Abstract

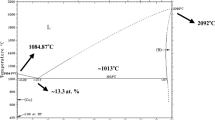

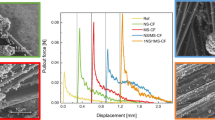

Zirconia ceramics exhibits high functional and strength properties. The range of its application is continuously expanding. The use of nanopowders makes it possible to obtain fine-grained ceramics with improved characteristics. Zirconium dioxide has a high hardness, which ensures increased mold wear. In addition, nanoparticles are prone to agglomeration, which affects compaction upon pressing and sintering. These problems can be solved by introducing microadditives, e.g., carbon. The effect of the type and concentration of a carbon additive on the parameters of zirconia ceramics fabricated from powder raw materials synthesized by sol‒gel and plasma-chemical methods has been explored. The shrinkage of the ceramic samples of two types with carbon additives of three types (multiwalled carbon nanotubes (MWNTs), amorphous carbon, and amorphous carbon with MWCNTs) has been studied by dilatometry. It has been established that the additives do not affect the shrinkage rate and that the highest rate of shrinkage of the sample is almost equal to the shrinkage rate upon sintering of the ceramics without additives. The effect of a carbon additive on the density and microhardness of the ceramics has been determined. It is shown that the additives introduced into the ceramics fabricated from the powders synthesized by the sol‒gel technology reduce the density and microhardness, while the density of the ceramics made of the plasma-chemical powders increases up to a certain additive concentration threshold for carbon of all the types discussed in this study.

Similar content being viewed by others

REFERENCES

S. Patil and D. R. Patil, Ceram. Int. 48, 21048 (2022).

A. Arena and F. Prete, Nanomaterials 9, 1393 (2019).

S. E. Porozova and A. G. Rogozhnikov, Refract. Ind. Ceram. 61, 659 (2021).

E. Gevorkyan and T. Prikhna, Compos. Struct. 259, 113443 (2021).

Y. Yu and F. Lin, J. Eur. Ceram. Soc. 41, 5269 (2021).

W. Yu and Y. Zheng, Ceram. Int. 47, 25264 (2021).

D. Peng and X. Wang, J. Sol–Gel Sci. Technol. 103, 62 (2022).

S. G. Chuklina and A. I. Pylinina, Russ. J. Phys. Chem. A 91, 862 (2017).

A. Indra and A. B. Putra, Mater. Today Sustain. 17, 100100 (2022).

I. Mysiura and O. Kalantaryan, in Proceedings of the IEEE 7th International Conference Nanomaterials: Application and Properties NAP (2017), p. 02MAN06-1.

Y. Xiong and L. Wang, Key Eng. Mater. 697, 173 (2016).

Z. Di and S. Shimai, Ceram. Int. 45, 12789 (2019).

S. A. Gyngazov and I. P. Vasiljev, Russ. Phys. J. 63, 2037 (2021).

A. O. Zhigachev and V. V. Rodaev, J. Mater. Res. Technol. 8, 6086 (2019).

Y. Ling, X. Hao, S. Zhang, J. Chen, L. Gao, M. Omran, and G. Chen, Ceram. Int. 48, 10547 (2022).

Y. Liu and Y. Fei, Ceram. Int. 48, 18257 (2022).

M. Al-Amin and H. T. Mumu, J. Korean Ceram. Soc. (2022)

A. Kumar and P. Kumar, J. Korean Ceram. Soc. 59, 370 (2022).

B.-K. Jang and J.-H. Lee, Ceram. Int. 47, 35287 (2021).

B. Milsom and H. Porwal, Mater. Des. 133, 325 (2017).

N. Obradovic and F. Kern, Ceram. Int. 44, 16931 (2018).

T. A. G. Restivo and M. Durazzo, J. Therm. Anal. Calorim. 131, 249 (2018).

M. A. Kazakova and S. I. Moseenkov, J. Alloys Compd. 844, 156107 (2020).

A. G. Zherlitsyn and D. V. Korzhenko, Gazov. Prom-st’, No. 11, 777 (2018).

Funding

This study was supported by the Russian Science Foundation, project no. 22-19-00183.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by E. Bondareva

Rights and permissions

About this article

Cite this article

Ghyngazov, S.A., Vasil’ev, I.P. & Boltueva, V.A. The Effect of a Carbon Additive on Compaction of Partially Stabilized Zirconia Powders upon Pressing and Sintering. Tech. Phys. Lett. 48, 311–315 (2022). https://doi.org/10.1134/S1063785022110037

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063785022110037