942

Q. Hongsu, Y. Hong, and H. Zhi, “Effect of samarium (Sm) addition on the microstructure and mechanical properties of Al–7Si–0.7Mg alloys,” J. Alloys Compd. 567, 77–81 (2013). https://doi.org/10.1016/j.jallcom.2013.03.050

A. I. Anikin, S. V. Balyaev, V. P. Zhereb, and V. I. Anikina, “Manipulatipon of silumin structure in liquid-solid condition, using heat treatment,” J. Sib. Fed. Univ., Eng. Technol. 5 (8), 582–593 (2015).

Y. Fukui, D. Nara, K. Fushimi, and N. Kumazava, “Application of the eyring equation in the evaluation of semi-solid forming-induced Si particle refinement in the hypereutectic Al–Si alloys,” Metall. Mater. Trans. A 1–8. https://doi.org/10.1007/s.11661-015-31436

P. Schumacher, S. Pogatcher, M. J. Starink, C. Shick, V. Mohles, and B. Milkereit, “Quench-induced preci pitates in Al–Si alloys: calorimetric determination of solute content and characterization of microstructure,” Thermochim. Acta 602, 63–73 (2015). https://doi.org/10.1016/j.tca.2014.12.023

V. Z. Kutzova, O. A. Nosko, T. A. Ayuopova, and A. O. Kupchinskaia, Izd. ZNTU, Novi Mater. Techn. Met. Mash., No. 2, 40 (2012).

A. G. Prigunova, N. A. Belov, Yu. N. Taran, V. S. Zolotarevsky, V. I. Napalkov, and S. S. Petrov, Silumins. Atlas of microstructures and fractograms of industrial alloys (MISiS, Moscow, 1996), 175 р. [in Russian].

E. Vandersluis, P. Emadi, B. Andilab, and C. Ravindran, “The role of silicon morphology in the electrical conductivity and mechanical properties of As-cast B329 alloy,” Metall. Mater. Trans. A, 51, 1874–1886 (2020). https://doi.org/10.1007/s11661-020-05650-2

M. Liu, H. Fu, L. Tian, Q. Peng, and C. Ma, “Nucleation and growth of nano-scaled Si precipitates in Al–7Si supersaturated solid solution,” Mater. Des. 121, 373–382 (2017). https://doi.org/10.1016/j.matdes.2017.02.082

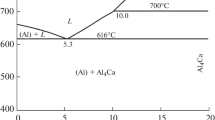

A. G. Padalko, T. K. Akopyan, E. V. Dediaeva, G. V. Talanova, L. I. Shvorneva, G. I. Zubarev, V. T. Fedotov, and A. N. Suchkov, “Phase transformations in a binary 10 at % Si–90 at % Al alloy at high pressures and temperatures”, Russ. Metall. (Metally), 5, 361–366 (2014). https://doi.org/10.1134/S0036029514050073

E. V. Dediaeva, P. N. Nikiforov, A. G. Padalko, and L. I. Shvorneva, “Effect of barothermal processing on the microstructure and properties of Al–10 at % Si hypoeutectic binary alloy, Inorg. Mater. 2 (7), 721–728 (2016). https://doi.org/10.1134/S002016851670049

R. E. Sokolov, Ph.D. Thesis (Sib. Fed. Universitet, Krasnoyarsk, 2011).

J. L. Murray and A. J. McAlister, “The Al–Si (aluminum–silicon) system,” Bull. Alloy Phase Diagrams 5, 74–84 (1984). https://doi.org/10.1007/BF02868729

I. K. Kikoin, Tables of physical quantities. Guide, Edited by I. K. Kikoin (Atomizdat, Moscow, 1976), 1008 p. [in Russian].

E. V. Dedyaeva, D. V. Zaitsev, E. A. Lukina, P. N. Nikiforov, A. G. Padalko, G. V. Talanova, and K. A. Solntsev, “Effect of barothermal processing on the solid-state formation of the structure and properties of 16 at % Si–Al hypereutectic alloy,” Inorg. Mater. 54 (2), 138–145 (2018). https://doi.org/10.1134/S0020168518020024

N. A. Belov, E. A. Naumova, and T. K. Akopian, Eutectic alloys based on aluminum: new alloying systems (Publishing House “Ore and metals”, Moscow, 2016), 256 p. [in Russian].

V. R. Baraz, V. P. Levchenko, and A. A. Povzner, Structure and physical properties of crystals (UGTU-UPI, Ekaterinburg, 2009), 164 p. [in Russian].

Funding

The work was carried out with financial support within the framework of the state task 075-00328-21-00.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Padalko, A.G., Pyrov, M.S., Karelin, R.D. et al. Barothermal Treatment, Cold Plastic Deformation, Microstructure and Properties of Binary Silumin Al–8 at % Si. Russ. Metall. 2021, 1155–1164 (2021). https://doi.org/10.1134/S0036029521090123

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521090123