1. Introduction

The dynamic wetting behaviour of liquid droplets on soft solid substrates has received a great deal of attention lately, due to its relevance in diverse applications (Bico, Reyssat & Roman Reference Bico, Reyssat and Roman2018) ranging from biology, i.e. the inhibition of the dispersal of cancer cells (Douezan, Dumond & Brochard-Wyart Reference Douezan, Dumond and Brochard-Wyart2012) or the control of medicine dispersal on tissues, to the control of the spreading of the deposited particles over a compliant substrate after the evaporation of ink-jetted microdroplets (Park & Moon Reference Park and Moon2006) and microfabrication of materials in technology (Bonaccurso et al. Reference Bonaccurso, Butt, Hankeln, Niesenhaus and Graf2005; Pericet-Camara et al. Reference Pericet-Camara, Best, Nett, Gutmann and Bonaccurso2007; Kong et al. Reference Kong, Tamargo, Kim, Johnson, Gupta, Koh, Chin, Steingart, Rand and McAlpine2014).

The evaporation of droplets on rigid substrates has been widely studied over the years, underlining various aspects of evaporation such as droplet lifetimes (Stauber et al. Reference Stauber, Wilson, Duffy and Sefiane2014, Reference Stauber, Wilson, Duffy and Sefiane2015), the impact of capillary flow on the coffee stain effect (Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten1997) or the effect of substrate properties (Erbil Reference Erbil2012). A key concept in droplet evaporation is the so-called shielding effect, where neighbouring droplets interact with each other, since the presence of the vapour from adjacent droplets reduces the evaporation rate and increases the droplet lifetime in comparison with those of a single isolated droplet (Fabrikant Reference Fabrikant1985; Wray, Duffy & Wilson Reference Wray, Duffy and Wilson2020; Masoud, Howell & Stone Reference Masoud, Howell and Stone2021; Wray et al. Reference Wray, Wray, Duffy and Wilson2021). On the contrary, the study of droplet evaporation on compliant solid substrates is not very substantial so far.

The unbalanced vertical forces acting on the contact line of the liquid result in a local deformation of the compliant substrate affecting droplet shape and, ultimately, the dynamics of the flow (Andreotti & Snoeijer Reference Andreotti and Snoeijer2020). This unique attribute of the compliant substrates is responsible for the creation of a macroscopic surface protrusion, most widely referred to as a wetting ridge (Shanahan Reference Shanahan1988; Park et al. Reference Park, Weon, Lee, Lee, Kim and Je2014; Chen et al. Reference Chen, Askounis, Koutsos, Valluri, Takata, Wilson and Sefiane2020). The structure of the wetting ridge is an immediate outcome of the balance between capillary and elastic forces, while a key role of the solid surface tension has been recently identified (Jerison et al. Reference Jerison, Xu, Wilen and Dufresne2011; Marchand et al. Reference Marchand, Das, Snoeijer and Andreotti2012; Style & Dufresne Reference Style and Dufresne2012; Style et al. Reference Style, Che, Wettlaufer, Wilen and Dufresne2013). Besides slowing down the contact line, the wetting ridge can also constitute the reason for periodic stick–slip behaviour, with a periodic depinning of the contact line (Kajiya et al. Reference Kajiya, Daerr, Narita, Royon, Lequeux and Limat2012, Reference Kajiya, Brunet, Royon, Daerr, Receveur and Limat2014; Lopes & Bonaccurso Reference Lopes and Bonaccurso2013; Yu, Wang & Zhao Reference Yu, Wang and Zhao2013; Karpitschka et al. Reference Karpitschka, Pandey, Lubbers, Weijs, Botto, Das, Andreotti and Snoeijer2016; van Gorcum et al. Reference van Gorcum, Andreotti, Snoeijer and Karpitschka2018; Mokbel, Aland & Karpitschka Reference Mokbel, Aland and Karpitschka2022). Starting from a rigid substrate, when we increase the substrate softness we observe an initial strong increase in the wetting ridge size while the droplet footprint is kept relatively constant, which is replaced by a strong depression of the substrate under the droplet in much softer substrates (Charitatos & Kumar Reference Charitatos and Kumar2020; Henkel, Snoeijer & Thiele Reference Henkel, Snoeijer and Thiele2021). The arising solid angle is governed by a balance of surface tensions (Marchand et al. Reference Marchand, Das, Snoeijer and Andreotti2012; Style & Dufresne Reference Style and Dufresne2012; Style et al. Reference Style, Che, Wettlaufer, Wilen and Dufresne2013). The possible strain dependence of the solid surface tension (i.e. the Shuttleworth effect) (Andreotti & Snoeijer Reference Andreotti and Snoeijer2016; Xu et al. Reference Xu, Jensen, Boltyanskiy, Sarfati, Style and Dufresne2017; Pandey et al. Reference Pandey, Andreotti, Karpitschka, van Zwieten, van Brummelen and Snoeijer2020; Henkel et al. Reference Henkel, Essink, Hoang, van Zwieten, van Brummelen, Thiele and Snoeijer2022) gives rise to another complexity.

Depending on a combination of capillarity and bulk elasticity, adjacent droplets on solid substrates can interact, leading either to droplet attraction and even coalescence on thick substrates, or to droplet repulsion on thinner substrates (Hernández-Sánchez et al. Reference Hernández-Sánchez, Lubbers, Eddi and Snoeijer2012; Karpitschka et al. Reference Karpitschka, Pandey, Lubbers, Weijs, Botto, Das, Andreotti and Snoeijer2016; Leong & Le Reference Leong and Le2020). Karpitschka et al. (Reference Karpitschka, Pandey, Lubbers, Weijs, Botto, Das, Andreotti and Snoeijer2016) described the droplet interaction when deposited on soft solids as the ‘inverse Cheerios effect’ with direct reference to the liquid-on-solid analogue of the so-called ‘Cheerios effect’ (Vella & Mahadevan Reference Vella and Mahadevan2005); the latter refers to solid particles’ attraction when floating on liquids, mediated by surface tension forces, and it has been named after the sticking of breakfast cereals either to the walls of a bowl or to each other. However, there are substantial differences between the ‘Cheerios effect’ and the ‘inverted Cheerios effect’ regarding the driving force and the mechanism which mediates the interaction. The shape of the liquid interface in the ‘Cheerios effect’ is specified by the balance between surface tension and gravity, while the interaction is driven by a change in gravitational potential energy. On the contrary, in the ‘inverse Cheerios effect’ there is no gravity involved and the shape of the solid interface is specified by elastocapillarity (Karpitschka et al. Reference Karpitschka, Das, van Gorcum, Perrin, Andreotti and Snoeijer2015).

Despite the innumerable studies concerning droplet coalescence (Eggers, Lister & Stone Reference Eggers, Lister and Stone1999; Aarts et al. Reference Aarts, Lekkerkerker, Guo, Wegdam and Bonn2005), not many of them consider the role that a compliant substrate might play in the process. More recently, Henkel et al. (Reference Henkel, Snoeijer and Thiele2021) investigated the two basic coarsening modes of two droplets on soft substrates without evaporation; the volume or mass transfer mode (also referred to as drop collapse mode, diffusion-controlled ripening or Ostwald ripening) and the translation mode (also referred to as coalescence, collision or migration mode). On the one hand, in the mass transfer mode, material is transferred from the small drop to the larger one until the smaller drop has completely vanished, while the centres of mass of each droplet remain constant. This mass transfer might occur either through the vapour phase in case of volatile droplets, or through an adsorption layer in case of non-evaporating partially wetting fluids. On the other hand, in the translation mode, there is droplet migration towards each other, until their contact lines touch, leading to coalescence (Henkel et al. Reference Henkel, Snoeijer and Thiele2021).

When compared with rigid substrates, early experimental studies (Lopes & Bonaccurso Reference Lopes and Bonaccurso2012; Pu & Severtson Reference Pu and Severtson2012; Lopes & Bonaccurso Reference Lopes and Bonaccurso2013; Yu et al. Reference Yu, Wang and Zhao2013; Chuang et al. Reference Chuang, Chu, Lin and Chen2014; Gerber et al. Reference Gerber, Lendenmann, Eghlidi, Schutzius and Poulikakos2019) highlighted the faster evaporation of droplets observed on softer substrates, due to the longer pinning of the contact line throughout evaporation, caused by the formation of the wetting ridge. In addition, some of these experimental studies (Lopes & Bonaccurso Reference Lopes and Bonaccurso2013; Yu et al. Reference Yu, Wang and Zhao2013) revealed that while in the initial stages of evaporation, the droplet appears to remain pinned, while the contact angle is decreased. After the droplet depins, the opposite behaviour is observed, i.e. the contact angle remains constant and the contact radius decreases. Then, at the late stages of droplet evaporation, the contact angle slightly increases, before ultimately decrease until the droplet completely evaporates.

As it has been established in studies for rigid substrates, the dynamics of the contact line plays a crucial role on droplet evaporation (Lopes & Bonaccurso Reference Lopes and Bonaccurso2012, Reference Lopes and Bonaccurso2013; Pu & Severtson Reference Pu and Severtson2012; Yu et al. Reference Yu, Wang and Zhao2013; Chuang et al. Reference Chuang, Chu, Lin and Chen2014; Gerber et al. Reference Gerber, Lendenmann, Eghlidi, Schutzius and Poulikakos2019) and in order to model the contact line motion an approach, followed by several researchers, has been to introduce the effect of disjoining pressure, by assuming the presence of an adsorbed precursor film ahead of the droplet, which is stabilised by the action of intermolecular interactions between the two interfaces. The presence of the precursor film is evident in experimental studies with microscopic techniques (Kavehpour, Ovryn & McKinley Reference Kavehpour, Ovryn and McKinley2003; Xu et al. Reference Xu, Shirvanyants, Beers, Matyjaszewski, Rubinstein and Sheiko2004; Hoang & Kavehpour Reference Hoang and Kavehpour2011) and constitutes the reason for the levelled transition from the contact line to the flat gas–solid interface, circumventing the singularity arising from the shear stress (Wang et al. Reference Wang, Karapetsas, Valluri, Sefiane, Williams and Takata2021), due to the contradiction between the non-zero displacement on the contact line and the no-slip boundary condition on the liquid–solid interface on the same point. This approach has been widely implemented for the modelling of not only perfectly wetting fluids (Bonn et al. Reference Bonn, Eggers, Indekeu, Meunier and Rolley2009), but also partially wetting fluids (Schwartz Reference Schwartz1998; Schwartz & Eley Reference Schwartz and Eley1998; Gomba & Homsy Reference Gomba and Homsy2010). A similar approach has been also used by Charitatos & Kumar (Reference Charitatos and Kumar2021) to examine droplet evaporation on partially wetted soft viscoelastic substrates.

To account for the droplet evaporation, two approximations have been mostly used (Wilson & D'Ambrosio Reference Wilson and D'Ambrosio2023). In the so-called one-sided model, the attention is solely drawn to the liquid phase, since vapour viscosity, density and thermal conductivity are considered negligible. In this approach, evaporation is limited by the rate on which the molecules of the solvent are headed from the liquid towards the gas phase (Burelbach, Bankoff & Davis Reference Burelbach, Bankoff and Davis1988). On that principle, the work of Moosman & Homsy (Reference Moosman and Homsy1980), Ajaev & Homsy (Reference Ajaev and Homsy2001) and later Ajaev (Reference Ajaev2005) considered an adsorbed thin film ahead of the evaporating liquid, with non-zero film thickness, which is in thermodynamic equilibrium with both the solid and the gas phases. The work of Ajaev has been the grounding principle for many researchers studying, qualitatively, droplet spreading and evaporation of more complex systems, such as droplets with nanoparticles (Matar, Craster & Sefiane Reference Matar, Craster and Sefiane2007), the deposition of particles while in the presence of surfactants (Karapetsas, Sahu & Matar Reference Karapetsas, Sahu and Matar2016), as well as the evaporation of droplets which consist of ethanol–water or other binary mixtures (Williams et al. Reference Williams, Karapetsas, Mamalis, Sefiane, Matar and Valluri2021), or the vapour adsorption of hygroscopic aqueous solution droplets (Wang et al. Reference Wang, Karapetsas, Valluri, Sefiane, Williams and Takata2021). Concerning droplet evaporation on compliant substrates, the only theoretical work so far is the work of Charitatos & Kumar (Reference Charitatos and Kumar2021), where a one-sided model is developed to study the evaporation of a single droplet.

However, when the evaporation is diffusion-limited and, hence, the vapour phase cannot be considered irrelevant, quantitative results can only be achieved by employing a two-sided approximation (Sultan, Boudaoud & Amar Reference Sultan, Boudaoud and Amar2005; Schofield et al. Reference Schofield, Wray, Pritchard, Wilson and Sefiane2020; Wray et al. Reference Wray, Duffy and Wilson2020). Typically, one-sided models consider that the evaporation flux is only a function of pressure and temperature differences in the liquid–gas interface and the transport equations in the liquid phase are the only prerequisite for the system modelling. On the contrary, the diffusion-limited model includes the simultaneous solution of a diffusion equation concerning the vapour gas phase concentration. The second approach entails a higher computational cost but provides a more accurate description of phase change phenomena (Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten1997; Hu & Larson Reference Hu and Larson2005; Masoud & Felske Reference Masoud and Felske2009; Cazabat & Guéna Reference Cazabat and Guéna2010; Mikishev & Nepomnyashchy Reference Mikishev and Nepomnyashchy2013; Larson Reference Larson2014). A common assumption to reduce the computational cost, is to consider that the droplet retains a spherical-cap shape. This assumption, though, is not always safe, since the droplet shape might be significantly distorted by forces, such as gravitational forces (e.g. evaporation on inclined substrates), the effect of Marangoni or elastic stresses, etc. Hartmann et al. (Reference Hartmann, Diddens, Jalaa and Thiele2023) recently developed a long-wave model of a sessile shallow droplet of evaporating partially wetting fluid on a rigid substrate, which, similarly to the earlier work of Sultan et al. (Reference Sultan, Boudaoud and Amar2005), captured the transition between the diffusion-limited and the one-sided model.

Several authors have also investigated the effect of Marangoni stresses on droplet spreading and evaporation. Marangoni flows can be induced by thermal gradients, a variation in the concentration of surfactants, or by the presence of binary mixtures (Dunn et al. Reference Dunn, Duffy, Wilson and Holland2009a; Wang et al. Reference Wang, Karapetsas, Valluri, Sefiane, Williams and Takata2021; Williams et al. Reference Williams, Karapetsas, Mamalis, Sefiane, Matar and Valluri2021). The coffee-ring effect may be suppressed by the action of Marangoni stresses (Karapetsas et al. Reference Karapetsas, Sahu and Matar2016; Seo et al. Reference Seo, Yang, Chae and Shin2017), since they counter the outward liquid flow facilitated by contact-line pinning. Additionally, the coalescence of merging droplets with different surface tensions (such as water and ethanol) has been shown to be strongly delayed (Karpitschka & Riegler Reference Karpitschka and Riegler2010; Chen et al. Reference Chen, Gao, Xia, Li, Liu and Ding2021). Concerning evaporating droplets, Talbot et al. (Reference Talbot, Berson, Brown and Bain2012), Schofield et al. (Reference Schofield, Wilson, Pritchard and Sefiane2018) and Dunn et al. (Reference Dunn, Wilson, Duffy, David and Sefiane2009b) showed that the thermal effects can significantly extend the droplet lifetime.

There have been different approaches in the literature to describe soft substrate wetting, ranging from the development of long-wave models (Kumar & Matar Reference Kumar and Matar2004; Matar, Gkanis & Kumar Reference Matar, Gkanis and Kumar2005; Gielok et al. Reference Gielok, Lopes, Bonaccurso and Gambaryan-Roisman2017; Gomez & Velay-Lizancos Reference Gomez and Velay-Lizancos2020) to full-scale computational studies (Bueno et al. Reference Bueno, Bazilevs, Juanes and Gomez2017, Reference Bueno, Bazilevs, Juanes and Gomez2018). Kumar & Matar (Reference Kumar and Matar2004) and Matar et al. (Reference Matar, Gkanis and Kumar2005) first developed a long-wave approach to study the nonlinear evolution of thin liquid films dewetting near soft elastomeric layers. Charitatos & Kumar (Reference Charitatos and Kumar2020) followed Matar's work for droplet spreading on soft solid substrates, while Charitatos & Kumar (Reference Charitatos and Kumar2021), extended their own work developing a one-sided model to examine droplet evaporation on viscoelastic substrates.

Building on the latter model, the present paper presents a detailed and comprehensive theoretical model for the investigation of the dynamics of a system of two evaporating droplets residing on a compliant solid substrate. The droplets may interact through the developed elastic stresses in the viscoelastic substrate which is modelled using the Kelvin–Voigt model. When the droplets are exposed to the atmosphere, a further question is raised, concerning the effect of the local variations in vapour concentration on the evaporation rate of the droplets. To this end, we develop a two-sided evaporation model following a similar approach with earlier studies for rigid substrates (Sultan et al. Reference Sultan, Boudaoud and Amar2005; Doumenc & Guerrier Reference Doumenc and Guerrier2011). Thus, apart from the viscoelastic substrate, our model unravels the potential of communication of the droplets through the atmosphere, while also taking fully into consideration the effects of evaporative cooling and induced thermocapillary phenomena. To remove the stress singularity that arises at the moving contact line, we assume the presence of a sufficiently thin precursor film. The precursor film is stabilised and evaporation therein is suppressed through the inclusion of a disjoining pressure.

The rest of the paper is organised as follows. The problem is formulated in § 2 and the equations governing the flow dynamics are discussed. The scaling and resulting evolution equations are presented in §§ 3 and 4, respectively. Results are presented and discussed in § 5, followed by concluding remarks in § 6.

2. Problem statement and model formulation

2.1. Description of the problem

We consider the behaviour of a single droplet or a system of two two-dimensional sessile evaporating droplets, with initial cross-sectional area ![]() $\hat {V}$, placed on an incompressible linear viscoelastic solid substrate, which is also referred to as soft substrate. At

$\hat {V}$, placed on an incompressible linear viscoelastic solid substrate, which is also referred to as soft substrate. At ![]() $\hat {t}=0$, the droplet is resting on the soft substrate and has an initial footprint half-width

$\hat {t}=0$, the droplet is resting on the soft substrate and has an initial footprint half-width ![]() $\hat {l}_0$ and an initial height

$\hat {l}_0$ and an initial height ![]() $\hat {h}_0$ (figure 1a). The liquid–solid interface is originally located at

$\hat {h}_0$ (figure 1a). The liquid–solid interface is originally located at ![]() $\hat {z}=0$. The soft substrate is originally undistorted and attached to a rigid substrate at

$\hat {z}=0$. The soft substrate is originally undistorted and attached to a rigid substrate at ![]() $\hat {z}=-\hat {H}$; the rigid substrate is highly conductive with constant temperature

$\hat {z}=-\hat {H}$; the rigid substrate is highly conductive with constant temperature ![]() $\hat {T}_b$. The soft substrate is characterised by density

$\hat {T}_b$. The soft substrate is characterised by density ![]() $\hat {\rho }_s$, viscosity

$\hat {\rho }_s$, viscosity ![]() $\hat {\eta }_s$, thermal conductivity

$\hat {\eta }_s$, thermal conductivity ![]() $\hat {\lambda }_w$, shear modulus

$\hat {\lambda }_w$, shear modulus ![]() $\hat {E}$ and constant liquid–solid interfacial tension

$\hat {E}$ and constant liquid–solid interfacial tension ![]() $\hat {\gamma }$, which is independent of strain; the presence of an immiscible liquid solvent in the soft substrate is assumed. The droplet is assumed to have constant density

$\hat {\gamma }$, which is independent of strain; the presence of an immiscible liquid solvent in the soft substrate is assumed. The droplet is assumed to have constant density ![]() $\hat {\rho }_l$, viscosity

$\hat {\rho }_l$, viscosity ![]() $\hat {\eta }_l$, thermal conductivity

$\hat {\eta }_l$, thermal conductivity ![]() $\hat {\lambda }$, specific heat capacity

$\hat {\lambda }$, specific heat capacity ![]() $\hat {c}_p$ and saturation temperature

$\hat {c}_p$ and saturation temperature ![]() $\hat {T}_{sat}$. The liquid–gas interfacial tension,

$\hat {T}_{sat}$. The liquid–gas interfacial tension, ![]() $\hat {\sigma }$, is assumed to be a linear function of temperature:

$\hat {\sigma }$, is assumed to be a linear function of temperature:

where ![]() $\hat {\sigma }_0$ is the surface tension at the reference temperature

$\hat {\sigma }_0$ is the surface tension at the reference temperature ![]() $\hat {T}_{ref}$, and

$\hat {T}_{ref}$, and ![]() $\hat {T}_s$ is the local temperature at the liquid–gas interface. The reference temperature was considered to be equal to the bulk temperature of the gas

$\hat {T}_s$ is the local temperature at the liquid–gas interface. The reference temperature was considered to be equal to the bulk temperature of the gas ![]() $\hat {T}_{b}$.

$\hat {T}_{b}$.

Figure 1. Schematic diagram of model geometry. (a) Initial configuration of a droplet with initial half-width ![]() $\hat {l}_0$ and initial height

$\hat {l}_0$ and initial height ![]() $\hat {h}_0$ resting on an undeformed compliant substrate at

$\hat {h}_0$ resting on an undeformed compliant substrate at ![]() $\hat {z}=0$, which is attached to a rigid substrate at

$\hat {z}=0$, which is attached to a rigid substrate at ![]() $\hat {z}=-\hat {H}$. (b) The soft solid deforms while the system of two droplets spreads and evaporates. (c) Magnified view of the contact line, where

$\hat {z}=-\hat {H}$. (b) The soft solid deforms while the system of two droplets spreads and evaporates. (c) Magnified view of the contact line, where ![]() $\hat {\beta }$ is the precursor film thickness,

$\hat {\beta }$ is the precursor film thickness, ![]() $\hat {\theta }$ is the apparent contact angle and

$\hat {\theta }$ is the apparent contact angle and ![]() $\hat {\xi }_{max}$ denotes the maximum height of the wetting ridge. The local thickness of each droplet is given by

$\hat {\xi }_{max}$ denotes the maximum height of the wetting ridge. The local thickness of each droplet is given by ![]() $\hat {h}(\hat {x},\hat {t})=\hat {\zeta }(\hat {x},\hat {t})-\hat {\xi }(\hat {x},\hat {t})$.

$\hat {h}(\hat {x},\hat {t})=\hat {\zeta }(\hat {x},\hat {t})-\hat {\xi }(\hat {x},\hat {t})$.

At ![]() $\hat {t}>0$, the droplet, being in an unsaturated environment, evaporates causing the deformation of the soft solid substrate. The liquid–solid interface is located at

$\hat {t}>0$, the droplet, being in an unsaturated environment, evaporates causing the deformation of the soft solid substrate. The liquid–solid interface is located at ![]() $\hat {z}=\hat {\xi }(\hat {x},\hat {t})$, with an outward normal unit vector of

$\hat {z}=\hat {\xi }(\hat {x},\hat {t})$, with an outward normal unit vector of ![]() $\hat {\boldsymbol{n}}_s=(-{\partial \hat {\xi }}/{\partial \hat {x}},1) / \sqrt {1+({\partial \hat {\xi }}/{\partial \hat {x}})^2}$ while the liquid–air interface is located at

$\hat {\boldsymbol{n}}_s=(-{\partial \hat {\xi }}/{\partial \hat {x}},1) / \sqrt {1+({\partial \hat {\xi }}/{\partial \hat {x}})^2}$ while the liquid–air interface is located at ![]() $\hat {z}=\hat {\zeta }(\hat {x},\hat {t})$, with an outward normal unit vector of

$\hat {z}=\hat {\zeta }(\hat {x},\hat {t})$, with an outward normal unit vector of ![]() $\hat {\boldsymbol{n}}_l=(-{\partial \hat {\zeta }}/{\partial \hat {x}},1) / \sqrt {1+({\partial \hat {\zeta }}/{\partial \hat {x}})^2}$. The tangential unit vectors are

$\hat {\boldsymbol{n}}_l=(-{\partial \hat {\zeta }}/{\partial \hat {x}},1) / \sqrt {1+({\partial \hat {\zeta }}/{\partial \hat {x}})^2}$. The tangential unit vectors are ![]() $\hat {\boldsymbol{t}}_s=(1, {\partial \hat {\xi }}/{\partial \hat {x}}) / \sqrt {1+({\partial \hat {\xi }}/{\partial \hat {x}})^2}$ and

$\hat {\boldsymbol{t}}_s=(1, {\partial \hat {\xi }}/{\partial \hat {x}}) / \sqrt {1+({\partial \hat {\xi }}/{\partial \hat {x}})^2}$ and ![]() $\hat {\boldsymbol{t}}_l=(1, {\partial \hat {\zeta }}/{\partial \hat {x}}) / \sqrt {1+({\partial \hat {\zeta }}/{\partial \hat {x}})^2}$ for the liquid–solid and the liquid–air interface, respectively.

$\hat {\boldsymbol{t}}_l=(1, {\partial \hat {\zeta }}/{\partial \hat {x}}) / \sqrt {1+({\partial \hat {\zeta }}/{\partial \hat {x}})^2}$ for the liquid–solid and the liquid–air interface, respectively.

We assume that the droplet is released into a thin precursor film; evaporation in the film is stabilised by the disjoining pressure which accounts for intermolecular van der Waals interactions. The inclusion of the precursor film removes the stress singularity that can arise at the moving contact line (see figure 1c). This approach also allows us to easily account for the evaporation of multiple droplets as well as their interactions; in figure 1(b) we depict a system of two evaporating droplets, of the same initial radius and height. Ahead of the contact line the dimensional precursor film thickness is denoted with ![]() $\hat {\beta }$ (see figure 1c) and the apparent contact angle is

$\hat {\beta }$ (see figure 1c) and the apparent contact angle is ![]() $\hat {\theta }$. Concerning the wetting ridge, its maximum height is denoted as

$\hat {\theta }$. Concerning the wetting ridge, its maximum height is denoted as ![]() $\hat {\xi }_{max}$. Moreover, the length of each droplet, that is the distance between the two contact lines, is denoted as

$\hat {\xi }_{max}$. Moreover, the length of each droplet, that is the distance between the two contact lines, is denoted as ![]() $\Delta \hat {x}_{cl}$, while the length of the computational domain is denoted as

$\Delta \hat {x}_{cl}$, while the length of the computational domain is denoted as ![]() $\hat{L}_x$ (i.e.

$\hat{L}_x$ (i.e. ![]() $0<\hat {x}<\hat {L}_x$). In this domain, the global centre of mass of the system is located at

$0<\hat {x}<\hat {L}_x$). In this domain, the global centre of mass of the system is located at ![]() $\hat {x}=\hat {x}_{cm,g}$ and the centre of mass of each droplet is located at

$\hat {x}=\hat {x}_{cm,g}$ and the centre of mass of each droplet is located at ![]() $\hat {x}=\hat {x}_{cm,l}$ and

$\hat {x}=\hat {x}_{cm,l}$ and ![]() $\hat {x}=\hat {x}_{cm,r}$, respectively. Consequently, the distance between the two centres of mass is denoted as

$\hat {x}=\hat {x}_{cm,r}$, respectively. Consequently, the distance between the two centres of mass is denoted as ![]() $\Delta \hat {x}_{cm}=\hat {x}_{cm,r}-\hat {x}_{cm,l}$. The presented model geometry in figure 1 constitutes the reference layout for the rest of this paper.

$\Delta \hat {x}_{cm}=\hat {x}_{cm,r}-\hat {x}_{cm,l}$. The presented model geometry in figure 1 constitutes the reference layout for the rest of this paper.

In the present work, the droplets are assumed to be so thin that the droplet aspect ratio ![]() $\mathbf {\epsilon }=\hat {h}_0/\hat {R}_0$ is considered to be much smaller than unity;

$\mathbf {\epsilon }=\hat {h}_0/\hat {R}_0$ is considered to be much smaller than unity; ![]() $\hat {R}_0$ is a characteristic length scale, defined as

$\hat {R}_0$ is a characteristic length scale, defined as ![]() $\hat {R}_0=2\hat {l}_0/3$. Under this assumption, we will employ the lubrication approximation to derive a reduced set of governing evolution equations. Furthermore, gravitational forces are neglected, since the solid and liquid Bond numbers

$\hat {R}_0=2\hat {l}_0/3$. Under this assumption, we will employ the lubrication approximation to derive a reduced set of governing evolution equations. Furthermore, gravitational forces are neglected, since the solid and liquid Bond numbers ![]() $Bo_s=\hat {\rho }_s\hat {g}\hat {R}_0^2/\hat {\sigma }$ and

$Bo_s=\hat {\rho }_s\hat {g}\hat {R}_0^2/\hat {\sigma }$ and ![]() $Bo_l=\hat {\rho }_l\hat {g}\hat {R}_0^2/\hat {\sigma }$ are assumed to be less than unity; this condition typically holds for small droplets. A two-dimensional Cartesian coordinate system

$Bo_l=\hat {\rho }_l\hat {g}\hat {R}_0^2/\hat {\sigma }$ are assumed to be less than unity; this condition typically holds for small droplets. A two-dimensional Cartesian coordinate system ![]() $(\hat {x},\hat {z})$ is used to model the velocity field, which is described by a function of

$(\hat {x},\hat {z})$ is used to model the velocity field, which is described by a function of ![]() $\hat {\boldsymbol {v}}=(\hat {v}_x, \hat {v}_z)$, whereas the solid displacement is given by

$\hat {\boldsymbol {v}}=(\hat {v}_x, \hat {v}_z)$, whereas the solid displacement is given by ![]() $\hat {\boldsymbol {u}}=(\hat {u}_x, \hat {u}_z)$. Our model can describe a typical system of water droplets drying on polydimethylsiloxane (PDMS) substrates and the physical properties of such a system are given in table 1.

$\hat {\boldsymbol {u}}=(\hat {u}_x, \hat {u}_z)$. Our model can describe a typical system of water droplets drying on polydimethylsiloxane (PDMS) substrates and the physical properties of such a system are given in table 1.

Table 1. Properties of water and PDMS at 20 ![]() $^\circ$C and 1 atm.

$^\circ$C and 1 atm.

2.2. Liquid phase

The mass, momentum and energy conservation equations for the liquid are given by

where ![]() $\hat {p}_l$ is the liquid pressure,

$\hat {p}_l$ is the liquid pressure, ![]() $\hat {\boldsymbol {\nabla }}=(\partial _{\hat {x}},\partial _{\hat {y}})$ is the gradient operator,

$\hat {\boldsymbol {\nabla }}=(\partial _{\hat {x}},\partial _{\hat {y}})$ is the gradient operator, ![]() $\hat {T}$ is the temperature and

$\hat {T}$ is the temperature and ![]() $\hat {\alpha }_l={\hat {\lambda }}/{(\hat {\rho }_l \hat {c}_p)}$ is the thermal diffusivity of the liquid. Along the free interface

$\hat {\alpha }_l={\hat {\lambda }}/{(\hat {\rho }_l \hat {c}_p)}$ is the thermal diffusivity of the liquid. Along the free interface ![]() $\hat {z}=\hat {\zeta }(\hat {x},\hat {t})$, the liquid velocity

$\hat {z}=\hat {\zeta }(\hat {x},\hat {t})$, the liquid velocity ![]() $\hat {\boldsymbol {v}}=(\hat {v}_x, \hat {v}_z)$ differs from the velocity of the interface

$\hat {\boldsymbol {v}}=(\hat {v}_x, \hat {v}_z)$ differs from the velocity of the interface ![]() $\hat {\boldsymbol {v}}_{\boldsymbol {s}}=(\hat {v}_{xs}, \hat {v}_{zs})$. If the evaporative flux is denoted by

$\hat {\boldsymbol {v}}_{\boldsymbol {s}}=(\hat {v}_{xs}, \hat {v}_{zs})$. If the evaporative flux is denoted by ![]() $\hat {J}$, then

$\hat {J}$, then

Furthermore, along the free interface, the local mass, energy and force balances are given by

where ![]() $\hat {\rho }_g$,

$\hat {\rho }_g$, ![]() $\hat {\lambda }_g$,

$\hat {\lambda }_g$, ![]() $\hat {\boldsymbol {v}}_{\boldsymbol {g}}$ and

$\hat {\boldsymbol {v}}_{\boldsymbol {g}}$ and ![]() $\hat {T}_g$ denote the density, the thermal conductivity, the velocity and the temperature of the gas phase, respectively. Here

$\hat {T}_g$ denote the density, the thermal conductivity, the velocity and the temperature of the gas phase, respectively. Here ![]() $\hat {L}_v$ is the specific latent internal heat of vaporisation,

$\hat {L}_v$ is the specific latent internal heat of vaporisation, ![]() $\boldsymbol{\mathsf{I}}$ is the identity tensor,

$\boldsymbol{\mathsf{I}}$ is the identity tensor, ![]() $\hat {\kappa }_l$ is the mean curvature of the free interface, while

$\hat {\kappa }_l$ is the mean curvature of the free interface, while ![]() $\hat {\boldsymbol {\nabla }}_s$ is the surface gradient operator. In the above equations,

$\hat {\boldsymbol {\nabla }}_s$ is the surface gradient operator. In the above equations, ![]() $\hat {\kappa }_l=\hat {\boldsymbol {\nabla }}_s \boldsymbol{\cdot} \hat {\boldsymbol {n}}_{\boldsymbol {l}}$ and

$\hat {\kappa }_l=\hat {\boldsymbol {\nabla }}_s \boldsymbol{\cdot} \hat {\boldsymbol {n}}_{\boldsymbol {l}}$ and ![]() $\hat {\boldsymbol {\nabla }}_s=(I-\hat {\boldsymbol {n}}_{\boldsymbol {l}} \hat {\boldsymbol {n}}_{\boldsymbol {l}}) \boldsymbol{\cdot} \hat {\boldsymbol {\nabla }}$. Finally,

$\hat {\boldsymbol {\nabla }}_s=(I-\hat {\boldsymbol {n}}_{\boldsymbol {l}} \hat {\boldsymbol {n}}_{\boldsymbol {l}}) \boldsymbol{\cdot} \hat {\boldsymbol {\nabla }}$. Finally, ![]() $\hat {\varPi }$ stands for the disjoining pressure, which, taking into consideration the van der Waals interaction, is equal to

$\hat {\varPi }$ stands for the disjoining pressure, which, taking into consideration the van der Waals interaction, is equal to

\begin{equation} \hat{\varPi}=\hat{A}_1 \left[\left(\frac{\hat{A}_2}{\hat{h}}\right)^n - \left(\frac{\hat{A}_2}{\hat{h}}\right)^c \right], \end{equation}

\begin{equation} \hat{\varPi}=\hat{A}_1 \left[\left(\frac{\hat{A}_2}{\hat{h}}\right)^n - \left(\frac{\hat{A}_2}{\hat{h}}\right)^c \right], \end{equation}

where ![]() $\hat {A}_1=\hat {A}_{Ham}/\hat {A}_2^3$, is a constant that describes the intermolecular interactions between the liquid–gas and the liquid–solid interfaces,

$\hat {A}_1=\hat {A}_{Ham}/\hat {A}_2^3$, is a constant that describes the intermolecular interactions between the liquid–gas and the liquid–solid interfaces, ![]() $\hat {A}_{Ham}$ the Hamaker constant,

$\hat {A}_{Ham}$ the Hamaker constant, ![]() $\hat {A}_2$ is a constant of the same order of magnitude as the precursor film thickness

$\hat {A}_2$ is a constant of the same order of magnitude as the precursor film thickness ![]() $\hat {\beta }$.

$\hat {\beta }$. ![]() $\hat {h}$ denotes the droplet thickness and

$\hat {h}$ denotes the droplet thickness and ![]() $n>c>1$. Moreover, the kinematic boundary condition along the moving interface

$n>c>1$. Moreover, the kinematic boundary condition along the moving interface ![]() $\hat {z}=\hat {\zeta }(\hat {x},\hat {t})$, is described as

$\hat {z}=\hat {\zeta }(\hat {x},\hat {t})$, is described as

2.3. Gas phase

The gas phase is assumed to comprise air and vapour, but it is not saturated by vapour. Typically, we may consider that ![]() $\varLambda _g={\hat {\lambda }}/{\hat {\lambda }_g}\ll 1$, and under this assumption the bulk temperature of the gas can be assumed to be constant and equal to

$\varLambda _g={\hat {\lambda }}/{\hat {\lambda }_g}\ll 1$, and under this assumption the bulk temperature of the gas can be assumed to be constant and equal to ![]() $\hat {T}_b$. Moreover, we assume that the viscosity of the gas,

$\hat {T}_b$. Moreover, we assume that the viscosity of the gas, ![]() $\hat {\eta }_g$, is much smaller than the viscosity of the liquid phase, i.e.

$\hat {\eta }_g$, is much smaller than the viscosity of the liquid phase, i.e. ![]() $\hat {\eta }_g/\hat {\eta }_l \ll 1$ and therefore the gas can be considered as inviscid and passive with respect to the fluid.

$\hat {\eta }_g/\hat {\eta }_l \ll 1$ and therefore the gas can be considered as inviscid and passive with respect to the fluid.

The droplet evaporation is approached using the generalised diffusion-limited model developed by Sultan et al. (Reference Sultan, Boudaoud and Amar2005), in which evaporation is considered limited by the solvent vapour diffusion in the air; this model is able to capture the transition between the diffusion-limited and the one-sided model. The vapour concentration ![]() $\hat {\rho }^v$ in the gas phase is described by the Laplace's equation, due to the fact that the gas phase is considered to be at rest and the characteristic evaporation time is much larger than the respectivediffusion time. As a result, we get

$\hat {\rho }^v$ in the gas phase is described by the Laplace's equation, due to the fact that the gas phase is considered to be at rest and the characteristic evaporation time is much larger than the respectivediffusion time. As a result, we get

The vapour mass flux ![]() $\hat {J}$ is assumed to be limited by the rate of diffusion and thus

$\hat {J}$ is assumed to be limited by the rate of diffusion and thus

where ![]() $\mathcal {\hat {D}}_v$ the diffusion vapour coefficient. Considering also that the vapour mass flux

$\mathcal {\hat {D}}_v$ the diffusion vapour coefficient. Considering also that the vapour mass flux ![]() $\hat {J}$ is proportional to the departure from equilibrium at the liquid–gas interface (Schrage Reference Schrage1953; Plesset & Prosperetti Reference Plesset and Prosperetti1976; Moosman & Homsy Reference Moosman and Homsy1980), the following linear constitutive equation, most commonly known as the Hertz–Knudsen equation, for

$\hat {J}$ is proportional to the departure from equilibrium at the liquid–gas interface (Schrage Reference Schrage1953; Plesset & Prosperetti Reference Plesset and Prosperetti1976; Moosman & Homsy Reference Moosman and Homsy1980), the following linear constitutive equation, most commonly known as the Hertz–Knudsen equation, for ![]() $\hat {J}$ can be used:

$\hat {J}$ can be used:

\begin{equation} \hat{J}=\alpha \left(\frac{\hat{R} \hat{T}_{s}}{2{\rm \pi} \hat{M}}\right)^{{1}/{2}} (\hat{\rho}^{ve}-\hat{\rho}^v|_{\hat{\zeta}}), \end{equation}

\begin{equation} \hat{J}=\alpha \left(\frac{\hat{R} \hat{T}_{s}}{2{\rm \pi} \hat{M}}\right)^{{1}/{2}} (\hat{\rho}^{ve}-\hat{\rho}^v|_{\hat{\zeta}}), \end{equation}

where ![]() $\alpha$ is the accommodation coefficient, usually considered equal to unity near equilibrium. Here

$\alpha$ is the accommodation coefficient, usually considered equal to unity near equilibrium. Here ![]() $\hat {R}$ denotes the universal gas constant,

$\hat {R}$ denotes the universal gas constant, ![]() $\hat {T}_{s}$ denotes the temperature of the liquid–gas interface,

$\hat {T}_{s}$ denotes the temperature of the liquid–gas interface, ![]() $\hat {\rho }^v$ is the local vapour concentration in the gas phase and

$\hat {\rho }^v$ is the local vapour concentration in the gas phase and ![]() $\hat {\rho }^{ve}$ is the equilibrium vapour concentration.

$\hat {\rho }^{ve}$ is the equilibrium vapour concentration.

In order to get a boundary condition for the vapour concentration ![]() $\hat {\rho }^v$ at

$\hat {\rho }^v$ at ![]() $\hat {z}=\hat {\zeta }$, we can combine (2.12) and (2.13), which leads to

$\hat {z}=\hat {\zeta }$, we can combine (2.12) and (2.13), which leads to

\begin{equation} -\mathcal{\hat{D}}_v(\hat{\boldsymbol{n}}_{\boldsymbol{l}} \boldsymbol{\cdot} \hat{\boldsymbol{\nabla}} \hat{\rho}^v)|_{\hat{\zeta}}=\alpha \left(\frac{\hat{R} \hat{T}_{s}}{2{\rm \pi} \hat{M}}\right)^{{1}/{2}} (\hat{\rho}^{ve}-\hat{\rho}^v|_{\hat{\zeta}}). \end{equation}

\begin{equation} -\mathcal{\hat{D}}_v(\hat{\boldsymbol{n}}_{\boldsymbol{l}} \boldsymbol{\cdot} \hat{\boldsymbol{\nabla}} \hat{\rho}^v)|_{\hat{\zeta}}=\alpha \left(\frac{\hat{R} \hat{T}_{s}}{2{\rm \pi} \hat{M}}\right)^{{1}/{2}} (\hat{\rho}^{ve}-\hat{\rho}^v|_{\hat{\zeta}}). \end{equation}Finally, following a similar procedure as described by (Moosman & Homsy Reference Moosman and Homsy1980), the following equation for the equilibrium vapour concentration can be derived:

\begin{equation} \hat{\rho}^{ve}=\hat{\rho}^v_{ref}+\frac{\hat{M} \hat{\rho}^v_{ref}}{\hat{\rho}_l \hat{R} \hat{T}_{ref}}({-}2\hat{H}_l \hat{\sigma} -\hat{\varPi})+\frac{\hat{L}_v \hat{M} \hat{\rho}^v_{ref}}{\hat{R} \hat{T}^2_{ref}}(\hat{T}_s-\hat{T}_{ref}), \end{equation}

\begin{equation} \hat{\rho}^{ve}=\hat{\rho}^v_{ref}+\frac{\hat{M} \hat{\rho}^v_{ref}}{\hat{\rho}_l \hat{R} \hat{T}_{ref}}({-}2\hat{H}_l \hat{\sigma} -\hat{\varPi})+\frac{\hat{L}_v \hat{M} \hat{\rho}^v_{ref}}{\hat{R} \hat{T}^2_{ref}}(\hat{T}_s-\hat{T}_{ref}), \end{equation}

where ![]() $\hat {\rho }^v_{ref}$ is the equilibrium vapour concentration at the reference temperature.

$\hat {\rho }^v_{ref}$ is the equilibrium vapour concentration at the reference temperature.

At the far-field boundary, the most natural choice would be to impose a constant vapour concentration at infinity. However, since it is known that for the diffusion-limited model there is no analytical solution in two-dimensional half-space (Schofield et al. Reference Schofield, Wray, Pritchard, Wilson and Sefiane2020), we follow a similar approach to Schofield et al. (Reference Schofield, Wray, Pritchard, Wilson and Sefiane2020) considering a finite domain of the gas phase and the far-field condition is replaced by a similar Dirichlet condition at a distant, but finite, boundary. Thus, far from the droplet (![]() $\hat {z}=\hat {d}_g$), the vapour concentration is maintained at a constant initial vapour concentration

$\hat {z}=\hat {d}_g$), the vapour concentration is maintained at a constant initial vapour concentration ![]() $\hat {\rho }_{vi}$:

$\hat {\rho }_{vi}$:

2.4. Soft solid substrate

The mass, momentum and energy conservation equations for the soft solid substrate are given by

where ![]() $\hat {p}_s$ is the pressure in the solid,

$\hat {p}_s$ is the pressure in the solid, ![]() $\hat {\alpha }_w$ is the thermal diffusivity of the solid,

$\hat {\alpha }_w$ is the thermal diffusivity of the solid, ![]() $\hat {T}_w$ is the temperature of the solid surface and

$\hat {T}_w$ is the temperature of the solid surface and ![]() $\hat {\boldsymbol{\mathsf{T}}}_s$ is the solid stress tensor. Following the work of Kumar & Matar (Reference Kumar and Matar2004), Matar et al. (Reference Matar, Gkanis and Kumar2005) and Charitatos & Kumar (Reference Charitatos and Kumar2020, Reference Charitatos and Kumar2021), who modelled the soft elastomer layer as a linear viscoelastic material, we consider that the viscoelastic solid is described by the Kelvin–Voigt model and therefore the solid stress tensor is defined as

$\hat {\boldsymbol{\mathsf{T}}}_s$ is the solid stress tensor. Following the work of Kumar & Matar (Reference Kumar and Matar2004), Matar et al. (Reference Matar, Gkanis and Kumar2005) and Charitatos & Kumar (Reference Charitatos and Kumar2020, Reference Charitatos and Kumar2021), who modelled the soft elastomer layer as a linear viscoelastic material, we consider that the viscoelastic solid is described by the Kelvin–Voigt model and therefore the solid stress tensor is defined as

Finally, (2.18) gives

At ![]() $\hat {z}=-\hat {H}$, the application of the no-slip and no-displacement boundary condition yields

$\hat {z}=-\hat {H}$, the application of the no-slip and no-displacement boundary condition yields ![]() $\hat {v}_x=\hat {v}_z=0$ and

$\hat {v}_x=\hat {v}_z=0$ and ![]() $\hat {u}_x=\hat {u}_z=0$, while the temperature at the bottom of the solid substrate is considered to be equal to

$\hat {u}_x=\hat {u}_z=0$, while the temperature at the bottom of the solid substrate is considered to be equal to ![]() $\hat {T}_b$, i.e.

$\hat {T}_b$, i.e. ![]() $\hat {T}_w|_{\hat {z}=-\hat {H}}=\hat {T}_b$.

$\hat {T}_w|_{\hat {z}=-\hat {H}}=\hat {T}_b$.

Along the liquid–solid interface, at ![]() $\hat {z}=\hat {\xi }(\hat {x},\hat {t})$, we consider thermal equilibrium

$\hat {z}=\hat {\xi }(\hat {x},\hat {t})$, we consider thermal equilibrium ![]() $\hat {T}_w|_{\hat {\xi }}=\hat {T}|_{\hat {\xi }}$ and continuity of thermal flux,

$\hat {T}_w|_{\hat {\xi }}=\hat {T}|_{\hat {\xi }}$ and continuity of thermal flux,

In addition, the combination of the no-slip and the no-penetration boundary conditions at ![]() $\hat {z}=\hat {\xi }(\hat {x},\hat {t})$, that is the liquid–solid interface, form the continuity-of-velocity boundary condition,

$\hat {z}=\hat {\xi }(\hat {x},\hat {t})$, that is the liquid–solid interface, form the continuity-of-velocity boundary condition,

The normal and tangential force balances on the liquid–solid interface lead to

where ![]() $\hat {\kappa }_s=\hat {\nabla }_s \boldsymbol{\cdot} \hat {\boldsymbol {n}}_{\boldsymbol {s}}$ and

$\hat {\kappa }_s=\hat {\nabla }_s \boldsymbol{\cdot} \hat {\boldsymbol {n}}_{\boldsymbol {s}}$ and ![]() $\hat {\boldsymbol{\mathsf{T}}}_l$ stands for the liquid stress tensor, defined as

$\hat {\boldsymbol{\mathsf{T}}}_l$ stands for the liquid stress tensor, defined as ![]() $\hat {\boldsymbol{\mathsf{T}}}_l= -\hat {p}_l \boldsymbol{\mathsf{I}}+\hat {\eta }_l[\hat {\boldsymbol {\nabla }} \hat {\boldsymbol {v}}+ (\hat {\boldsymbol {\nabla }} \hat {\boldsymbol {v}})^{\rm T}]$.

$\hat {\boldsymbol{\mathsf{T}}}_l= -\hat {p}_l \boldsymbol{\mathsf{I}}+\hat {\eta }_l[\hat {\boldsymbol {\nabla }} \hat {\boldsymbol {v}}+ (\hat {\boldsymbol {\nabla }} \hat {\boldsymbol {v}})^{\rm T}]$.

3. Scaling

In order to render the aforementioned equations and boundary conditions non-dimensional, we use the scalings

\begin{equation} \left.\begin{array}{l} \displaystyle (\hat{x}, \hat{z}, \hat{\xi}, \hat{\zeta}) = \hat{R}_0 (x, \epsilon z, \epsilon \xi, \epsilon \zeta), \quad \hat{t} = \dfrac{\hat{R}_0}{{\hat{U}}} t; \\ \displaystyle \hat{\sigma} = \hat{\sigma}_0 \sigma, \quad (\hat{p}_l, \hat{p}_s, \hat{\varPi}) = \dfrac{\hat{\eta}_l {\hat{U}}}{\epsilon^2 \hat{R}_0} (p_l, p_s, \varPi); \\ \displaystyle (\hat{u}_x, \hat{u}_z)=\hat{R}_0 (u_x, \epsilon u_z), \quad (\hat{v}_x, \hat{v}_z)=\hat{U} (v_x,\epsilon v_z); \\ \displaystyle \hat{T} = \hat{T}_{ref} + T\Delta\hat{T},\quad \hat{J} = \dfrac{\hat{\lambda} \Delta \hat{T}}{\hat{L}_v \hat{h}_0} J, \quad \hat{\rho}^v = \hat{\rho}^{v}_{ref} \rho^v; \end{array} \right\} \end{equation}

\begin{equation} \left.\begin{array}{l} \displaystyle (\hat{x}, \hat{z}, \hat{\xi}, \hat{\zeta}) = \hat{R}_0 (x, \epsilon z, \epsilon \xi, \epsilon \zeta), \quad \hat{t} = \dfrac{\hat{R}_0}{{\hat{U}}} t; \\ \displaystyle \hat{\sigma} = \hat{\sigma}_0 \sigma, \quad (\hat{p}_l, \hat{p}_s, \hat{\varPi}) = \dfrac{\hat{\eta}_l {\hat{U}}}{\epsilon^2 \hat{R}_0} (p_l, p_s, \varPi); \\ \displaystyle (\hat{u}_x, \hat{u}_z)=\hat{R}_0 (u_x, \epsilon u_z), \quad (\hat{v}_x, \hat{v}_z)=\hat{U} (v_x,\epsilon v_z); \\ \displaystyle \hat{T} = \hat{T}_{ref} + T\Delta\hat{T},\quad \hat{J} = \dfrac{\hat{\lambda} \Delta \hat{T}}{\hat{L}_v \hat{h}_0} J, \quad \hat{\rho}^v = \hat{\rho}^{v}_{ref} \rho^v; \end{array} \right\} \end{equation}

where ![]() $\Delta \hat {T}=\epsilon ^2 \hat {T}_{ref}$. As

$\Delta \hat {T}=\epsilon ^2 \hat {T}_{ref}$. As ![]() $\hat {T}_{ref}$ we consider the constant bulk temperature of the gas phase,

$\hat {T}_{ref}$ we consider the constant bulk temperature of the gas phase, ![]() $\hat {T}_b$. As characteristic velocity we use

$\hat {T}_b$. As characteristic velocity we use ![]() $\hat {U}=\epsilon ^3 \hat {\sigma }_0 / \hat {\eta }_l$. Note that henceforth all the variables in the following equations are dimensionless.

$\hat {U}=\epsilon ^3 \hat {\sigma }_0 / \hat {\eta }_l$. Note that henceforth all the variables in the following equations are dimensionless.

3.1. Liquid phase

By substituting these scalings and taking into consideration that ![]() $\epsilon \ll 1$, the leading-order equations for the liquid are

$\epsilon \ll 1$, the leading-order equations for the liquid are

Along the free interface, i.e. ![]() $z=\zeta (x,t)$, we get for the mass, energy and force balances in the normal and tangential coordinate,

$z=\zeta (x,t)$, we get for the mass, energy and force balances in the normal and tangential coordinate,

where ![]() $\sigma =1-Ma T_s$,

$\sigma =1-Ma T_s$, ![]() $C_l={\hat {\eta }_l \hat {U}}/{\epsilon ^3 \hat {\sigma }_0}$,

$C_l={\hat {\eta }_l \hat {U}}/{\epsilon ^3 \hat {\sigma }_0}$, ![]() $Ma=({\partial \hat {\sigma }}/{\partial \hat {T}})({\Delta \hat {T}}/{\hat {\sigma }_0})$ and

$Ma=({\partial \hat {\sigma }}/{\partial \hat {T}})({\Delta \hat {T}}/{\hat {\sigma }_0})$ and ![]() $E={\hat {\lambda } \Delta \hat {T}}/{\hat {L}_v \hat {h}_0 \hat {\rho }_l \hat {U} \epsilon }$ the evaporation number, which represents the ratio between the capillary time

$E={\hat {\lambda } \Delta \hat {T}}/{\hat {L}_v \hat {h}_0 \hat {\rho }_l \hat {U} \epsilon }$ the evaporation number, which represents the ratio between the capillary time ![]() $t_c=\hat {R}_0/\hat {U}$ and the evaporation time

$t_c=\hat {R}_0/\hat {U}$ and the evaporation time ![]() $t_e={\hat {h}^{2}_0 \hat {\rho }_l \hat {L}_v}/{\hat {\lambda } \Delta \hat {T}}$, as it is derived from the scaling. In (3.8) the gas pressure has been set equal to zero (datum pressure) without loss of generality.

$t_e={\hat {h}^{2}_0 \hat {\rho }_l \hat {L}_v}/{\hat {\lambda } \Delta \hat {T}}$, as it is derived from the scaling. In (3.8) the gas pressure has been set equal to zero (datum pressure) without loss of generality.

The kinematic equation, i.e. (2.10) in combination with (3.6) gives the evolution equation for the liquid–gas interface ![]() $z=\zeta (x,t)$:

$z=\zeta (x,t)$:

Finally, the scaled disjoining pressure is given by the following expression:

where ![]() $B={\hat {A}_2}/{\hat {h}_0}$ and

$B={\hat {A}_2}/{\hat {h}_0}$ and ![]() $\mathcal {A}=({\hat {A}_{Ham}}/{\hat {A}_2^3}) ({\epsilon \hat {h}_0}/{\hat {\eta }_l \hat {U}})$ the dimensionless Hamaker constant.

$\mathcal {A}=({\hat {A}_{Ham}}/{\hat {A}_2^3}) ({\epsilon \hat {h}_0}/{\hat {\eta }_l \hat {U}})$ the dimensionless Hamaker constant.

3.2. Soft solid substrate

Using the same scaling, the leading equations for the soft solid become

where ![]() $m=\hat {\eta }_s/\hat {\eta }_l$. The ratio of elastic forces to interfacial tension forces is defined as

$m=\hat {\eta }_s/\hat {\eta }_l$. The ratio of elastic forces to interfacial tension forces is defined as ![]() $G=\epsilon ^{-3} \hat {R}_0/\hat {l}_{ec}$, where

$G=\epsilon ^{-3} \hat {R}_0/\hat {l}_{ec}$, where ![]() $\hat {l}_{ec}=\hat {\sigma }_0/\hat {E}$ denotes the elastocapillary length which sets the characteristic size of the deformation of the elastic substrate.

$\hat {l}_{ec}=\hat {\sigma }_0/\hat {E}$ denotes the elastocapillary length which sets the characteristic size of the deformation of the elastic substrate.

As far as the boundary conditions are concerned, at ![]() $z=\xi (x,t)$ we get

$z=\xi (x,t)$ we get ![]() $T_w \vert _{\xi }=T\vert _{\xi }$, whereas at

$T_w \vert _{\xi }=T\vert _{\xi }$, whereas at ![]() $z=-H$ we get

$z=-H$ we get ![]() $v_x=v_z=0$,

$v_x=v_z=0$, ![]() $u_x=u_z=0$ and we set

$u_x=u_z=0$ and we set ![]() $T_w\vert _{-H}=0$. The dimensionless continuity of thermal flux along

$T_w\vert _{-H}=0$. The dimensionless continuity of thermal flux along ![]() $z=\xi (x,t)$ is given by

$z=\xi (x,t)$ is given by

where ![]() $\varLambda _w=\hat {\lambda }_w/\hat {\lambda }$ denotes the ratio of thermal conductivity between the solid and the liquid.

$\varLambda _w=\hat {\lambda }_w/\hat {\lambda }$ denotes the ratio of thermal conductivity between the solid and the liquid.

At the liquid–solid interface, i.e. ![]() $z=\xi (x,t)$, both the continuity-of-velocity and the normal and tangential force balances render to the following form:

$z=\xi (x,t)$, both the continuity-of-velocity and the normal and tangential force balances render to the following form:

where ![]() $p_{cap,l}=-{C_l}^{-1}\sigma \partial ^2 \zeta /\partial x^2$ and

$p_{cap,l}=-{C_l}^{-1}\sigma \partial ^2 \zeta /\partial x^2$ and ![]() $p_{cap,s}=-{C_s}^{-1} \partial ^2 \xi /\partial x^2$ the capillary-like pressures in the liquid and the solid, respectively, with

$p_{cap,s}=-{C_s}^{-1} \partial ^2 \xi /\partial x^2$ the capillary-like pressures in the liquid and the solid, respectively, with ![]() $C_s={\hat {\eta }_l \hat {U}}/{\epsilon ^3 \hat {\gamma }}$ denoting the capillary number at the liquid–solid interface.

$C_s={\hat {\eta }_l \hat {U}}/{\epsilon ^3 \hat {\gamma }}$ denoting the capillary number at the liquid–solid interface.

3.3. Gas phase

Since the gas phase in the atmosphere may extend to large distances above the liquid phase, the scaling in the ![]() $z$-direction shown in (3.1) is not appropriate and therefore we employ the same scaling with the

$z$-direction shown in (3.1) is not appropriate and therefore we employ the same scaling with the ![]() $x$-direction (i.e.

$x$-direction (i.e. ![]() $\hat {z} = \hat {R}_0 z'$ and

$\hat {z} = \hat {R}_0 z'$ and ![]() $\hat {\zeta }= \hat {R}_0 \zeta '$). The dimensionless conservation equation for the vapour concentration is then given by

$\hat {\zeta }= \hat {R}_0 \zeta '$). The dimensionless conservation equation for the vapour concentration is then given by

The above equation is subjected to the following boundary conditions far from the droplet (![]() $z'=d_g$) and along the liquid–gas interface (

$z'=d_g$) and along the liquid–gas interface (![]() $z'=\zeta '(x,t)$):

$z'=\zeta '(x,t)$):

where ![]() $\mathcal {H}=\hat {\rho }^{vi}/\hat {\rho }^{v}_{ref}$ denotes the relative humidity and

$\mathcal {H}=\hat {\rho }^{vi}/\hat {\rho }^{v}_{ref}$ denotes the relative humidity and ![]() $Pe_v={\hat {\lambda } \Delta \hat {T} \hat {R}_0}/{\hat {h}_0\mathcal {\hat {D}}_v \hat {\rho }^{v}_{ref}\hat {L}_v}$.

$Pe_v={\hat {\lambda } \Delta \hat {T} \hat {R}_0}/{\hat {h}_0\mathcal {\hat {D}}_v \hat {\rho }^{v}_{ref}\hat {L}_v}$.

Solving (3.21)–(3.23) we evaluate the vapour concentration in the gas phase, therefore making it possible to compute the vapour mass flux using the following dimensionless constitutive equation:

where ![]() $K=({\hat {\lambda } \Delta \hat {T}}/{\alpha \hat {\rho }^v_{ref} \hat {L}_v \hat {h}_0}) \sqrt {{2 {\rm \pi}\hat {M}}/{\hat {R} T_s}}$. In the above equation the equilibrium vapour concentration is given by

$K=({\hat {\lambda } \Delta \hat {T}}/{\alpha \hat {\rho }^v_{ref} \hat {L}_v \hat {h}_0}) \sqrt {{2 {\rm \pi}\hat {M}}/{\hat {R} T_s}}$. In the above equation the equilibrium vapour concentration is given by

where ![]() $\delta ={\hat {M} \hat {\eta }_l \hat {U}}/{\hat {\rho }_l \hat {R} \hat {T}_{ref} \epsilon ^2 \hat {R}_0}$ and

$\delta ={\hat {M} \hat {\eta }_l \hat {U}}/{\hat {\rho }_l \hat {R} \hat {T}_{ref} \epsilon ^2 \hat {R}_0}$ and ![]() $\psi ={\hat {L}_v \hat {M} \Delta \hat {T}}/{\hat {R} \hat {T}^2_{ref}}$.

$\psi ={\hat {L}_v \hat {M} \Delta \hat {T}}/{\hat {R} \hat {T}^2_{ref}}$.

In order to evaluate the precursor film thickness ![]() $\beta$, we can combine (3.24) with (3.25). Taking into account that far from the droplets the film is flat and at equilibrium with the environment, the following equation is derived:

$\beta$, we can combine (3.24) with (3.25). Taking into account that far from the droplets the film is flat and at equilibrium with the environment, the following equation is derived:

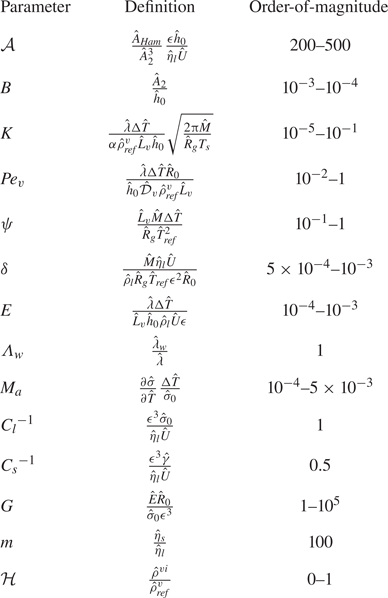

An estimation of the order-of-magnitude of certain dimensionless parameters is depicted in table 2.

Table 2. Order-of-magnitude estimate for the dimensionless parameters assuming ![]() $\epsilon =0.1$,

$\epsilon =0.1$, ![]() $\Delta \hat {T}=3$ K.

$\Delta \hat {T}=3$ K.

4. Evolution equations

In order to derive the evolution equations, we make an approximation that the streamwise displacement follows a parabolic profile in ![]() $z$, since this is the simplest solution that satisfies (3.13) (Matar et al. Reference Matar, Gkanis and Kumar2005; Ghosh, Bandyopadhyay & Sharma Reference Ghosh, Bandyopadhyay and Sharma2016; Charitatos & Kumar Reference Charitatos and Kumar2020, Reference Charitatos and Kumar2021) for the soft solid,

$z$, since this is the simplest solution that satisfies (3.13) (Matar et al. Reference Matar, Gkanis and Kumar2005; Ghosh, Bandyopadhyay & Sharma Reference Ghosh, Bandyopadhyay and Sharma2016; Charitatos & Kumar Reference Charitatos and Kumar2020, Reference Charitatos and Kumar2021) for the soft solid,

in which ![]() $b_1$,

$b_1$, ![]() $b_2$ and

$b_2$ and ![]() $b_3$ are functions of both space and time that will be determined later; a detailed derivation is given in Appendix A.

$b_3$ are functions of both space and time that will be determined later; a detailed derivation is given in Appendix A.

Using the boundary condition at ![]() $z=-H$, i.e.

$z=-H$, i.e. ![]() $u_x=0$, we get for

$u_x=0$, we get for ![]() $b_3(x,t)$ the following:

$b_3(x,t)$ the following:

Regarding the coefficient ![]() $b_1(x,t)$, introducing (4.1) into the

$b_1(x,t)$, introducing (4.1) into the ![]() $x$-component of the solid momentum, i.e. (3.13), yields the following expression:

$x$-component of the solid momentum, i.e. (3.13), yields the following expression:

From (3.19), using (4.1) and (3.13), as well as the expression of the ![]() $x$-component of the liquid velocity (i.e. (A9) derived in Appendix A), we conclude to an expression for the coefficient

$x$-component of the liquid velocity (i.e. (A9) derived in Appendix A), we conclude to an expression for the coefficient ![]() $b_2(x,t)$,

$b_2(x,t)$,

In order to derive the evolution equation for ![]() $\zeta (x,t)$, we use the kinematic equation for the liquid, i.e. (3.10). Using the expressions of

$\zeta (x,t)$, we use the kinematic equation for the liquid, i.e. (3.10). Using the expressions of ![]() $v_x$ and

$v_x$ and ![]() $v_z$ (i.e. (A9) and (A11), respectively, derived in Appendix A), and setting

$v_z$ (i.e. (A9) and (A11), respectively, derived in Appendix A), and setting ![]() $z=\zeta$, we get

$z=\zeta$, we get

\begin{align} \frac{\partial \zeta}{\partial t} &= \frac{\partial}{\partial x} \left[ \frac{1}{3} \frac{\partial p_l}{\partial x} (\zeta-\xi)^3 - \frac{1}{2} ( \epsilon^2 C_l )^{{-}1} \frac{\partial \sigma}{\partial x} (\zeta-\xi)^2 - H \zeta \left( \frac{\partial b_2}{\partial t} - H \frac{\partial b_1}{\partial t}\right) \right] \nonumber\\ &\quad + \xi \frac{\partial}{\partial x} \left(H \frac{\partial b_2}{\partial t} -H^2 \frac{\partial b_1}{\partial t}\right) + \frac{2 H^3}{3} \frac{\partial^2 b_1}{\partial x \partial t} - \frac{H^2}{2} \frac{\partial^2 b_2}{\partial x \partial t}- EJ. \end{align}

\begin{align} \frac{\partial \zeta}{\partial t} &= \frac{\partial}{\partial x} \left[ \frac{1}{3} \frac{\partial p_l}{\partial x} (\zeta-\xi)^3 - \frac{1}{2} ( \epsilon^2 C_l )^{{-}1} \frac{\partial \sigma}{\partial x} (\zeta-\xi)^2 - H \zeta \left( \frac{\partial b_2}{\partial t} - H \frac{\partial b_1}{\partial t}\right) \right] \nonumber\\ &\quad + \xi \frac{\partial}{\partial x} \left(H \frac{\partial b_2}{\partial t} -H^2 \frac{\partial b_1}{\partial t}\right) + \frac{2 H^3}{3} \frac{\partial^2 b_1}{\partial x \partial t} - \frac{H^2}{2} \frac{\partial^2 b_2}{\partial x \partial t}- EJ. \end{align}

Using the expressions of the material derivatives of ![]() $\xi$ and

$\xi$ and ![]() $u_z(x,0,t)$, (i.e. (A12) and (A13), respectively, derived in Appendix A), leads to an evolution equation for

$u_z(x,0,t)$, (i.e. (A12) and (A13), respectively, derived in Appendix A), leads to an evolution equation for ![]() $\xi (x,t)$:

$\xi (x,t)$:

Furthermore, we can easily find an evolution equation for the droplet thickness ![]() $h(x,t)=\zeta (x,t)-\xi (x,t)$ by subtracting (4.6) from (4.5), as follows:

$h(x,t)=\zeta (x,t)-\xi (x,t)$ by subtracting (4.6) from (4.5), as follows:

where the liquid flow rate, ![]() $q$, is given by

$q$, is given by

By integrating the energy equation, i.e. (3.15), with respect to ![]() $z$, and using the continuity of thermal flux at

$z$, and using the continuity of thermal flux at ![]() $z=\xi (x,t)$, i.e. (3.16) and the boundary condition,

$z=\xi (x,t)$, i.e. (3.16) and the boundary condition, ![]() $T_w\vert _{-H}=0$, the following evolution equation for the temperature in the soft solid substrate can be derived:

$T_w\vert _{-H}=0$, the following evolution equation for the temperature in the soft solid substrate can be derived:

Similarly, by integrating the energy equation, (3.5), with respect to ![]() $z$, and using the energy balance, (3.7), and the fact that

$z$, and using the energy balance, (3.7), and the fact that ![]() $T |_\xi =T_w\vert _{\xi }$, the following evolution equation for the temperature in the liquid phase can be derived:

$T |_\xi =T_w\vert _{\xi }$, the following evolution equation for the temperature in the liquid phase can be derived:

In summary, we solve numerically the evolution equations (4.3), (4.4), (4.6), (4.7) and (3.24) on the domain ![]() $0< x< L_x$ and (3.21) on the two-dimensional domain

$0< x< L_x$ and (3.21) on the two-dimensional domain ![]() $0< x< L_x$,

$0< x< L_x$, ![]() $0< z< L_z$. The latter equation is subjected to boundary conditions (3.22) and (3.23) in the

$0< z< L_z$. The latter equation is subjected to boundary conditions (3.22) and (3.23) in the ![]() $z$-direction and to the following condition in the

$z$-direction and to the following condition in the ![]() $x$-direction:

$x$-direction:

The numerical solution of the evolution equations (4.3), (4.4), (4.6) and (4.7) is subjected to the following conditions at ![]() $x=0$ and

$x=0$ and ![]() $x=L_x$:

$x=L_x$:

\begin{equation} \left. \begin{array}{c}

\displaystyle \dfrac{\partial \zeta}{\partial x} =

\dfrac{\partial \xi}{\partial x} = \dfrac{\partial^3

\zeta}{\partial x^3} = \dfrac{\partial^3 \xi}{\partial x^3}

= \dfrac{\partial b_1}{\partial x} = \dfrac{\partial

b_2}{\partial x} =0, \\ \zeta-\xi = \beta, \end{array}

\right\} \end{equation}

\begin{equation} \left. \begin{array}{c}

\displaystyle \dfrac{\partial \zeta}{\partial x} =

\dfrac{\partial \xi}{\partial x} = \dfrac{\partial^3

\zeta}{\partial x^3} = \dfrac{\partial^3 \xi}{\partial x^3}

= \dfrac{\partial b_1}{\partial x} = \dfrac{\partial

b_2}{\partial x} =0, \\ \zeta-\xi = \beta, \end{array}

\right\} \end{equation}

where ![]() $\beta =\hat {\beta }/\hat {h}_0$ is the dimensionless precursor film height. These conditions were decided upon, after the assumptions that both

$\beta =\hat {\beta }/\hat {h}_0$ is the dimensionless precursor film height. These conditions were decided upon, after the assumptions that both ![]() $\zeta$ and

$\zeta$ and ![]() $\xi$ are horizontal at

$\xi$ are horizontal at ![]() $x=0$ and

$x=0$ and ![]() $x=L$ and that the dimensionless precursor film thickness is equal to the distance between the two interfaces at these positions. Furthermore, the liquid flow rate and the solid displacement in the

$x=L$ and that the dimensionless precursor film thickness is equal to the distance between the two interfaces at these positions. Furthermore, the liquid flow rate and the solid displacement in the ![]() $z$-direction were considered equal to zero at all ends.

$z$-direction were considered equal to zero at all ends.

Concerning the initial conditions, we assumed a flat liquid–solid interface at ![]() $t=0$:

$t=0$:

As far as the initial shape of the droplet thickness is concerned, we use a fourth-order polynomial which satisfies ![]() ${\partial h}/{\partial x} = {\partial ^3 h}/{\partial x^3} =0$ at the droplet centre (

${\partial h}/{\partial x} = {\partial ^3 h}/{\partial x^3} =0$ at the droplet centre (![]() $x=x_{cm,l}$ or

$x=x_{cm,l}$ or ![]() $x_{cm,r}$) and

$x_{cm,r}$) and ![]() ${\partial h}/{\partial x} = 0$ as well as

${\partial h}/{\partial x} = 0$ as well as ![]() $h = \beta$ at distance

$h = \beta$ at distance ![]() $l_0$ from the droplet centre, respectively. The length and height of the computational domain was taken equal to

$l_0$ from the droplet centre, respectively. The length and height of the computational domain was taken equal to ![]() $L_x=\hat {L}_x/\hat {R}_0=16$ and

$L_x=\hat {L}_x/\hat {R}_0=16$ and ![]() $L_z=\hat {L}_z/\hat {R}_0=5$, respectively. The dimensionless initial droplet footprint half-width,

$L_z=\hat {L}_z/\hat {R}_0=5$, respectively. The dimensionless initial droplet footprint half-width, ![]() $l_0$, was defined equal to

$l_0$, was defined equal to ![]() $l_0=1.5$ and the dimensionless initial droplet cross-sectional area was considered to be equal to

$l_0=1.5$ and the dimensionless initial droplet cross-sectional area was considered to be equal to ![]() $V=2/3$. Moreover, the initial centre of mass for each droplet was taken at

$V=2/3$. Moreover, the initial centre of mass for each droplet was taken at ![]() $x=x_{cm,l}=4$ and at

$x=x_{cm,l}=4$ and at ![]() $x=x_{cm,r}=12$, hence the initial distance between the two centres of mass was given by

$x=x_{cm,r}=12$, hence the initial distance between the two centres of mass was given by ![]() $\Delta x_{cm}=x_{cm,r}-x_{cm,l}=8$, while the centre of mass of the system was initially located at

$\Delta x_{cm}=x_{cm,r}-x_{cm,l}=8$, while the centre of mass of the system was initially located at ![]() $x=x_{cm,g}=8$.

$x=x_{cm,g}=8$.

The above set of equations were solved using the finite element method, and it was implemented in COMSOL Multiphysics commercial software. We applied a fully implicit finite difference scheme to solve the system of the evolution equations and we selected the PARDISO iterative solver for the intermediate time-stepping. Typically we use 10 000 elements for the discretisation of the system geometry and the moving mesh of the surrounding atmosphere was appropriately refined using free triangular cells; numerical checks showed that increasing the number of elements further led to negligible changes. The simulations stop when the system mass has decreased by 80 %.

5. Results and discussion

Droplet evaporation on compliant substrates is a parametrically rich problem. We begin our study by examining the case of the evaporation of a single droplet on a soft substrate in § 5.1, while in § 5.2 we proceed with simulations for a system of two interacting droplets. Numerical solutions were obtained over a wide range of parameter values. The ‘base’ case, however, has broadly typical values of ![]() $\epsilon =0.1$,

$\epsilon =0.1$, ![]() $l_0=1.5$,

$l_0=1.5$, ![]() $H=0.1$,

$H=0.1$, ![]() $A=500$,

$A=500$, ![]() $B=0.005$,

$B=0.005$, ![]() $n=3$,

$n=3$, ![]() $c=2$,

$c=2$, ![]() $E=10^{-4}$,

$E=10^{-4}$, ![]() $\mathcal {H}=0.5$,

$\mathcal {H}=0.5$, ![]() $K=0.2$,

$K=0.2$, ![]() $\psi =0.1$,

$\psi =0.1$, ![]() $Pe_v=0.1$,

$Pe_v=0.1$, ![]() $\delta =10^{-3}$,

$\delta =10^{-3}$, ![]() $m=100$,

$m=100$, ![]() $C_l^{-1}=1$,

$C_l^{-1}=1$, ![]() $C_s^{-1}=0.5$, unless noted otherwise in the text. In the figures that follow, we define a scaled time

$C_s^{-1}=0.5$, unless noted otherwise in the text. In the figures that follow, we define a scaled time ![]() $t'=t/t_{ev}$ where

$t'=t/t_{ev}$ where ![]() $t_{ev}$ is defined as the time that the system mass has decreased by 80 %.

$t_{ev}$ is defined as the time that the system mass has decreased by 80 %.

5.1. Evaporation of a single droplet

5.1.1. Effect of thermocapillarity

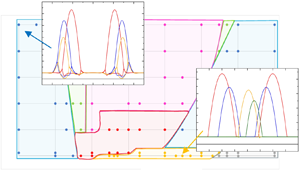

To set the stage, we begin with the simplest configuration, i.e. the evaporation of a single droplet on a soft substrate. Figure 2 depicts the typical time evolution of the liquid–gas and the liquid–solid interfaces for a single sessile evaporating droplet, highlighting the contact line region in the inset of the same figure. Charitatos & Kumar (Reference Charitatos and Kumar2021) considered a system similar to the present set-up, albeit ignoring the effect of thermocapillarity and employing the one-sided model. In order to examine the effect of thermocapillary phenomena, we present in figure 2(a) the evolution for ![]() $M_a=0$ and in figure 2(b) for

$M_a=0$ and in figure 2(b) for ![]() $M_a=0.005$. In the absence of thermocapillary stresses (figure 2a), in line with Charitatos & Kumar (Reference Charitatos and Kumar2021), we notice a gradual decrease in the droplet footprint, which is accompanied by a small deformation of the soft substrate, due to the balance of the capillary forces along the liquid–solid interface and in the contact line region. Consequently, a wetting ridge is formed and as the droplet dries out, both the contact line and the wetting ridge retract as a result of the decrease in the droplet volume.

$M_a=0.005$. In the absence of thermocapillary stresses (figure 2a), in line with Charitatos & Kumar (Reference Charitatos and Kumar2021), we notice a gradual decrease in the droplet footprint, which is accompanied by a small deformation of the soft substrate, due to the balance of the capillary forces along the liquid–solid interface and in the contact line region. Consequently, a wetting ridge is formed and as the droplet dries out, both the contact line and the wetting ridge retract as a result of the decrease in the droplet volume.

Figure 2. Time evolution of the liquid–air (![]() $\zeta$) and the liquid–solid (

$\zeta$) and the liquid–solid (![]() $\xi$) interfaces for a single droplet for (a)

$\xi$) interfaces for a single droplet for (a) ![]() $M_a=0$ (

$M_a=0$ (![]() $t_{ev}=4242$) and (b)

$t_{ev}=4242$) and (b) ![]() $M_a=5\times 10^{-3}$ (

$M_a=5\times 10^{-3}$ (![]() $t_{ev}=5366$), respectively, for

$t_{ev}=5366$), respectively, for ![]() $G=3$. The inset is an enlargement of the contact line region. The rest of the system parameters are the same with the ‘base’ case.

$G=3$. The inset is an enlargement of the contact line region. The rest of the system parameters are the same with the ‘base’ case.

On the other hand, in the presence of thermocapillarity (see figure 2b), the Marangoni stresses drive liquid towards the colder region (i.e. at droplet apex, see figure 3b) causing a faster retraction of the droplet. The faster motion of the contact line results in significantly larger substrate deformation, since for example at ![]() $t=100$ the maximum deformation of the wetting ridge (evaluated as the

$t=100$ the maximum deformation of the wetting ridge (evaluated as the ![]() $z$-position of the contact line, see figure 1c), is

$z$-position of the contact line, see figure 1c), is ![]() $\xi _{max}= 0.038$ and

$\xi _{max}= 0.038$ and ![]() $\xi _{max}= 0.068$, in figures 2(a) and 2(b), respectively. Furthermore, it can be deduced from figure 2(b) that for finite values of

$\xi _{max}= 0.068$, in figures 2(a) and 2(b), respectively. Furthermore, it can be deduced from figure 2(b) that for finite values of ![]() $M_a$ the loss of droplet mass is retarded;

$M_a$ the loss of droplet mass is retarded; ![]() $t_{ev}$ is considerably larger in figure 2(b) as compared with figure 2(a). This is due to the fact that the action of thermocapillary stresses leads to a considerably smaller droplet footprint with larger distance of the droplet apex from the rigid solid (at

$t_{ev}$ is considerably larger in figure 2(b) as compared with figure 2(a). This is due to the fact that the action of thermocapillary stresses leads to a considerably smaller droplet footprint with larger distance of the droplet apex from the rigid solid (at ![]() $z=-H$). The increased droplet height inhibits the supply of heat from the substrate (maintained at a constant temperature) to the interface, which is continuously being cooled due to the effect of latent heat. This consequently leads to lower temperature along the liquid–gas interface and in turn results in the overall decrease of the evaporation rate; the evolution of the local evaporation flux is presented in figure 3(a).

$z=-H$). The increased droplet height inhibits the supply of heat from the substrate (maintained at a constant temperature) to the interface, which is continuously being cooled due to the effect of latent heat. This consequently leads to lower temperature along the liquid–gas interface and in turn results in the overall decrease of the evaporation rate; the evolution of the local evaporation flux is presented in figure 3(a).

Figure 3. Time evolution of (a) the evaporation rate ![]() $J$ and (b) the interfacial temperature

$J$ and (b) the interfacial temperature ![]() $T_s$, for a single droplet for

$T_s$, for a single droplet for ![]() $M_a=5\times 10^{-3}$ and

$M_a=5\times 10^{-3}$ and ![]() $G=3$ (

$G=3$ (![]() $t_{ev}=5366$).The rest of the system parameters are the same with the ‘base’ case.

$t_{ev}=5366$).The rest of the system parameters are the same with the ‘base’ case.

To illustrate the vapour concentration field in the gas phase, we present the corresponding contour plot in figure 4, for the case of ![]() $M_a=0.005$. It is noted that the far-field boundary is taken to be very far from the droplet (i.e. at

$M_a=0.005$. It is noted that the far-field boundary is taken to be very far from the droplet (i.e. at ![]() $z=\epsilon ^{-1} z'=50$) and as a result the droplet is difficult to see in this figure. We notice, though, that in the neighbourhood of the droplet the vapour concentration is high and decreases moving away from the droplet, as expected.

$z=\epsilon ^{-1} z'=50$) and as a result the droplet is difficult to see in this figure. We notice, though, that in the neighbourhood of the droplet the vapour concentration is high and decreases moving away from the droplet, as expected.

Figure 4. Gas phase concentration profiles at different time instants for ![]() $M_a=5\times 10^{-3}$ and

$M_a=5\times 10^{-3}$ and ![]() $G=3$: (a)

$G=3$: (a) ![]() $t'=0$; (b)

$t'=0$; (b) ![]() $t' = 0.02$; (c)

$t' = 0.02$; (c) ![]() $t'=0.4$; (d)

$t'=0.4$; (d) ![]() $t'=0.8$. The rest of the system parameters are the same with the ‘base’ case.

$t'=0.8$. The rest of the system parameters are the same with the ‘base’ case.

5.1.2. Effect of substrate elasticity and thickness

Here, we examine the effect of elasticity of the substrate by varying ![]() $G={\hat {E} \hat {R}_0}/{\hat {\sigma }_0 \epsilon ^3}$; this parameter measures the ratio of elastic to liquid–gas interfacial tension forces. Here

$G={\hat {E} \hat {R}_0}/{\hat {\sigma }_0 \epsilon ^3}$; this parameter measures the ratio of elastic to liquid–gas interfacial tension forces. Here ![]() $G$ is proportional to the shear modulus of the soft solid and therefore smaller values correspond to the case of softer substrates. By letting

$G$ is proportional to the shear modulus of the soft solid and therefore smaller values correspond to the case of softer substrates. By letting ![]() $G\rightarrow \infty$, the case of the rigid substrate can be recovered. In figure 5(a), we investigate the effect of substrate elasticity on the deformation of the soft solid, by plotting the evolution of the maximum deformation of the wetting ridge,

$G\rightarrow \infty$, the case of the rigid substrate can be recovered. In figure 5(a), we investigate the effect of substrate elasticity on the deformation of the soft solid, by plotting the evolution of the maximum deformation of the wetting ridge, ![]() $\xi _{max}$, with time. Naturally, it can be seen that the softer substrates deform more easily. Figures 5(b) and 5(c) depict the time evolution of the contact radius and the apparent contact angle, respectively, of a single droplet evaporating on a rigid (

$\xi _{max}$, with time. Naturally, it can be seen that the softer substrates deform more easily. Figures 5(b) and 5(c) depict the time evolution of the contact radius and the apparent contact angle, respectively, of a single droplet evaporating on a rigid (![]() $G=10^7$) and on soft solid substrates with

$G=10^7$) and on soft solid substrates with ![]() $G=1$, 3, 10, 100. Following the work of Charitatos & Kumar (Reference Charitatos and Kumar2021), the apparent contact angle is defined as the largest angle between the tangent of the liquid–air interface,

$G=1$, 3, 10, 100. Following the work of Charitatos & Kumar (Reference Charitatos and Kumar2021), the apparent contact angle is defined as the largest angle between the tangent of the liquid–air interface, ![]() $z=\zeta (x,t)$ and

$z=\zeta (x,t)$ and ![]() $z=0$. On the other hand, the contact radius is defined as the intersection point between the tangent of the largest angle and

$z=0$. On the other hand, the contact radius is defined as the intersection point between the tangent of the largest angle and ![]() $z=0$.

$z=0$.

Figure 5. Time evolution of (a) the point of maximum deformation of the wetting ridge ![]() $\xi _{max}$, (b) the contact radius

$\xi _{max}$, (b) the contact radius ![]() $r$ and (c) the apparent contact angle

$r$ and (c) the apparent contact angle ![]() $\theta$ for a single droplet, varying substrate elasticity

$\theta$ for a single droplet, varying substrate elasticity ![]() $G$ and for

$G$ and for ![]() $M_a=0.005$. (d) Space–time plot of the droplet profiles at a soft substrate with

$M_a=0.005$. (d) Space–time plot of the droplet profiles at a soft substrate with ![]() $G=1$ and for

$G=1$ and for ![]() $M_a=0.005$. The inset is a magnified view of the wetting ridge profiles during droplet spreading. The rest of the system parameters are the same with the ‘base’ case.

$M_a=0.005$. The inset is a magnified view of the wetting ridge profiles during droplet spreading. The rest of the system parameters are the same with the ‘base’ case.