NOMENCLATURE

- a

-

speed of sound

- BPR

-

by-pass ratio

- D

-

nozzle exit or jet diameter

- EPN

-

effective perceived noise

- f

-

frequency

- FWH

-

Ffowcs Williams–Hawkings

- H 12

-

boundary-layer shape factor (

$\delta^{\ast\!}/\theta$

)

$\delta^{\ast\!}/\theta$

) - IR

-

infra-red

- k

-

turbulence kinetic energy

- L

-

axial length

- LES

-

large-eddy simulation

- M

-

Mach number

- NPR

-

nozzle pressure ratio (p t,j /p amb)

- NTR

-

nozzle temperature ratio (T t,j /T s,amb)

- OASPL

-

overall sound pressure level

- p

-

pressure

- PSD

-

power spectral density

- r

-

radial distance, shear-layer velocity ratio

- r ij,kl

-

dimensional two-point two-time correlation

- R ij,kl

-

non-dimensional two-point two-time correlation

- RANS

-

Reynolds-averaged Navier–Stokes

- Re

-

Reynolds number

- s

-

shear-layer density ratio

- St

-

Strouhal number

- T

-

temperature

- t

-

jet/ambient static temperature ratio (T s,j /T s,a )

- U, V, W

-

velocity components

- u, v, w

-

rms turbulence fluctuating velocity components

- x, y, z

-

spatial co-ordinates

GREEK SYMBOLS

-

${\delta}^{\ast}$

${\delta}^{\ast}$

-

displacement thickness

-

${\delta}$

’

${\delta}$

’

-

shear-layer growth rate

- ɛ

-

turbulence energy dissipation rate

- η

-

spatial separation

-

${\theta}$

${\theta}$

-

momentum thickness, azimuthal angle, polar angle

-

${\mu}$

${\mu}$

-

viscosity

- ρ

-

density

- τ

-

temporal separation

-

${\phi}$

${\phi}$

-

observer polar angle

-

${\omega}$

${\omega}$

-

vorticity

Subscripts

-

$a,\,\textrm{amb}$

$a,\,\textrm{amb}$

-

atmospheric ambient property

- bp

-

by-pass property

- c

-

convective

- cl

-

centreline property

- core

-

jet core property

- fs

-

flight stream property

-

$i,\,j,\,k,\,l$

$i,\,j,\,k,\,l$

-

tensor indices

- j

-

jet/nozzle exit property

- on

-

onset flow

- PC

-

potential core

- rms

-

root mean square

- s

-

static property

- t

-

total property

- 1,2

-

fast and slow streams in planar shear layer

1.0 Introduction

Examples abound of turbulent jet flows in both the natural and engineering world. Jet flows occur in all engineering disciplines: water outfalls, cooling tower plumes and ventilation flows in civil/building engineering, mixing and reaction vessels in chemical engineering, cooling of electronic components, and mixing, heating and cooling technologies in mechanical engineering. The present focus is on aerospace (space rocketry and missiles excluded) where jets generate propulsive thrust for flight in both civil and military aircraft.

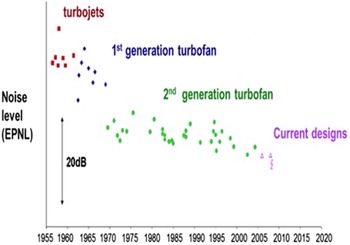

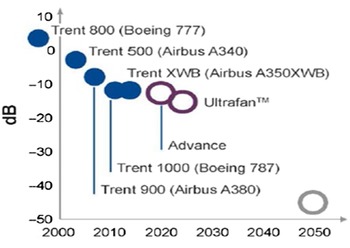

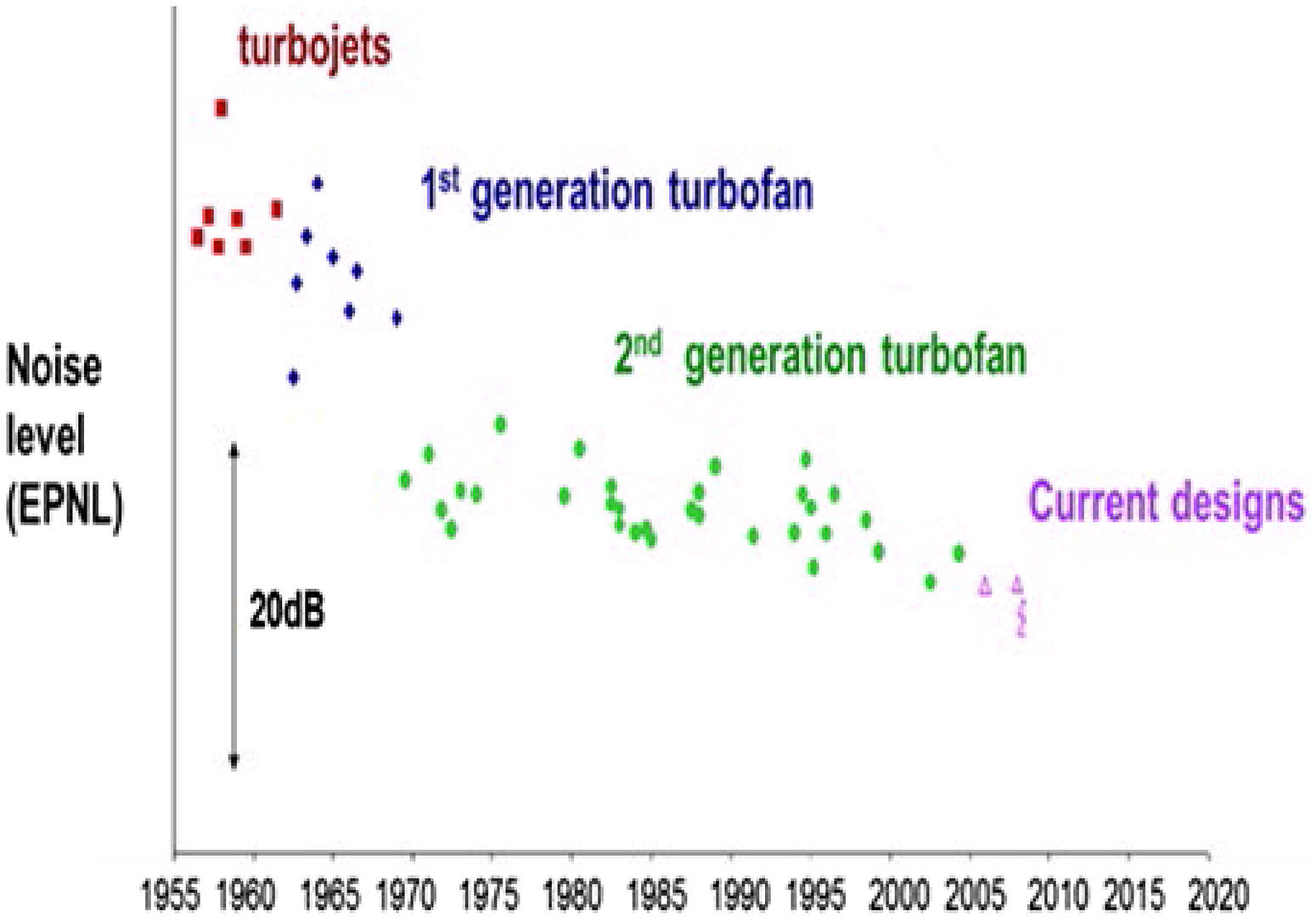

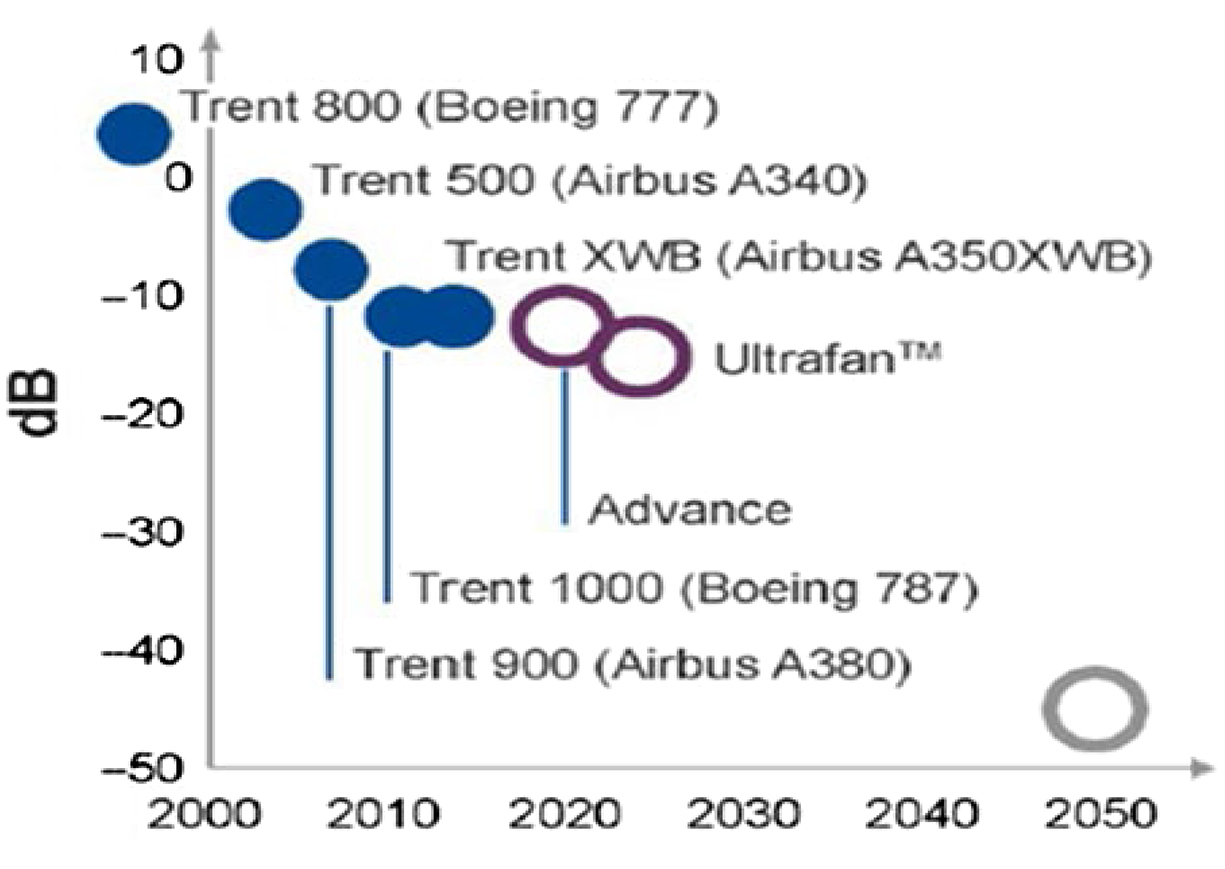

In civil aerospace, designers require an understanding of jet plume development from engine exhaust nozzles and methods to manipulate this to meet legislation governing aircraft noise. The International Civil Aviation Organization (ICAO) via its Committee on Aviation Environmental Protection (CAEP) sets international environmental standards for civil aviation. The CAEP has published a series of regulations for subsonic aircraft noise: originally Chapter 3 in 1977, and mandating further reductions over time relative to Chapter 3 in 2006 (–10dB) and 2017 (–17dB). Engine manufacturers have continually designed to achieve reduced noise (Fig. 1). In 2000, the European Union (EU) set aircraft/engine manufacturers performance improvement targets for CO2, pollutant emissions and noise reduction: Vison 2020 (2) and Flightpath 2050 (2050 target shown by open circle in Fig. 2) (3). Figure 2 illustrates the progress made by Rolls-Royce, whose engines are now 20–30dB quieter than early turbojets; noise level is reducing by

![]() $\sim$

0.5dB/year but further and faster progress is required.

$\sim$

0.5dB/year but further and faster progress is required.

Figure 1. Aircraft noise reduction over time, effective perceived noise level from Ref. Reference Astley, Agarwal, Joseph, Self, Smith, Sugimoto and Tester1.

Figure 2. Flightpath 2050-driven noise level reductions in Rolls-Royce engines.

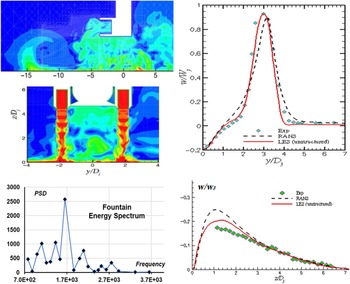

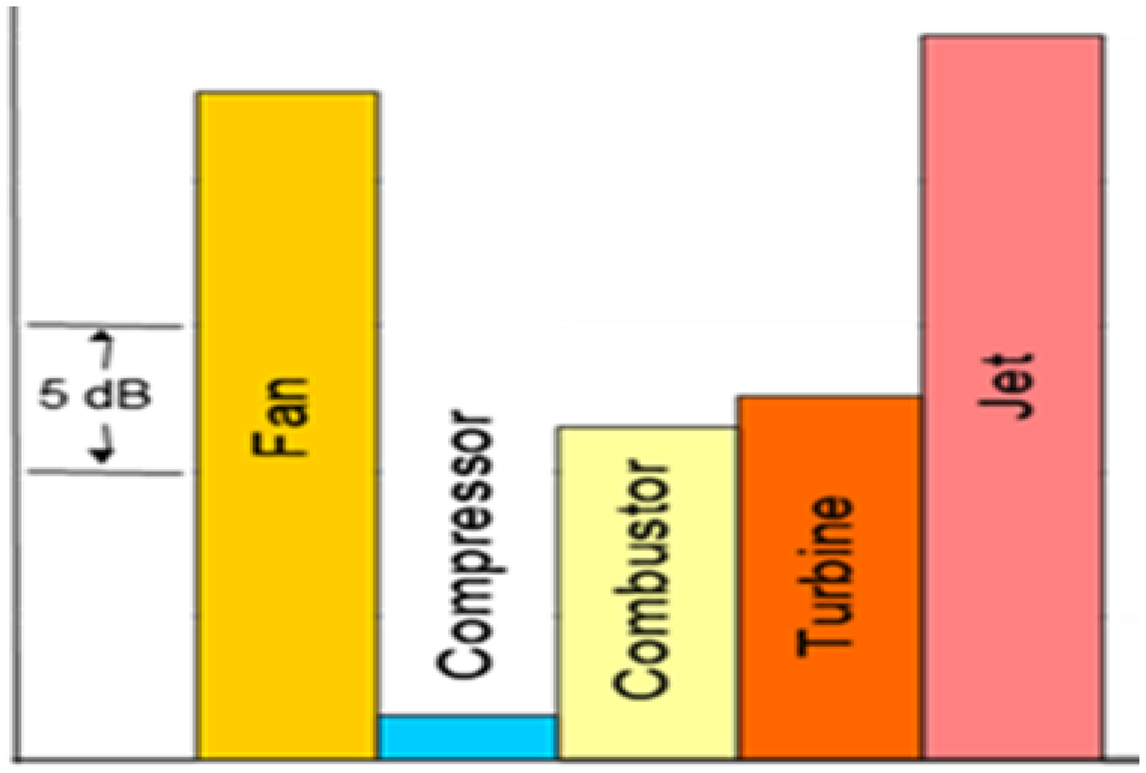

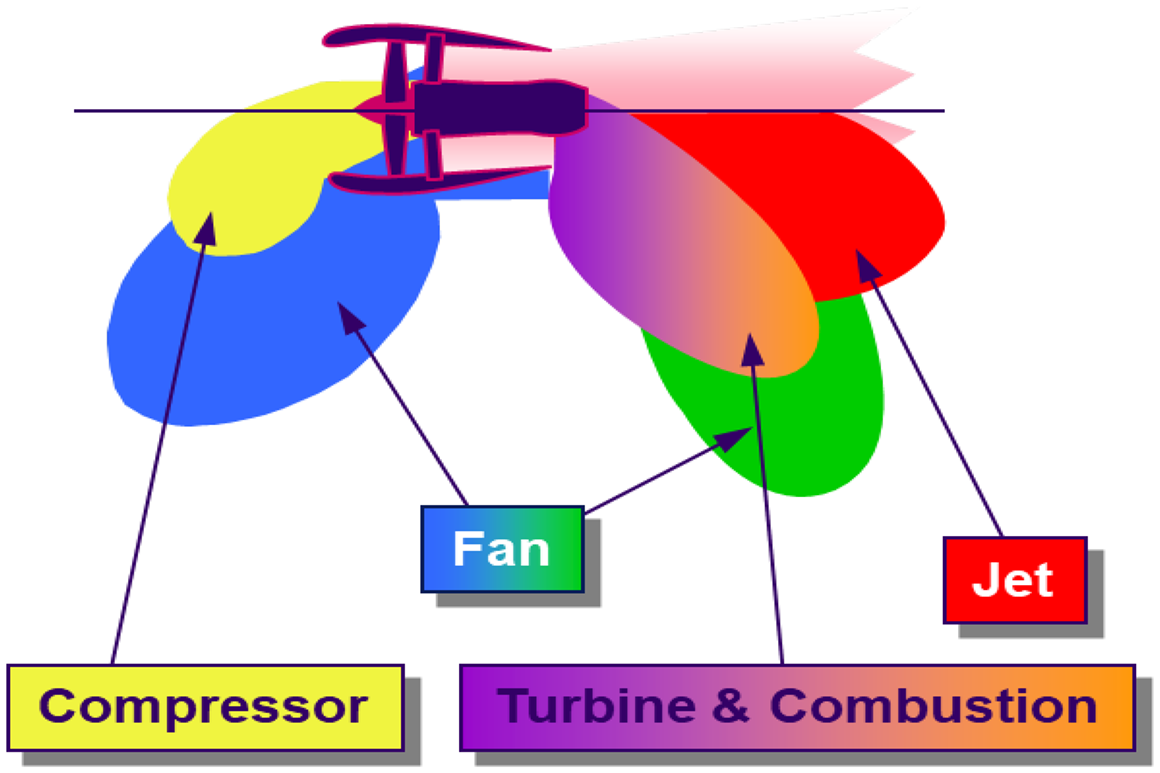

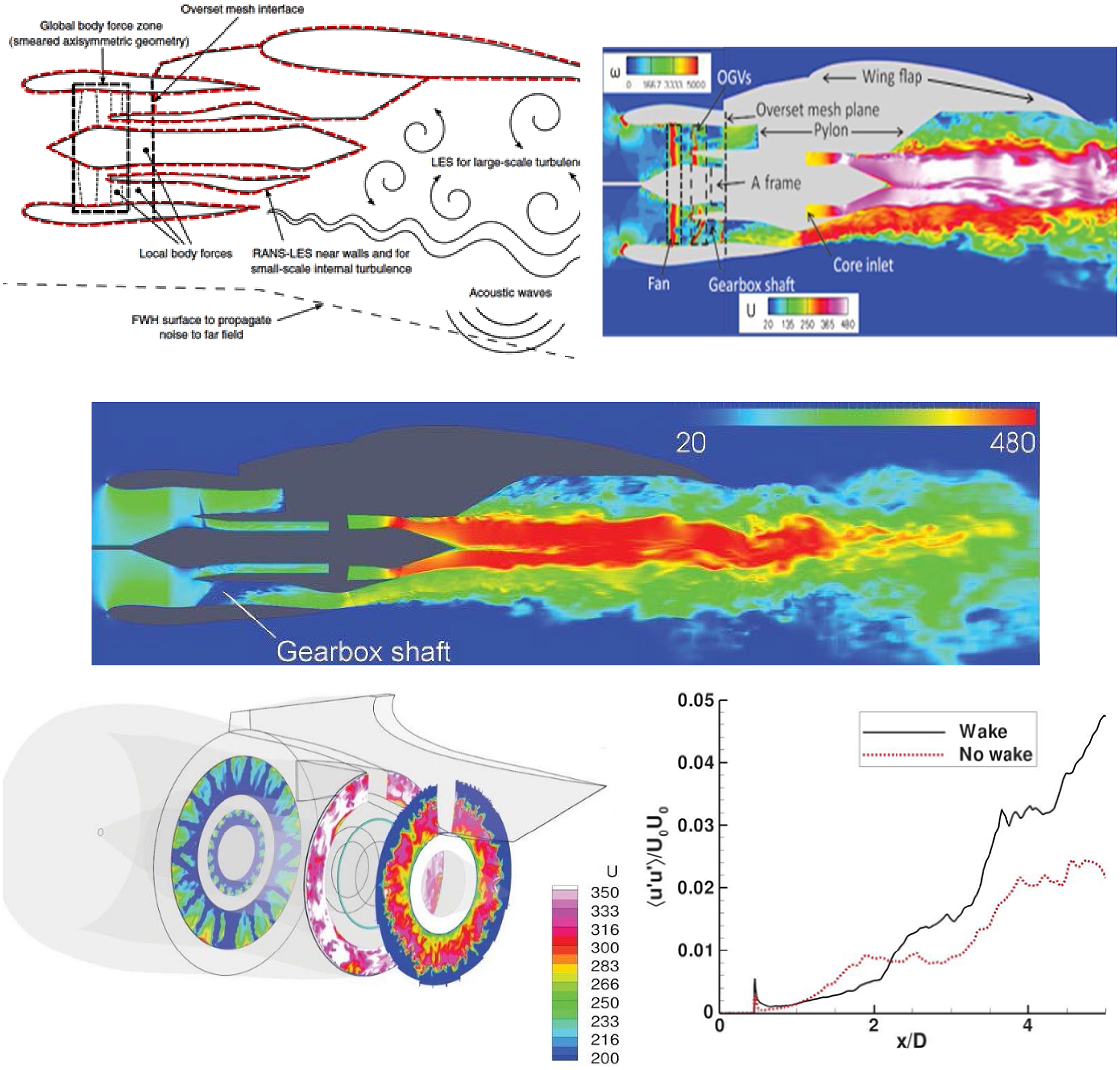

Several engine noise sources contribute to aircraft noise; see Fig. 3 for typical conditions at departure. In modern engines with high by-pass ratio, whilst combustor and compressor/turbine turbomachinery make a contribution, fan and jet noise are dominant components at take-off; the ‘bubbles’ in Fig. 4 indicate the regions/directions where each component is influential. Reducing jet noise is thus the primary reason civil aeroengine designers require accurate knowledge of propulsion jet aerodynamics/aeroacoustics.

Figure 3. Noise source contributions for aircraft departure conditions from Ref. Reference Astley, Agarwal, Joseph, Self, Smith, Sugimoto and Tester1.

Figure 4. Noise source distribution for a modern engine from Ref. Reference Astley, Agarwal, Joseph, Self, Smith, Sugimoto and Tester1.

In terms of the velocity at the exhaust nozzle exit (U

j

), the move from turbojet to turbofan, and the growth in by-pass ratio (BPR = by-pass flow/core flow) and fan diameter has brought about a large reduction in U

j

. Theoretical analysis of jet aeroacoustics by Lighthill (Reference Lighthill4) indicated that jet noise is a strong function of jet velocity (

![]() $\sim$

U

j

8); lowering U

j

is thus an important approach to decrease the jet noise contribution (Fig. 1). That work also revealed that the noise source was driven by turbulence created in the jet–ambient mixing process. It also indicated that high-order turbulent correlations are involved – fourth-order spatio-temporal correlations – making CFD prediction of jet noise challenging. However, recent progress in advanced methods based on LES CFD is promising, although as described below, inadequacies still exist and computational cost is high.

$\sim$

U

j

8); lowering U

j

is thus an important approach to decrease the jet noise contribution (Fig. 1). That work also revealed that the noise source was driven by turbulence created in the jet–ambient mixing process. It also indicated that high-order turbulent correlations are involved – fourth-order spatio-temporal correlations – making CFD prediction of jet noise challenging. However, recent progress in advanced methods based on LES CFD is promising, although as described below, inadequacies still exist and computational cost is high.

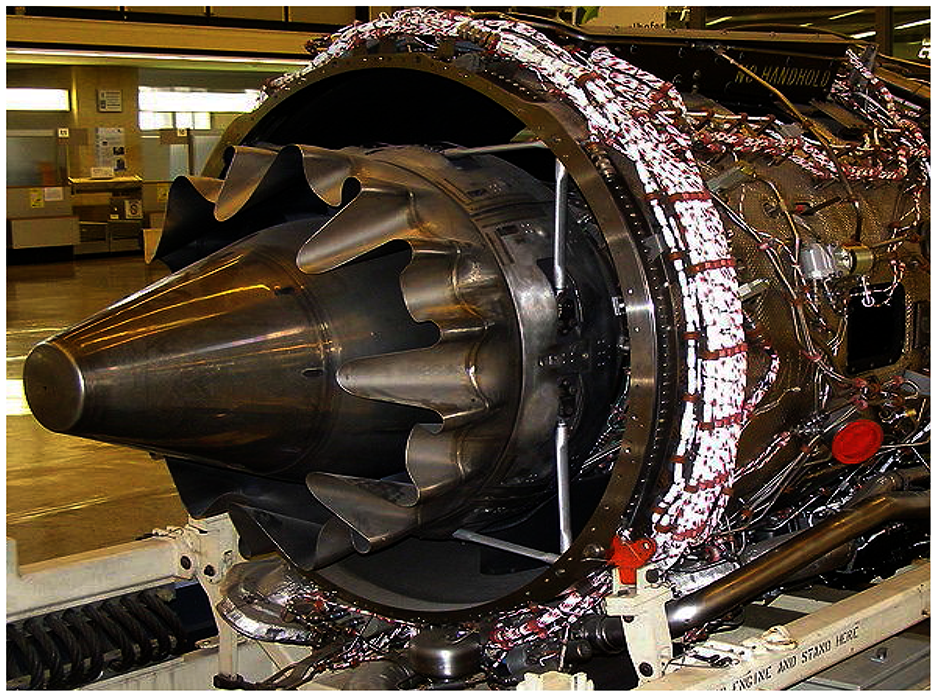

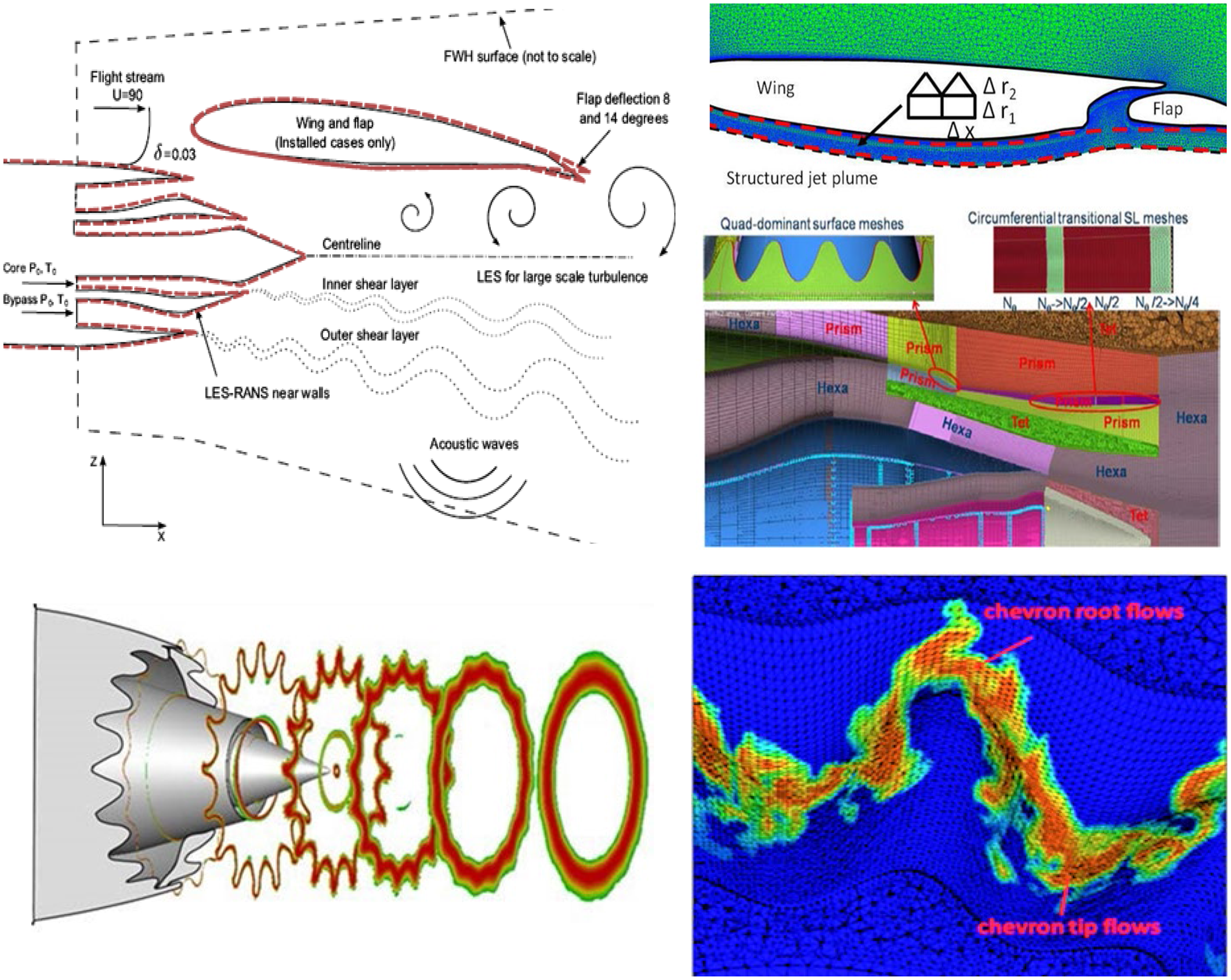

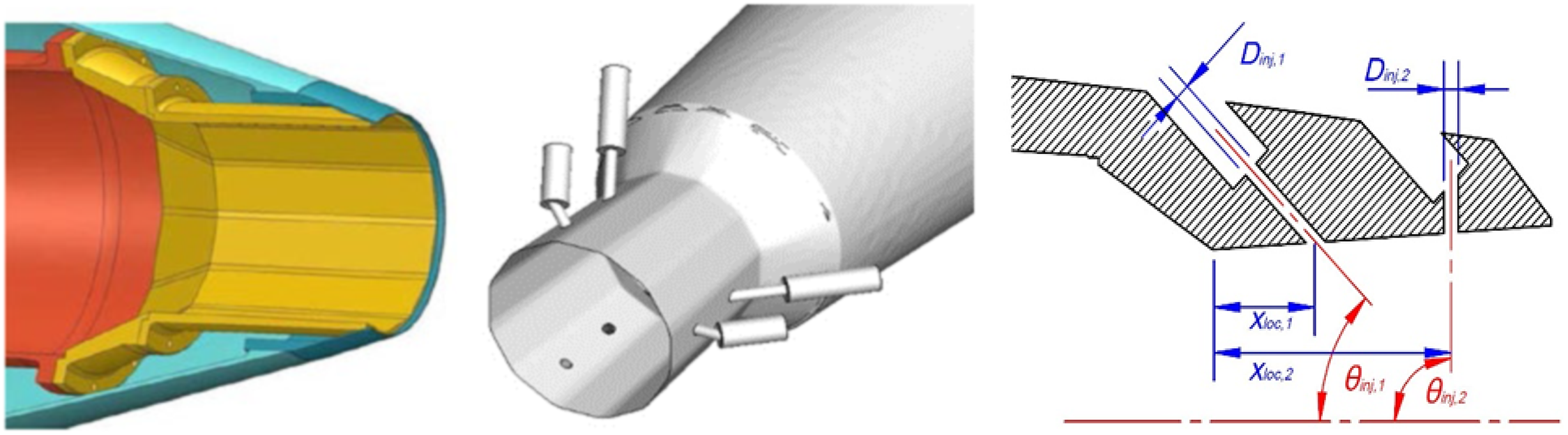

As the BPR increases (>10 is typical), the slow by-pass and faster core flow can be mixed to lower the mass-average U J . This leads to the introduction of so-called forced mixers with various geometries but typically comprising multiple azimuthally distributed variously shaped lobes (plain, scarfed, scalloped, etc.), as illustrated in Fig. 5. Whilst mixing by-pass and core flows is beneficial to jet noise, mixing device total pressure losses and extra weight/increased cowl length (drag penalty) mean that a trade-off is required depending on aircraft design mission length to determine whether such devices are affordable. In recent years, more subtle devices have become popular – serrations or chevrons cut into the by-pass nozzle (and possibly also the core), as shown in Fig. 6. Detailed mechanisms behind this technology are described below.

Figure 5. Lobed mixer (by-pass nozzle wall removed) BR715 engine, Boeing 717 aircraft.

Figure 6. Serrated nozzles on both by-pass and core ducts on Boeing 787 aircraft.

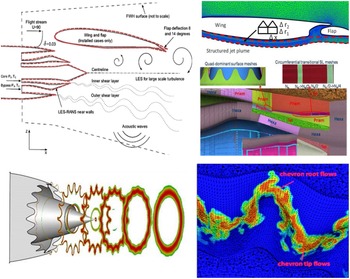

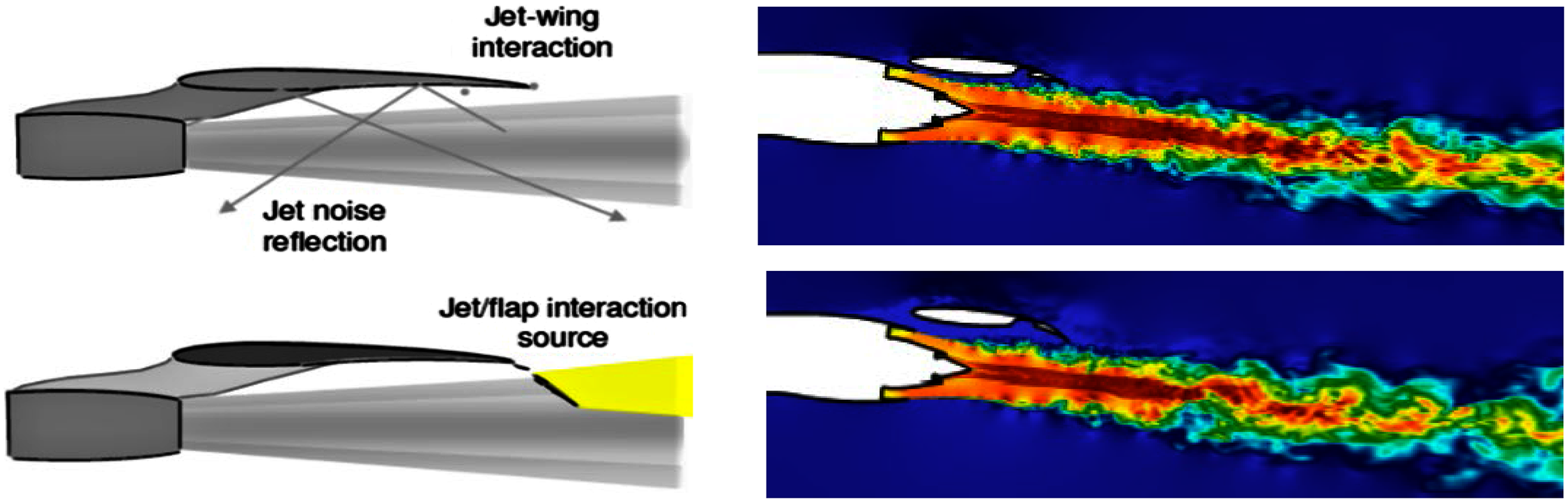

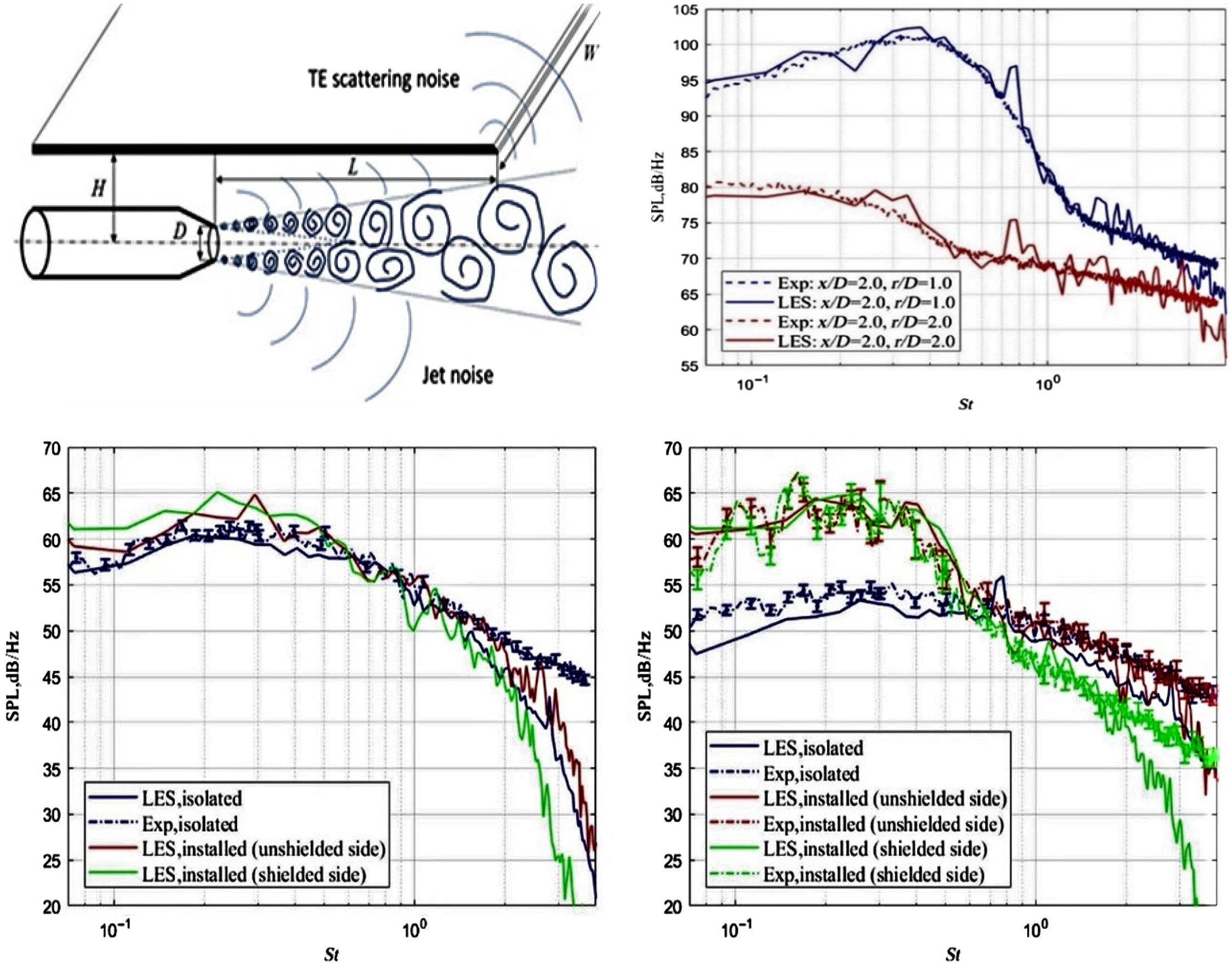

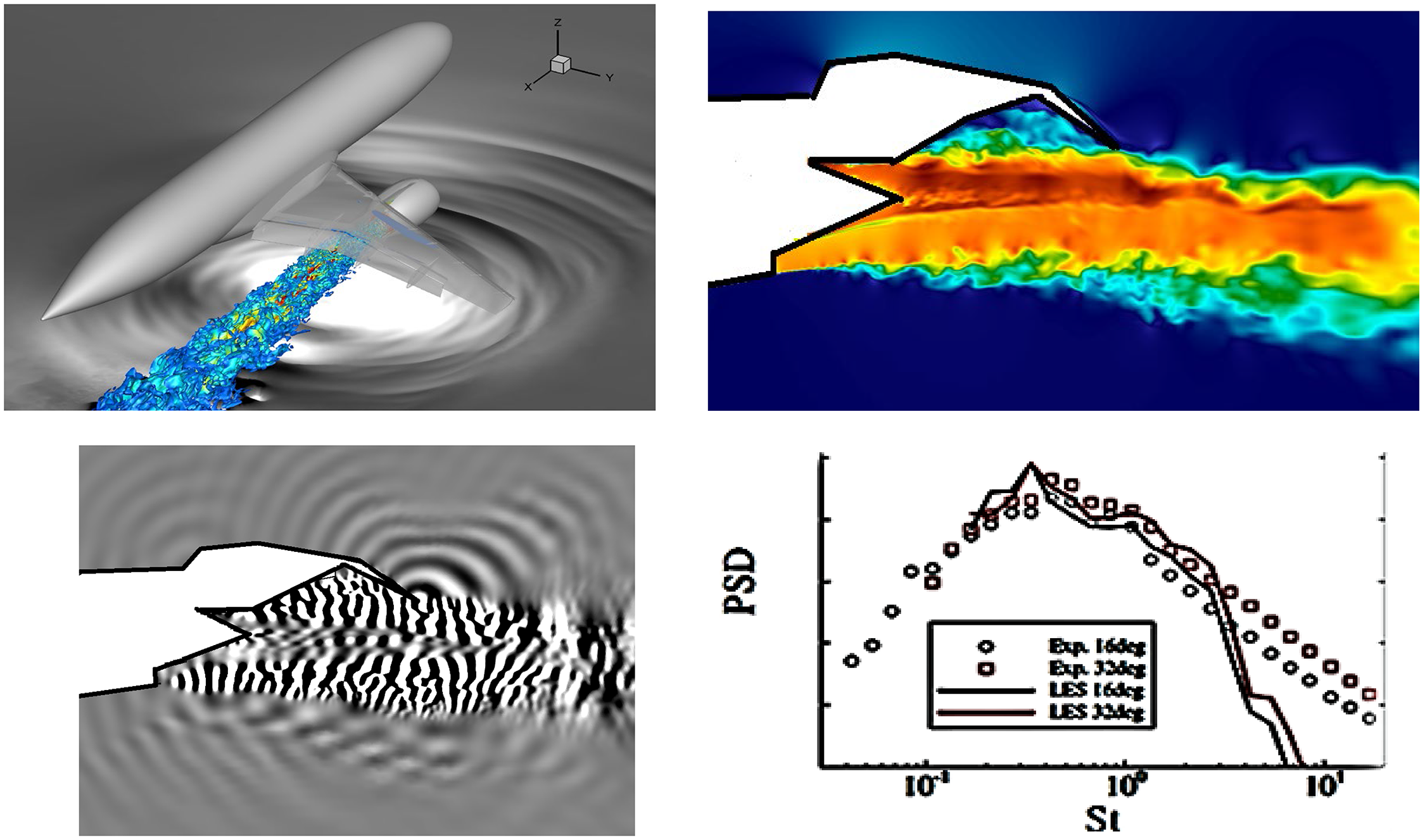

A further civil aerospace mixed aerodynamic–aeroacoustic application involving the jet plume is jet installation noise (Fig. 7). This illustrates an increasingly more common scenario as turbofan diameter increases and (to avoid longer undercarriage) engines are installed closer to the wing. The left-hand image indicates the extra noise phenomena introduced by jet–wing interactions. The first occurs when jet/ambient shear-layer noise is reflected towards the ground by the wing under-surface. The second results from jet–surface aerodynamic interactions – the flow field in the wing/flap vicinity is modified by the jet flow, thus altering the generation of trailing-edge noise. If high-lift devices on the wing are fully deployed, the spreading jet edge flow may even impinge on the flap. The right-hand images in Fig. 7 are taken from an LES CFD study (Reference Angelino, Moratilla-Vega, Howlett, Xia and Page5) described below and indicate how the flow is influenced by different flap deflections and engine–wing separations.

Figure 7. Jet wing interaction noise – from Ref. Reference Astley, Agarwal, Joseph, Self, Smith, Sugimoto and Tester1 (left) and Reference Angelino, Moratilla-Vega, Howlett, Xia and Page5 (right).

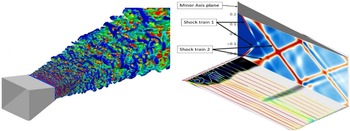

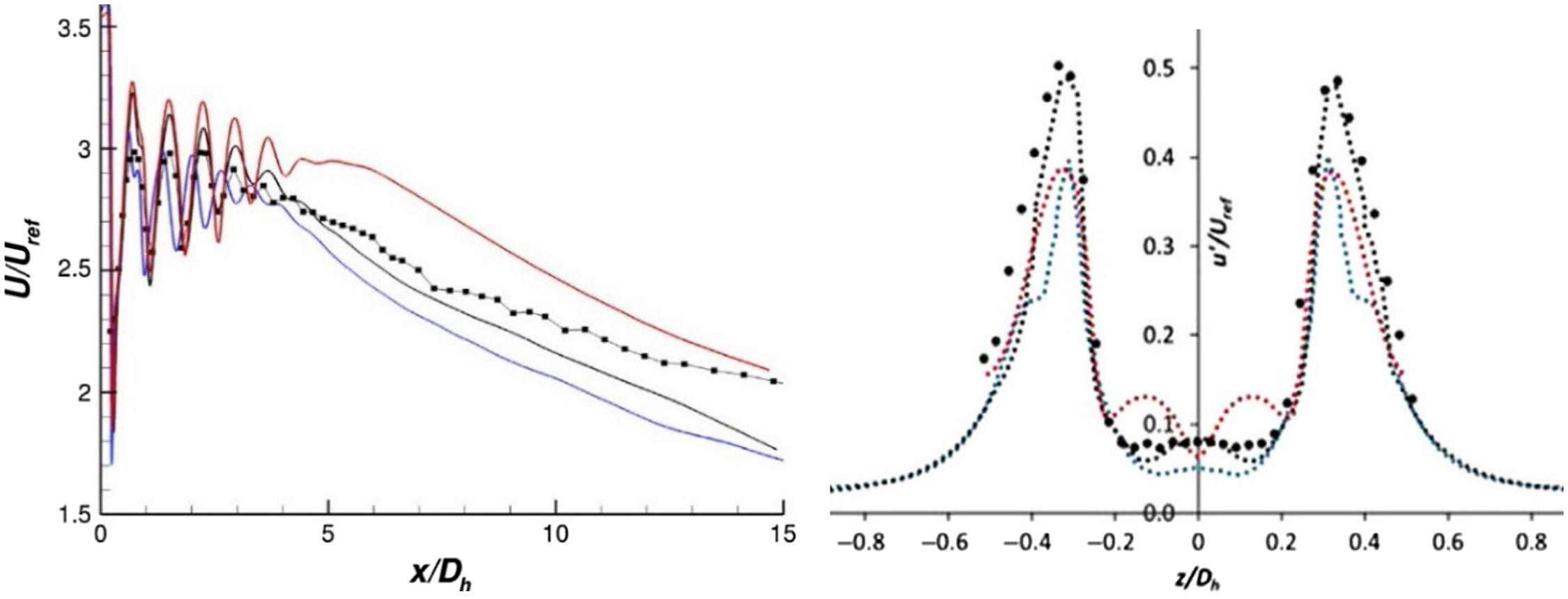

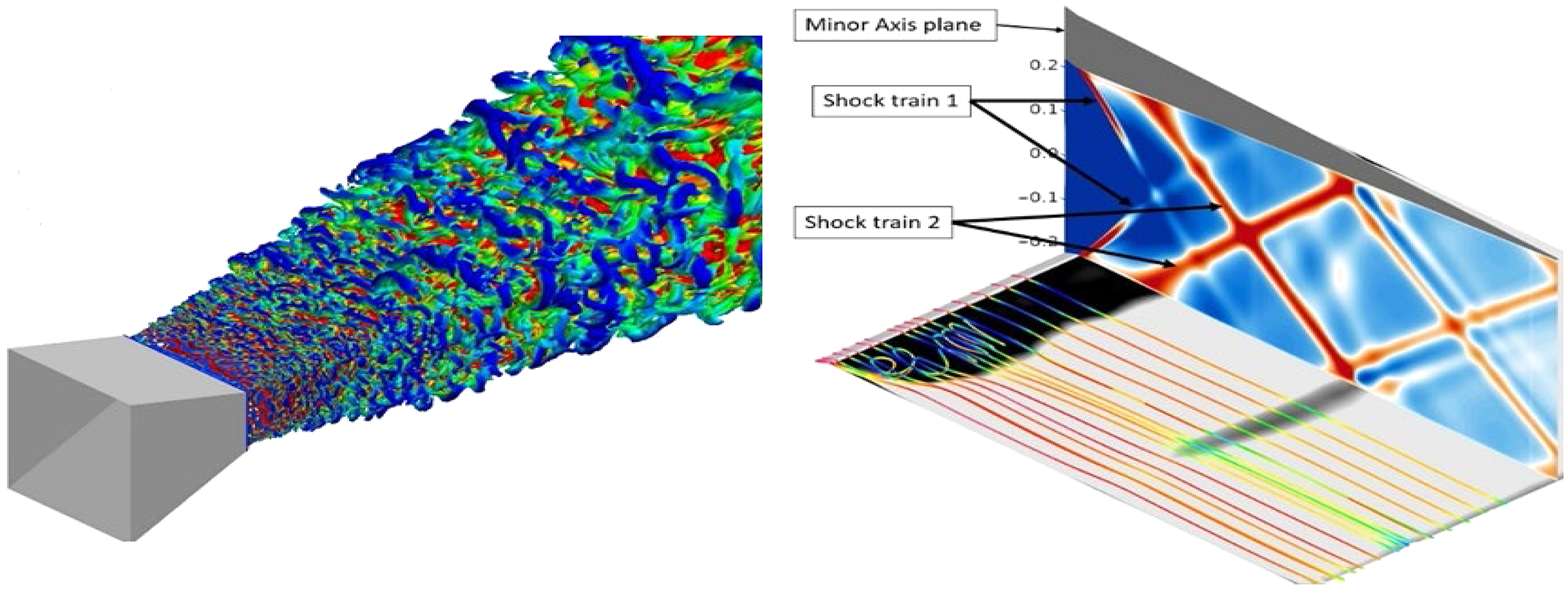

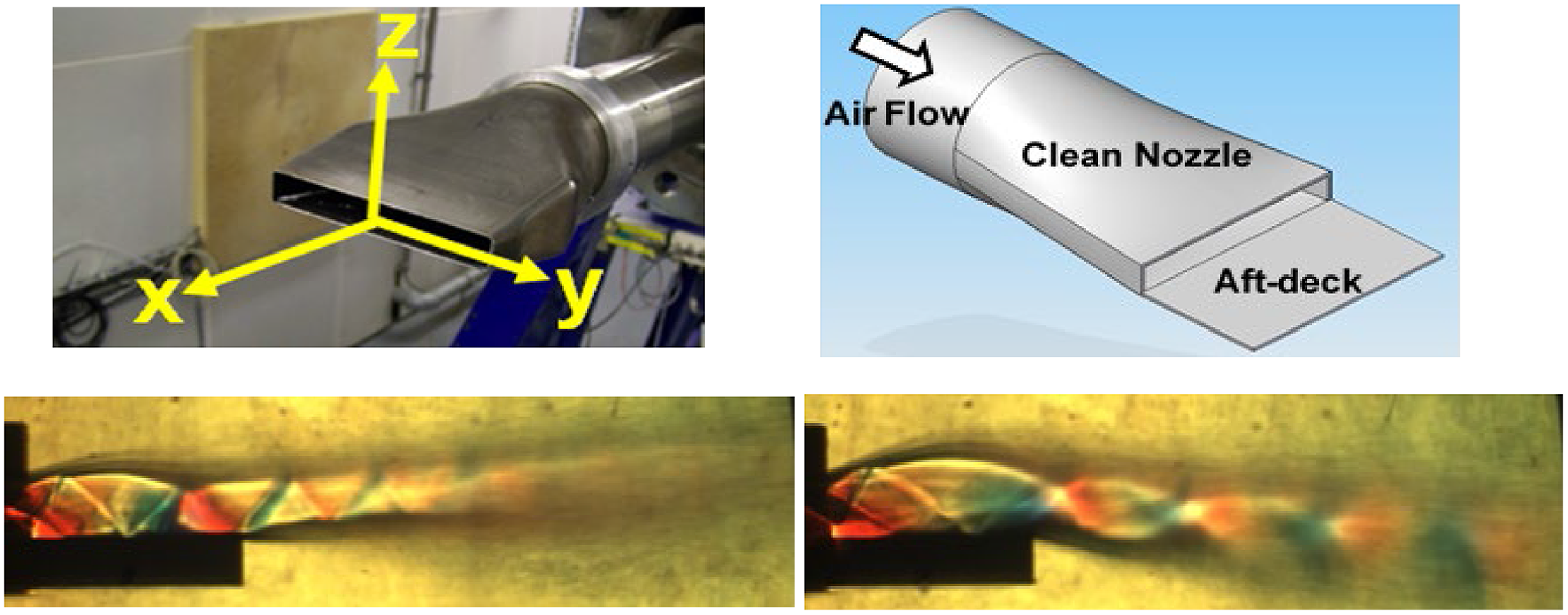

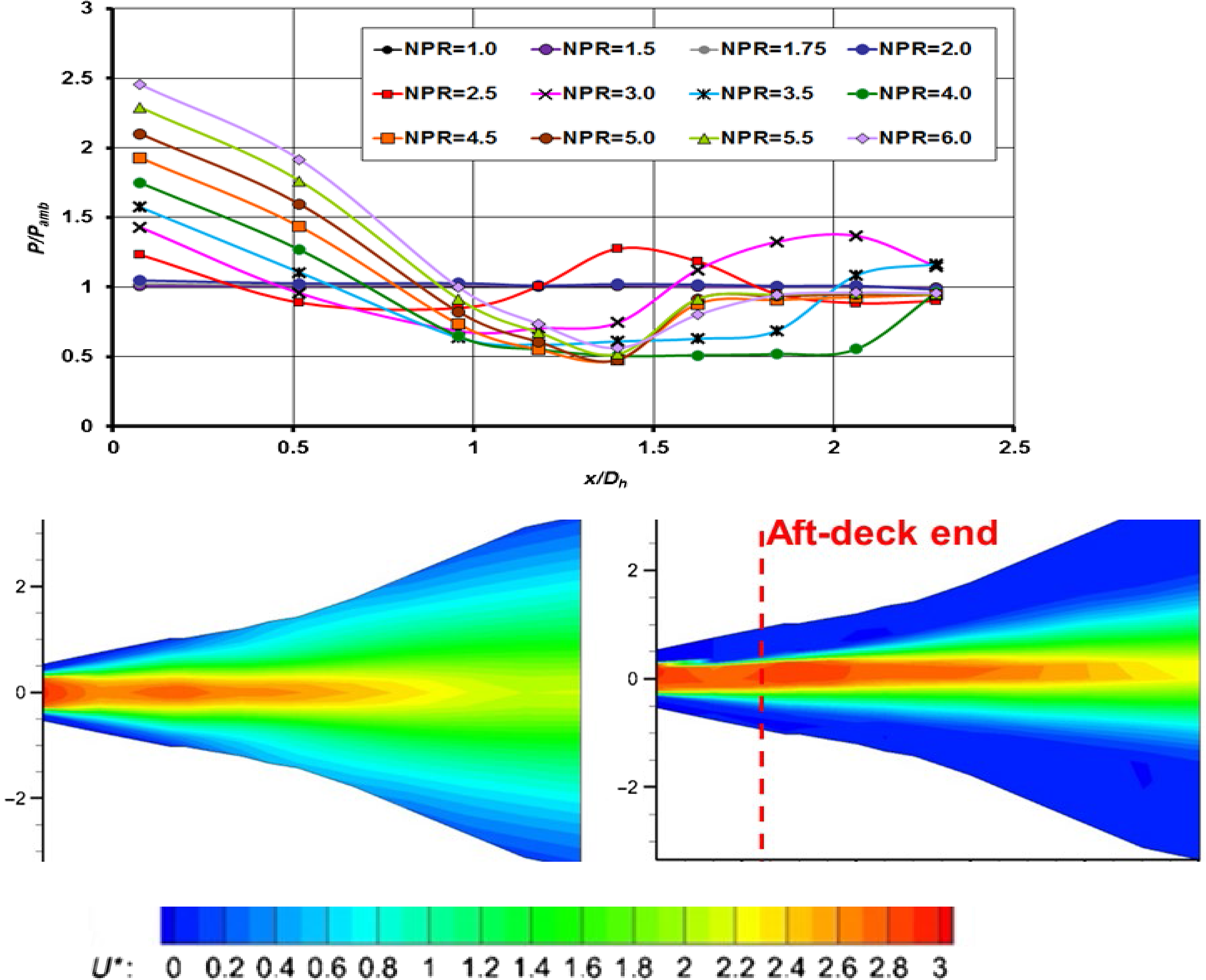

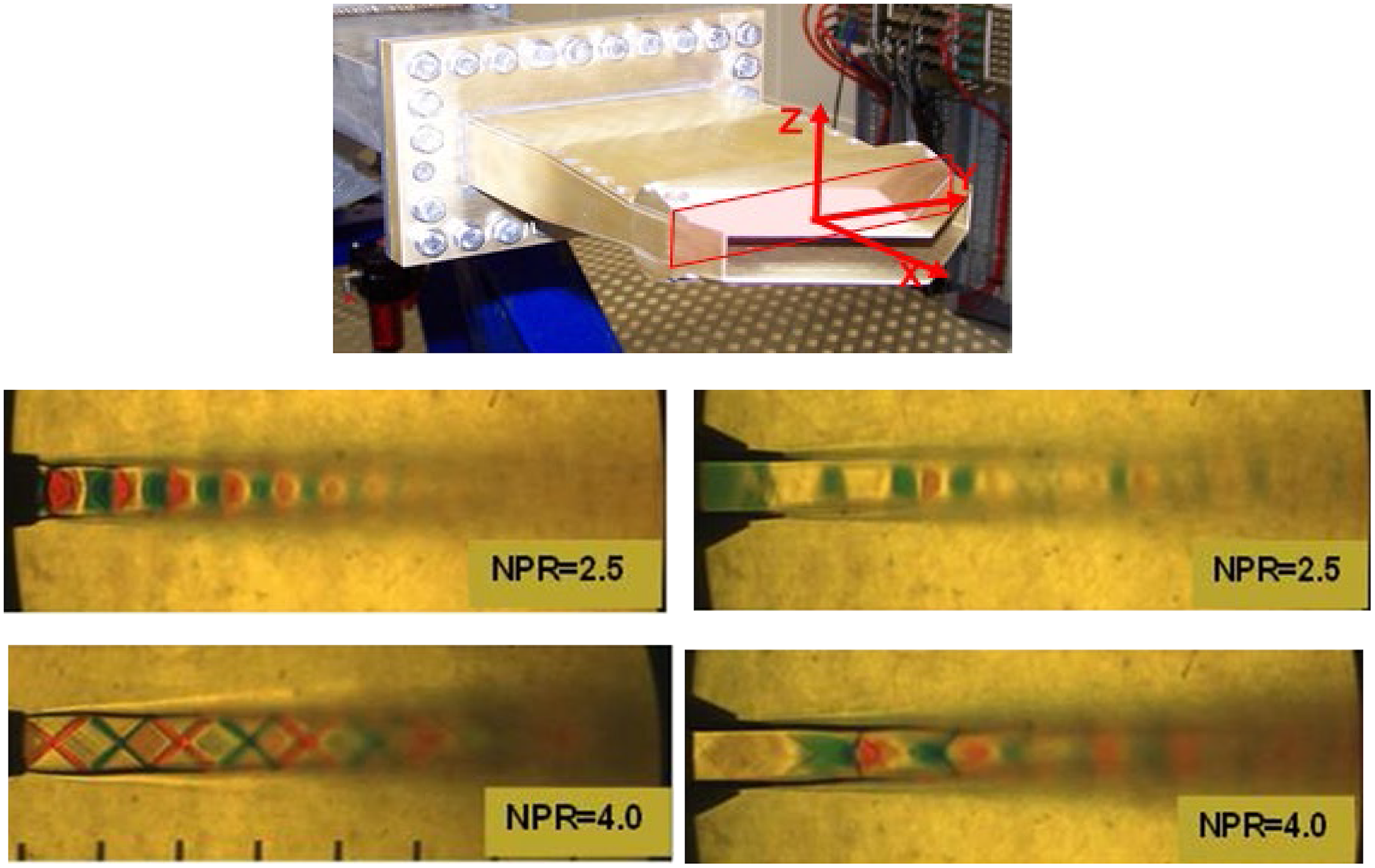

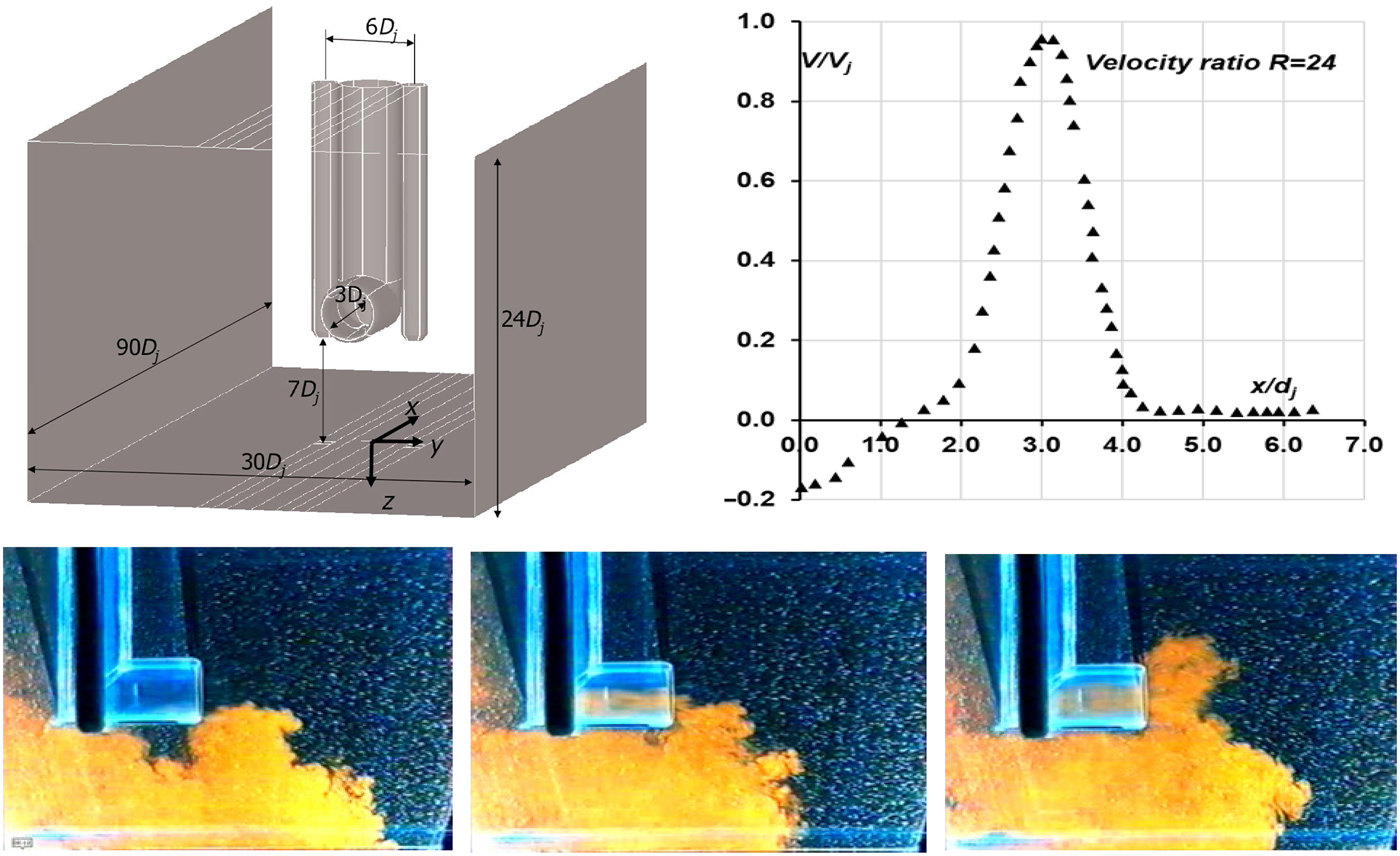

In military aircraft, jet velocities can be supersonic and improperly expanded, causing ‘shock diamonds’ in the jet plume (Fig. 8). Depending on the Nozzle Pressure Ratio (NPR = nozzle inlet total pressure/ambient static pressure), an additional acoustic effect – screech – can also occur. This is self-sustaining, high-intensity, tonal noise caused by an aeroacoustic resonance loop within the flow. If sufficiently intense and at a frequency close to structural resonances, damage can result. It is clearly essential for designers to understand the NPRs at which this occurs and be able to predict the intensity of pressure oscillations. Figure 8 also shows that, in this application (with afterburners), the jet plume is significantly hotter than in civil applications. A second design motivation is thus to enhance jet plume mixing to reduce the aircraft’s Infra-Red (IR) signature and improve low observability. Nozzle cross-sections that enhance mixing and technologies to increase mixing (tabs, fluid injection and plasma actuators) are also of design interest. Letterbox rectangular nozzles, aligned to match the aircraft shape and discharging over an ‘aft-deck’, are of potential interest, (Fig. 9), requiring effects of shape, entrainment restriction, etc. to be accurately captured.

Figure 8. Examples of shock-containing hot jet plumes.

Figure 9. Non-axisymmetric nozzle cross-section with aft-deck: B2 (left) and BAeS-Taranis (right).

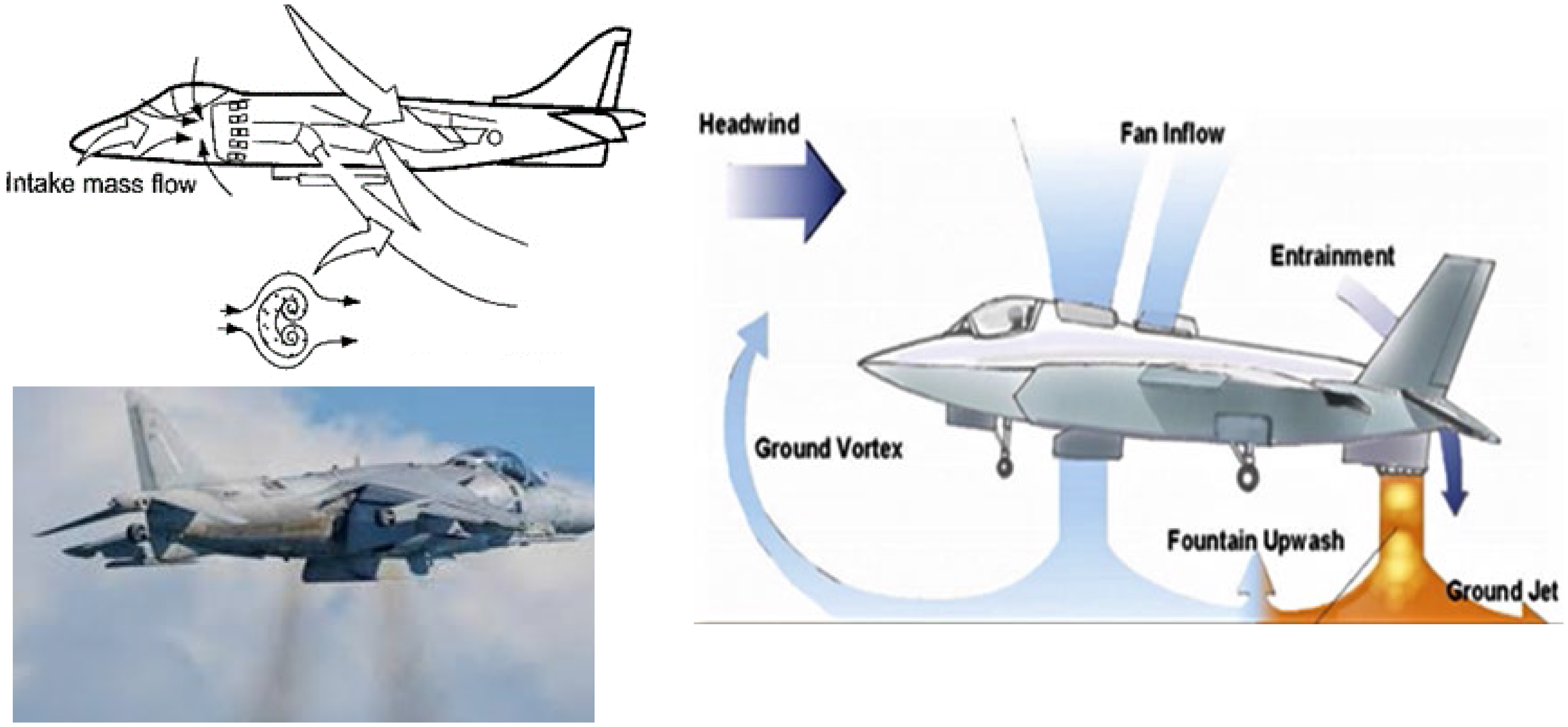

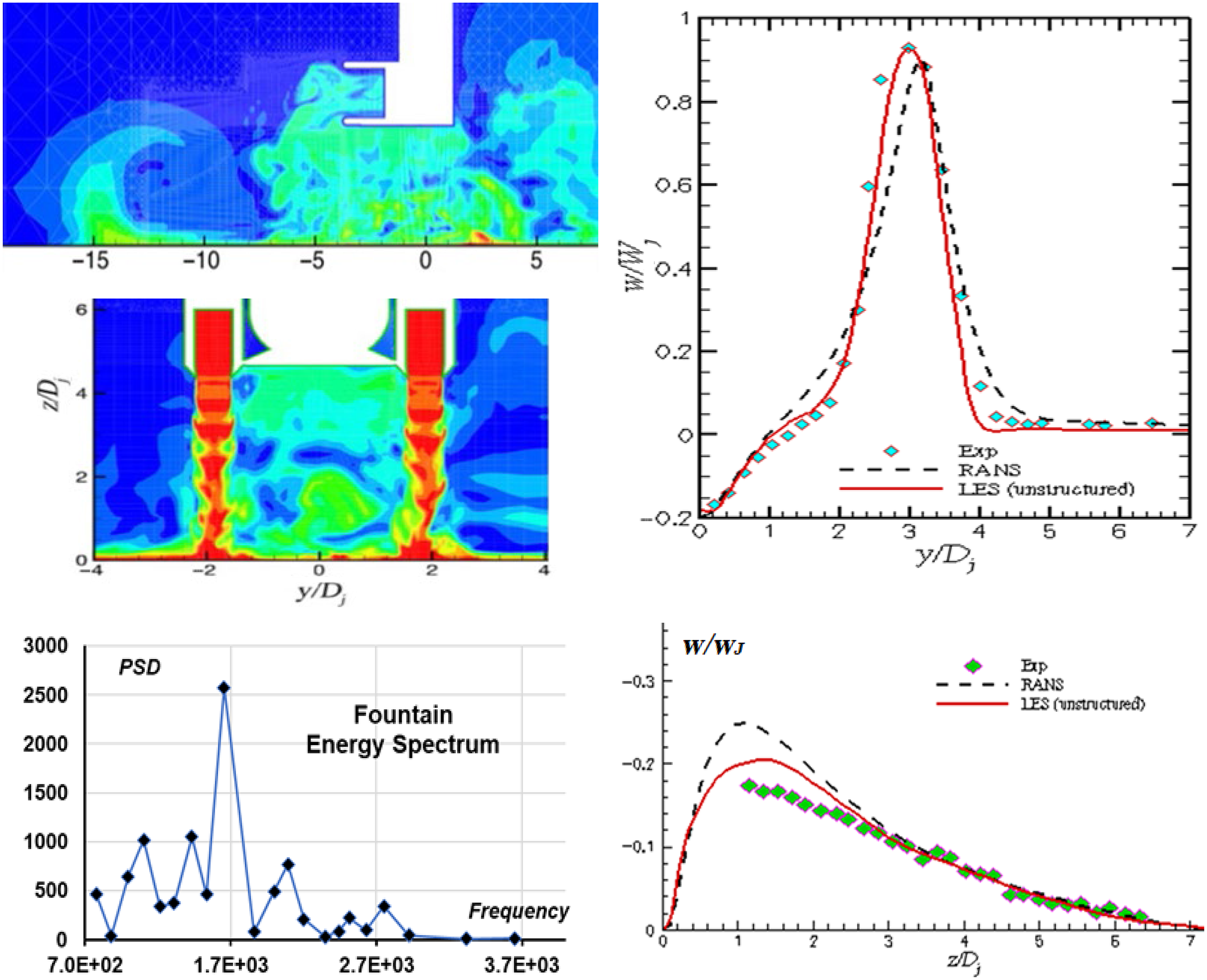

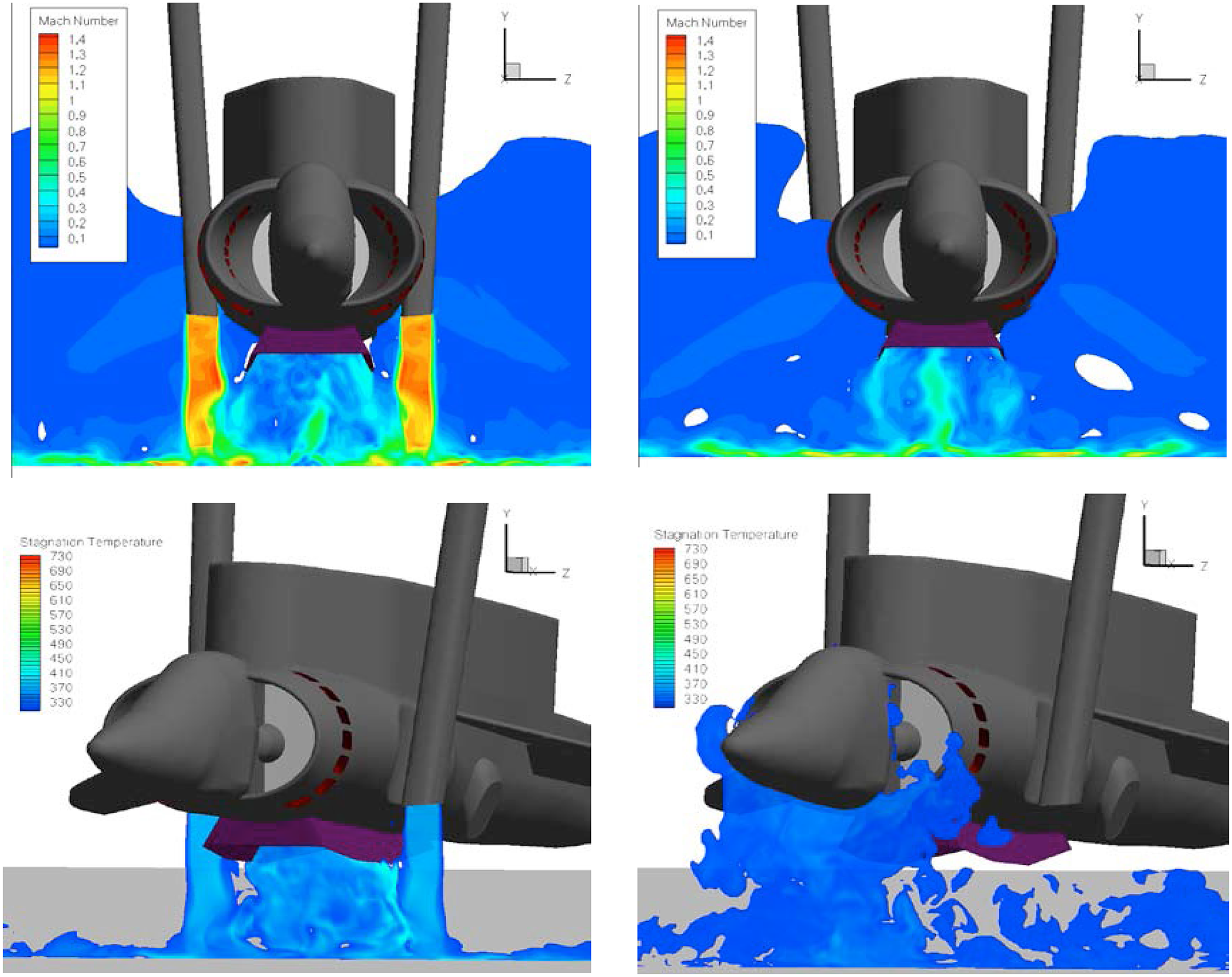

Finally, for VSTOL aircraft such as the Harrier or F-35, the influence of the propulsion jet plume(s) on the overall aircraft aerodynamics is particularly complex. This is the case for manoeuvres such as the transition from forward flight into vertical descent and the vertical landing itself, where phenomena such as lift jet splay angle, hot-gas ingestion, fountain upwash and ground vortex flows, illustrated in Fig. 10, must be carefully assessed.

Figure 10. V/STOL aircraft aerodynamics for BAe Harrier (left) and F35 (right).

The above brief review reveals and illustrates the several challenges faced by aerospace engineers when considering aspects of engine or airframe design which are influenced by propulsion jet plume development. The rest of this paper is organised as follows: firstly, in Section 2, fundamental aerodynamic and aeroacoustic processes which influence jets are summarised; secondly, in Sections 3 and 4, the progress made over the last decade or two in developing LES-based predictive approaches for the various civil and military applications described is outlined. Particular emphasis is placed on the extent to which these approaches have been validated against carefully chosen measurements. Finally, Section 5 provides a summary, the conclusions and suggestions for further work.

2.0 Fundamental characteristics of jet flows

2.1 Aerodynamics aspects

Jet flow pattern

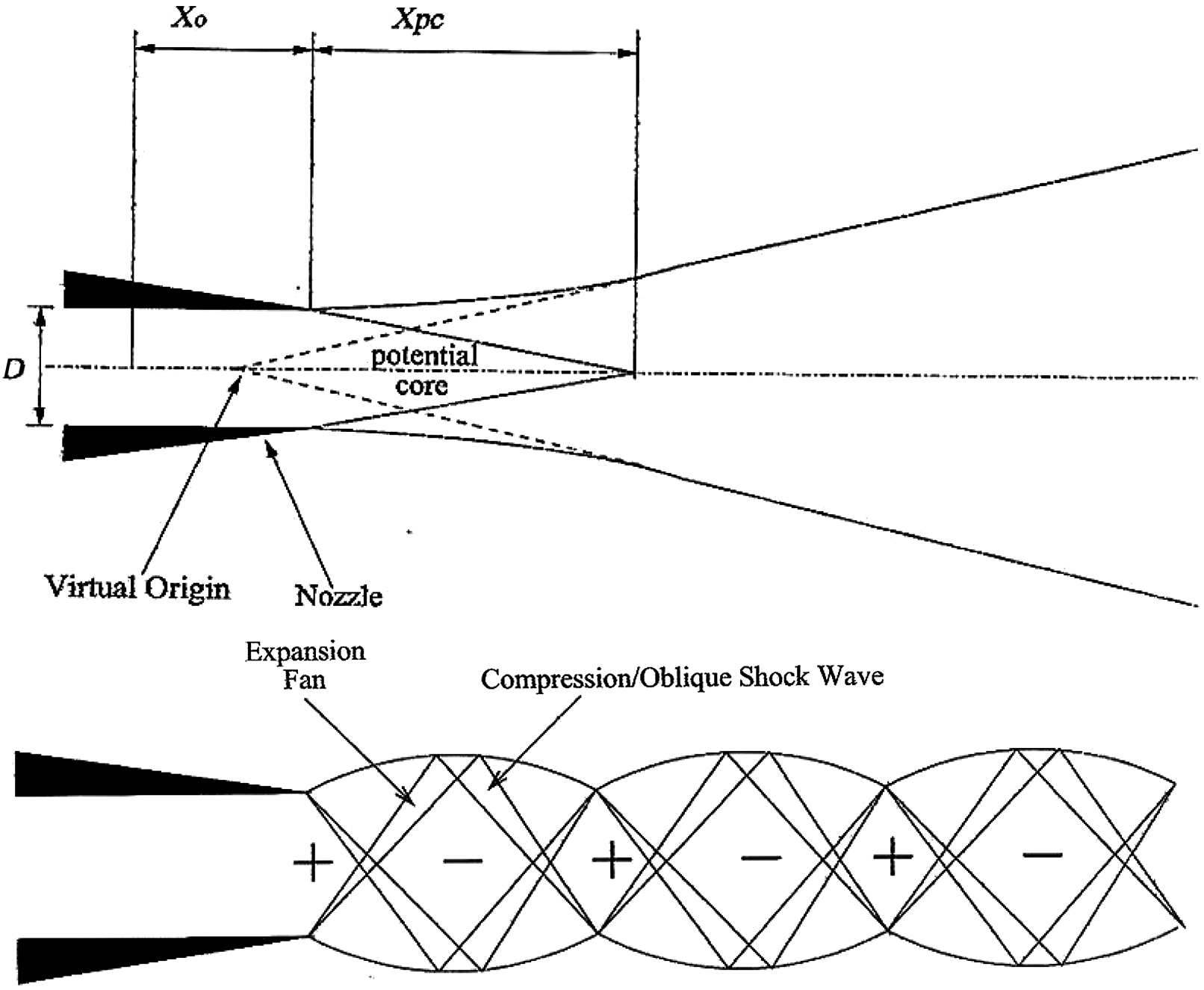

The basic fluid mechanics of a simple round jet in stagnant surroundings is sketched in Fig. 11. At the nozzle exit, two regions form: a potential core (of length X PC) within which velocity remains at U J , and an annular shear layer growing with x. For the Re j = ρ j U j D j /μ j values of practical configurations (on the order of 106–107), the nozzle exit boundary layer will be turbulent and turbulent mixing dominates shear-layer growth; these exit conditions influence the transformation from the initial shear layer to a fully formed, round jet as well as X PC. The region of interest here is the jet near field (x/D j < 20); it is thus important that the flow/turbulence conditions at the exit be considered in both CFD predictions and laboratory experiments if these are to be representative (although, until recently, this was rarely the case, as discussed below). Further downstream (x/D j > 30) a self-similarity region is found (Reference Pope6), with the value of the asymptotic growth rate playing an important role in calibrating constants in RANS turbulence models.

Figure 11. Jet flow development from convergent round nozzle: subsonic and supersonic.

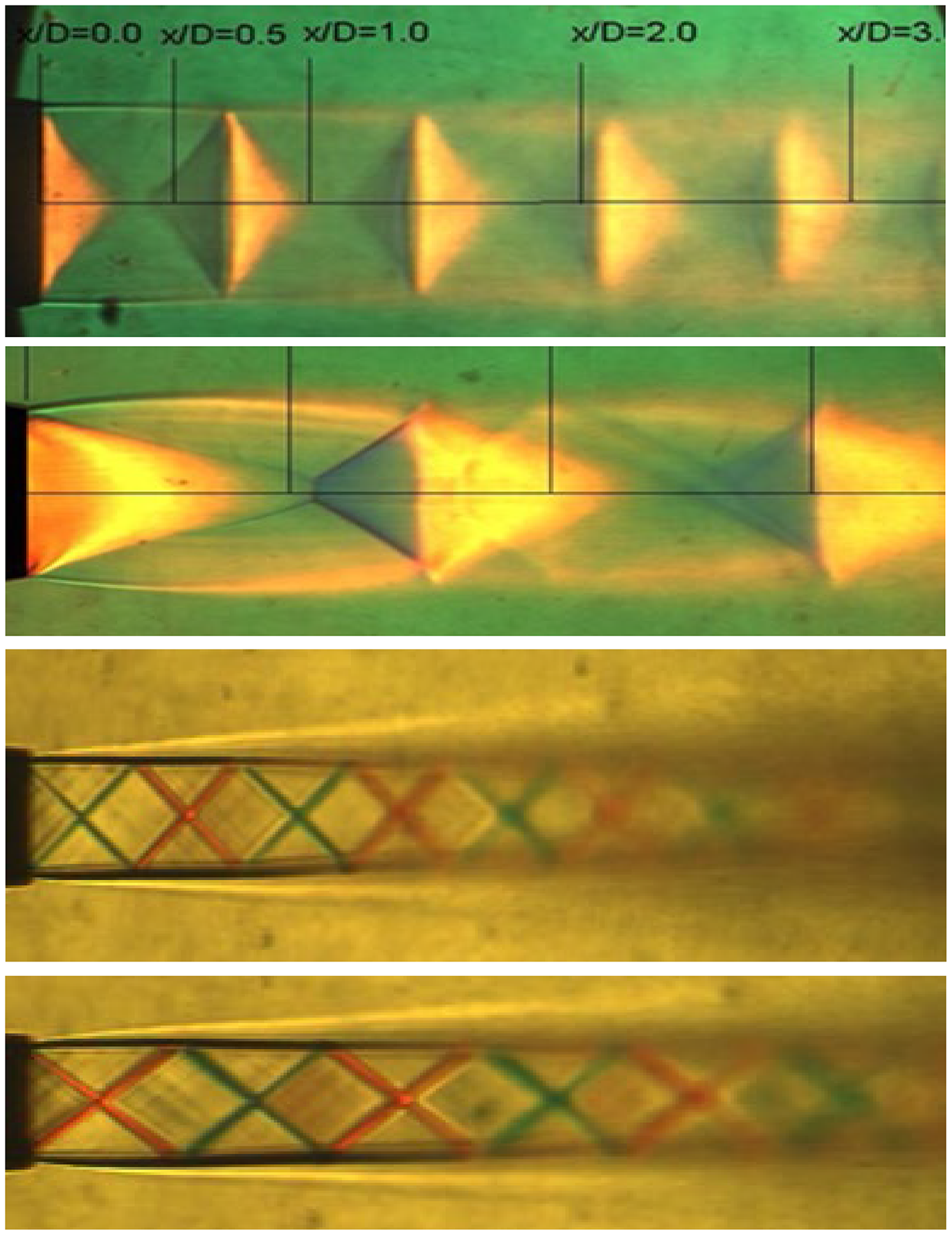

This description is relevant to low-speed jets (Mach no. M j < 0.5), whereas aerospace applications involve transonic and supersonic M j . At nozzle NPRs >1.89 (for air), shock-containing under-expanded (convergent nozzle) or under- and over-expanded jets (con-di nozzle) are possible. Expansion and oblique shock waves appear in the jet near-field; see Fig. 11 for a moderately under-expanded convergent nozzle. The colour Schlieren photographs in Fig. 12 are typical of high-speed aerospace applications; the upper two images correspond to a convergent round nozzle producing a weakly under-expanded jet (NPR = 2.3) and a moderately under-expanded jet with stronger shock waves (NPR = 4.0), whereas the lower two images show con-di nozzle under- and over-expanded flows (nozzle geometry design NPR = 3.5).

Figure 12. Schlieren images: under-expanded, NPR 2.3, 4.0 (top) and con-di, NPR = 3.3, 3.8 (bottom).

Jet Reynolds number effects/nozzle exit conditions

Potential core length is an important parameter for military applications since this is the region of highest temperature and IR signature; it is also the parameter most likely to be affected by nozzle exit conditions. Adequate consideration of these in laboratory studies intended to be relevant to propulsion nozzles has only recently been realised. Literature reviewed in Trumper et al. (Reference Trumper, Behrouzi and McGuirk7) indicates that early experimental studies considered too low Re

j

or exit profiles far removed from operating conditions relevant to aero-propulsion. Even early LES studies commonly reduced the computed Re

j

by a factor of

![]() $\sim$

10 to ease the mesh resolution requirement. To match operational conditions, minimum laboratory test values for Re

j

are important. Birch (Reference Birch8) concluded that “laminar viscosity has little influence on jet mixing, Re

j

enters the problem only because the thickness of the initial wall boundary layer depends on Re

j

….it is the initial boundary layer that is the controlling factor not Re

j

…”. Based on this, a minimum value of Re

j

= 4 × 105 was recommended. Further complication is introduced by the acceleration within the nozzle, which can lead to boundary layer relaminarisation (Reference Narasimha and Sreenivasan9). Probably the first set of measurements to pay attention to this issue was reported by Bridges and Wernet (Reference Bridges and Wernet10), who used a hot-wire probe to characterise the nozzle exit boundary layer and clearly illustrated the problem of high acceleration and too low Re

j

. Two nozzle convergence geometries were used: the first produced a boundary layer shape factor of H

12

$\sim$

10 to ease the mesh resolution requirement. To match operational conditions, minimum laboratory test values for Re

j

are important. Birch (Reference Birch8) concluded that “laminar viscosity has little influence on jet mixing, Re

j

enters the problem only because the thickness of the initial wall boundary layer depends on Re

j

….it is the initial boundary layer that is the controlling factor not Re

j

…”. Based on this, a minimum value of Re

j

= 4 × 105 was recommended. Further complication is introduced by the acceleration within the nozzle, which can lead to boundary layer relaminarisation (Reference Narasimha and Sreenivasan9). Probably the first set of measurements to pay attention to this issue was reported by Bridges and Wernet (Reference Bridges and Wernet10), who used a hot-wire probe to characterise the nozzle exit boundary layer and clearly illustrated the problem of high acceleration and too low Re

j

. Two nozzle convergence geometries were used: the first produced a boundary layer shape factor of H

12

![]() $\sim$

2.4 (clearly laminar), while the second lowered this (2.0) but still resulted in a transitional boundary layer. To avoid these problems, Trumper et al. (Reference Trumper, Behrouzi and McGuirk7) combined a higher bulk Re

j

(

$\sim$

2.4 (clearly laminar), while the second lowered this (2.0) but still resulted in a transitional boundary layer. To avoid these problems, Trumper et al. (Reference Trumper, Behrouzi and McGuirk7) combined a higher bulk Re

j

(

![]() $\sim$

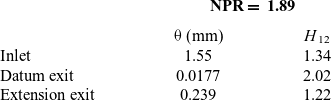

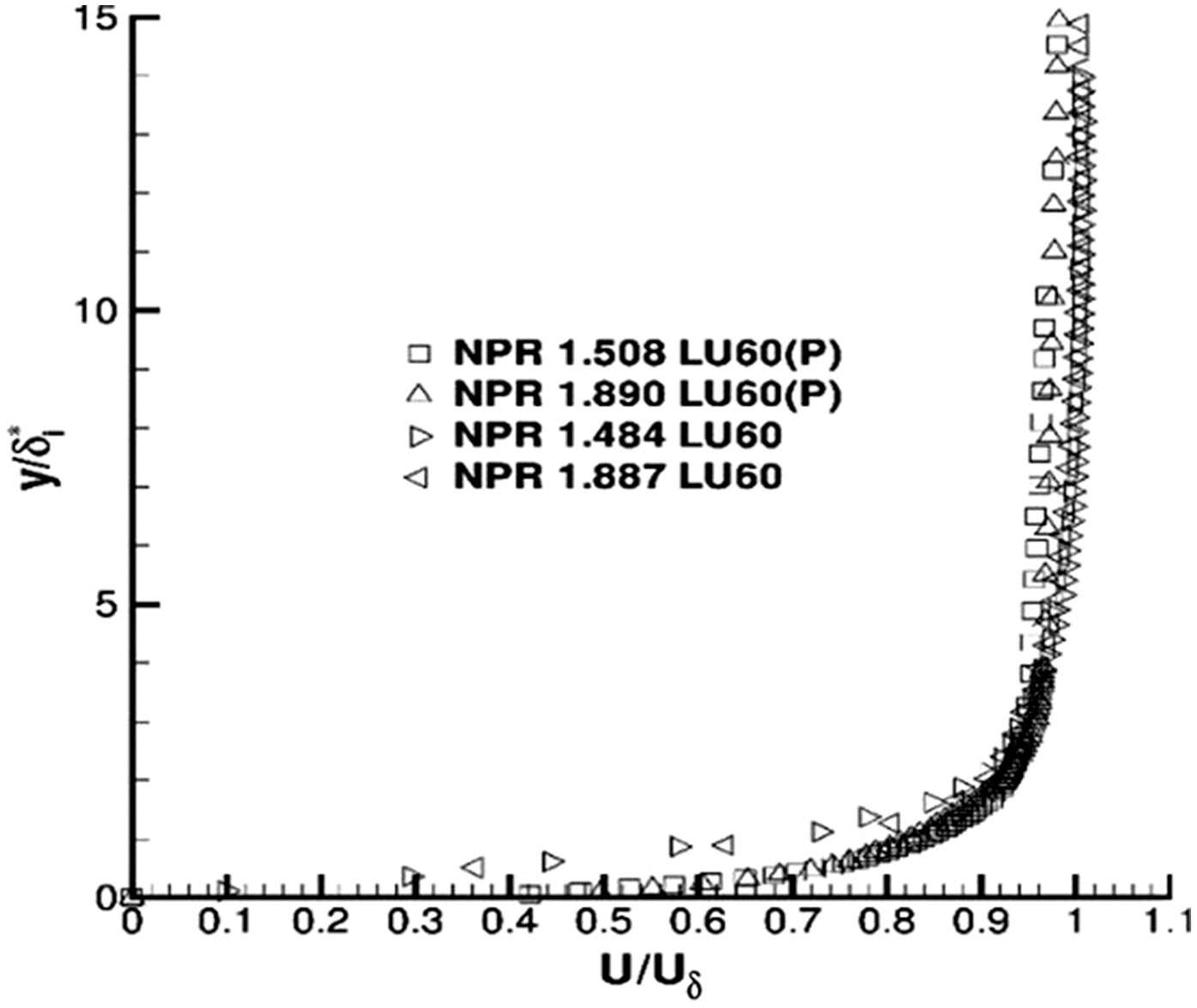

106) with a small parallel-wall extension at the nozzle exit to allow boundary-layer recovery, whilst maintaining an acceleration broadly similar to the BAE Systems Hawk aircraft nozzle. The success of this strategy is indicated in Fig. 13 and Table 1. The former shows that the exit velocity profile with extension (LU60(P)) is clearly more turbulent. Table 1 illustrates that the short exit extension produces a fully turbulent shape factor (1.22) as opposed to the laminar-like nature of the datum nozzle with no extension (2.02). The exit momentum thickness increased by a factor of

$\sim$

106) with a small parallel-wall extension at the nozzle exit to allow boundary-layer recovery, whilst maintaining an acceleration broadly similar to the BAE Systems Hawk aircraft nozzle. The success of this strategy is indicated in Fig. 13 and Table 1. The former shows that the exit velocity profile with extension (LU60(P)) is clearly more turbulent. Table 1 illustrates that the short exit extension produces a fully turbulent shape factor (1.22) as opposed to the laminar-like nature of the datum nozzle with no extension (2.02). The exit momentum thickness increased by a factor of

![]() $\sim$

14, although the boundary layer was still substantially thinner (by a factor of

$\sim$

14, although the boundary layer was still substantially thinner (by a factor of

![]() $\sim$

6) than at the nozzle inlet.

$\sim$

6) than at the nozzle inlet.

Table 1. Momentum thickness and shape factor at nozzle inlet/exit from Ref. Reference Trumper, Behrouzi and McGuirk7

Figure 13. Nozzle exit axial velocity profiles from Ref. Reference Trumper, Behrouzi and McGuirk7. Datum nozzle (LU60) and with extension (LU60P).

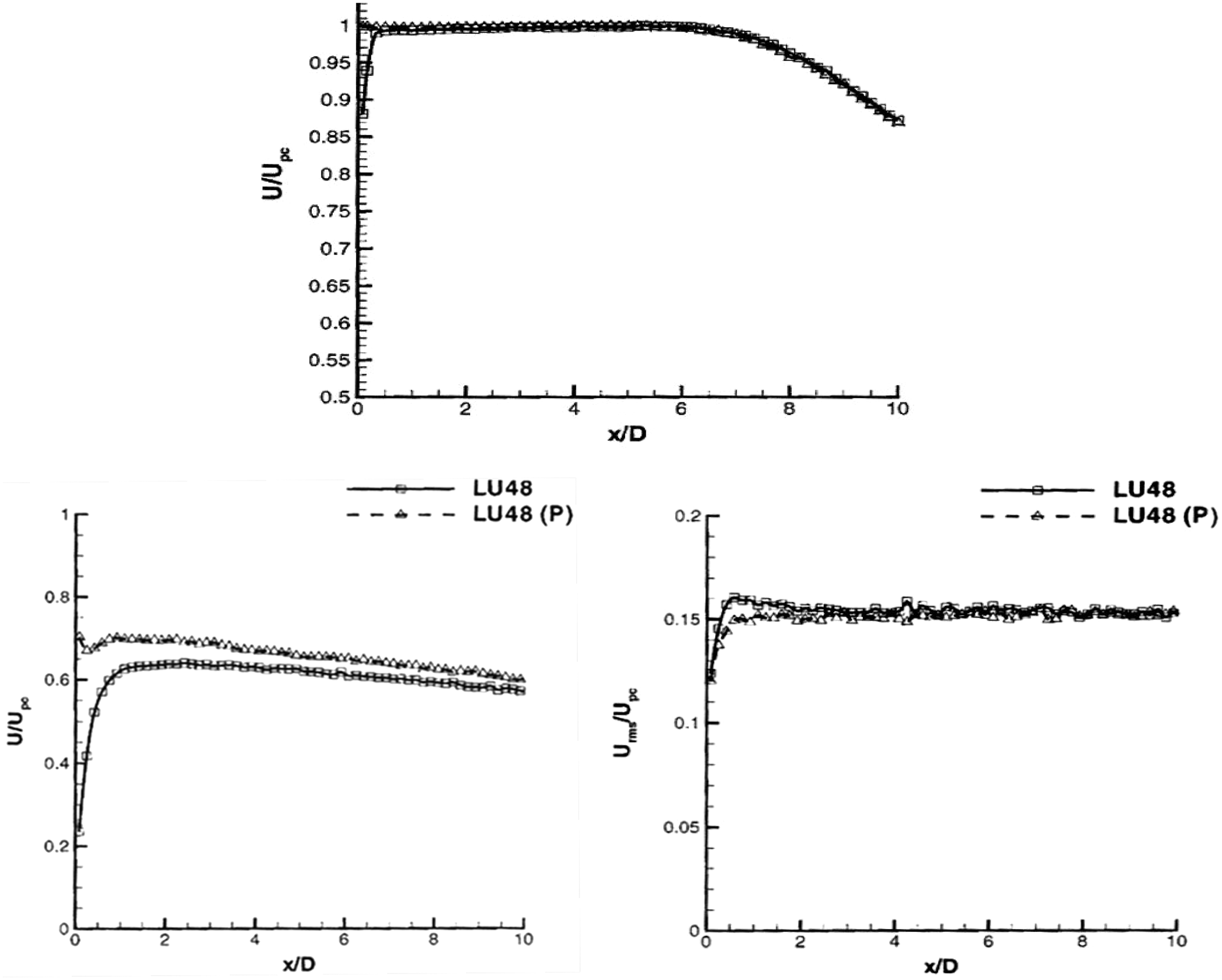

The sensitivity of the developing jet shear layer to changed nozzle exit conditions is quantified in Fig. 14, which shows the measured mean axial velocity along the centreline (top) and the nozzle lipline (bottom with axial velocity on the left and axial rms on the right). Centreline and lipline velocities for the datum nozzle are lower than with an extension, only for a short distance on the centreline but larger differences were observed on the lipline up to x/D = 5. Lipline axial rms turbulence is

![]() $\sim$

7% larger without extension, but this difference disappears after

$\sim$

7% larger without extension, but this difference disappears after

![]() $\sim$

2D. These are relatively small changes, but they may contribute to differences in high-frequency noise generation since this is dominated by the early shear-layer region. Measuring velocity and turbulence conditions at the nozzle inlet and exit is useful in all measurements, but especially for CFD validation data.

$\sim$

2D. These are relatively small changes, but they may contribute to differences in high-frequency noise generation since this is dominated by the early shear-layer region. Measuring velocity and turbulence conditions at the nozzle inlet and exit is useful in all measurements, but especially for CFD validation data.

Figure 14. NPR = 1.89: centreline, axial velocity (top) and lipline axial velocity (bottom left) and axial rms (bottom right) from Ref. Reference Trumper, Behrouzi and McGuirk7.

Jet Mach number effects

An experimental study of planar shear layers between two high-speed streams by Papamoschou and Roshko (Reference Papamoschou and Roshko11) produced evidence that the layer thickness growth rate was reduced by compressibility (where the shear-layer thickness was defined via the vorticity thickness

![]() ${\delta _\omega } = ({U_1} - {U_2})/{(\partial U/\partial y)_{\max }}$

, where the velocities of the fast and slow streams are U

1 and U

2. The reduction was correlated well by the convective Mach number (M

c

), the Mach number in a frame of reference moving with the speed of shear layer instability waves or disturbances such as turbulent structures. If both streams are pressure matched and have the same ratio of specific heats, M

c

is defined by Equation (1), where a

1

and a

2

are the speed of sound in each stream. M

c

assumes the form of Equation (2) for the case of a jet in stagnant surroundings (U

1 = U

j

and U

2

= 0), where

${\delta _\omega } = ({U_1} - {U_2})/{(\partial U/\partial y)_{\max }}$

, where the velocities of the fast and slow streams are U

1 and U

2. The reduction was correlated well by the convective Mach number (M

c

), the Mach number in a frame of reference moving with the speed of shear layer instability waves or disturbances such as turbulent structures. If both streams are pressure matched and have the same ratio of specific heats, M

c

is defined by Equation (1), where a

1

and a

2

are the speed of sound in each stream. M

c

assumes the form of Equation (2) for the case of a jet in stagnant surroundings (U

1 = U

j

and U

2

= 0), where

![]() ${T_{s,j}},{T_a}$

are static temperatures in jet and ambient, respectively, with

${T_{s,j}},{T_a}$

are static temperatures in jet and ambient, respectively, with

![]() $t = {T_{s,j}}/{T_a}$

. For isothermal jets, Mc = 0.5M

j

, although if the jet total temperature ratio is >1.0 (Nozzle Temperature Ratio (NTR) > 1), the factor will differ.

$t = {T_{s,j}}/{T_a}$

. For isothermal jets, Mc = 0.5M

j

, although if the jet total temperature ratio is >1.0 (Nozzle Temperature Ratio (NTR) > 1), the factor will differ.

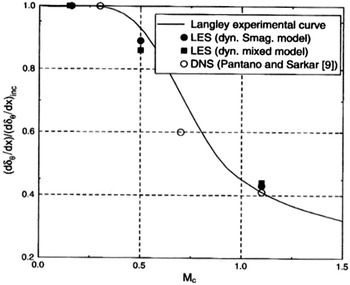

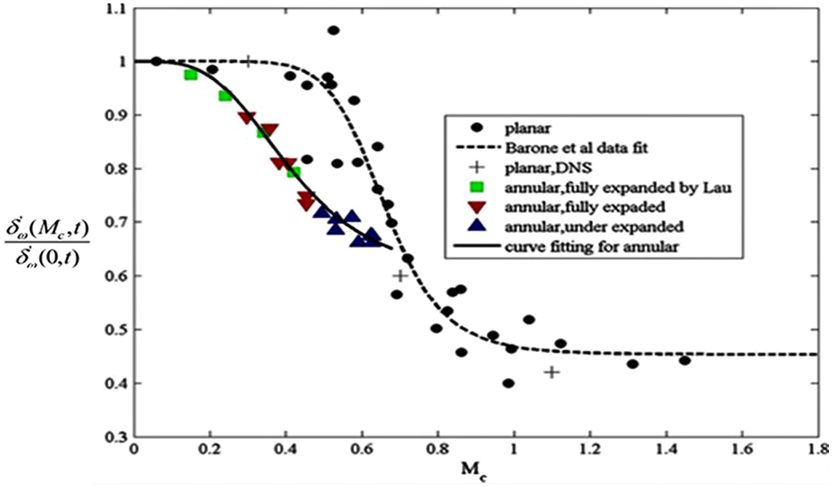

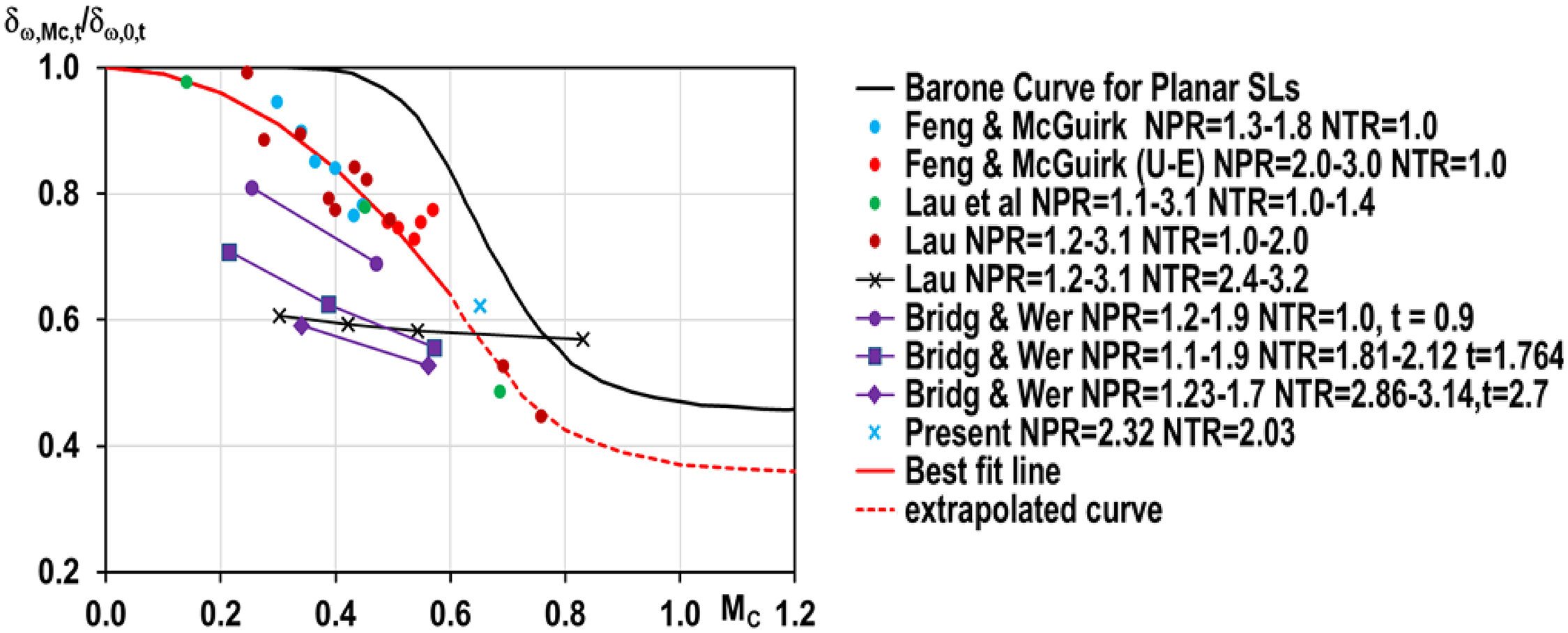

This mechanism is very important for propulsive jets which have M

j

above 0.7 for civil and above 1.0 for military applications. The mechanism will increase the potential core length for high-Mach-number jets, and CFD must capture this for accurate IR signature estimation. Barone et al. (Reference Barone, Oberkampf and Blottner12) conducted a survey of several experimental investigations to confirm and expand on Ref. Reference Papamoschou and Roshko11. The black data points in Fig. 15 represent the data compiled, while the black dashed line shows the regression fit. The effect is significant, with the spreading rate halving for M

c

![]() $\sim$

0.8. Barone et al. (Reference Barone, Oberkampf and Blottner12) also compared their recommended curve against predictions from several RANS turbulence models, reaching the conclusion that all models captured the growth rate decrease but mainly based on incorrect assumptions. Recently, Feng and McGuirk (Reference Feng and McGuirk13), extending an earlier study by Lau et al. (Reference Lau, Morris and Fisher14), focused specifically on annular shear layers with greater relevance to the jet near field. This data, shown by the coloured points in Fig. 15, demonstrated that a similar effect as in planar shear layers was present, but with stronger suppression of growth rate with M

c

. Note also that, since the spreading rate is dependent on both M

c

and t (see below), the reduction in Fig. 15 is expressed relative to an incompressible shear layer with the same value of t (

$\sim$

0.8. Barone et al. (Reference Barone, Oberkampf and Blottner12) also compared their recommended curve against predictions from several RANS turbulence models, reaching the conclusion that all models captured the growth rate decrease but mainly based on incorrect assumptions. Recently, Feng and McGuirk (Reference Feng and McGuirk13), extending an earlier study by Lau et al. (Reference Lau, Morris and Fisher14), focused specifically on annular shear layers with greater relevance to the jet near field. This data, shown by the coloured points in Fig. 15, demonstrated that a similar effect as in planar shear layers was present, but with stronger suppression of growth rate with M

c

. Note also that, since the spreading rate is dependent on both M

c

and t (see below), the reduction in Fig. 15 is expressed relative to an incompressible shear layer with the same value of t (

![]() ${\delta _\omega }(0,t)$

). The temperature ratio t influences mixing even when compressibility is absent, as described in the next sub-section.

${\delta _\omega }(0,t)$

). The temperature ratio t influences mixing even when compressibility is absent, as described in the next sub-section.

Figure 15. Compressibility-induced shear-layer spreading rate reduction from Refs Reference Barone, Oberkampf and Blottner12, Reference Feng and McGuirk13.

Jet temperature effects

Analogous to the study of compressibility in planar turbulent shear layers, Brown and Roshko (Reference Brown and Rosko15) carried out experiments to examine the effect of the density ratio across the shear layer

![]() $s = {\rho _2}/{\rho _1}$

(equivalent to

$s = {\rho _2}/{\rho _1}$

(equivalent to

![]() $t = {T_1}/{T_2} = {T_{s,j}}/{T_a}$

neglecting pressure effects). Measurements identified the dependence of shear layer growth rate on both velocity ratio

$t = {T_1}/{T_2} = {T_{s,j}}/{T_a}$

neglecting pressure effects). Measurements identified the dependence of shear layer growth rate on both velocity ratio

![]() $r = {U_2}/{U_1} = {U_a}/{U_j}$

and t. The implication for the shear layer growth rate for a hot jet in stagnant surroundings (r = 0) was a square-root dependence on temperature ratio:

$r = {U_2}/{U_1} = {U_a}/{U_j}$

and t. The implication for the shear layer growth rate for a hot jet in stagnant surroundings (r = 0) was a square-root dependence on temperature ratio:

This implies a fairly weak effect, with the growth rate increasing by 37% for a static temperature ratio increase of 300%. Nevertheless, this mechanism cannot be ignored since it influences the potential core length but in the opposite sense to compressibility. In aerospace propulsive jets, both mechanisms are present simultaneously. The effect of higher jet temperature is significant also since it has a known effect on jet noise; Fisher et al. (Reference Fisher, Lush and Harper-Bourne16) demonstrated that hot jets were noisier than cold jets for Mach numbers lower than 0.7 but quieter at higher M j , while Tanna (Reference Tanna17) carried out what is considered to be the reference case for temperature effects on high-speed jet noise, showing an influence of t on amplitude and directivity.

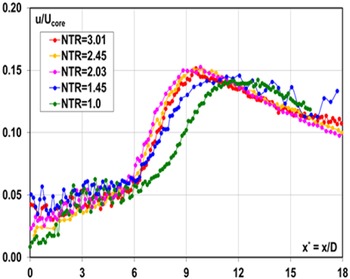

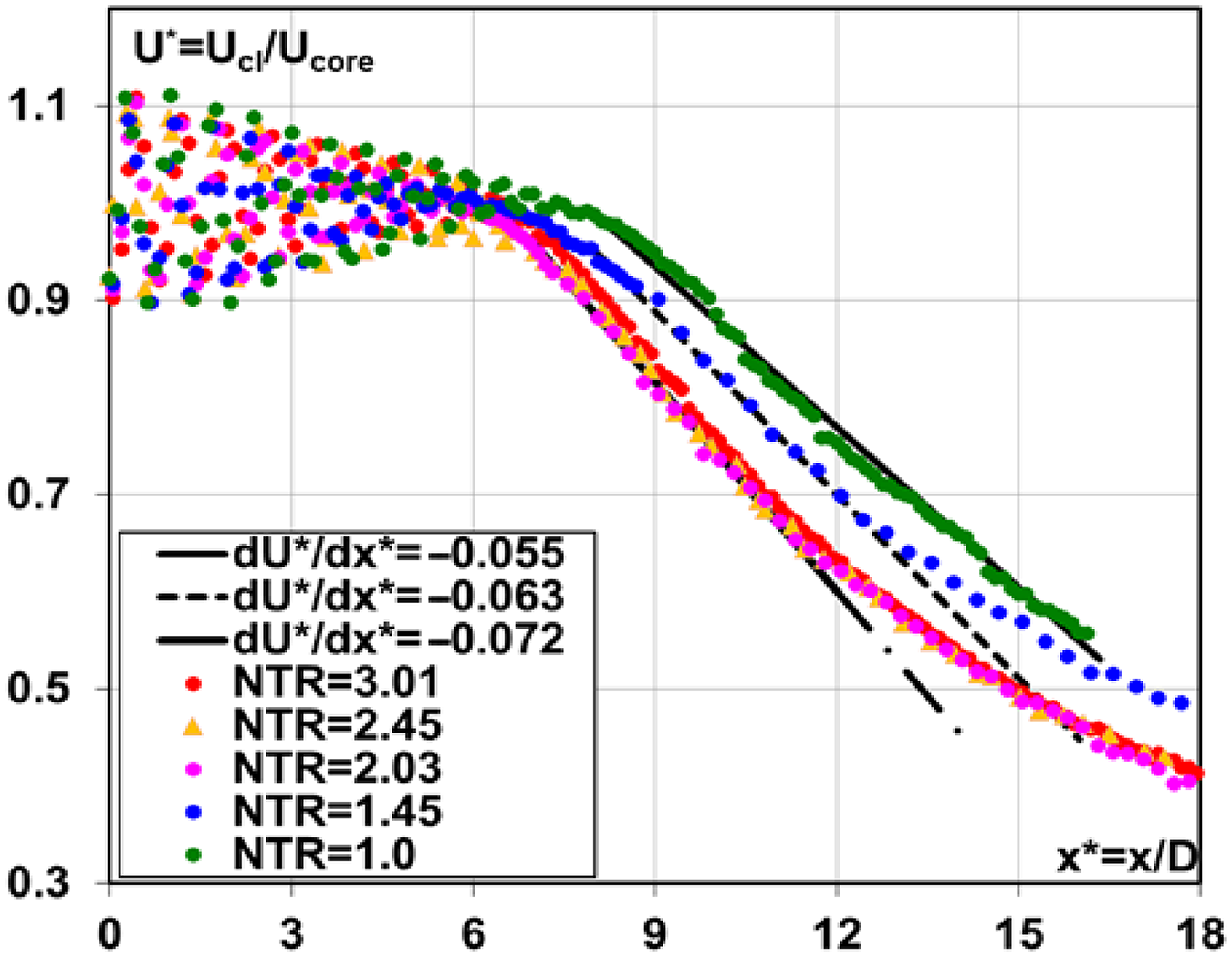

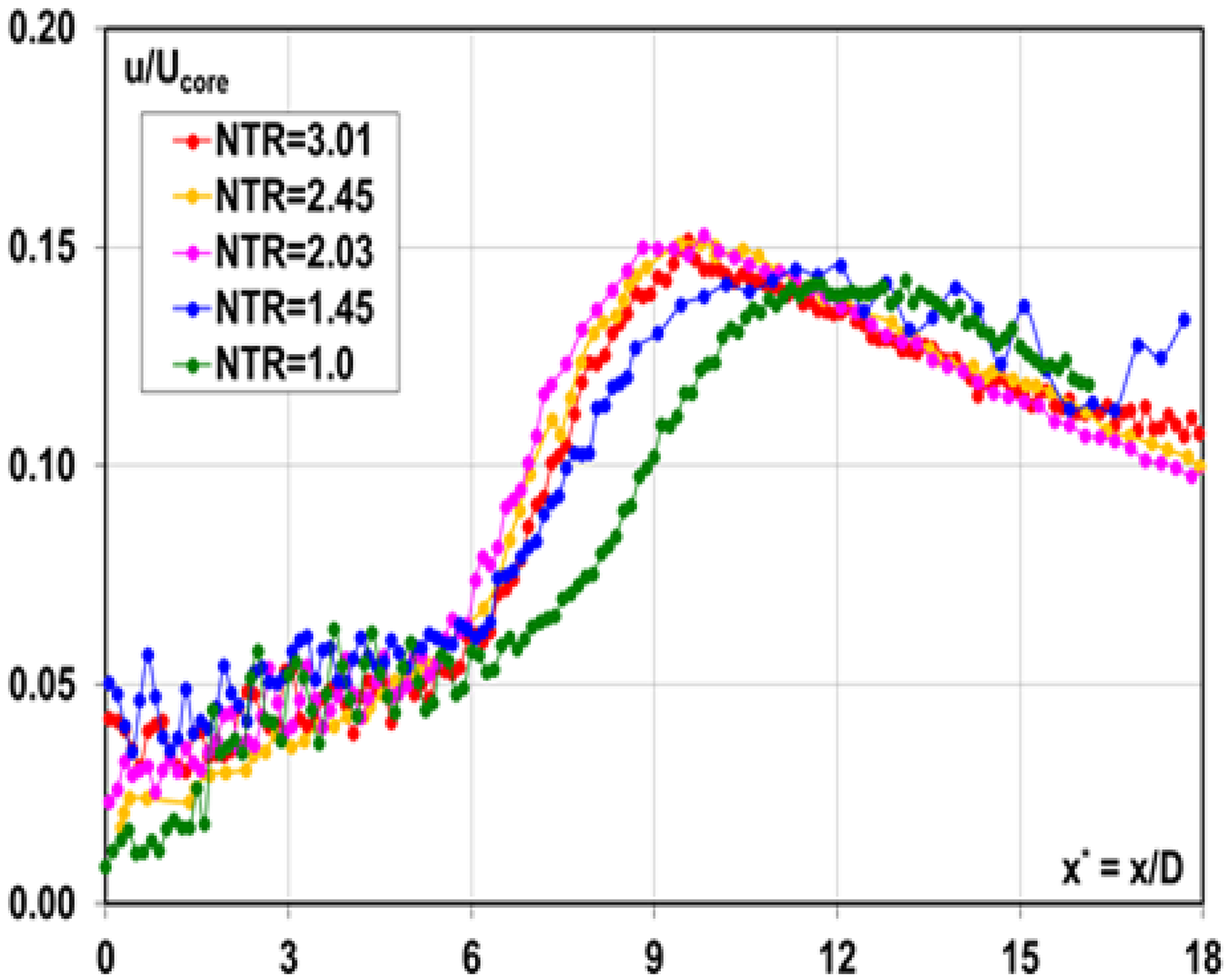

To investigate combined jet temperature–compressibility effects, McGuirk and Feng (Reference McGuirk and Feng18) used the same nozzle as employed in Ref. Reference Feng and McGuirk13 for an under-expanded (NPR = 2.32) jet and for NTRs up to 3.0. Non-dimensional data for the mean centreline axial velocity and turbulence rms are shown in Figs 16 and 17. The oscillations with magnitude of 16–21% of the core velocity identify the region of oblique shock waves as the jet static pressure decreases back to the ambient value. The potential core length clearly shortens while the decay rate steepens as the NTR increases, although these trends cease after NTR = 2.03. The potential core length is increased by jet heating, but less so than it would be in the absence of compressibility. A similar diminishing effect of temperature ratio is visible in the centreline axial turbulence development (Fig. 17); the peak rms increases slightly with the NTR, and its location moves upstream, but once again a temperature effect is not observed above NTR = 2.03.

Figure 16. Centreline mean axial velocity at NPR = 2.32 with various NTR from Ref. Reference McGuirk and Feng18.

Figure 17. Centreline axial turbulence at NPR = 2.32 with various NTR from Ref. Reference McGuirk and Feng18.

Analysis of radial profiles over the potential core length enables evaluation of the shear-layer growth rate. This and other data on hot jets from the literature have been added to the compressibility reduction diagram in Fig. 15 to obtain Fig. 18. Some data (Fig. 18, black and purple symbols) deviate from the best-fit line identified by the majority of data (Fig. 18, red line, extrapolated for high values of M c parallel to the black line of Ref. Reference Barone, Oberkampf and Blottner12). This best-fit line is supported by a range of measurements taken in different facilities and would appear to be a distinctive feature of jet-related shear layers.

Figure 18. Compressibility-induced growth rate reduction for various NPR and NTR from Ref. Reference McGuirk and Feng18.

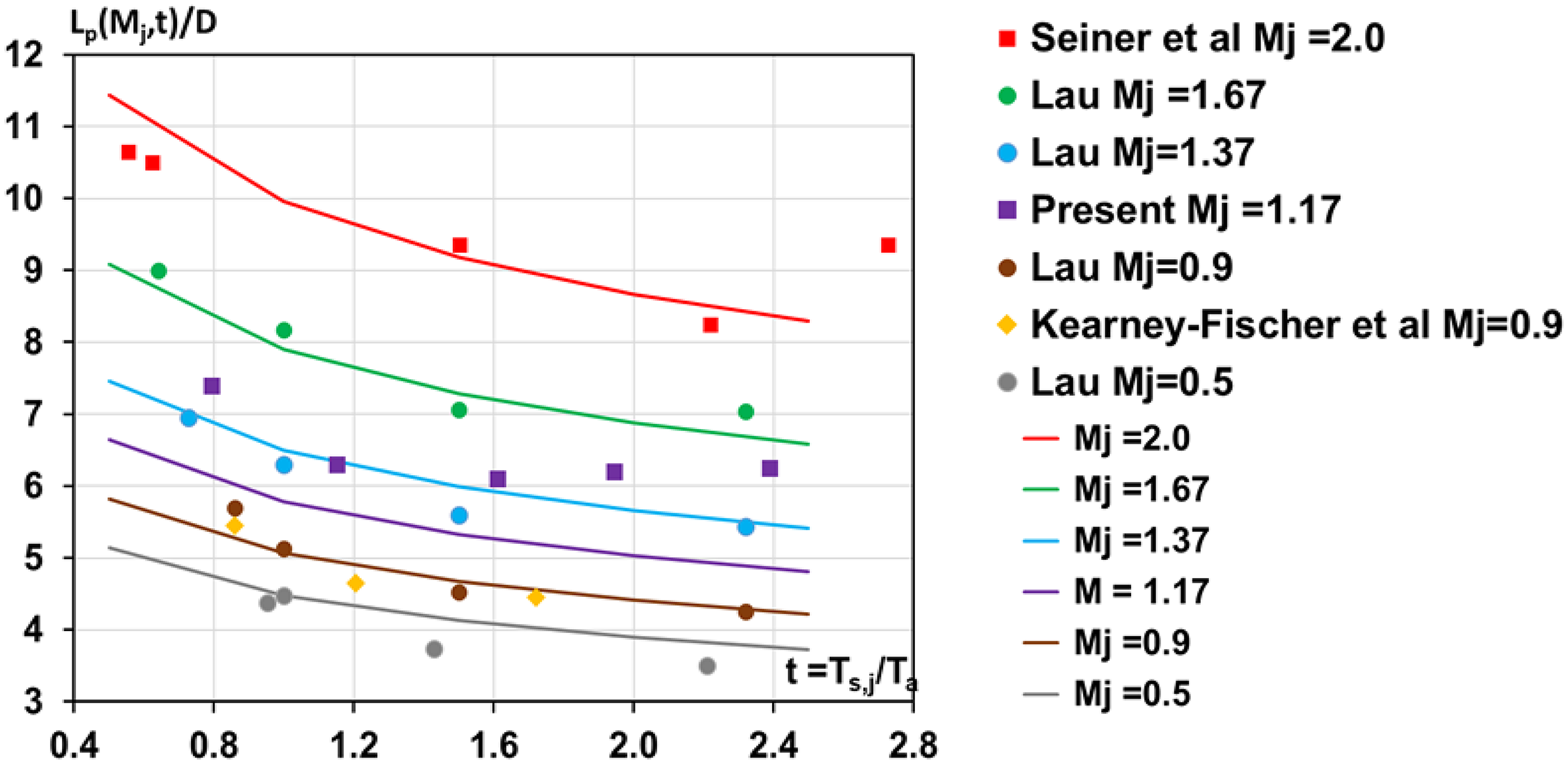

Given the importance of the potential core length, an empirical correlation was evaluated in Ref. Reference McGuirk and Feng18 based on the concept of competing compressibility and temperature effects. The correlation derived for the potential core length (L p ) as a function of both M j and t is given in Equation (4) and compared with available data in Fig. 19. Whilst not perfect, the correlation of Equation (4) covers the wide ranges of Mach number and temperature ratio of interest in aerospace engineering and represents a valuable design aid.

Turbulence modelling

The descriptions above highlight the crucial role played by turbulent mixing. Accurate and generally applicable turbulence modelling is essential. Various approaches including RANS, LES and Direct Numerical Simulation (DNS) have all been used for propulsive jet aerodynamics (turbulence modelling impact on aeroacoustics is dealt with in Subsection 2.2). DNS, due to its high mesh dependency on Re, has mainly been applied to canonical flows, for example a low-Re round jet (Re j = 2,000 in Ref. Reference Taub, Lee, Balachandar and Sherif19), and RANS or LES are the principal options.

Figure 19. L p (Mj,t) correlation (lines) compared with measurements (symbols) from Ref. Reference McGuirk and Feng18.

The performance of RANS for propulsive jet flows was reviewed in 2006 by Georgiadis and DeBonis (Reference Georgiadis and DeBonis20) and a decade later by Yoder at al. (Reference Yoder, DeBonis and Georgiadis21). The overall conclusion was that standard two-equation models (k–

![]() $\varepsilon$

, k–

$\varepsilon$

, k–

![]() $\omega$

etc.) were unable to predict (with the accuracy required by designers) the variation of the potential core length with compressibility, temperature or the 3D nozzle shapes of engineering interest. As noted in Ref. Reference Barone, Oberkampf and Blottner12, attempts to introduce compressibility effects, whilst superficially successful, were based on incorrect physical assumptions. This situation has improved in only one aspect: Gomez et al. (Reference Gomez and Girimaji22) proposed a modified pressure–strain model (in an algebraic stress form of the Reynolds stress transport equations), which correctly reproduced compressibility-induced damping. However, the model has so far not been applied to high-speed jets. Similarly, eddy viscosity model improvements to capture temperature ratio effects have been put forward by Tam and Ganesan (Reference Tam and Ganesan23), Abdol-Hamid et al. (Reference Abdol-Hamid, Paul Pao, Massey and Elmiligui24) and Truemner and Mundt (Reference Truemner and Mundt25). By adding a total temperature gradient correction to the production terms in the turbulence equations, the tendency of the k–ɛ model to overpredict the potential core length and underestimate the turbulence intensity in hot jets was corrected. It is difficult, however, to conclude that this approach has general validity; it is totally empirical with no physically justified basis, simply introducing an ad hoc adjustment. It seems premature to conclude with any confidence that the problem of RANS hot jet modelling has been resolved.

$\omega$

etc.) were unable to predict (with the accuracy required by designers) the variation of the potential core length with compressibility, temperature or the 3D nozzle shapes of engineering interest. As noted in Ref. Reference Barone, Oberkampf and Blottner12, attempts to introduce compressibility effects, whilst superficially successful, were based on incorrect physical assumptions. This situation has improved in only one aspect: Gomez et al. (Reference Gomez and Girimaji22) proposed a modified pressure–strain model (in an algebraic stress form of the Reynolds stress transport equations), which correctly reproduced compressibility-induced damping. However, the model has so far not been applied to high-speed jets. Similarly, eddy viscosity model improvements to capture temperature ratio effects have been put forward by Tam and Ganesan (Reference Tam and Ganesan23), Abdol-Hamid et al. (Reference Abdol-Hamid, Paul Pao, Massey and Elmiligui24) and Truemner and Mundt (Reference Truemner and Mundt25). By adding a total temperature gradient correction to the production terms in the turbulence equations, the tendency of the k–ɛ model to overpredict the potential core length and underestimate the turbulence intensity in hot jets was corrected. It is difficult, however, to conclude that this approach has general validity; it is totally empirical with no physically justified basis, simply introducing an ad hoc adjustment. It seems premature to conclude with any confidence that the problem of RANS hot jet modelling has been resolved.

It is perhaps not surprising that RANS eddy viscosity models experience such difficulties for the present flow type. They are calibrated to match a range of Two-Dimensional (2D) free shear flow experimental data in which turbulent eddies have achieved an asymptotic state of development. The jet near field is far from this, comprising turbulence which originates in a wall-bounded flow and passes through a mixing layer phase, finally experiencing just the preliminary stage of development into a fully formed jet. This problem was recognised in Refs Reference Georgiadis and DeBonis20 and Reference Yoder, DeBonis and Georgiadis21, both of which concluded that the LES approach was more appropriate for flows where the large-scale structures are adjusting rapidly to their changing flow environment.

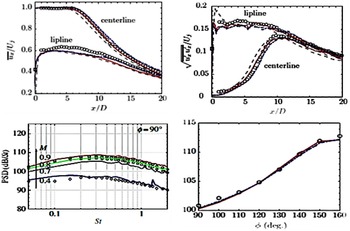

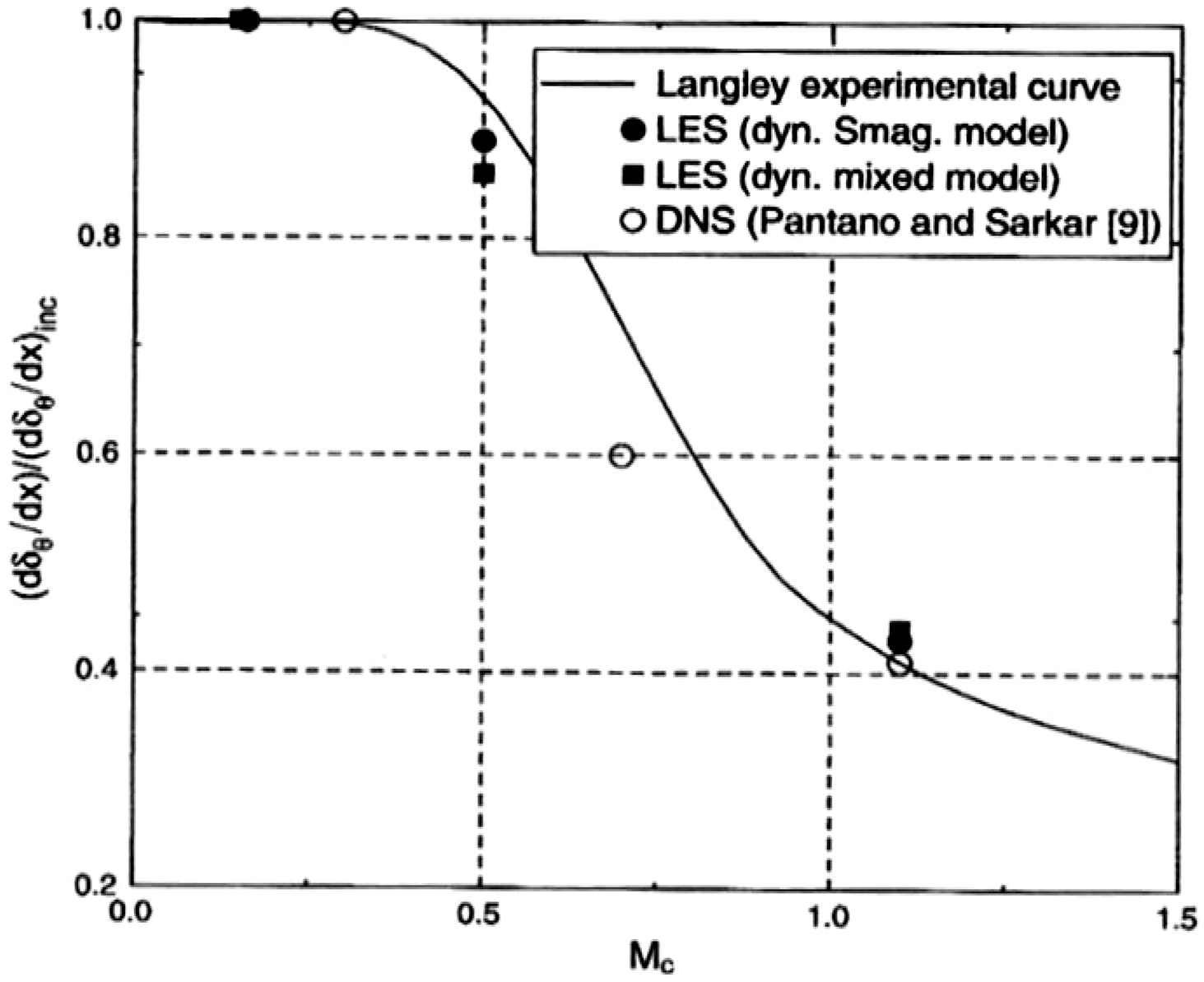

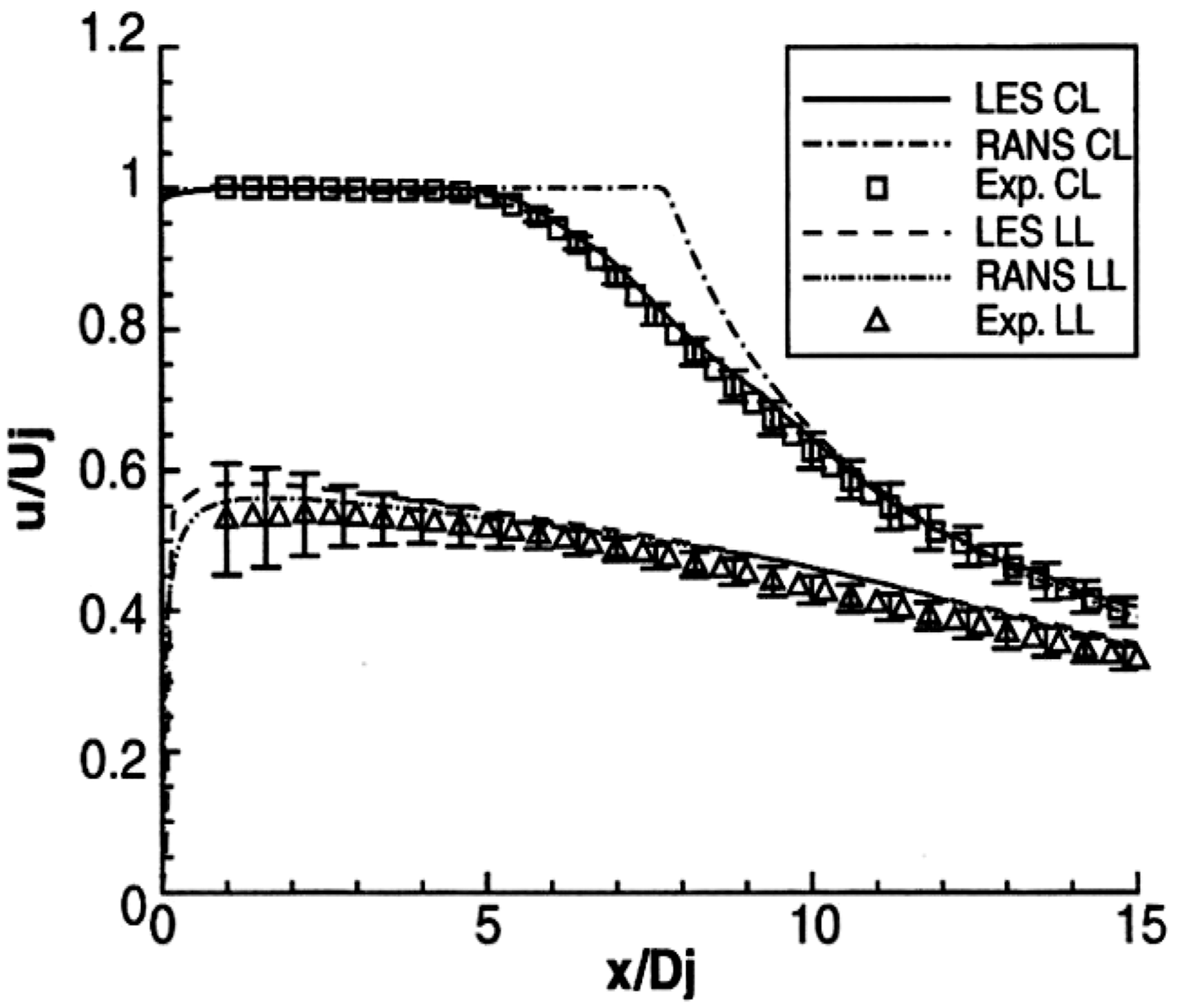

Doubts were, however, expressed in Refs Reference Georgiadis and DeBonis20 and Reference Yoder, DeBonis and Georgiadis21 regarding the robustness and maturity of several numerical aspects of LES CFD codes. This situation has improved in the intervening period, although access to High-Performance Computing (HPC) facilities and the cost or time resource involved remain significant issues. There is little doubt that LES has been proven a viable option that is capable of overcoming precisely the problems that are so difficult for RANS. McMullan et al. (Reference McMullan, Coats and Gao26) and Wang et al. (Reference Wang, Froelich, Michelassi and Rodi27), for example, show that LES accurately predicts the temperature ratio effect in incompressible planar shear layers and low-Mach-number jets, respectively. Le Ribault (Reference Le Ribault28) presented LES of a spatially developing high-speed planar shear layer at various convective Mach numbers and demonstrated excellent agreement with the data fit recommended by Barone et al. (Reference Barone, Oberkampf and Blottner12), as illustrated in Fig. 20. Bogey and Marsden (Reference Bogey and Marsden29) and DeBonis (Reference DeBonis30) confirmed that, with sufficiently fine meshes, LES performed very well in capturing the near field of single round jets in stagnant surroundings at M j = 0.9. Finally, examples of confidence-building results for LES for temperature effects in subsonic jets have also been reported. The results in Ref. Reference Bogey and Marsden29 did not match the experimental temperature ratios of Bridges (Reference Bridges31) exactly, but the change in the potential core length for hot jets was reproduced. For a temperature ratio of 1.6, the reduction in X pc was 21% (LES) versus 25% (experimentally). Similarly, in Ref. Reference DeBonis30, LES predictions were compared with the data of Bridges (Reference Bridges31) and demonstrated the clear superiority of LES versus RANS, as shown in Fig. 21.

Figure 20. LES prediction of compressibility-based reduction of shear layer growth from Ref. Reference Le Ribault28.

Figure 21. LES, RANS and experimental results for mean axial velocity, centreline/lipline from Ref. Reference DeBonis30.

As noted above, these improvements are accompanied by substantially increased computational cost. The LES mesh size is typically one to two orders of magnitude larger and, unlike in RANS, must increase as Re j increases. In DeBonis (Reference DeBonis30) the mesh comprised 36m points, and Bogey and Marsden (Reference Bogey and Marsden29) employed meshes as large as 250m. LES is also fundamentally an unsteady calculation, requiring perhaps O(105–106) timesteps to calculate statistically stationary values of first/second-order statistics (including a considerable ‘start-up’ time for the initial conditions to be ‘forgotten’). These numbers underline the need for access to large, multi-core HPC facilities for LES. The LES computational time is obviously not compatible with regular, repeated quick-turnaround design explorations. Hence, it is inevitable that RANS will continue to play a role in engineering design for the foreseeable future. LES at present can make its most useful contribution via: (i) helping to devise ways of modifying RANS turbulence models to allow better performance of specific aspects important to the flows considered, and (ii) increasing the precision of predictions for detailed analysis of down-selected concepts at a later stage of the design cycle.

LES mesh design is not as straightforward as for RANS, where regions of high mean spatial gradient are the only criterion. Guidance for LES has been provided by Choi and Moin (Reference Choi and Moin32), with the design strategy based broadly on the assumption that a ‘well-resolved’ LES mesh is one in which the cell size is everywhere able to capture >80% of the time-averaged turbulence energy in the ‘mesh-resolved scales’ (Reference Pope6), that is, <20% is at ‘sub-grid scale’ (SGS) accounted for by an SGS model or by the numerical discretisation scheme. Since the turbulence energy field is unknown before the LES calculation begins, resort has to be made to estimation using, for example, an a priori RANS calculation (Reference Dianat, McGuirk, Fokeer and Spencer33). In addition, constructing well-resolved LES meshes near walls is a considerable challenge, since the energy-containing, dynamically important eddies become smaller as the near-wall viscous region is approached and this feature is exacerbated as Re increases. This has led to the concept of ‘wall-modelled’ LES to avoid the strict near-wall resolution requirement. A popular proposal here is the wall stress approach of Kawai and Larsson (Reference Kawai and Larsson34) where the SGS model is used for all mesh points but the under-resolution of the boundary layer is corrected by imposing a wall-stress boundary condition. This is currently the most favoured approach for handling internal nozzle flow at high Re (Reference Angelino, Xia and Page35).

Finally, a perennial problem with LES, for which no definitive solution yet exists, is proper specification of inflow boundary conditions. Wu (Reference Wu36) and Dhamankar et al. (Reference Dhamankar, Blaisdell and Lyrintzis37) have provided reviews on this subject. Of the methods proposed, two have found application in jet flow applications: Synthetic Turbulence (ST) and the Recycling–Rescaling Method (R2M) The issue addressed is the demand in LES for a time-varying inflow specification comprising a correlated and self-consistent data set for all resolved length/time scales of motion present in the inflow. Incomplete or inconsistent specification results in an ‘adjustment’ length to develop correlated turbulent structures. An example of this in the current context is the specification of flow conditions for an LES calculation beginning at the nozzle exit. The realisation that the details of the initial shear layer development are influenced by the nozzle exit profile resulted in specific measurements being made. Variations in the measured potential core length at different facilities for the same operating conditions are generally believed to be primarily caused by differing nozzle exit profiles.

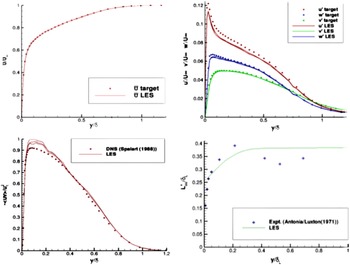

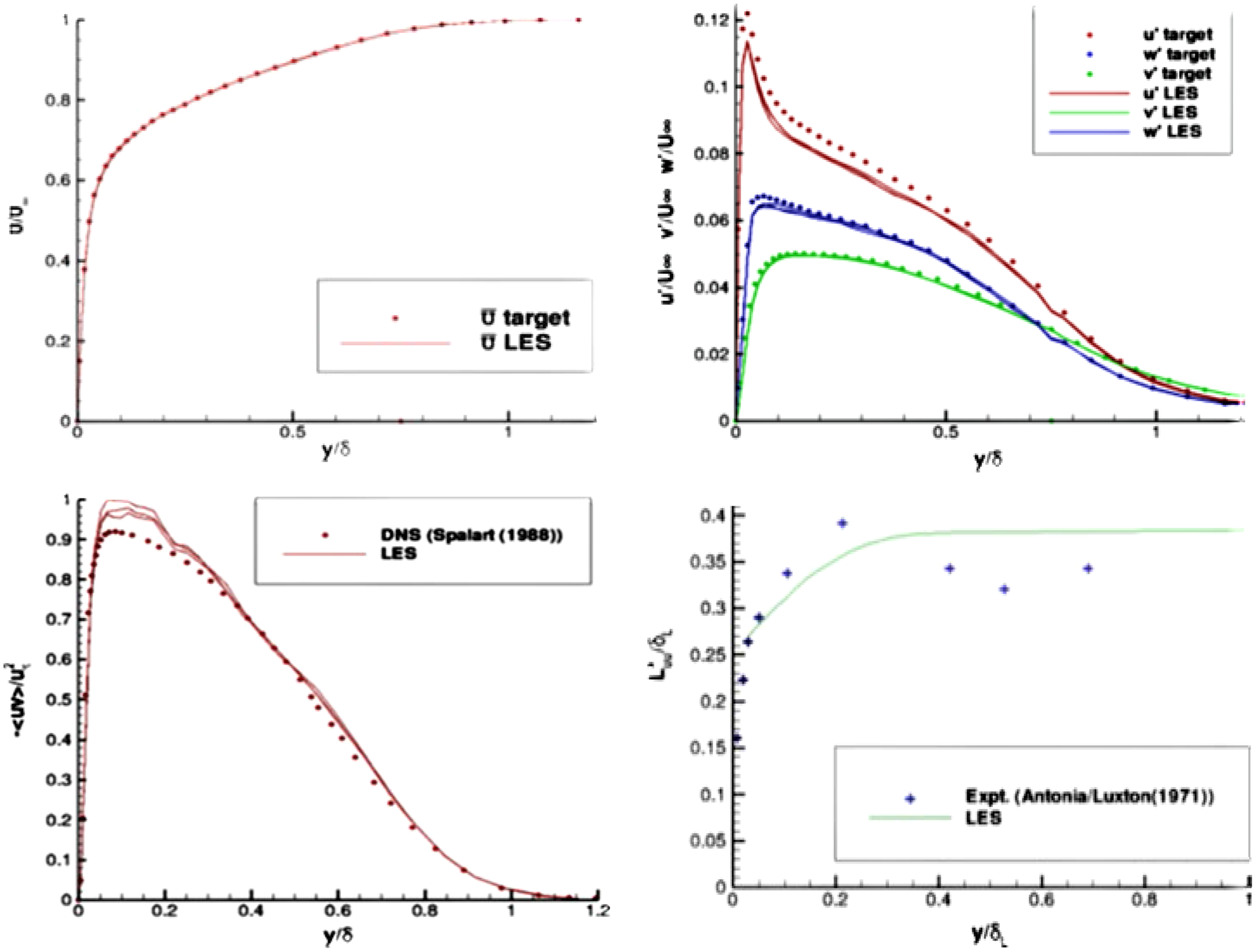

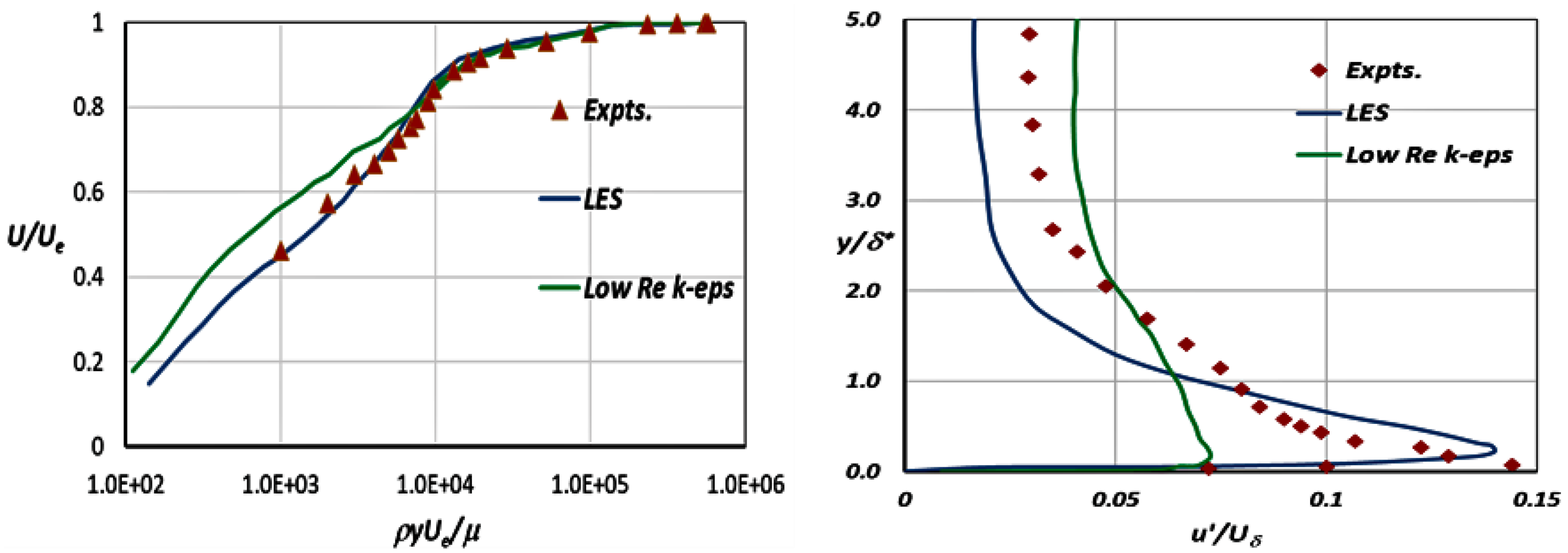

As noted above, Bridges and Wernet (Reference Bridges and Wernet10) conducted nozzle exit measurements in their creation of a validation data set for subsonic jet noise modelling, although surprisingly none of the published LES studies of the data in Ref. Reference Bridges and Wernet10 have made use of these exit measurements (e.g. Naqavi et al. (Reference Naqavi, Wang, Tucker, Mahak and Strange38)). The ST and R2M techniques allow experimental measurements to be incorporated into LES inlet conditions at various levels of self-consistency. The ST method known as digital filtering has been mainly adopted in LES jet flow predictions (Reference Brés, Jaunet, Le Rallic, Jordan, Colonius and Lele39,Reference Brés, Jordan, Jaunet, Le Rallic, Cavalieri, Towne, Lele, Colonius and Schmidt40), following Klein et al. (Reference Klein, Sadiki and Janicka41) by applying signal modelling techniques to manipulate the coefficients of a linear recursive filter. This creates a time series that is consistent with a specified ‘target’ data set of mean velocities and Reynolds normal stresses (from measurements). Approximations are introduced (principally the need to specify the turbulence length scale distribution and the spatial correlation function shape), hence the correct physical conditions cannot be matched exactly and some adjustment length is inevitable. These approximations are avoided in the R2M approach of Xiao et al. (Reference Xiao, Dianat and McGuirk42). In this technique, an LES solution within an extra ‘precursor’ domain is required. The inflow conditions within this precursor domain are generated by recycling the velocity field (after rescaling) back to the inlet from a user-selected downstream location. When the solution is statistically stationary, the velocity field at the outlet of the precursor domain represents the time-dependent inlet conditions for the main LES solution. In this version of R2M, continued rescaling acts as a forcing method and is applied throughout the precursor domain, whose streamwise dimension is chosen to ensure that turbulence length scales are unconstrained by boundary conditions. Rescaling forces the time-mean velocity and turbulence normal stresses to match user-specified profiles. Note that all the turbulent length scales and spatial (and temporal) correlations are self-generated and consistent with user-specified statistical input data. The disadvantage is that a second LES solution is required with its attendant cost. Figure 22 provides examples of this method’s ability to: (i) capture specified mean and turbulent stress profiles, and (ii) create shear stress/axial length scale profiles in agreement with experiments although not part of the user input. Examples of application to a nozzle flow are presented in Subsection 3.2.

Figure 22. R2M-generated inlet boundary layer profiles from Ref. Reference Xiao, Dianat and McGuirk42: mean axial velocity and rms turbulence (top) and shear stress and integral length scale (bottom).

2.2 Aeroacoustic aspects

Over the last 20 years, a transition from RANS-based to LES-based modelling has also begun in aeroacoustics; not a total shift, but rather a trend for increased use of LES is clear. Lighthill’s pioneering work (Reference Lighthill4) on propagation to the far field (where noise levels are regulated) of acoustic pressure fluctuations proposed a modification of the Navier–Stokes equations to have a left-hand side representing a homogeneous wave equation (pressure wave propagation at the ambient speed of sound) and a right-hand side viewed as acoustic noise sources. Further manipulation demonstrated (in a subsonic unheated jet, for example) that the far-field acoustic pressure intensity was defined by the volume integral of the fourth-order time derivative of the two-point two-time correlation of the fluctuating Reynolds stress tensor; this is defined in Equation (5) with and

![]() $\underline{\eta}$

spatial and τ temporal separations and the dash superscript indicating a turbulent velocity fluctuation:

$\underline{\eta}$

spatial and τ temporal separations and the dash superscript indicating a turbulent velocity fluctuation:

Morris and Farassat (Reference Morris and Farassat43) pointed out that assumptions about this property are an inherent part of all RANS-based jet noise models. If a physically accurate specification of the acoustic source term can be identified, solution of the wave equation using Green’s function techniques establishes the far-field sound.

In general, the approach taken has been to express the non-dimensional form of

![]() ${r_{ij,kl}}$

(

${r_{ij,kl}}$

(

![]() ${R_{ij,kl}}$

) via a correlation ‘shape function’ and recover the dimensional quantity at any point in the flow by multiplying by a local characteristic turbulence velocity scale raised to the fourth power. Guidance regarding the form of the shape function was sought from experimental measurements of space–time correlations. Initially (Reference Fisher and Davies44) these were undertaken using multiple hot-wire probes, but only for the second-order correlation

${R_{ij,kl}}$

) via a correlation ‘shape function’ and recover the dimensional quantity at any point in the flow by multiplying by a local characteristic turbulence velocity scale raised to the fourth power. Guidance regarding the form of the shape function was sought from experimental measurements of space–time correlations. Initially (Reference Fisher and Davies44) these were undertaken using multiple hot-wire probes, but only for the second-order correlation

![]() ${R_{ij}}(\underline x ,\underline \eta ,\tau )$

, and only for a few components and separation directions. Later, this was extended to measurements of fourth-order correlations, but again only for a restricted set and only in a round jet (Reference Morris and Zaman45). Typically, exponential or Gaussian shape functions have been used, with arguments

${R_{ij}}(\underline x ,\underline \eta ,\tau )$

, and only for a few components and separation directions. Later, this was extended to measurements of fourth-order correlations, but again only for a restricted set and only in a round jet (Reference Morris and Zaman45). Typically, exponential or Gaussian shape functions have been used, with arguments

![]() $(\underline x ,\underline \eta ,\tau )$

again made dimensionless using assumed local turbulence length/time scales. RANS turbulence predictions have typically been used to provide the variation throughout the jet of these turbulence scales (e.g. for the k–ɛ model, the velocity, length and time scales are

$(\underline x ,\underline \eta ,\tau )$

again made dimensionless using assumed local turbulence length/time scales. RANS turbulence predictions have typically been used to provide the variation throughout the jet of these turbulence scales (e.g. for the k–ɛ model, the velocity, length and time scales are

![]() ${k^{^{{\raise0.5ex\hbox{$\scriptstyle 1$}\kern-0.1em/\kern-0.15em\lower0.25ex\hbox{$\scriptstyle 2$}}}}},\,{k^{^{{\raise0.5ex\hbox{$\scriptstyle 3$}\kern-0.1em/\kern-0.15em\lower0.25ex\hbox{$\scriptstyle 2$}}}}}/\varepsilon ,\,k/\varepsilon $

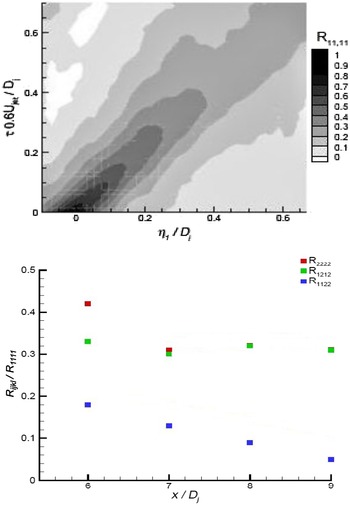

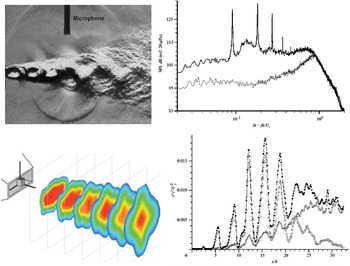

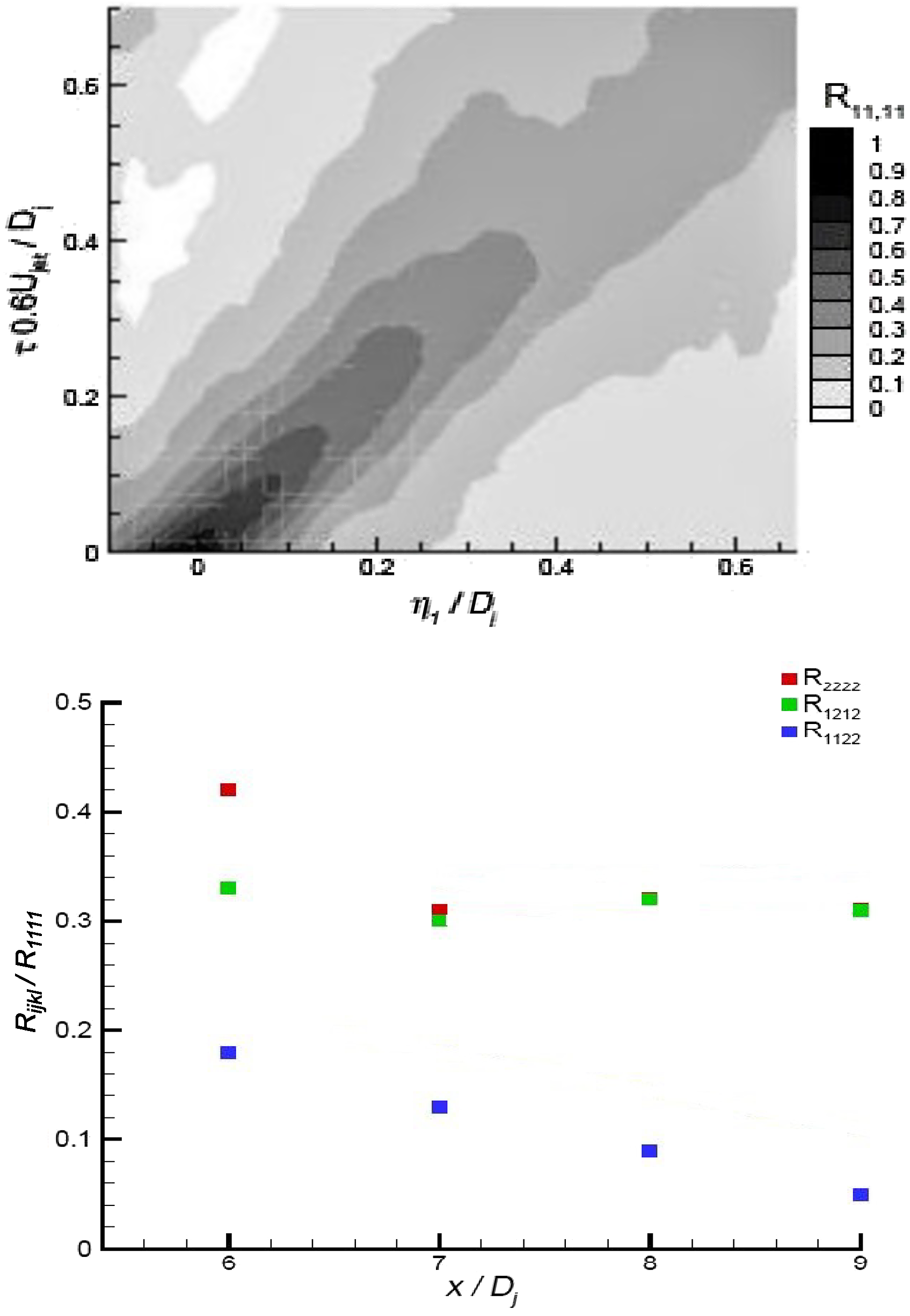

). Empirical coefficients to control the correlation magnitude and the assumed turbulence scales were introduced and adjusted to optimise accuracy. Reliance on a restricted set of measurements makes it difficult to apply this approach to other geometries/flow conditions. To address this problem, Karabasov et al. (Reference Karabasov, Afsar, Hynes, Dowling, McMullan, Pokora, Page and McGuirk46) proposed that the coefficients of the turbulence length/time scales should not be determined empirically but rather selected on the basis of information on turbulence scales taken from an LES solution. Confidence that LES can provide accurate predictions of space–time correlations was provide using the time-resolved Stereoscopic Particle Image Velocimetry (SPIV) data of Pokora and McGuirk (Reference Pokora and McGuirk47). Figure 23(a) indicates how the largest correlation (

${k^{^{{\raise0.5ex\hbox{$\scriptstyle 1$}\kern-0.1em/\kern-0.15em\lower0.25ex\hbox{$\scriptstyle 2$}}}}},\,{k^{^{{\raise0.5ex\hbox{$\scriptstyle 3$}\kern-0.1em/\kern-0.15em\lower0.25ex\hbox{$\scriptstyle 2$}}}}}/\varepsilon ,\,k/\varepsilon $

). Empirical coefficients to control the correlation magnitude and the assumed turbulence scales were introduced and adjusted to optimise accuracy. Reliance on a restricted set of measurements makes it difficult to apply this approach to other geometries/flow conditions. To address this problem, Karabasov et al. (Reference Karabasov, Afsar, Hynes, Dowling, McMullan, Pokora, Page and McGuirk46) proposed that the coefficients of the turbulence length/time scales should not be determined empirically but rather selected on the basis of information on turbulence scales taken from an LES solution. Confidence that LES can provide accurate predictions of space–time correlations was provide using the time-resolved Stereoscopic Particle Image Velocimetry (SPIV) data of Pokora and McGuirk (Reference Pokora and McGuirk47). Figure 23(a) indicates how the largest correlation (

![]() ${R_{11,11}}$

) varies with separation in both the x direction and time (

${R_{11,11}}$

) varies with separation in both the x direction and time (

![]() $\tau$

). The diagonal trajectory of the peak correlation indicates the eddy convection velocity (

$\tau$

). The diagonal trajectory of the peak correlation indicates the eddy convection velocity (

![]() $\sim$

0.6U

j

). The SPIV data revealed significant values of many components of

$\sim$

0.6U

j

). The SPIV data revealed significant values of many components of

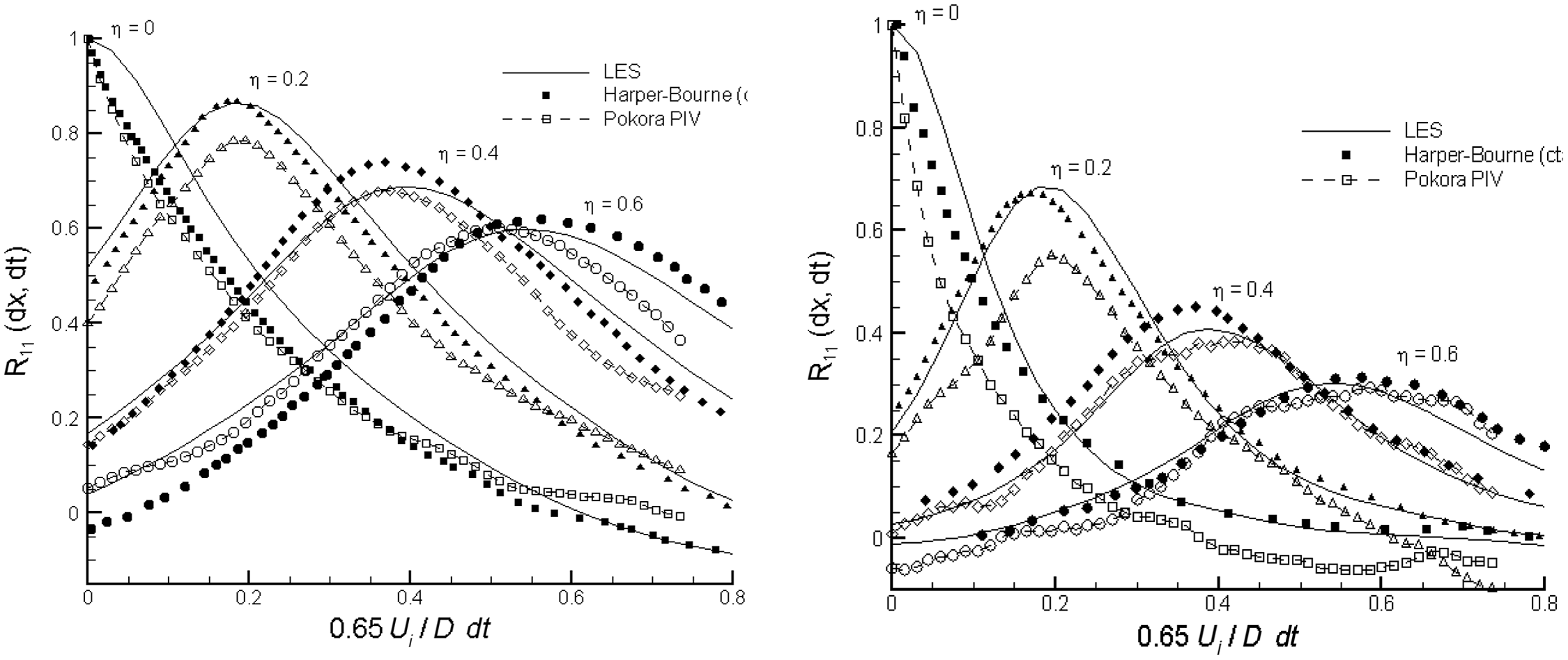

![]() ${R_{ij,kl}}(\underline x ,\underline \eta ,\tau )$

. The 81 components of the fourth-order tensor reduce with symmetry to 36, all of which were measured in Ref. Reference Lyrintzis and Coderoni48. Figure 23(b) presents the ratio of the peak amplitude of three components relative to the largest along the centreline, showing non-negligible values; even in an axisymmetric jet, many components are significant. Finally, Fig. 24, using SPIV data from Ref. Reference Pokora and McGuirk47, confirms that LES predicts high-order correlations accurately for second- and fourth-order spatio-temporal correlations.

${R_{ij,kl}}(\underline x ,\underline \eta ,\tau )$

. The 81 components of the fourth-order tensor reduce with symmetry to 36, all of which were measured in Ref. Reference Lyrintzis and Coderoni48. Figure 23(b) presents the ratio of the peak amplitude of three components relative to the largest along the centreline, showing non-negligible values; even in an axisymmetric jet, many components are significant. Finally, Fig. 24, using SPIV data from Ref. Reference Pokora and McGuirk47, confirms that LES predicts high-order correlations accurately for second- and fourth-order spatio-temporal correlations.

Figure 23. SPIV measured spatio-temporal correlation map for

![]() ${R_{11,11}}$

at (4D

j

, 0.5D

j

, 00) (top) and centreline variation of SPIV measured peak values relative to

${R_{11,11}}$

at (4D

j

, 0.5D

j

, 00) (top) and centreline variation of SPIV measured peak values relative to

![]() ${R_{11,11}}$

(bottom) from Ref. Reference Pokora and McGuirk47.

${R_{11,11}}$

(bottom) from Ref. Reference Pokora and McGuirk47.

Figure 24. Comparison of LES predictions with measurements of Ref. Reference Pokora and McGuirk47

![]() ${R_{11}}$

and

${R_{11}}$

and

![]() ${R_{1111}}$

from Ref. Reference Karabasov, Afsar, Hynes, Dowling, McMullan, Pokora, Page and McGuirk46.

${R_{1111}}$

from Ref. Reference Karabasov, Afsar, Hynes, Dowling, McMullan, Pokora, Page and McGuirk46.

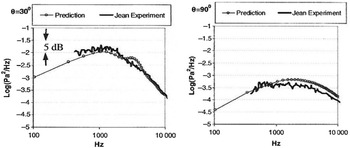

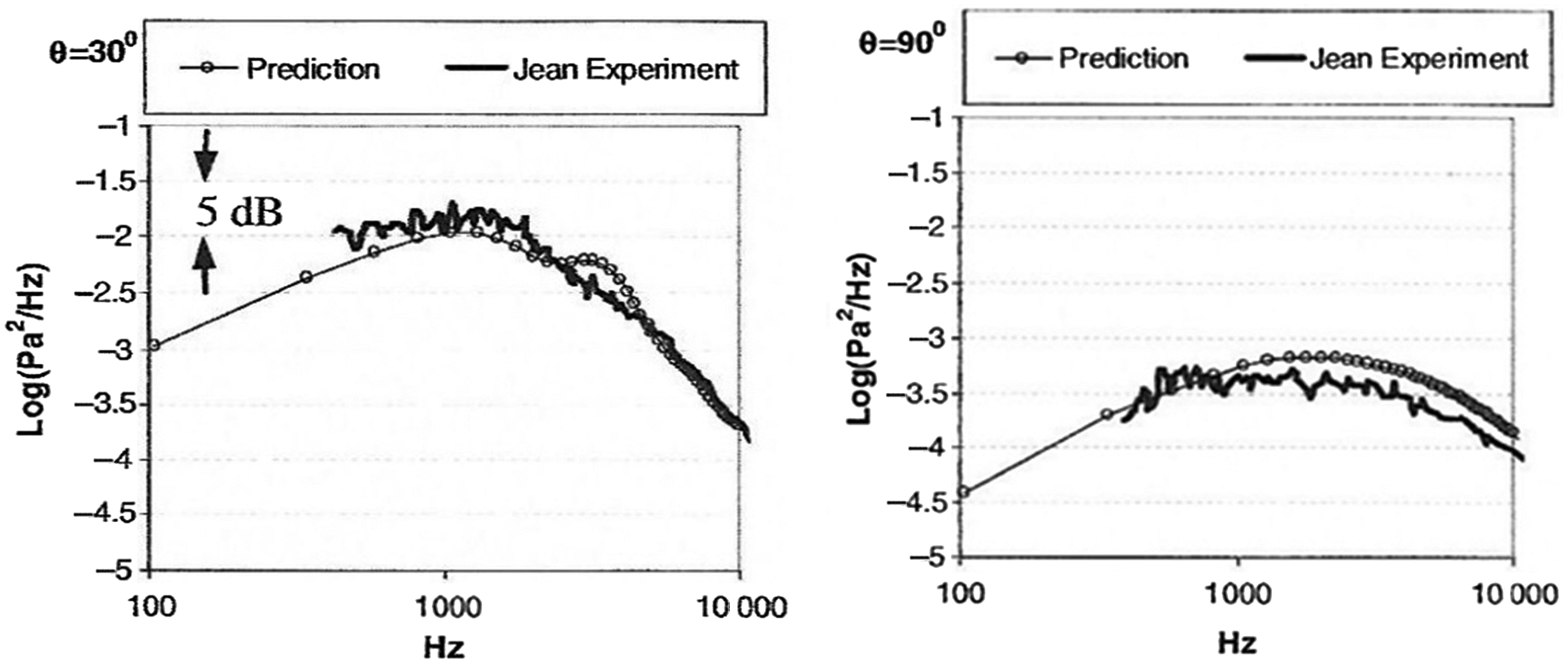

Following the procedure outlined above, RANS turbulence scales were manipulated in Ref. Reference Karabasov, Afsar, Hynes, Dowling, McMullan, Pokora, Page and McGuirk46 using LES information from Ref. Reference Pokora and McGuirk47. The method was then able to predict noise measurements at both peak noise (30°) and sideline (90°) angles, as shown in Fig. 25; this had not previously been possible with RANS-based methods.

Figure 25. Noise spectra comparison between RANS-based method and experiments at two angles from Ref. Reference Karabasov, Afsar, Hynes, Dowling, McMullan, Pokora, Page and McGuirk46.

There is, in principle, no reason why LES could not be used to capture both turbulent sources and propagation to the far field. However, since this lies

![]() $\sim$

50–75D away from the jet and LES is computationally expensive, such so-called direct LES computation of noise is likely to be prohibitively expensive and is not widely adopted, particularly for cases with complex geometry. The numerical techniques most widely used for LES complex applications are typically a blended mixture of second-order upwind and second-order central schemes, which are robust and have sufficiently low dissipation for turbulent flow, although not for wave propagation over long distances. A hybrid approach using one method for turbulence capture and another best suited to propagation is more appropriate.

$\sim$

50–75D away from the jet and LES is computationally expensive, such so-called direct LES computation of noise is likely to be prohibitively expensive and is not widely adopted, particularly for cases with complex geometry. The numerical techniques most widely used for LES complex applications are typically a blended mixture of second-order upwind and second-order central schemes, which are robust and have sufficiently low dissipation for turbulent flow, although not for wave propagation over long distances. A hybrid approach using one method for turbulence capture and another best suited to propagation is more appropriate.

A survey of all aspects of the application of LES to jet aeroacoustics has been provided by Lyrintzis and Coderoni (Reference Lyrintzis and Coderoni48). For the current purposes, it is sufficient to note that two techniques for propagation to the far field have been considered. The first is a surface-based technique such as the Linear Euler Equation (LEE) solver (Reference Bogey and Marsden49) or the Ffowcs Williams–Hawkings (FWH) approach (Reference Ffowcs Williams and Hawkings50); these are broadly equivalent, although the FWH approach is by far the more popular. LES information is extracted on a surface surrounding (and entirely enclosing) the turbulent noise sources and provides an interface to the propagation technique. The second technique is Acoustic Perturbation Equations (APE) proposed by Ewart and Schroeder (Reference Ewart and Schroeder51) (some promising results from this method (Reference Moratilla-Vega, Lackhove, Janicka, Xia and Page52) are shown in Section 3). The APE approach also follows Lighthill’s original idea but manipulates the governing equations into an LEE LHS and a RHS interpreted as a source vector for the LEE system, exciting vortical, entropic and acoustic modes. These equations are modified into an APE format by filtering the RHS source terms so that only acoustic modes appear. One important numerical property thereby introduced is the elimination of vortical modes which occur as instabilities in the LEE system. Note that APE is a volume rather than a surface method; the APE equations are solved in the entire region from near to far field.

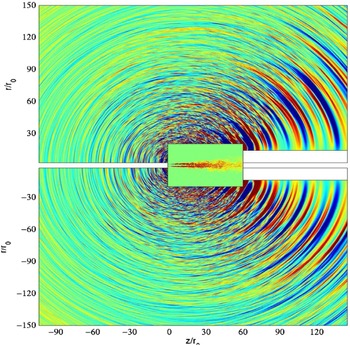

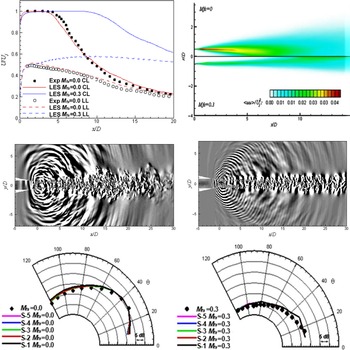

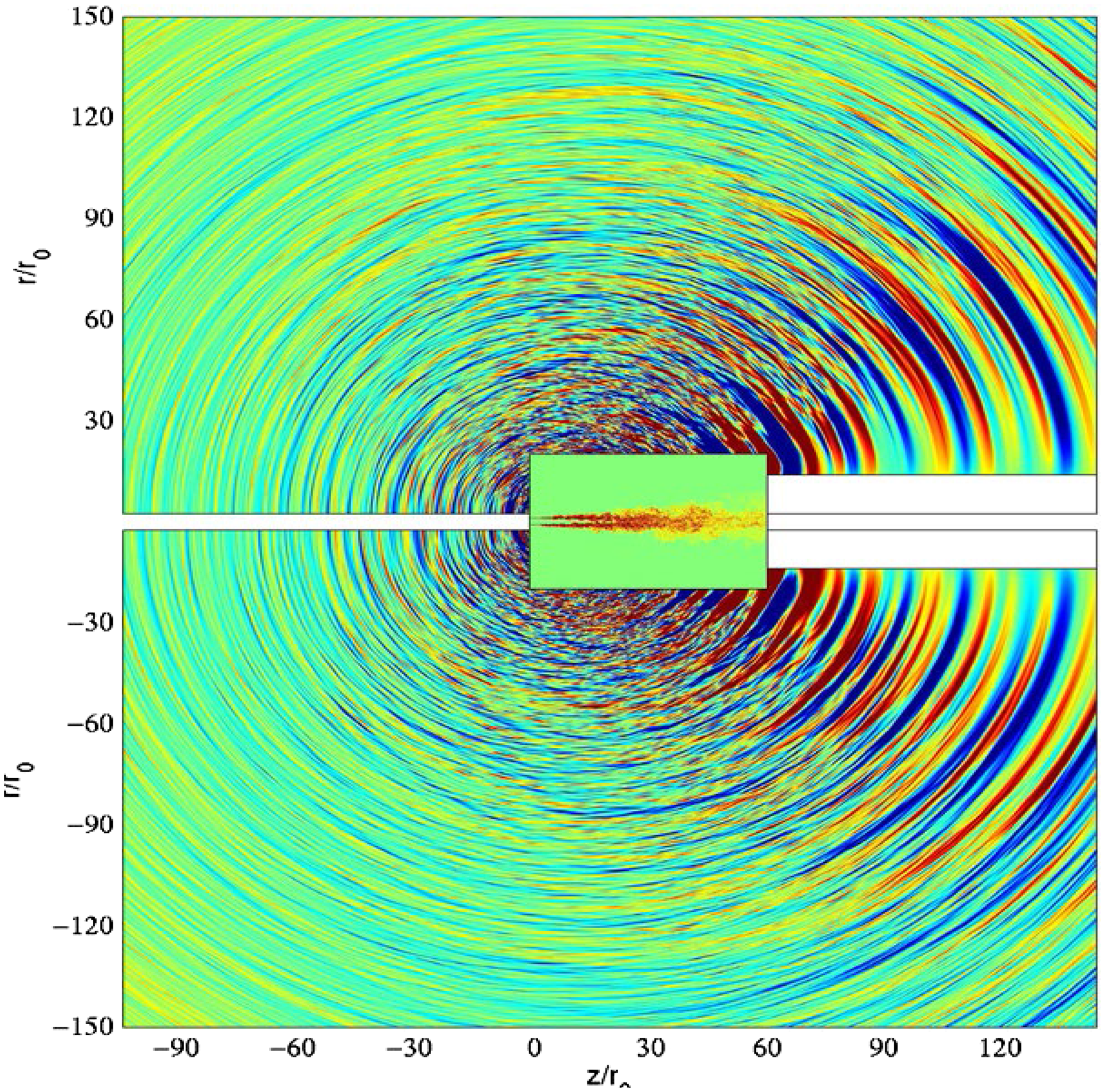

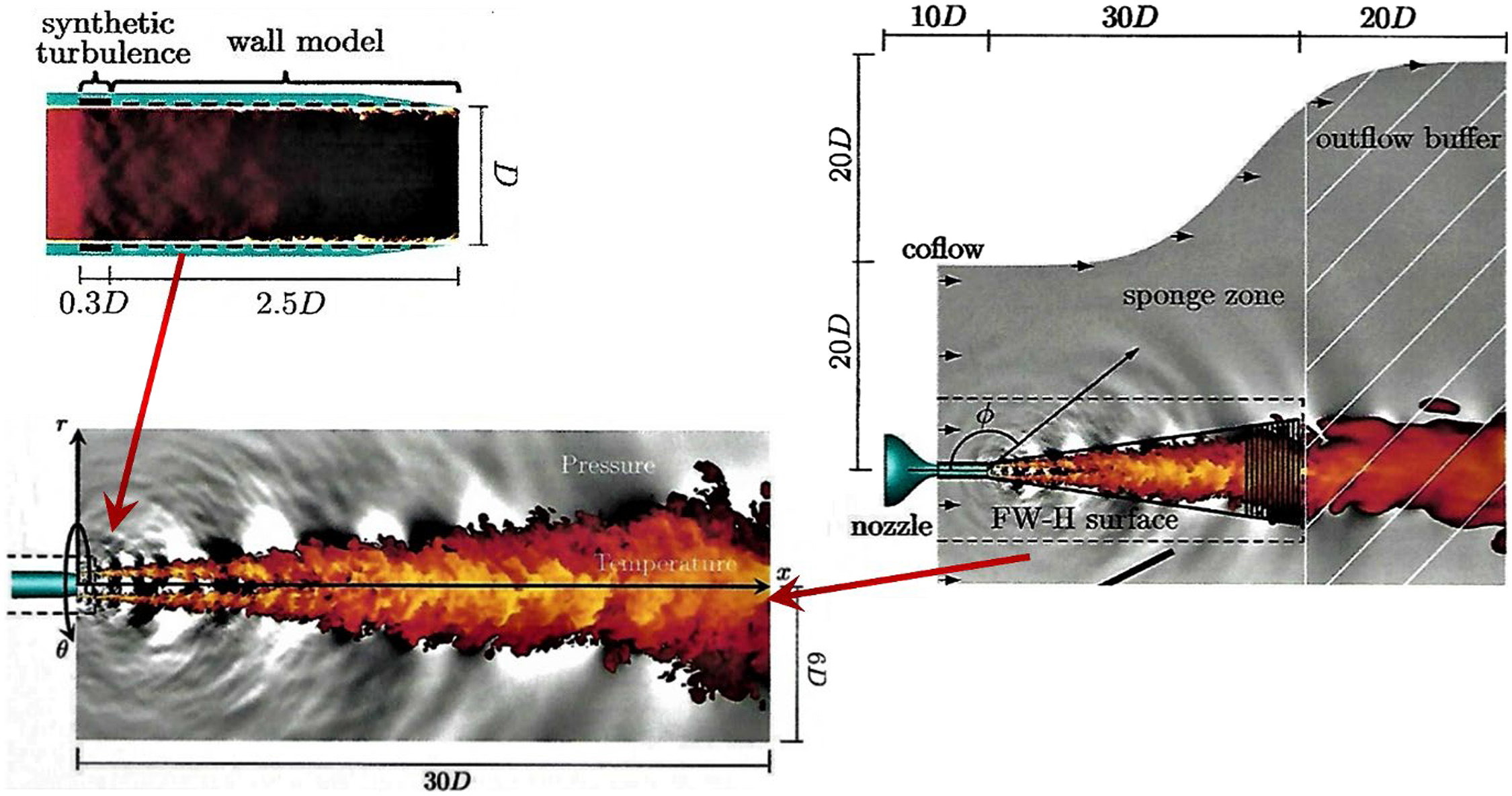

The hybrid concept is illustrated in Fig. 26, which presents results from the LES/LEE approach of Ref. Reference Bogey and Marsden49 for a round jet at M

j

= 0.9 and Re

j

= 105 with a static temperature ratio of 1.0 (FWH would produce similar results). The inner domain contains the jet (identified by fluctuating vorticity contours), while the outer LEE domain shows pressure fluctuation waves. The different discretisation requirements are indicated by the mesh sizes used (1Bn for LES, 1.8Bn for LEE in a study especially focussed on mesh density effects). The typical turbulent subsonic jet noise directivity pattern appears, with noise amplitude largest at an angle of

![]() $\sim$

30° to the jet axis. The interface surface enclosing the jet must be located with care. The jet pressure field consists of two components: hydrodynamic and acoustic. The acoustic part is defined via the property that it decays with distance following the law of geometrical acoustic spreading (inverse square law). The hydrodynamic part is linked to the turbulent vortical structures, which propagate at their convective speed (proportional to U

j

; see Fig. 23 (top)). The hydrodynamic component is dominant in the jet region but is evanescent, decaying exponentially with distance from the jet. Optimum placement of the surface involves a difficult trade-off as too close means that some noise sources are not LES resolved whereas too far will result in some acoustic propagation being resolved by the less appropriate LES mesh and numerics. Note that this difficulty is circumvented by the APE method, results from which are shown in Section 3.

$\sim$

30° to the jet axis. The interface surface enclosing the jet must be located with care. The jet pressure field consists of two components: hydrodynamic and acoustic. The acoustic part is defined via the property that it decays with distance following the law of geometrical acoustic spreading (inverse square law). The hydrodynamic part is linked to the turbulent vortical structures, which propagate at their convective speed (proportional to U

j

; see Fig. 23 (top)). The hydrodynamic component is dominant in the jet region but is evanescent, decaying exponentially with distance from the jet. Optimum placement of the surface involves a difficult trade-off as too close means that some noise sources are not LES resolved whereas too far will result in some acoustic propagation being resolved by the less appropriate LES mesh and numerics. Note that this difficulty is circumvented by the APE method, results from which are shown in Section 3.

Figure 26. Coupled LES (inner) jet domain and LEE (outer) acoustic propagation domain from Ref. Reference Bogey and Marsden49.

Additional LES numerical issues which influence noise prediction are related to mesh size/time step. The spectrum of frequencies (f) targeted for capture covers the Strouhal number (St) range of 0.01–10 (St = fD j /U j ). The LES grid resolution and time step limit high-frequency capture and accuracy, whereas low-frequency accuracy is determined by the length of the simulation record (accurate statistical sampling of large-eddy dynamics). However, reducing the cell size and time step have a dramatic effect on the computational cost; typically, doubling the highest St resolved increases the computational cost by a factor of 16 (the mesh increasing by 8× and Δt halved). There is the risk that higher frequencies are captured but that the computational time for adequate sampling of low-frequency events becomes unaffordable.

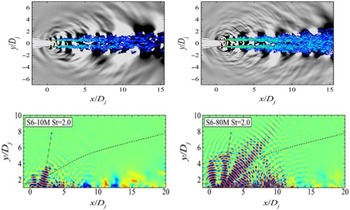

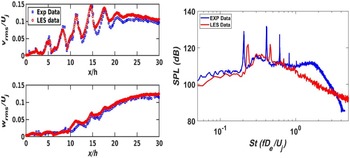

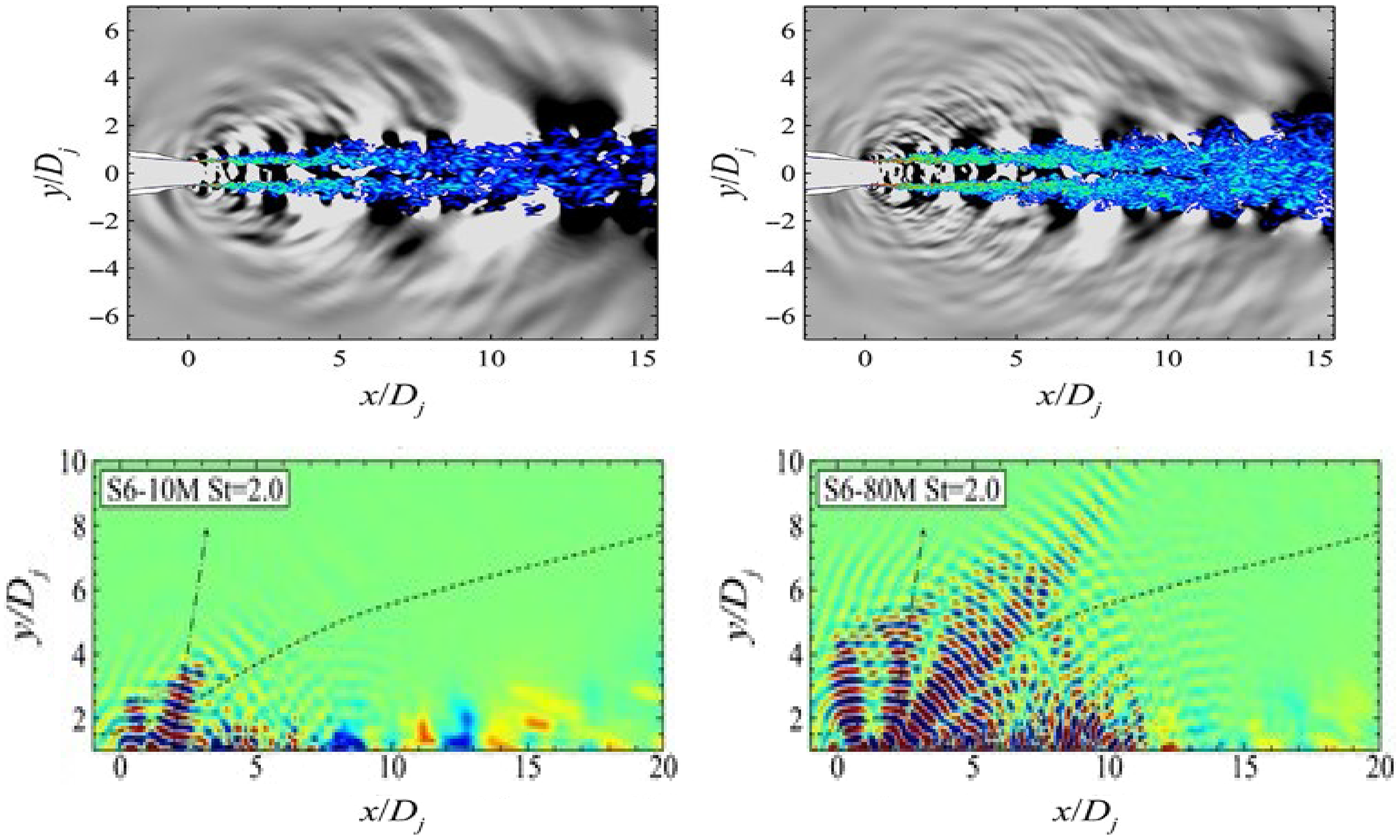

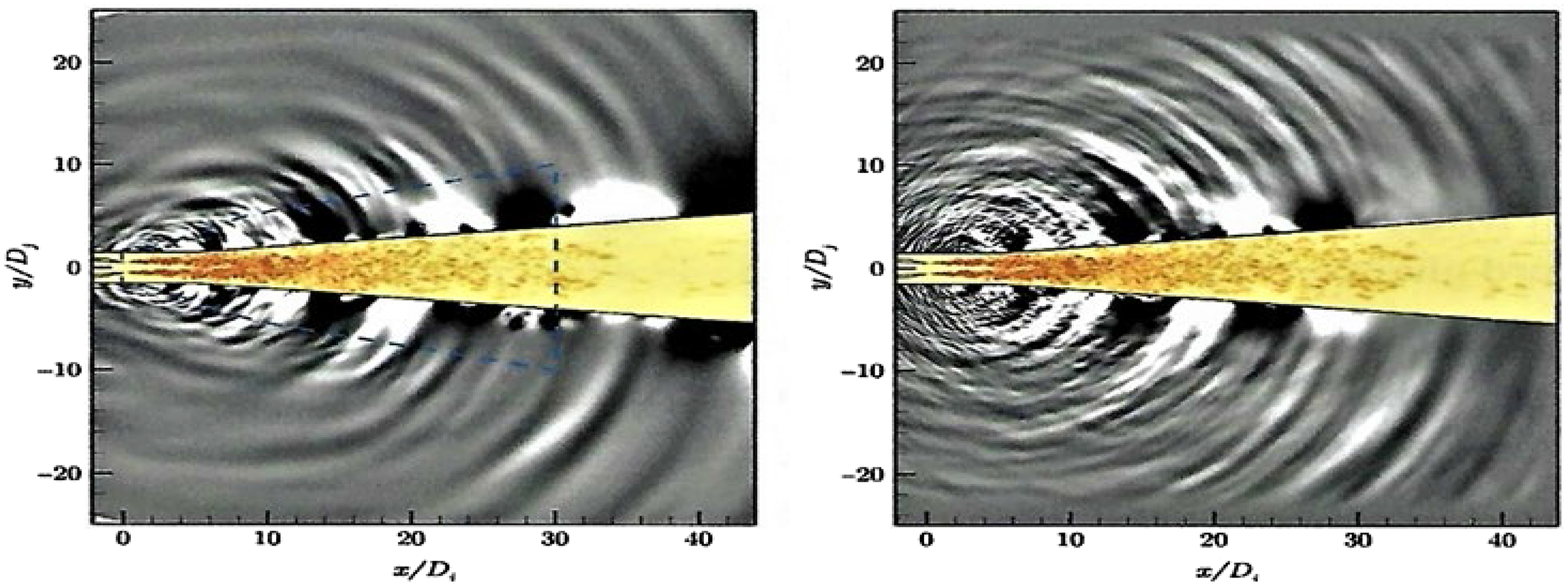

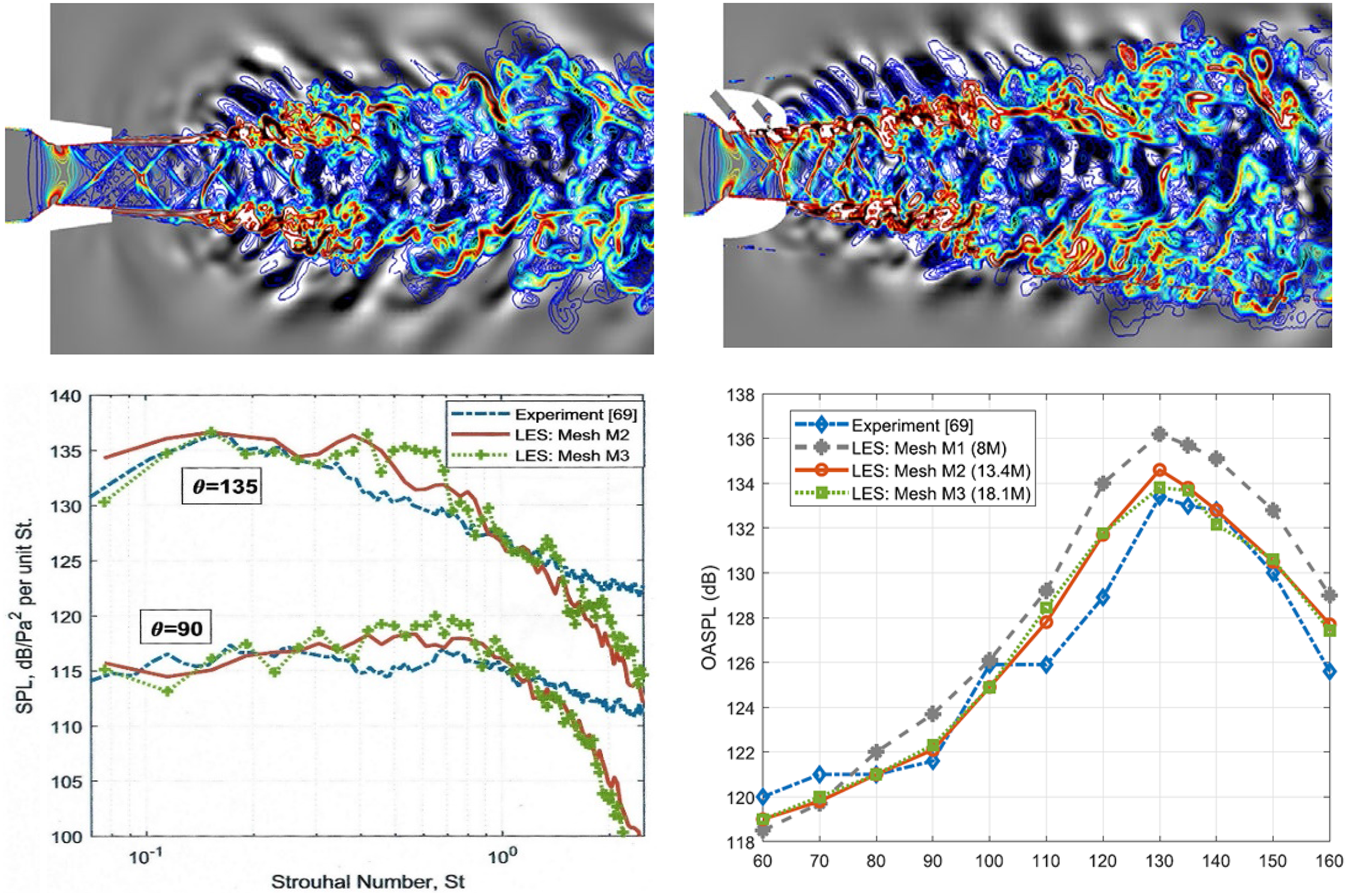

To illustrate the effect of grid refinement on high-frequency noise predictions, results from the LES/FWH study of Angelino et al. (Reference Angelino, Xia and Page53) are shown for a round nozzle at M j = 0.9 and Re j = 106 in Fig. 27. Two LES meshes of 10 × 106 and 80 × 106 cells are compared. The top images show vorticity and pressure contours, with the finer grid (right) demonstrating more small-scale vortex structures and shorter-wavelength sound waves appearing. To focus particular attention on higher-frequency content, a Fourier analysis of the fluctuating pressure field was carried out to examine the dissipative effect of coarser grids. Results for a Strouhal number of 2.0 are shown in the bottom two images (images for St < 1.0 produced two images in close agreement). For St = 2.0, it is clear that, on the coarser mesh (left), the high-frequency noise is unable to propagate far outside the jet edge before it is dissipated.

Figure 27. Near-field vorticity/acoustic fields (top) and St = 2.0 pressure fluctuations (bottom) from Ref. Reference Angelino, Xia and Page53.

2.3 Summary

The reviews in Subsections 2.1 and 2.2 have outlined the important, and challenging, aerodynamic and aeroacoustic characteristics of propulsive jets. Experimental measurements representing relevant but fundamentally simple test cases and the performance of various computational techniques proposed for modelling have also been outlined. The following Sections 3 and 4 are intended to illustrate the progress that has been made in validating and assessing modelling developments against measurement data taken in a series of flow scenarios of increasing complexity, moving ever closer to realistic application examples. Section 3 is focussed on civil and Section 4 on military applications.

3.0 Civil aerospace applications

3.1 Cold and hot single jet in stagnant surroundings

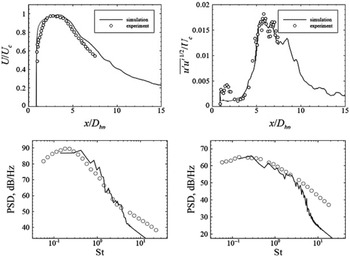

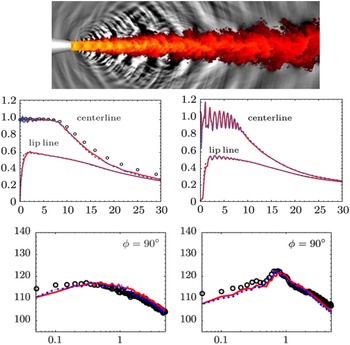

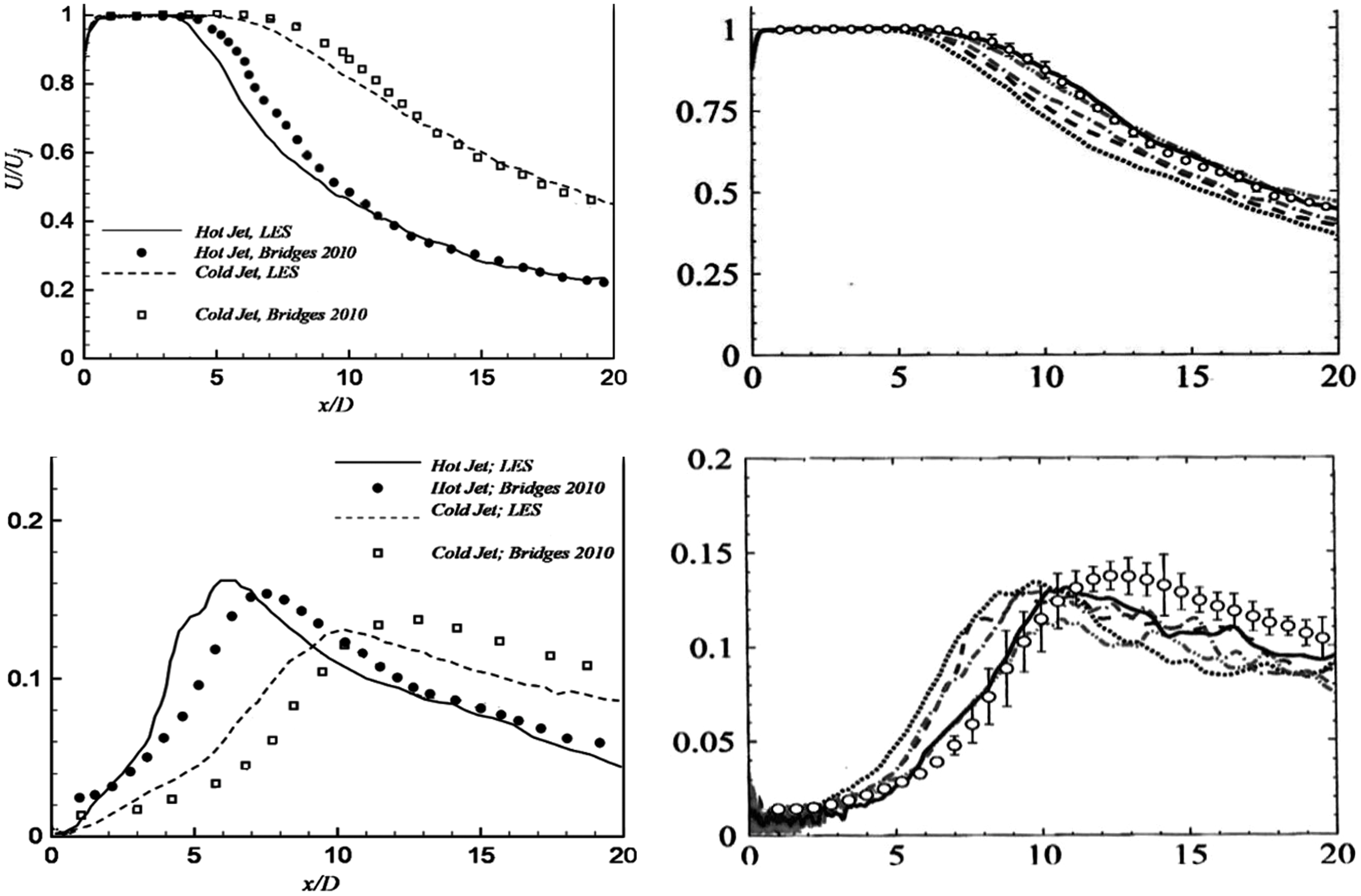

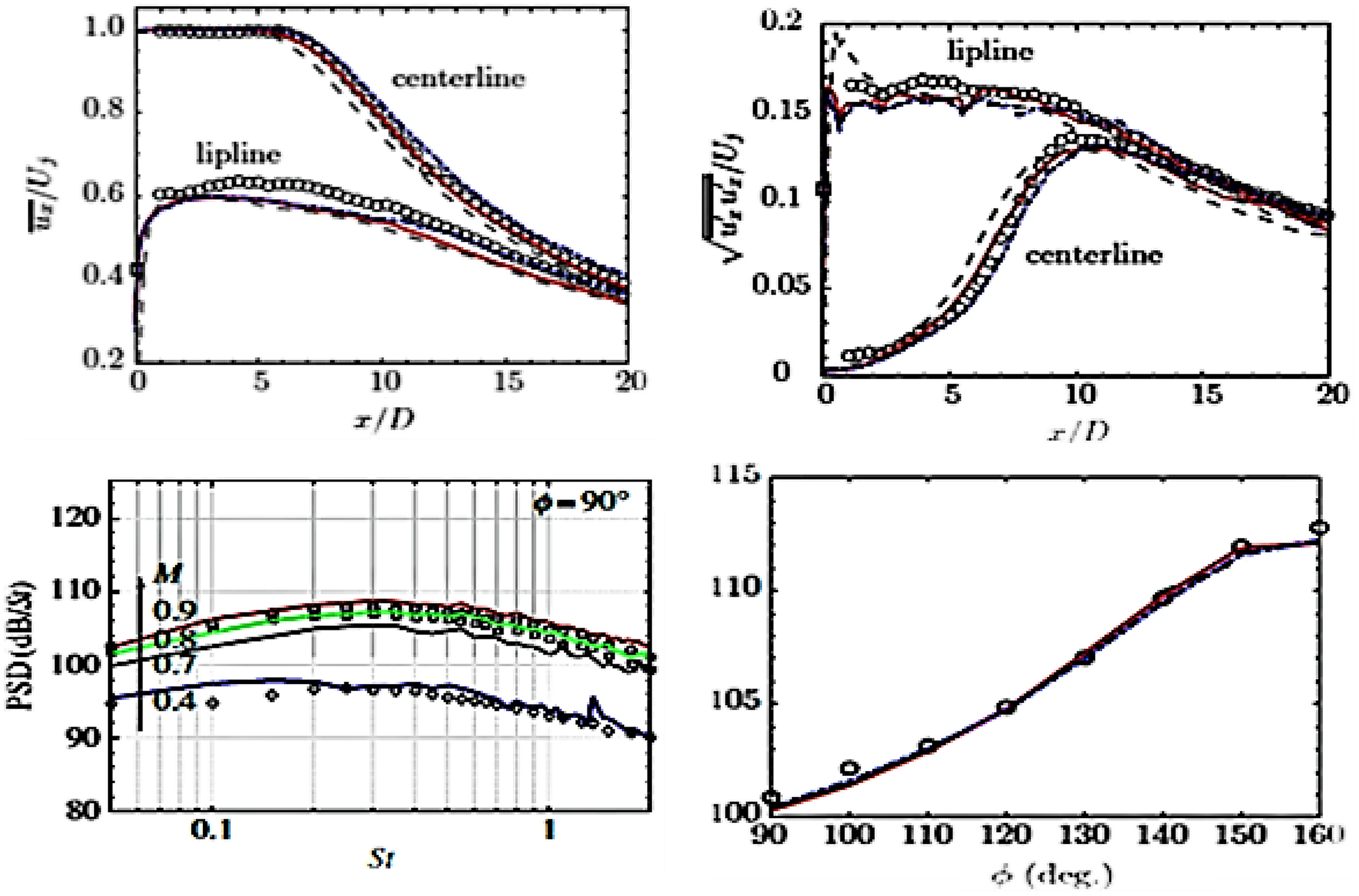

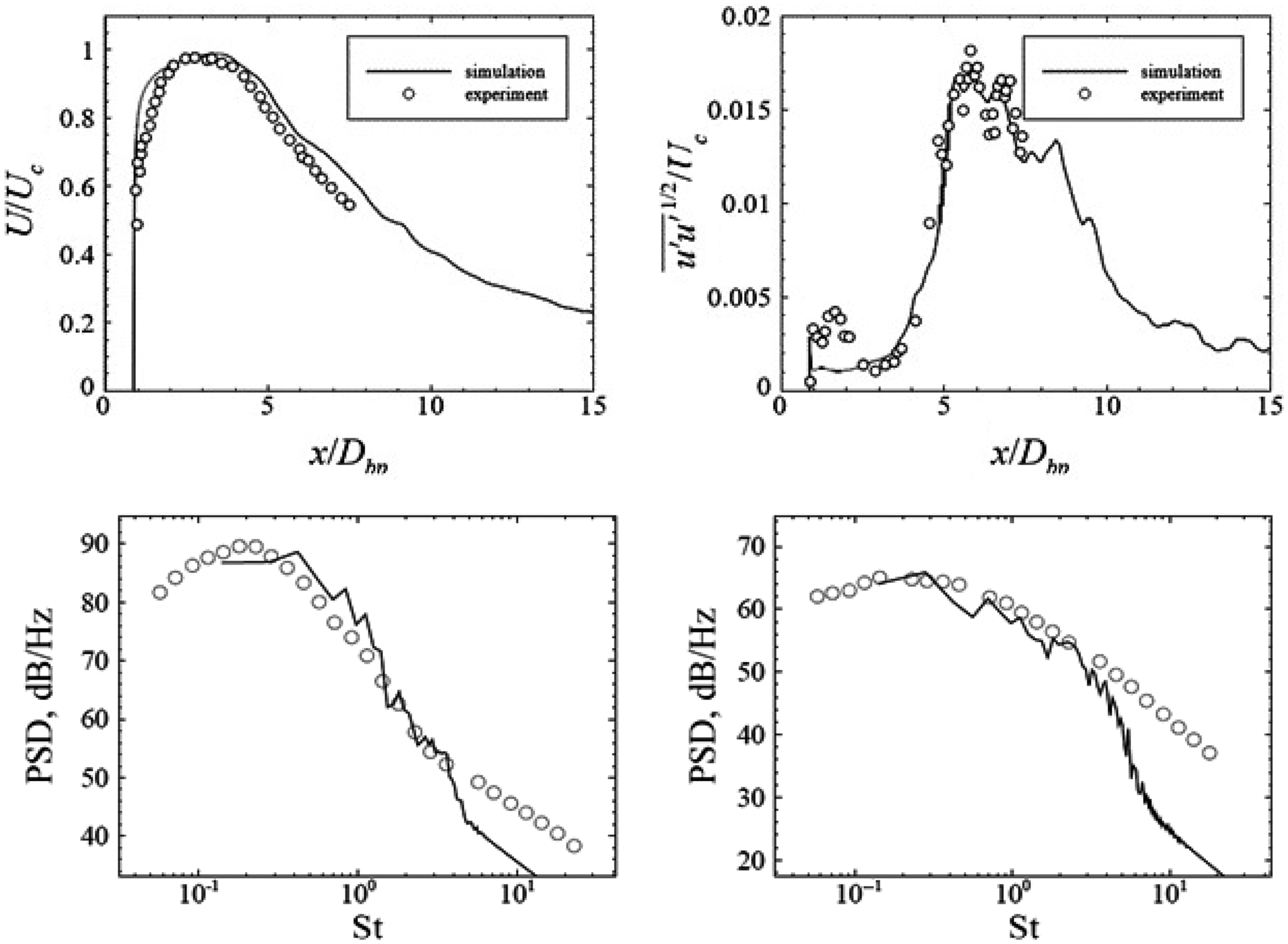

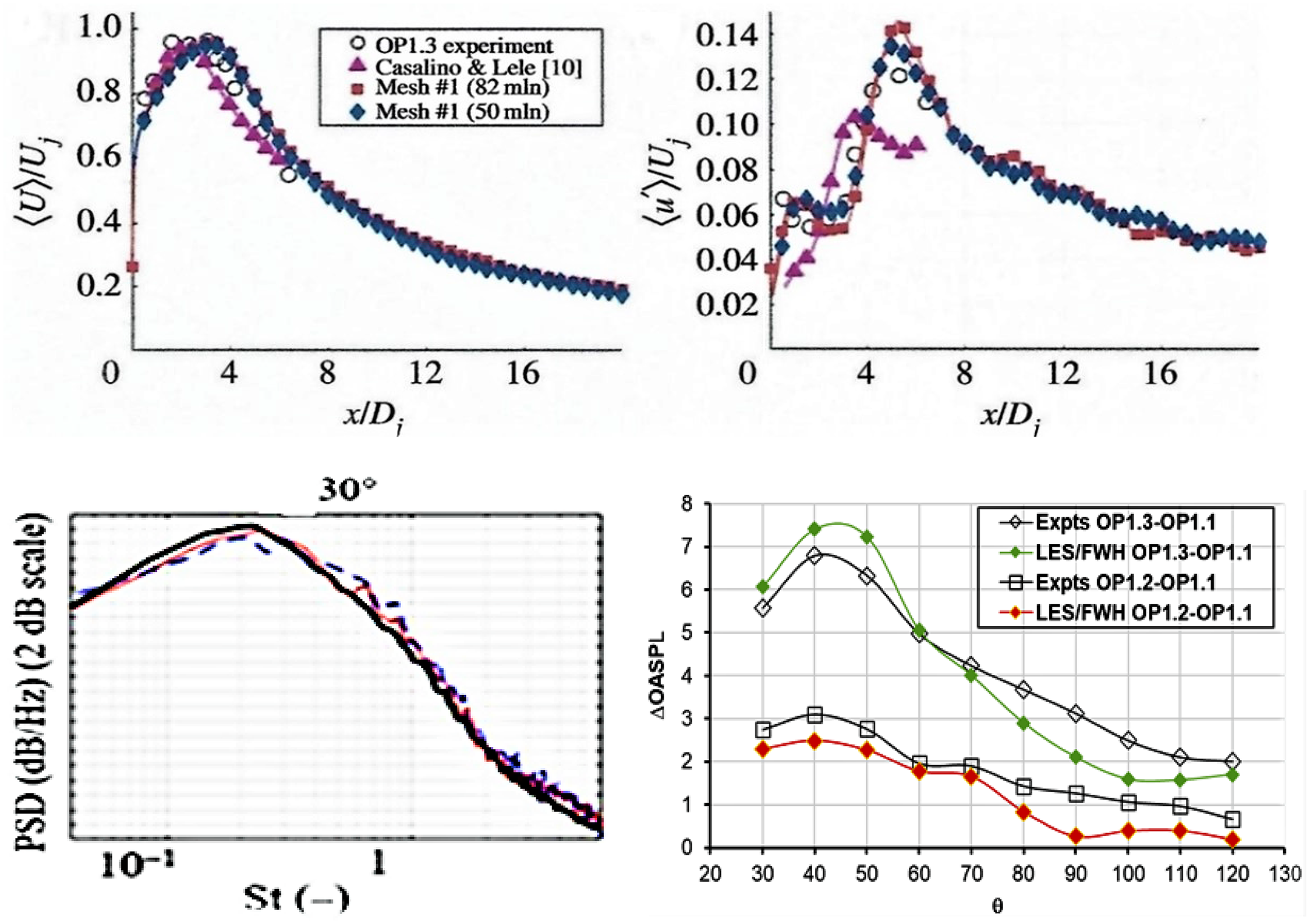

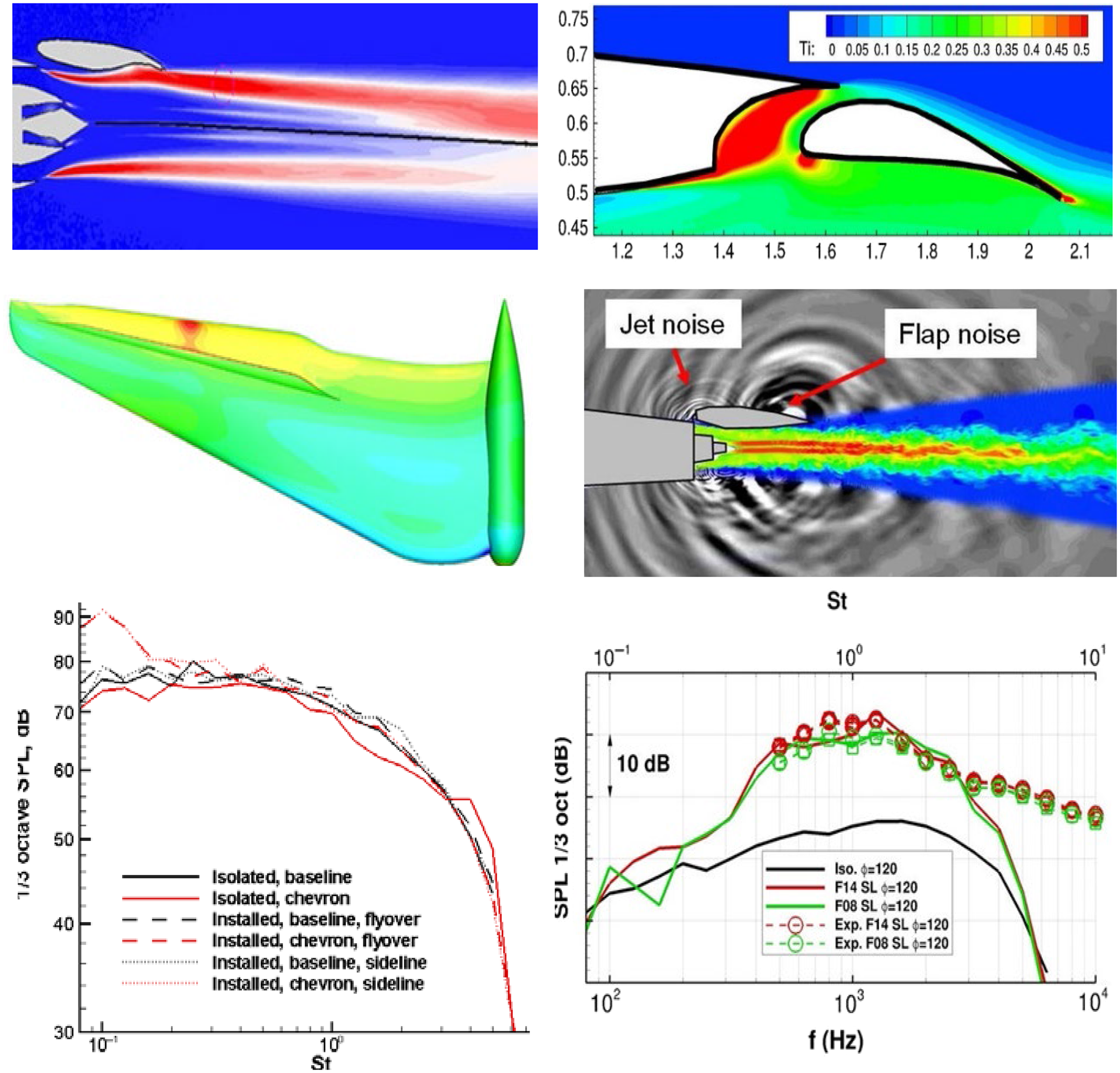

The most basic test cases for civil aerospace comprise the near-field aerodynamics and far-field acoustic signature of single round unheated (static temperature ratio 0.84) or heated (ratio = 2.7) jets in stagnant surroundings at high Re

j

(

![]() $\sim$

105) and high subsonic M

j

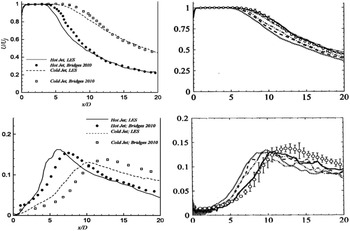

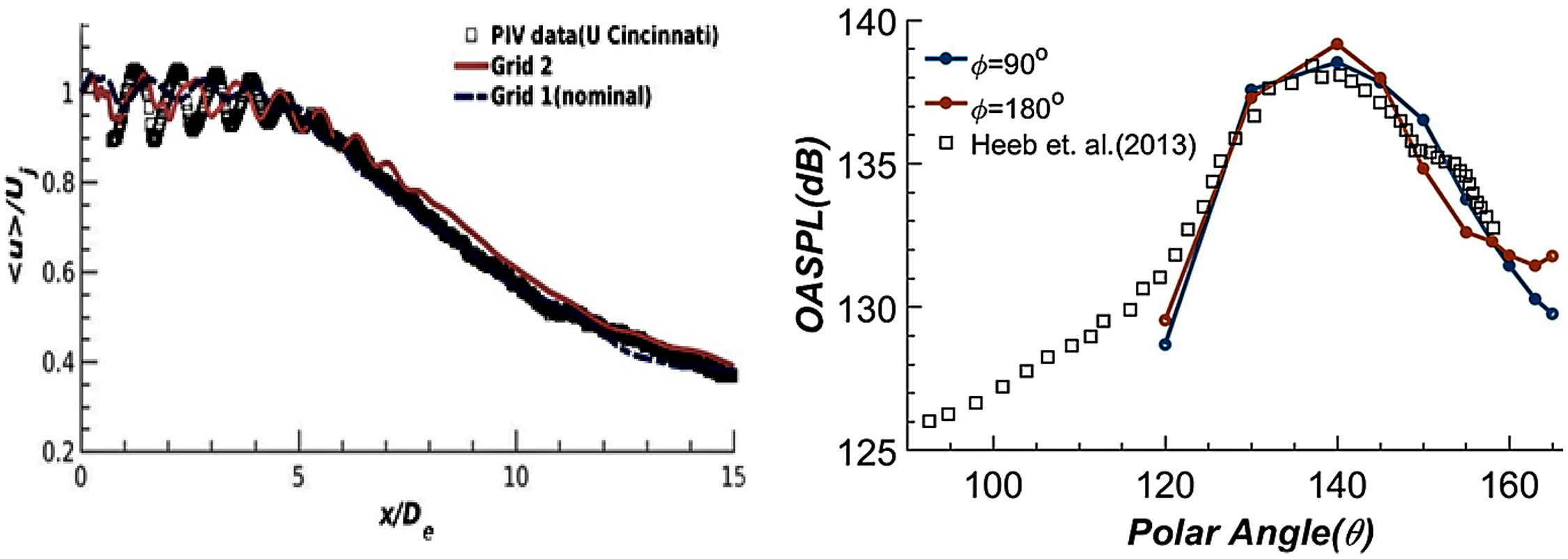

(0.9). Figures 28 and 29 provide examples of computational studies of this problem compared against flow and acoustic data from Bridges and Wernet (Reference Bridges and Wernet10) and Brown and Bridges (Reference Brown and Bridges54). Two computational techniques are contrasted, both combining LES and FWH methods. Naqavi et al. (Reference Naqavi, Wang, Tucker, Mahak and Strange38) opted for a combined RANS–LES approach where the RANS equations are solved internal to and surrounding the nozzle wall and gradually blended into an LES region where 48m cells were used. Angelino et al. (Reference Angelino, Xia and Page53) retained LES for both the internal nozzle (wall stress model) and jet flow and carried out a grid resolution study (with 5–80m cells) to explore the effect of finer meshes on flow/noise predictions. Both FWH treatments chose similarly located noise source containing surfaces and applied averaging or filtering over multiple ‘end plates’ to remove pseudo-sound generated by vortical structures crossing the FWH surface. Results from Ref. Reference Naqavi, Wang, Tucker, Mahak and Strange38 for the unheated jet in Fig. 28 (left) indicate an underpredicted potential core length, presumably due to the RANS nozzle treatment since this is captured better by the full LES approach of Ref. Reference Angelino, Xia and Page53 (right) on finer meshes where only 40 and 80m cell meshes capture the centreline development accurately. Both methods provide similar descriptions for axial turbulent rms, with the finer meshes of Ref. Reference Angelino, Xia and Page53 providing more accurate results in the first 10D, but still underpredicting slightly thereafter. The trend effect of jet heating is captured in the work of Ref. Reference Naqavi, Wang, Tucker, Mahak and Strange38 in Fig. 28 (left), reproducing the shortening of the potential core length and the upstream shift of the turbulence peak; quantitatively, however, these effects are overpredicted.

$\sim$

105) and high subsonic M

j

(0.9). Figures 28 and 29 provide examples of computational studies of this problem compared against flow and acoustic data from Bridges and Wernet (Reference Bridges and Wernet10) and Brown and Bridges (Reference Brown and Bridges54). Two computational techniques are contrasted, both combining LES and FWH methods. Naqavi et al. (Reference Naqavi, Wang, Tucker, Mahak and Strange38) opted for a combined RANS–LES approach where the RANS equations are solved internal to and surrounding the nozzle wall and gradually blended into an LES region where 48m cells were used. Angelino et al. (Reference Angelino, Xia and Page53) retained LES for both the internal nozzle (wall stress model) and jet flow and carried out a grid resolution study (with 5–80m cells) to explore the effect of finer meshes on flow/noise predictions. Both FWH treatments chose similarly located noise source containing surfaces and applied averaging or filtering over multiple ‘end plates’ to remove pseudo-sound generated by vortical structures crossing the FWH surface. Results from Ref. Reference Naqavi, Wang, Tucker, Mahak and Strange38 for the unheated jet in Fig. 28 (left) indicate an underpredicted potential core length, presumably due to the RANS nozzle treatment since this is captured better by the full LES approach of Ref. Reference Angelino, Xia and Page53 (right) on finer meshes where only 40 and 80m cell meshes capture the centreline development accurately. Both methods provide similar descriptions for axial turbulent rms, with the finer meshes of Ref. Reference Angelino, Xia and Page53 providing more accurate results in the first 10D, but still underpredicting slightly thereafter. The trend effect of jet heating is captured in the work of Ref. Reference Naqavi, Wang, Tucker, Mahak and Strange38 in Fig. 28 (left), reproducing the shortening of the potential core length and the upstream shift of the turbulence peak; quantitatively, however, these effects are overpredicted.

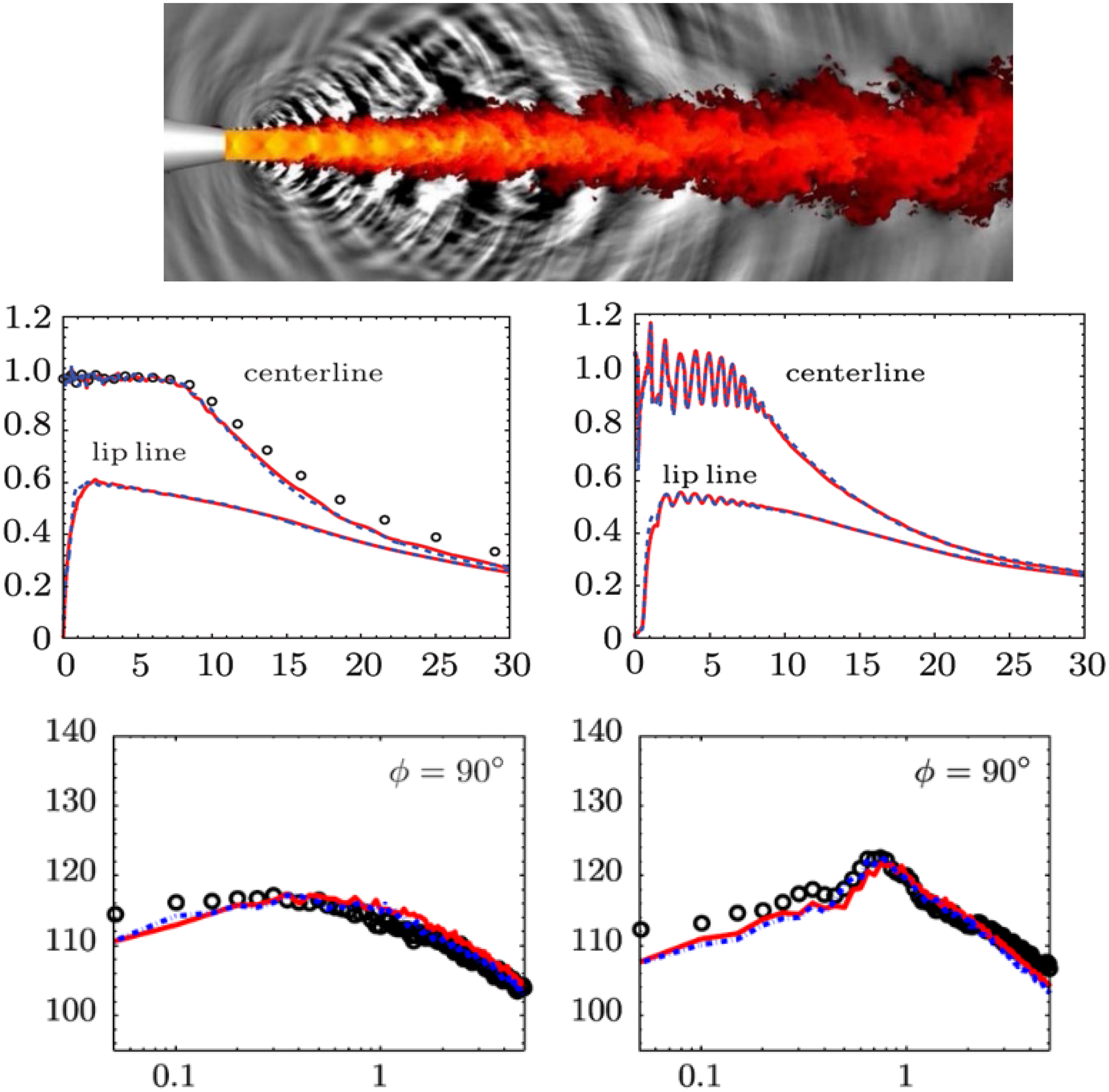

Figure 28. LES axial velocity and turbulence rms compared with experiments of Refs Reference Bridges and Wernet10, Reference Morris and Zaman45: cold and hot (static temperature ratio = 2.7) jets (left) from Ref. Reference Naqavi, Wang, Tucker, Mahak and Strange38 and cold M j = 0.9 jet (right) from Ref. Reference Angelino, Xia and Page53.

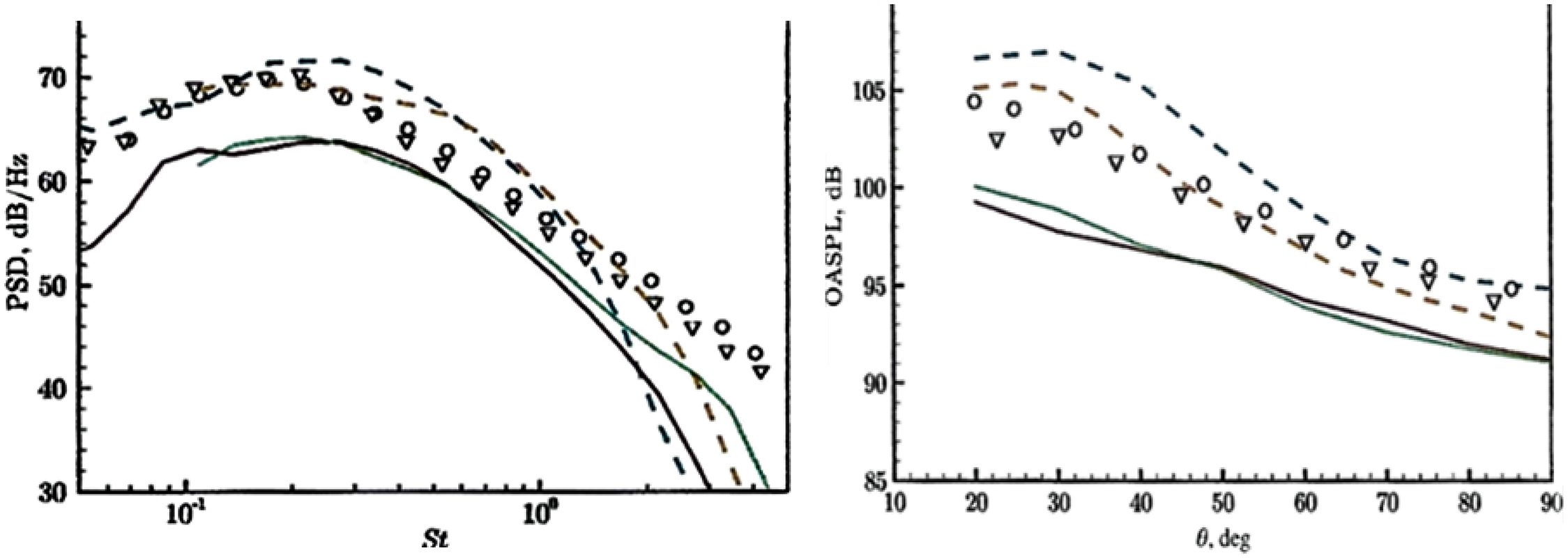

Figure 29. LES/FWH-predicted far-field PSD at

![]() $\theta\,=\,90^{\circ}$

compared with experiments of Ref. Reference Brown and Bridges54 from Ref. Reference Angelino, Xia and Page53 (left). LES/FWH-predicted OASPL compared with experiments of Refs Reference Tanna17, Reference Brown and Bridges54 from Ref. Reference Angelino, Xia and Page53 (right).

$\theta\,=\,90^{\circ}$

compared with experiments of Ref. Reference Brown and Bridges54 from Ref. Reference Angelino, Xia and Page53 (left). LES/FWH-predicted OASPL compared with experiments of Refs Reference Tanna17, Reference Brown and Bridges54 from Ref. Reference Angelino, Xia and Page53 (right).

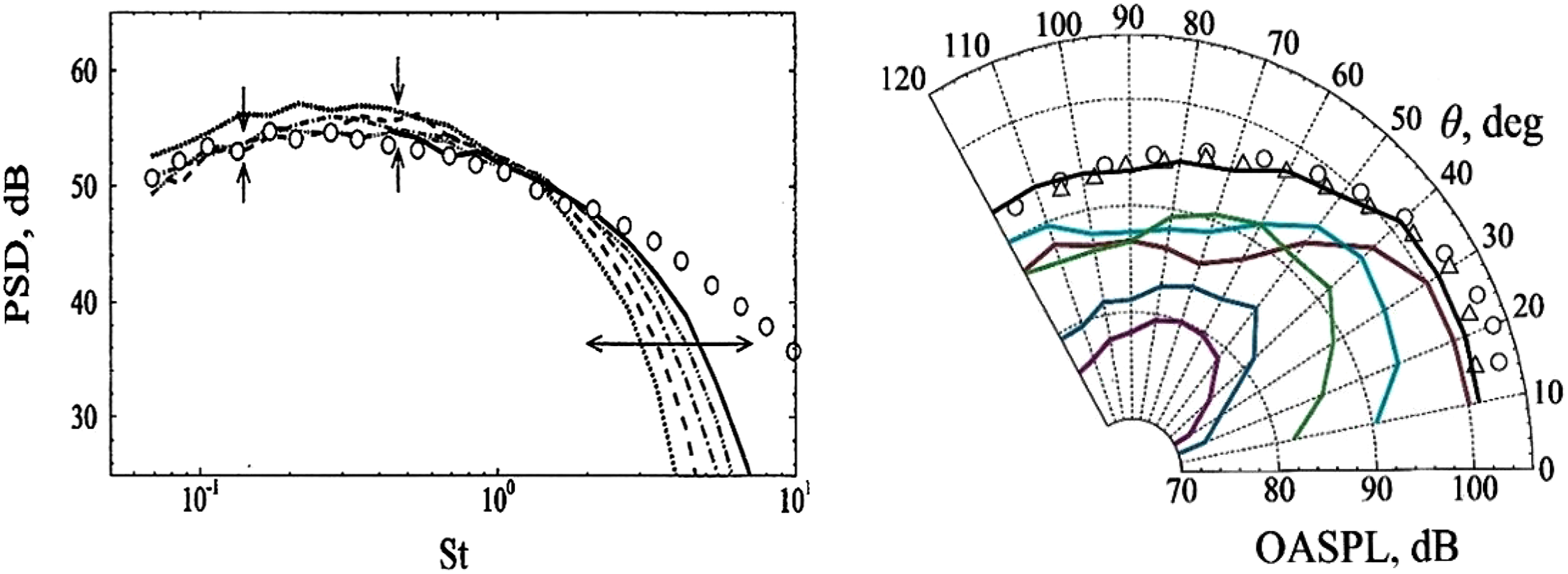

The far-field acoustic predictions are similar in both studies (being slightly better for the full LES model), with the trend when changing from a cold to a hot jet shown to be captured well by Ref. Reference Naqavi, Wang, Tucker, Mahak and Strange38. Figure 29 (left) shows a comparison from Ref. Reference Angelino, Xia and Page53 between the predicted and measured Power Spectral Density (PSD) of the sound field at a polar angle of

![]() $\theta\,=\,90^{\circ}$

(the sideline direction). The agreement is good for all meshes up to a maximum non-dimensional frequency (Strouhal number St) of

$\theta\,=\,90^{\circ}$

(the sideline direction). The agreement is good for all meshes up to a maximum non-dimensional frequency (Strouhal number St) of

![]() $\sim$

1.5. Greater mesh density improves the capture of lower-frequency amplitude by

$\sim$

1.5. Greater mesh density improves the capture of lower-frequency amplitude by

![]() $\sim$

1dB, but mesh refinement is more important for higher frequencies. The improvement is, however, rather slow: an increase in mesh density from 20 to 80 × 106 cells only improves the high- frequency capability by a factor of 2 (Stmax from 1.5 to 3). Note also that the finest mesh prediction is only plotted for St

$\sim$

1dB, but mesh refinement is more important for higher frequencies. The improvement is, however, rather slow: an increase in mesh density from 20 to 80 × 106 cells only improves the high- frequency capability by a factor of 2 (Stmax from 1.5 to 3). Note also that the finest mesh prediction is only plotted for St

![]() $\sim$

0.4 and above. This calculation could not be run for long enough to capture statistically stationary results at lower frequencies.

$\sim$

0.4 and above. This calculation could not be run for long enough to capture statistically stationary results at lower frequencies.

As seen below, this high-frequency issue affects all LES/FWH acoustic predictions and prompted a proposal in Ref. Reference Angelino, Xia and Page53 for the need for a ‘spectral broadening’ approach, that is, to combine noise spectra from simulations with different spatial and temporal resolution, although this would need to be done with some care to ensure consistency in the frequency region where LES solutions overlapped. A directivity map from Ref. Reference Angelino, Xia and Page53 showing the Overall Sound Pressure Level (OASPL) at different polar angles compared with measurements from Refs Reference Tanna17 and Reference Brown and Bridges54 is presented in Fig. 29 (right). The black line corresponds to the total signal, and the coloured lines to different azimuthal modes; lower-order modes (e.g. axisymmetric, m = 0) contribute most at polar angles close to the jet axis, but modes up to m = 7 are significant at larger polar angles, in good agreement with measurements.

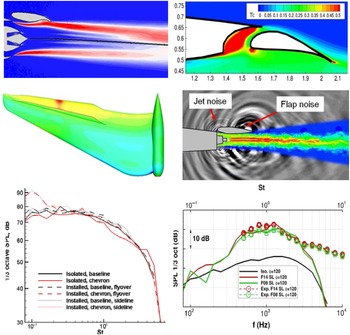

To examine whether the FWH procedure may be contributing to the high-frequency problem, Moratilla-Vega et al. (Reference Moratilla-Vega, Lackhove, Janicka, Xia and Page52) used the same LES as in Ref. Reference Angelino, Xia and Page53 but replaced the FWH element with the APE approach of Ref. Reference Ewart and Schroeder51, applying this to the same experimental test case as above. An LES mesh of 25 × 106 cells and an APE mesh of 4 × 106 cells were used (note that fifth-order methods are used in the APE code, see Ref. Reference Moratilla-Vega, Lackhove, Janicka, Xia and Page52). The pressure perturbation fields extracted from the LES/FWH and LES/APE solutions are shown in Fig. 30. The longer wavelengths at low polar angles and the peak directivity angle are similar when using both methods, but the enhanced higher-frequency content in the APE solution is evident, particularly at higher polar angles. Figure 31 examines the predicted far-field PSD at

![]() $\theta\,=\,90^{\circ}$

obtained from the two methods (one-third octave filtered); the LES/FWH data are shown by solid lines, and the LES/APE results by dashed lines. Two lines are shown for coarse (6.4/1m for LES/APE) and fine (25/4m) meshes. The LES/FWH results are lower than the data shown in Fig. 29 (left) due to the reduced mesh resolution. Note, however, that the LES/APE results are much closer to the measurements, and although the ‘fall-off’ at higher frequency is still noticeable, this is at an increased level of St, indicating a benefit of the higher-order discretisation method adopted in the APE code. Similar benefits are observed in the OASPL plot shown in Fig. 31 (right). Further exploration of the APE method is clearly justified.

$\theta\,=\,90^{\circ}$

obtained from the two methods (one-third octave filtered); the LES/FWH data are shown by solid lines, and the LES/APE results by dashed lines. Two lines are shown for coarse (6.4/1m for LES/APE) and fine (25/4m) meshes. The LES/FWH results are lower than the data shown in Fig. 29 (left) due to the reduced mesh resolution. Note, however, that the LES/APE results are much closer to the measurements, and although the ‘fall-off’ at higher frequency is still noticeable, this is at an increased level of St, indicating a benefit of the higher-order discretisation method adopted in the APE code. Similar benefits are observed in the OASPL plot shown in Fig. 31 (right). Further exploration of the APE method is clearly justified.

Figure 30. LES/FWH (left) and APE (right) predictions for round jet at M j = 0.9 with static temperature ratio of 0.84. Vorticity and pressure poerturbation contours: LES 25 × 106 cells, APE 4 × 106 cells. From Ref. Reference Moratilla-Vega, Lackhove, Janicka, Xia and Page52.

Figure 31. Left: LES/FWH (solid) and LES/APE (dashed) far-field PSD at

![]() $\theta\,=\,90^{\circ}$

with experiments from Refs Reference Brown and Bridges54, Reference Tanna17, from Ref. Reference Moratilla-Vega, Lackhove, Janicka, Xia and Page52. Right: LES/FWH (solid) and LES/APE (dashed) OASPL versus experiments of Refs Reference Brown and Bridges54, Reference Tanna17, from Ref. Reference Moratilla-Vega, Lackhove, Janicka, Xia and Page52.

$\theta\,=\,90^{\circ}$

with experiments from Refs Reference Brown and Bridges54, Reference Tanna17, from Ref. Reference Moratilla-Vega, Lackhove, Janicka, Xia and Page52. Right: LES/FWH (solid) and LES/APE (dashed) OASPL versus experiments of Refs Reference Brown and Bridges54, Reference Tanna17, from Ref. Reference Moratilla-Vega, Lackhove, Janicka, Xia and Page52.

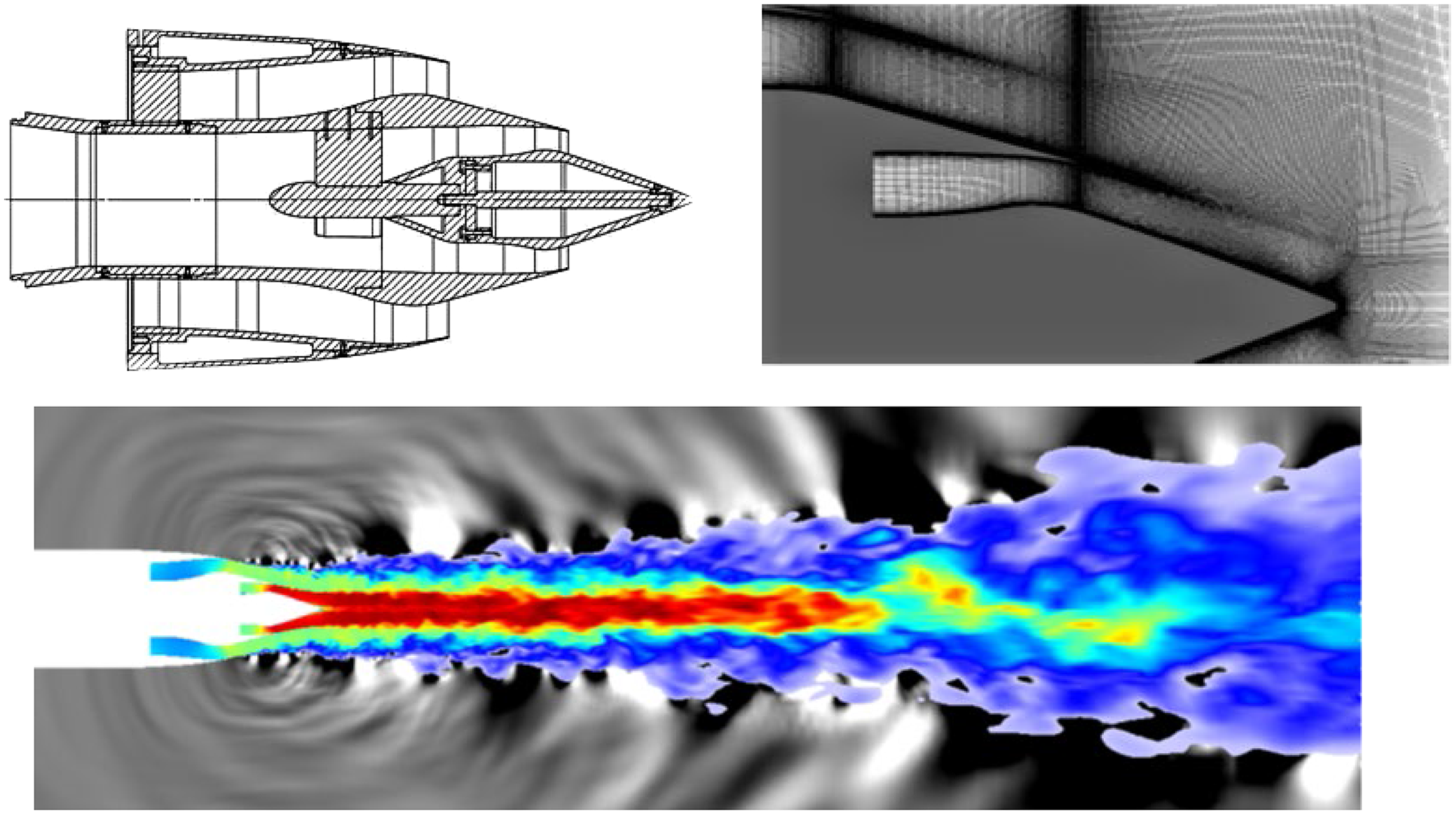

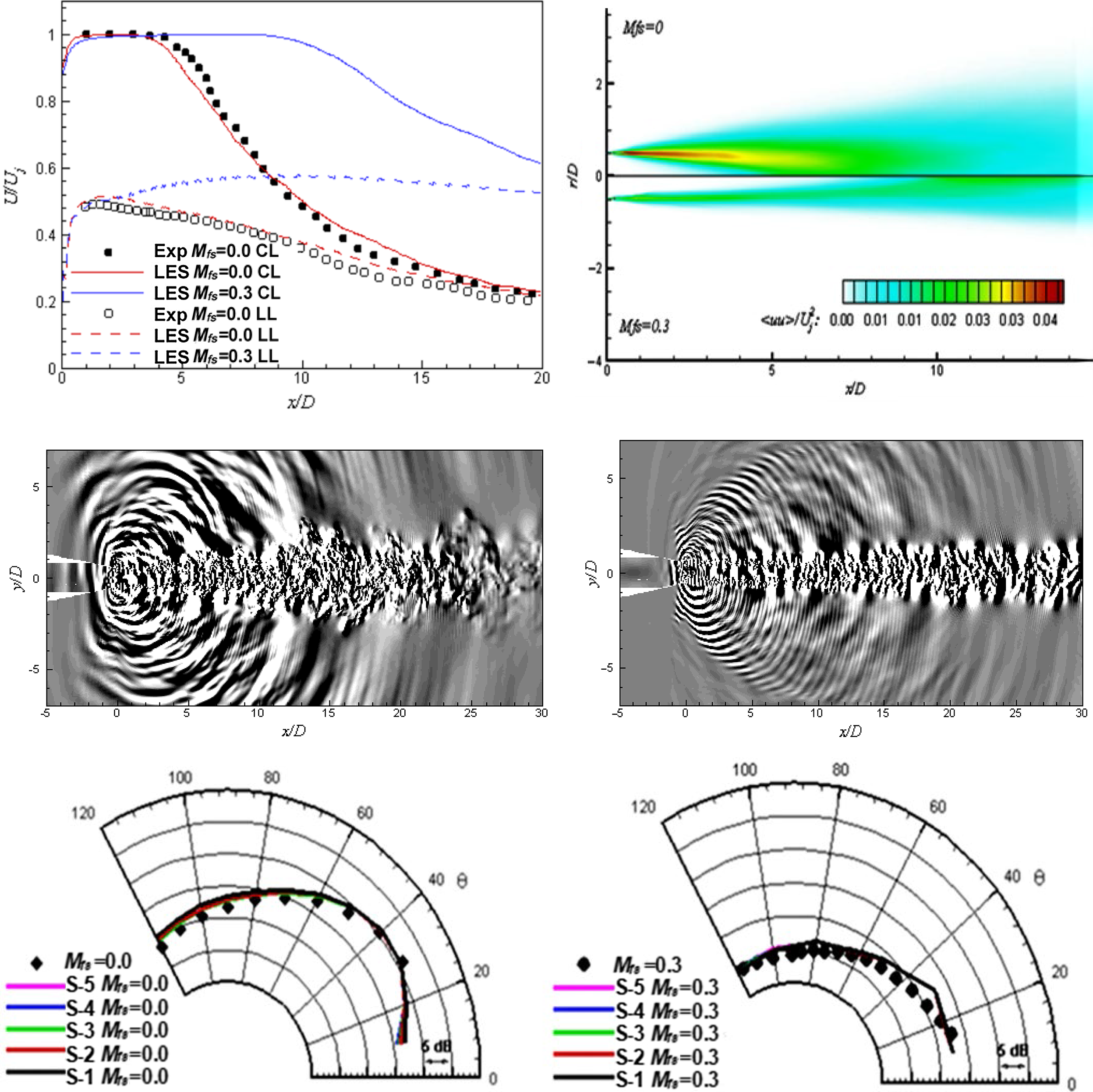

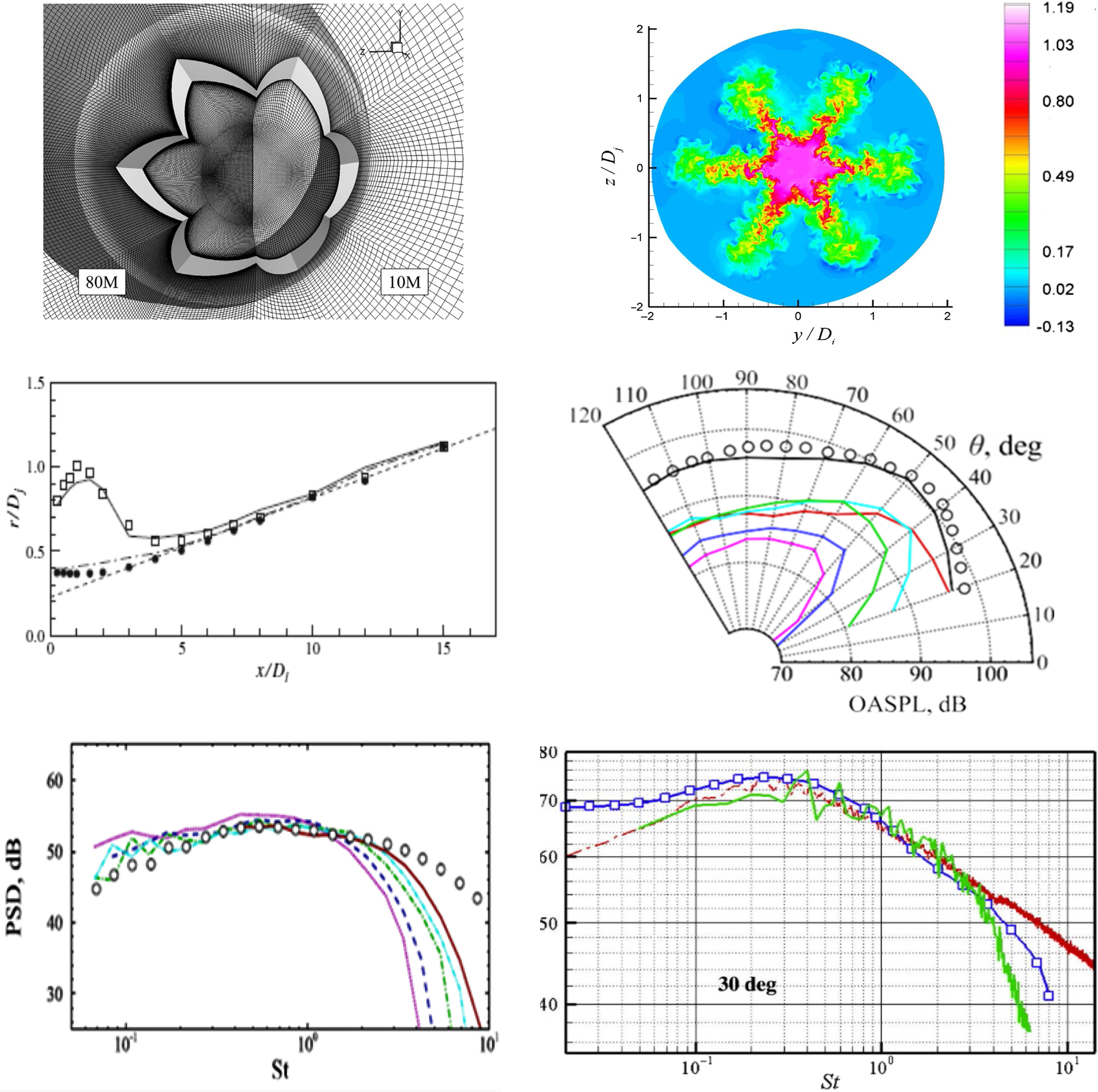

3.2 Detailed consideration of nozzle effects

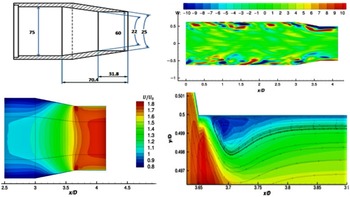

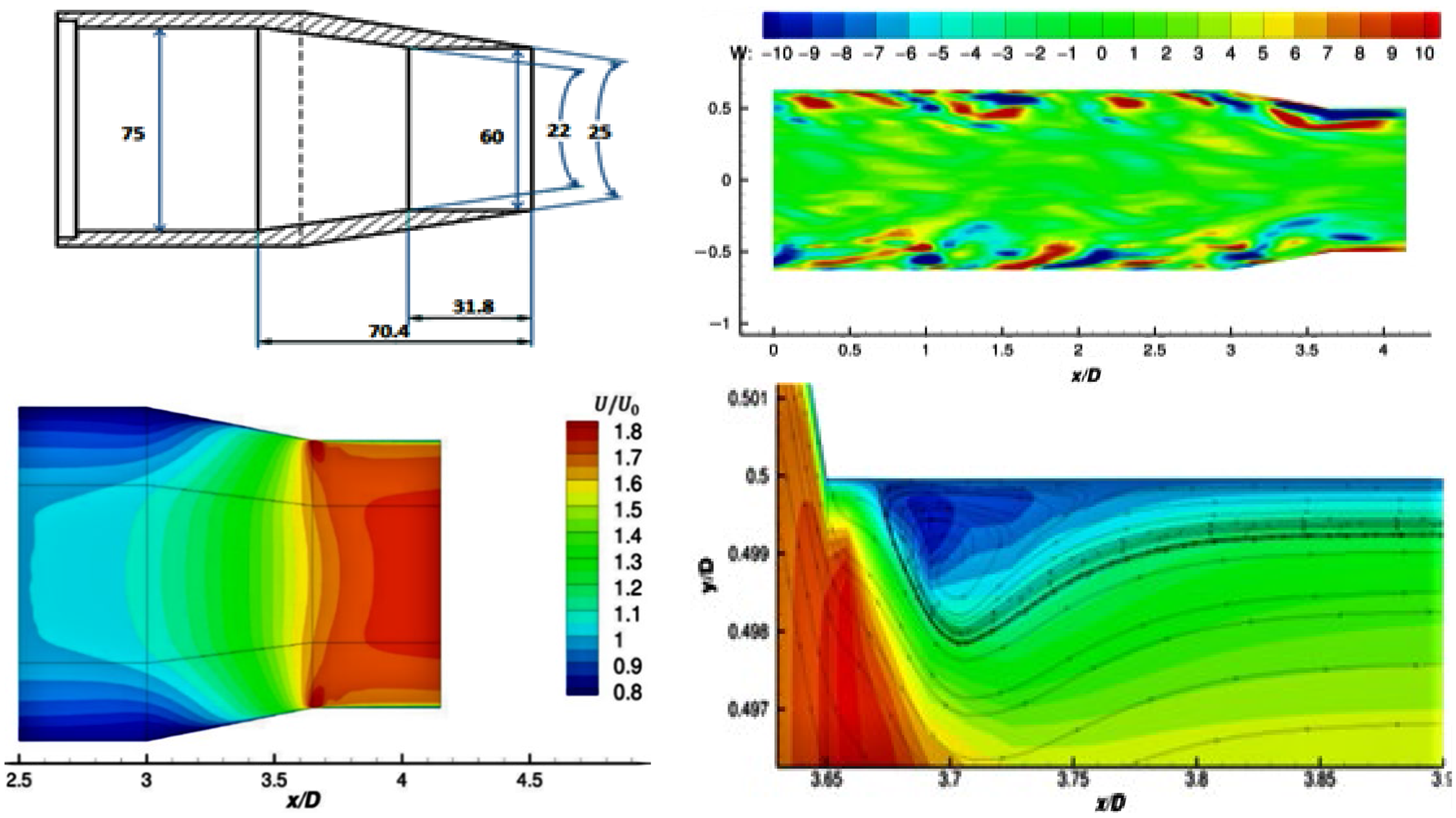

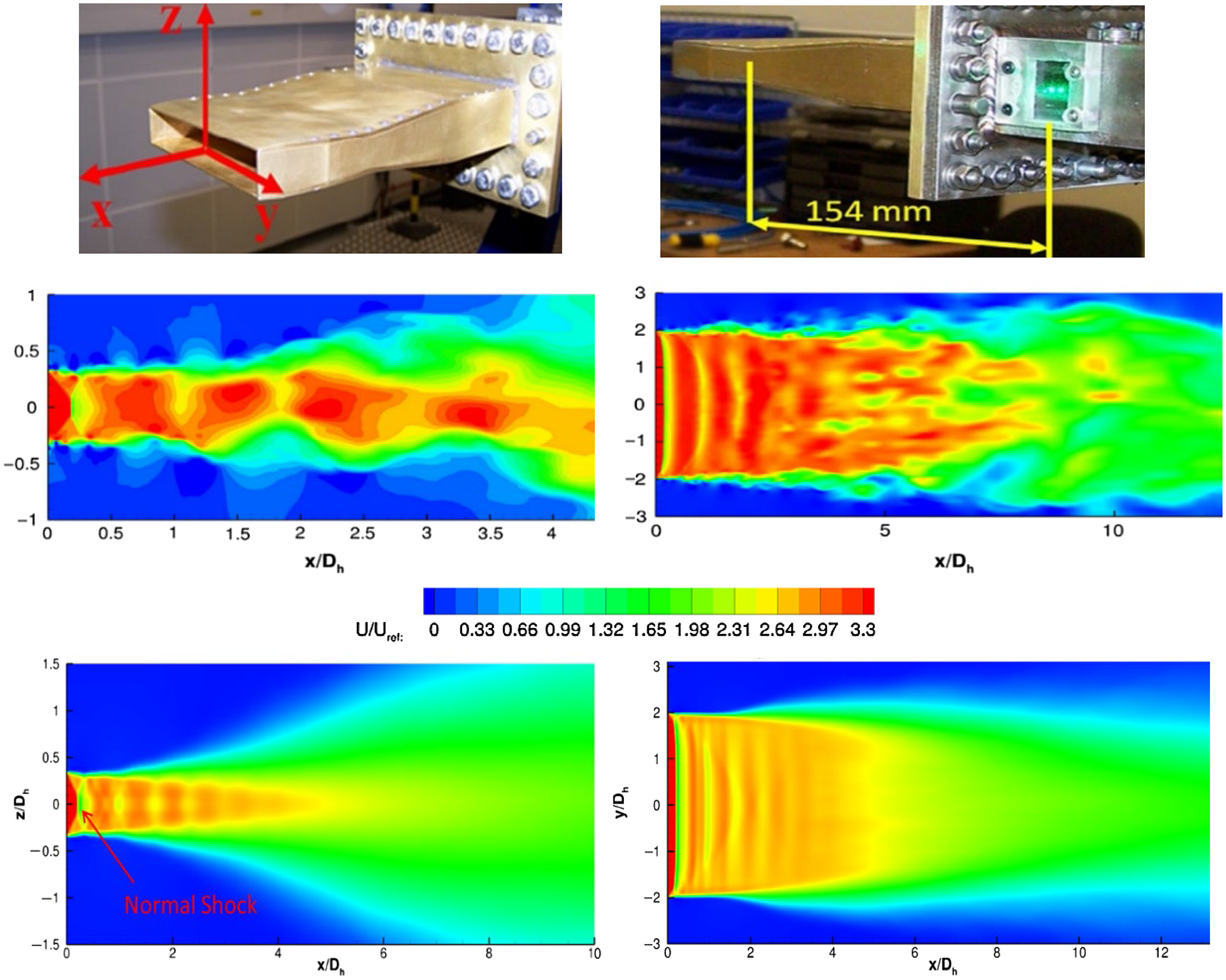

Arguments were put forward in Section 2, and by Brès et al. (Reference Brés, Jaunet, Le Rallic, Jordan, Colonius and Lele39,Reference Brés, Jordan, Jaunet, Le Rallic, Cavalieri, Towne, Lele, Colonius and Schmidt40), that for accurate simulation of high-frequency noise generated by the small-scale dynamically important eddies in the thin nozzle exit shear layer, it is important for exit boundary layer details to be accurately reproduced in the simulation. These have rarely been measured in experimental studies, and it is increasingly common for simulations to include internal nozzle flow. This is perhaps motivated by an assumption that detailed velocity/turbulence information is easier to obtain (or assumptions made in its estimation are less critical) at the nozzle inlet. This is certainly the case in laboratory/rig studies, and for realistic aeroengine geometries, CFD predictions of the flow upstream of the nozzle are now appearing (see below). To provide a test case for internal nozzle simulations, Trumper et al. (Reference Trumper, Behrouzi and McGuirk7) conducted an experimental study for a convergent nozzle with representative length/area change and at appropriate Re j and M j , providing the velocity and turbulence at the nozzle inlet and exit. Wang and McGuirk (Reference Wang and McGuirk55) reported LES for the same nozzle geometry, which is shown in Fig. 32 (top left).

Figure 32. Top: nozzle geometry (dimensions in mm) and instantaneous w-velocity contours. Bottom: LES mean axial velocity at nozzle exit, zoom-in for internal corner. From Ref. Reference Wang and McGuirk55.

The contracting area ratio is similar to that of the BAESystems Hawk aircraft. A small parallel extension at the nozzle exit was added to remove vena contracta effects and allow the thin, partially relaminarised, exit boundary layer to recover to the turbulent state expected of full-scale aeroengine conditions. The inlet measurements were used in the R2M LES inlet condition generation method of Ref. Reference Xiao, Dianat and McGuirk42 and captured measured inlet profiles very well (Fig. 22). An instantaneous snapshot of velocity contours from the simulation (Fig. 32, top right) illustrates the precursor (x/D up to 2.5) and main (2.5–4.17) LES domains. The w-component is plotted to illustrate the large-scale vortical structures in the boundary layer, angled away from the wall as observed in experiments; high acceleration within the nozzle stretches these longitudinally, reflecting experimental observations of increased streamwise integral scales in accelerated flows. The mean axial velocity field within the nozzle is shown in Fig. 32 (bottom left); the rapid acceleration reduces the boundary-layer thickness dramatically. The boundary layer begins to grow again in the short parallel extension: the

![]() $\delta_{99}$

layer thickness is 28% of the local diameter at the nozzle entry, 0.5% at the end of contraction and

$\delta_{99}$

layer thickness is 28% of the local diameter at the nozzle entry, 0.5% at the end of contraction and

![]() $\sim$

16% at the nozzle exit.

$\sim$

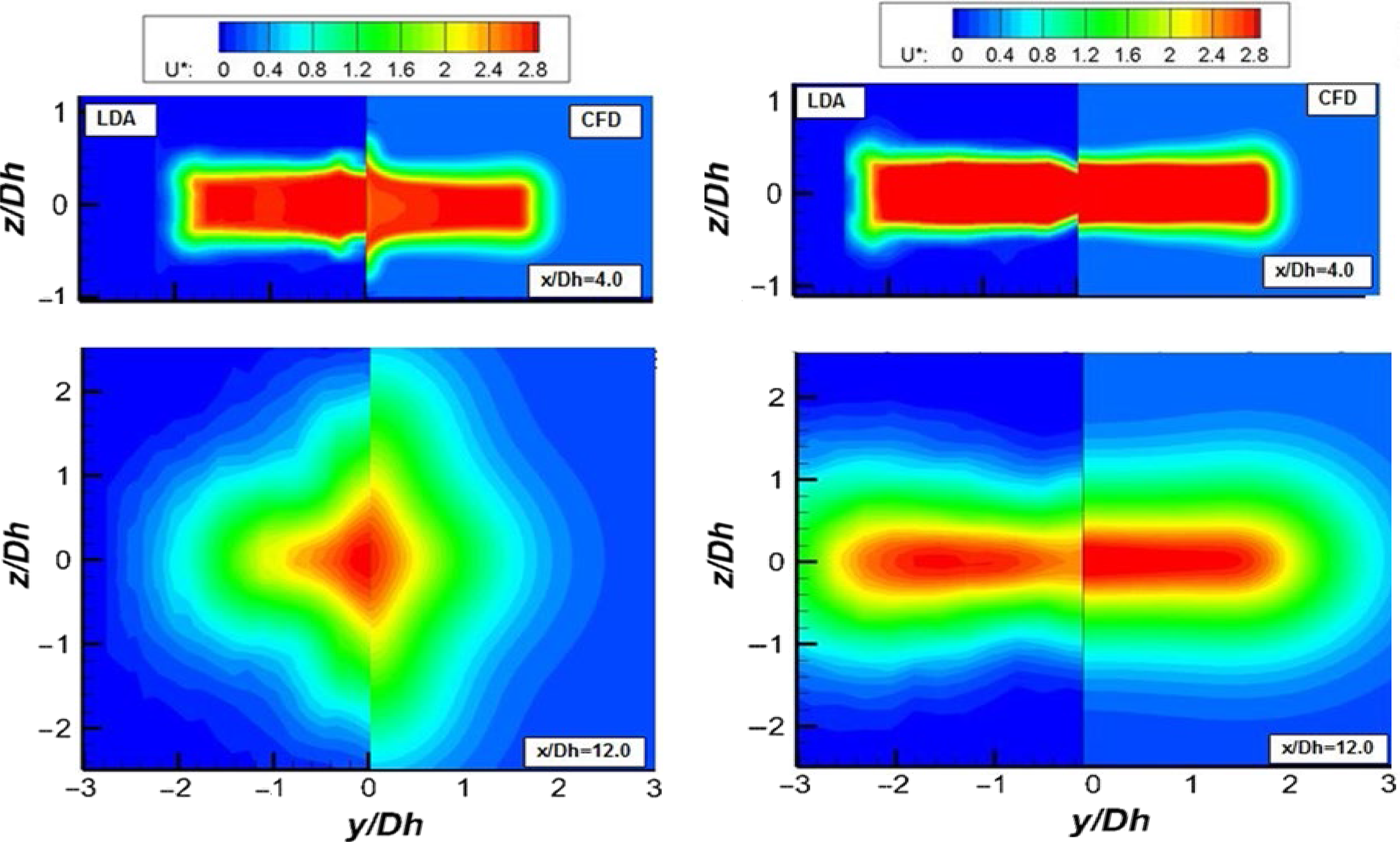

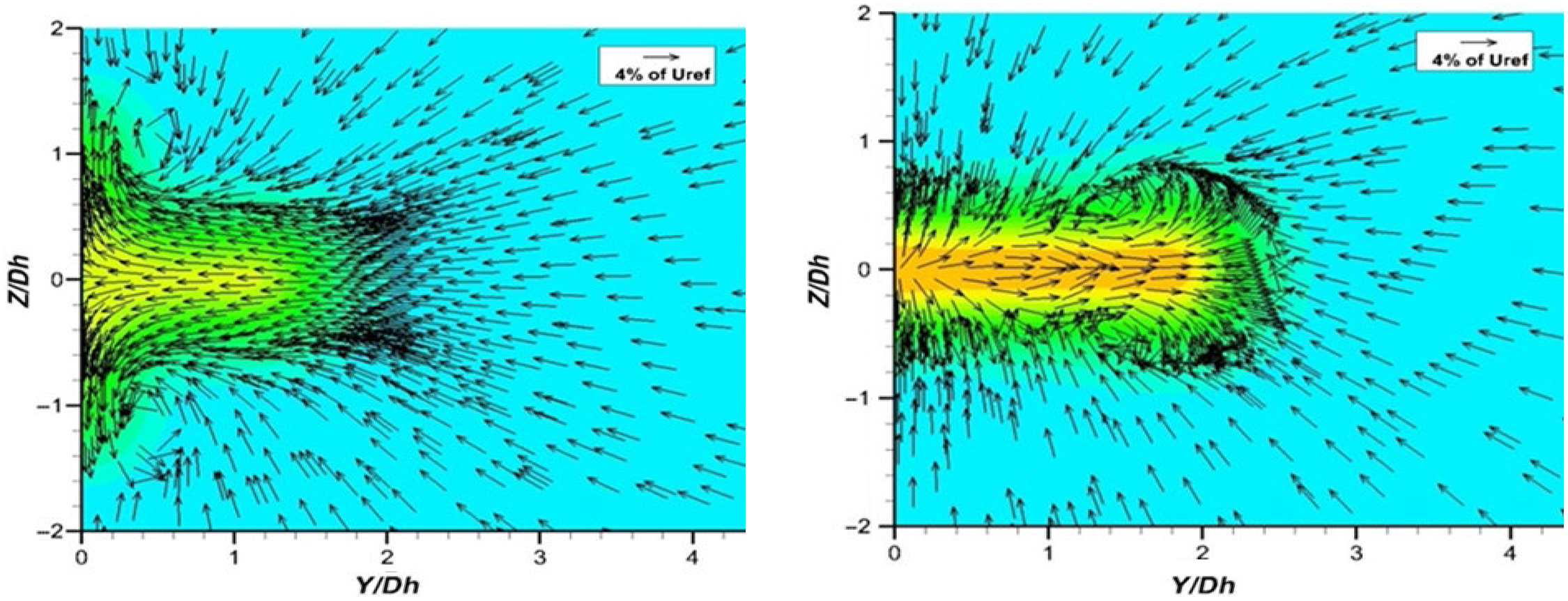

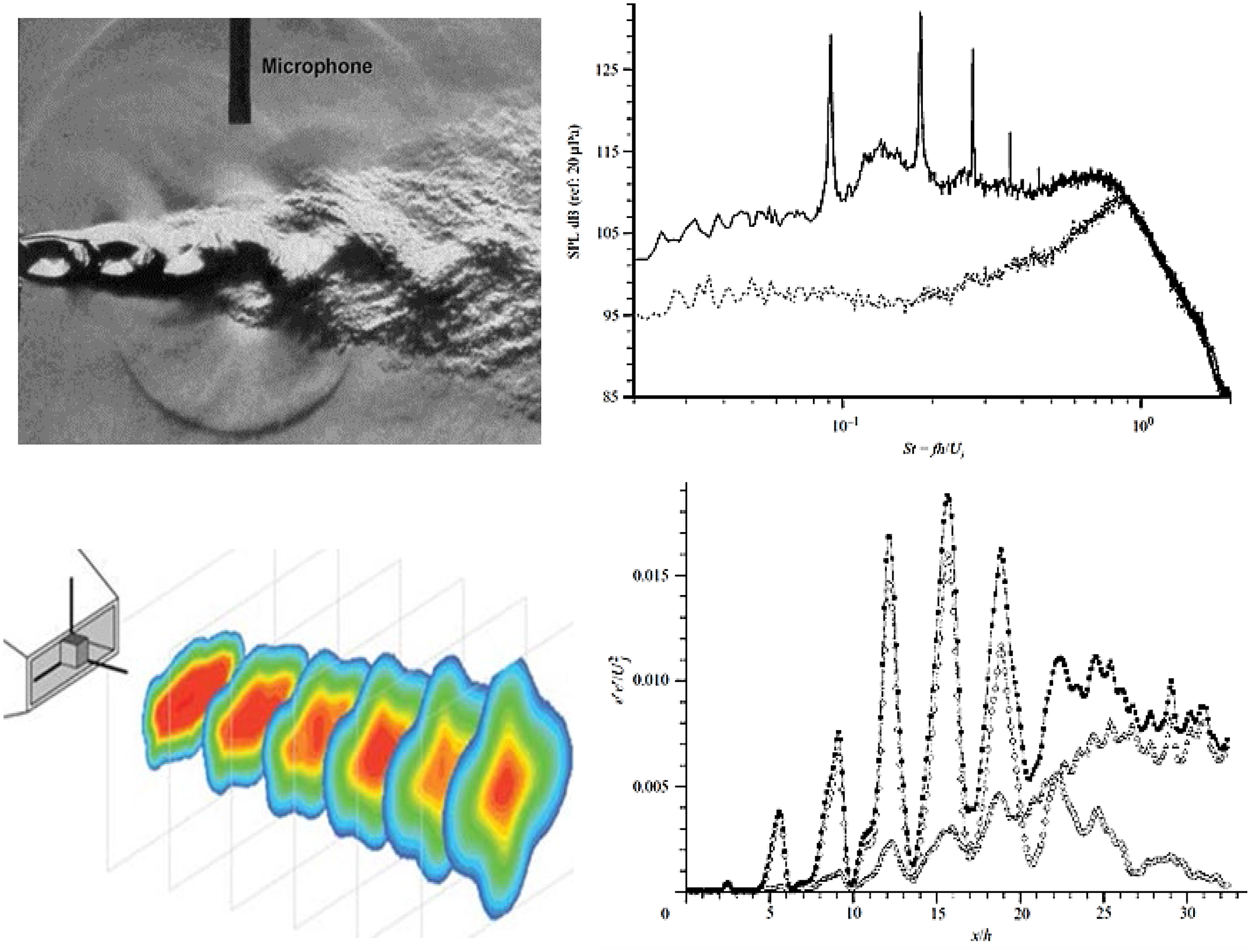

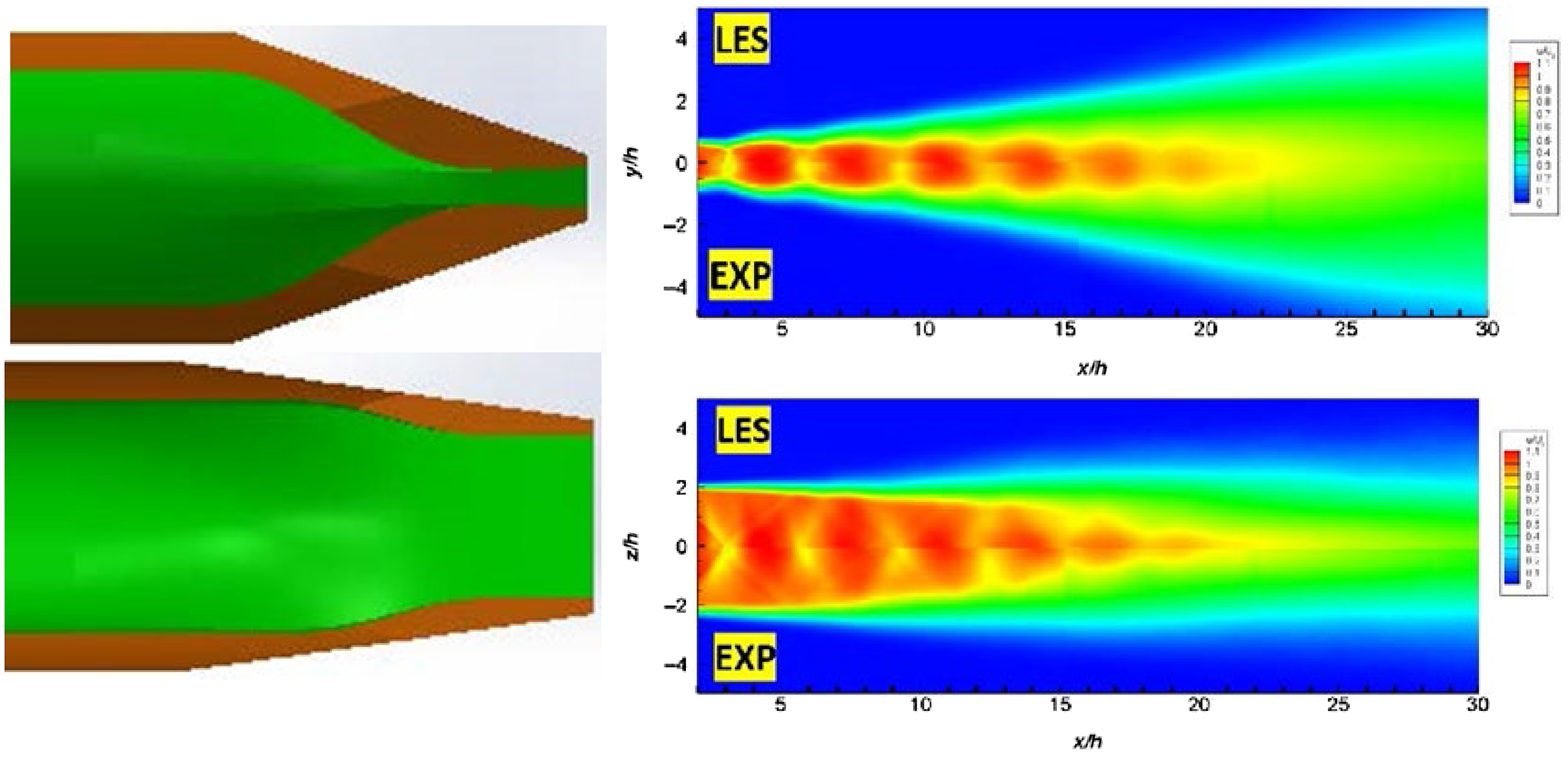

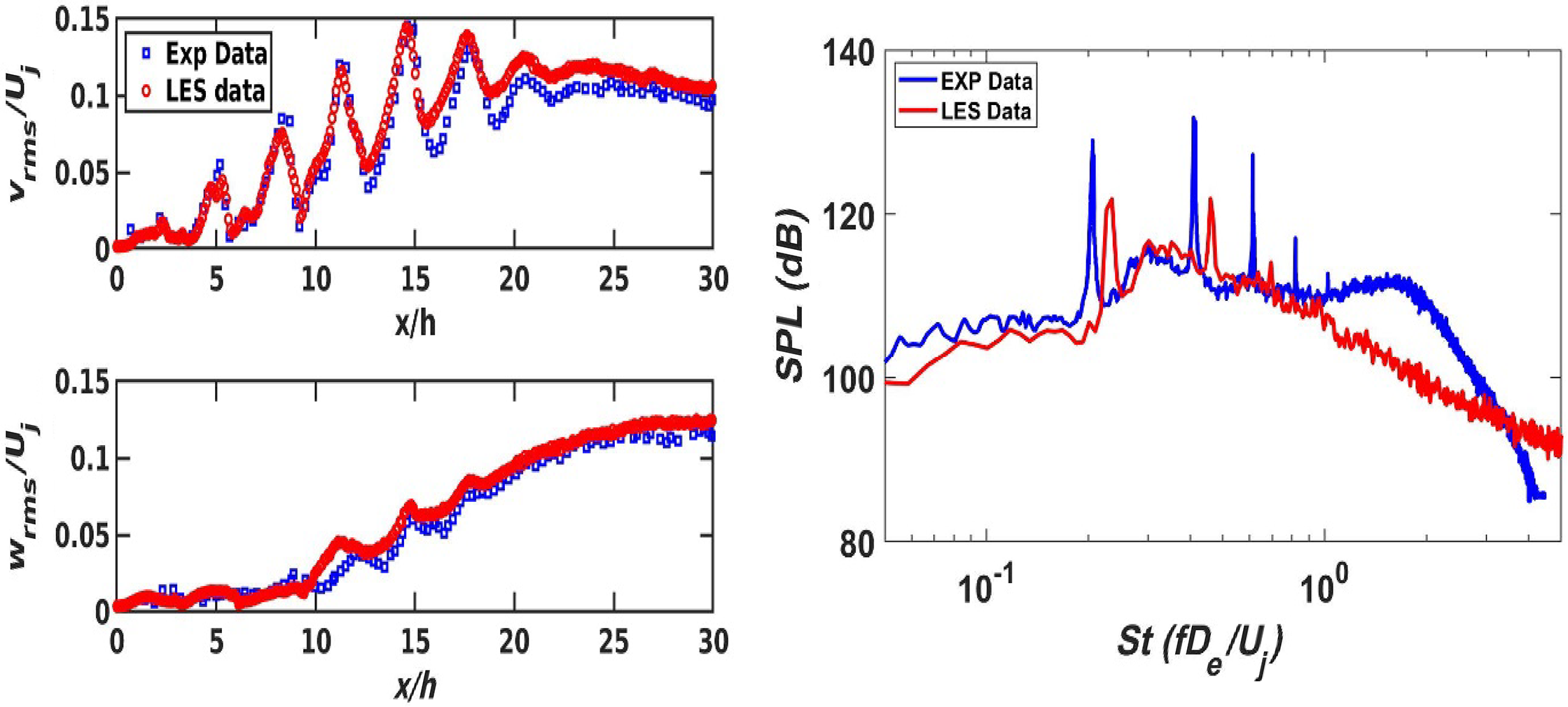

16% at the nozzle exit.