Barriers to Implement Lean Manufacturing in Malaysian Automotive Industry

DOI:

https://doi.org/10.11113/jt.v59.2571Keywords:

Lean manufacturing, barriers, survey approachAbstract

Implementing lean manufacturing in a developing country such as Malaysia is still considered to be a major challenge due to several barriers. It is essential for all managers to understand these barriers and try to minimize them and improve competition strength. The purpose of this study is to investigate the barriers of lean manufacturing in the automotive industry in Malaysia. A survey have been conducted and sent to 250 companies from automotive manufacturing plant and suppliers in Malaysia, giving a 20.8% response rate. The statistical package for the social science (SPSS) software was used to analyze the data from the surveys. The result shows that the lack of skilled is the highest obstacle implement lean and following by lack of awareness and company culture. Attempt was made at finding significance difference between small, medium and large companies on obstacle in lean implementation. The findings of this research provide invaluable information to all desire to implement lean manufacturing and to assist the development of an effective strategic plas as well as to design programs to overcome the lean manufacturing barriers. The findings culminate with conclusion together with some proposed future research directions.References

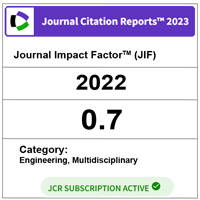

Deros, B. M., Yusof, S., Salleh, A. 2006. A Survey on Critical Factors and Problems in Implementing Benchmarking Towards Achieving Business Competitiveness in SMEs. Jurnal Kejuruteraan. 18: 29–37.

Balle, M. 2005. Lean Attitute–lean Application Often Fail to Deliver the Expected Benefits but Could the Missing Link for Succesful Implementations be Attitude? Manufacturing Engineer. 84: 14–19.

Narasimhan,R., Swink, M., Kim, S. W. 2006. Disentangling Leanness and Agility: An Empirical Investigation. Journal of Operations Management. 24: 440–457.

Shah, R and Ward, P. T. 2007. Defining and Developing Measure of Lean Production. Journal of Operation Management. 25: 785–805.

Eswaramoorthi, M. 2011. A Survey on Lean Practices in Indian Machine Tool Industries. International Journal Advance Manufacturing Technology. 52: 1091–1101.

Bhasin, S. 2008. Lean and Performance Measurement. Journal of Manufacturing Technology. 19: 670–684.

Sim, K. L. and Rogers, J. W. 2009. Implementing Lean Production System: Barriers to Change. Management Research News. 32: 37–49.

Wong, Y. C., Wong, K. Y., Ali, A. 2009. A study on Lean Manufacturing Implementation in the Malaysian Electrical and Electronics Industry. European Journal of Scientific Research. 38: 521–525.

Nordin, N., Deros, B.M., Abdul.Wahab, D. 2011. Lean Manufacturing Implementation in Malaysian Automotive Industry: An Exploratory Study. Operation and Supply Chain Management. 4: 21–30.

Crute, V., Ward, Y., Brown, S. and Graves, A. 2003. Implementing Lean in Aerospace-Challenging the Assumptions and Understanding the Challenges. Technovation. 23: 917–928.

Manzouri, M., Abd. Rahman, M. N., Arshad, H., Ismail, A. R. 2010. Barriers of supply chain management impelementation in manufacturing companies: a comparison between Iranian and Malaysian companies. Journal of the Chinese Institute of Industrial Engineers. 27: 456–472.

Nahm, A. Y., Vonderembse, M. A., Koufteros, X. A. 2003. The Impact of Organizational Structure on Time-Based Manufacturing and Plant Performance. Journal of Operation Management. 21: 281–306.

Li, S., Rao, S.S., Ragu-Nathan, T. and Ragu-Nathan, B. 2005. Development and Validation of a Measurement Instrument for Studying Supply Chain Management Practices. Journal of Operation Management. 21: 281–306.

Yusof, S. M. and Aspinwall, E. M. 2000. Critical success factors in small and medium enterprise: survey results. The TQM Magazine. 11: 448–462.

Zadry, H. R and Yusof, S. M. 2006. Total Quality Management and Theory of Constraints Implementaion in Malaysian Automotive Supplier: A Survey Result. Journal of Total Quality Management. 17: 999–1020.

Abd. Rahman, M. N. 2002. A survey findings on quality management practices in Malaysian SMEs. Standard and Quality. 95: 2–7.

Downloads

Published

Issue

Section

License

Copyright of articles that appear in Jurnal Teknologi belongs exclusively to Penerbit Universiti Teknologi Malaysia (Penerbit UTM Press). This copyright covers the rights to reproduce the article, including reprints, electronic reproductions, or any other reproductions of similar nature.