Abstract

In this study, the effect of sintering temperature on microstructure and mechanical properties of Ni–BaZrxCe0.8−xY0.1Yb0.1O3-δ (Ni–BZCYYb); x = 0.1 and 0.5, cermet anodes for protonic ceramic fuel cells (PCFCs) were investigated. A 2-dimensional (2D) stereological method which involves viable image processing was used to quantify the effect of sintering temperature on the volume fraction and interconnectivity of pores and solid phases between 1300 and 1450 °C. 3-point bending test indicates that bending strength (σ) for Ni–BaZr0.1Ce0.7Y0.1Yb0.1O3-δ (Ni–BZCYYb17) are higher than those for Ni–BaZr0.5Ce0.3Y0.1Yb0.1O3-δ (Ni–BZCYYb53) specimens, and the specimens sintered at 1400 °C have highest value of bending strength. To complement the results obtained from the bending strength and image processing, the Weibull modulus (m) values of the Ni–BZCYYb cermets were calculated.

Similar content being viewed by others

Data availability

Data available upon reasonable request.

References

D. Kim, I. Jeong, K.J. Kim, K.T. Bae, D. Kim, J. Koo, H. Yu, K.T. Lee, A brief review of heterostructure electrolytes for high-performance solid oxide fuel cells at reduced temperatures. J. Korean Ceram. Soc. 59, 131–152 (2022). https://doi.org/10.1007/s43207-021-00175-9

H. Jeong, B. Sharma, S. Jo, Y.H. Kim, J.-H. Myung, Electrochemical characteristics of La0.8Sr0.2MnO3 (LSM)–scandia-stabilized zirconia (ScSZ) composite cathode. J. Korean Ceram. Soc. 59, 473–479 (2022). https://doi.org/10.1007/s43207-022-00200-5

W. Ye, T.W. Kim, D.-H. Park, Layered double hydroxide nanomaterials for bifunctional ORR/OER electro-catalyst. J. Korean Ceram. Soc. 59, 763–774 (2022). https://doi.org/10.1007/s43207-022-00241-w

I.Y. Kim, J. Ko, T.-Y. Ahn, H.-W. Cheong, Y.S. Yoon, Energy materials for energy conversion and storage: focus on research conducted in Korea. J. Korean Ceram. Soc. 58, 645–661 (2021). https://doi.org/10.1007/s43207-021-00152-2

S.-H. Lee, Y.J. Kwak, J.-W. Park, K.-T. Lee, Systematic study on the Ni exsolution behavior of NiAl2O4 catalysts for steam methane reforming. J. Korean Ceram. Soc. 60, 536–546 (2023). https://doi.org/10.1007/s43207-022-00283-0

L. Mathur, Y. Namgung, H. Kim, S.-J. Song, Recent progress in electrolyte-supported solid oxide fuel cells: a review. J. Korean Ceram. Soc. 60, 614–636 (2023). https://doi.org/10.1007/s43207-023-00296-3

N. Mahato, A. Banerjee, A. Gupta, S. Omar, K. Balani, Progress in material selection for solid oxide fuel cell technology: a review. Prog. Mater. Sci. 72, 141–337 (2015). https://doi.org/10.1016/j.pmatsci.2015.01.001

E.D. Wachsman, K.T. Lee, Lowering the temperature of solid oxide fuel cells. Science 334, 935–939 (2011). https://doi.org/10.1126/science.1204090

S. Im, J.-H. Lee, H.-I. Ji, PrBa0.5Sr0.5Co1.5Fe0.5O5+δ composite cathode in protonic ceramic fuel cells. J. Korean Ceram. Soc. 58, 351–358 (2021). https://doi.org/10.1007/s43207-021-00109-5

J. Seo, H.-W. Kim, J.H. Yu, H.J. Park, Electrochemical properties of Ba0.5Sr0.5Co0.8Fe0.2O3 and BaZr0.65Ce0.20Y0.15O3 composite cathodes on Y-doped barium–cerium–zirconium oxide solid electrolyte. J. Korean Ceram. Soc. 59, 217–223 (2022). https://doi.org/10.1007/s43207-021-00169-7

S. Ahmed, W.W. Kazmi, A. Hussain, M.Z. Khan, S. Bibi, M. Saleem, R.H. Song, Z. Sajid, A. Ullah, M.K. Khan, Facile and low-temperature synthesis approach to fabricate Sm0.5Sr0.5CoO3−δ cathode material for solid oxide fuel cell. J. Korean Ceram. Soc. 60, 272–282 (2023). https://doi.org/10.1007/s43207-022-00261-6

L. Mathur, I.-H. Kim, A. Bhardwaj, B. Singh, J.-Y. Park, S.-J. Song, Structural and electrical properties of novel phosphate based composite electrolyte for low-temperature fuel cells. Compos. B Eng. 202, 108405 (2020). https://doi.org/10.1016/j.compositesb.2020.108405

L. Mathur, A. Kumar, I.-H. Kim, H. Bae, J.-Y. Park, S.-J. Song, Novel organic-inorganic polyphosphate based composite material as highly dense and robust electrolyte for low temperature fuel cells. J. Power Sour. 493, 229696 (2021). https://doi.org/10.1016/j.jpowsour.2021.229696

H.-I. Ji, J.-H. Lee, J.-W. Son, K.J. Yoon, S. Yang, B.-K. Kim, Protonic ceramic electrolysis cells for fuel production: a brief review. J. Korean Ceram. Soc. 57, 480–494 (2020). https://doi.org/10.1007/s43207-020-00059-4

K.D. Kreuer, Aspects of the formation and mobility of protonic charge carriers.pdf. Solid State Ion. 125, 285–302 (2021)

E. Fabbri, D. Pergolesi, E. Traversa, Electrode materials: a challenge for the exploitation of protonic solid oxide fuel cells. Sci. Technol. Adv. Mater. (2010). https://doi.org/10.1088/1468-6996/11/4/044301

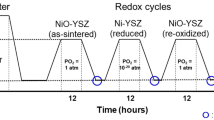

J.H. Park, H.-N. Im, K.T. Lee, Understanding redox cycling behavior of Ni–YSZ anodes at 500 °C in solid oxide fuel cells by electrochemical impedance analysis. J. Korean Ceram. Soc. 58, 606–613 (2021). https://doi.org/10.1007/s43207-021-00136-2

S. Jo, B. Sharma, D.-H. Park, J. Myung, Materials and nano-structural processes for use in solid oxide fuel cells: a review. J. Korean Ceram. Soc. 57, 135–151 (2020). https://doi.org/10.1007/s43207-020-00022-3

S.-K. Rha, M.-J. Lee, Y.-S. Lee, Catalytic characteristics of Ni(B)-coated YSZ powder by neutral electroless plating. J. Korean Ceram. Soc. 57, 338–344 (2020). https://doi.org/10.1007/s43207-020-00034-z

S. Choi, Electrochemical properties of Sr-doped layered perovskite as a promising anode material for direct hydrocarbon SOFCs. J. Korean Ceram. Soc. 57, 409–415 (2020). https://doi.org/10.1007/s43207-020-00045-w

W. Li, B. Guan, L. Ma, S. Hu, N. Zhang, X. Liu, High performing triple-conductive Pr2NiO4+: δ anode for proton-conducting steam solid oxide electrolysis cell. J. Mater. Chem. A 6, 18057–18066 (2018). https://doi.org/10.1039/c8ta04018d

K. Bae, H.-S. Noh, D.Y. Jang, J. Hong, H. Kim, K.J. Yoon, J.-H. Lee, B.-K. Kim, J.H. Shim, J.-W. Son, High-performance thin-film protonic ceramic fuel cells fabricated on anode supports with a non-proton-conducting ceramic matrix. J. Mater. Chem. A 4, 6395–6404 (2016). https://doi.org/10.1039/c5ta10670b

M.A. Azimova, S. Mcintosh, On the choice of anode electrocatalyst for alcohol fuelled proton conducting solid oxide fuel cells. J. Electrochem. Soc. 158, B1532 (2011). https://doi.org/10.1149/2.101112jes

E. Fabbri, D. Pergolesi, E. Traversa, Materials challenges toward proton-conducting oxide fuel cells: a critical review. Chem. Soc. Rev. 39, 4355–4369 (2010). https://doi.org/10.1039/b902343g

J. Dailly, G. Railades, M. Ancelin, P. Pers, M. Marrony, High performing BaCe0.8Zr0.1Y0.1O3-Δ-Sm0.5Sr0.5CoO3-Δ based protonic ceramic fuel cell. J. Power Sour. 361, 221–226 (2017). https://doi.org/10.1016/j.jpowsour.2017.06.089

A. Tarutin, J. Lyagaeva, A. Farlenkov, S. Plaksin, G. Vdovin, A. Demin, D. Medvedev, A reversible protonic ceramic cell with symmetrically designed Pr2NiO4+δ-based electrodes: fabrication and electrochemical features. Materials (Basel) 12, 118 (2019). https://doi.org/10.3390/ma12010118

L. Bi, E. Fabbri, E. Traversa, Effect of anode functional layer on the performance of proton-conducting solid oxide fuel cells (SOFCs). Electrochem. Commun. 16, 37–40 (2012). https://doi.org/10.1016/j.elecom.2011.12.023

Y. Chen, S. Yoo, Y. Choi, J.H. Kim, Y. Ding, K. Pei, R. Murphy, Y. Zhang, B. Zhao, W. Zhang, H. Chen, Y. Chen, W. Yuan, C. Yang, M. Liu, A highly active, CO2-tolerant electrode for the oxygen reduction reaction. Energy Environ. Sci. 11, 2458–2466 (2018). https://doi.org/10.1039/c8ee01140k

C. Duan, R. Kee, H. Zhu, N. Sullivan, L. Zhu, L. Bian, D. Jennings, R. O’hayre, Highly efficient reversible protonic ceramic electrochemical cells for power generation and fuel production. Nat. Energy 4, 230–240 (2019). https://doi.org/10.1038/s41560-019-0333-2

C. Chen, Y. Dong, L. Li, Z. Wang, M. Liu, B.H. Rainwater, Y. Bai, Electrochemical properties of micro-tubular intermediate temperature solid oxide fuel cell with novel asymmetric structure based on BaZr0.1Ce0.7Y0.1Yb0.1O3−Δ proton conducting electrolyte. Int. J. Hydrog. Energy 44, 16887–16897 (2019). https://doi.org/10.1016/j.ijhydene.2019.04.264

C. Chen, M. Liu, Y. Bai, L. Yang, E. Xie, M. Liu, Anode-supported tubular SOFCs based on BaZr0.1Ce 0.7Y0.1Yb0.1O3-δ electrolyte fabricated by dip coating. Electrochem. Commun. 13, 615–618 (2011). https://doi.org/10.1016/j.elecom.2011.03.025

P. Pers, V. Mao, M. Tailades, G. Tailades, Electrochemical behavior and performances of Ni–BaZr0·1Ce0·7Y0.1Yb0.1O3−δ cermet anodes for protonic ceramic fuel cell. Int. J. Hydrog. Energy 43, 2402–2409 (2018). https://doi.org/10.1016/j.ijhydene.2017.12.024

Y. Zhang, D. Xie, B. Chi, J. Pu, J. Li, D. Yan, Basic properties of proton conductor BaZr0.1Ce0.7Y0.1Yb0.1O3-δ (BZCYYb) material. Asia Pac. J. Chem. Eng. 14, 1–10 (2019). https://doi.org/10.1002/apj.2322

I.-H. Kim, D.-K. Lim, H. Bae, A. Bhardwaj, J.-Y. Park, S.-J. Song, Determination of partial conductivities and computational analysis of the theoretical power density of BaZr0.1Ce0.7Y0.1Yb0.1O3-:δ (BZCYYb1711) electrolyte under various PCFC conditions. J. Mater. Chem. A 7, 21321–21328 (2019). https://doi.org/10.1039/c9ta07135k

S. Sun, O. Awadallah, Z. Cheng, Poisoning of Ni-based anode for proton conducting SOFC by H2S, CO2, and H2O as fuel contaminants. J. Power. Sour. 378, 255–263 (2018). https://doi.org/10.1016/j.jpowsour.2017.12.056

L. Yang, S. Wang, K. Blinn, M. Liu, Z. Liu, Z. Cheng, M. Liu, Enhanced sulfur and coking tolerance of a mixed ion conductor for SOFCs: BaZr0.1Ce0.7y0.2-XYb xO3-δ. Science 326, 126–129 (2009). https://doi.org/10.1126/science.1174811

Y. Guo, Y. Lin, R. Ran, Z. Shao, Zirconium doping effect on the performance of proton-conducting BaZryCe0.8-yY0.2O3-δ (0.0 ≤ y ≤ 0.8) for fuel cell applications. J. Power Sour. 193, 400–407 (2009). https://doi.org/10.1016/j.jpowsour.2009.03.044

A.R. Hanifi, N.K. Sandhu, T.H. Etsell, J.-L. Luo, P. Sarkar, Fabrication and characterization of a tubular ceramic fuel cell based on BaZr0.1Ce0.7Y0.1Yb0.1O3-δ proton conducting electrolyte. J. Power Sour. 341, 264–269 (2017). https://doi.org/10.1016/j.jpowsour.2016.12.010

J. Lyagaeva, G. Vdovin, L. Hakimova, D. Medvedev, A. Demin, P. Tsiakars, BaCe0.5Zr0.3Y0.2–xYbxO3–δ proton-conducting electrolytes for intermediate-temperature solid oxide fuel cells. Electrochim. Acta 251, 554–561 (2017). https://doi.org/10.1016/j.electacta.2017.08.149

Z. Shi, W. Sun, W. Liu, Synthesis and characterization of BaZr0.3Ce0.5Y 0.2-xYbxO3-δ proton conductor for solid oxide fuel cells. J. Power Sour. 245, 953–957 (2014). https://doi.org/10.1016/j.jpowsour.2013.07.060

S.-M. Bae, Y.-H. Kim, Y.-H. You, J.-H. Hwang, Extraction of quantitative parameters for describing the microstructure of solid oxide fuel cells. Microsc. Microanal. 19, 140–144 (2013). https://doi.org/10.1017/S1431927613012518

S.-M. Bae, H.-Y. Jung, J.-H. Lee, J.-H. Hwang, Microstructural characterization of composite electrode materials in solid oxide fuel cells via image processing analysis. J. Korean Ceram. Soc. 47, 86–91 (2010). https://doi.org/10.4191/KCERS.2010.47.1.086

Z. Jiao, N. Shikazono, Prediction of nickel morphological evolution in composite solid oxide fuel cell anode using modified phase field model. J. Electrochem. 165, F55–F63 (2018). https://doi.org/10.1149/2.0681802jes

J.W. Kim, K. Bae, H.J. Kim, J.-W. Son, N. Kim, S. Stenfelt, F.B. Prinz, J.H. Shim, Three-dimensional thermal stress analysis of the re-oxidized Ni-YSZ anode functional layer in solid oxide fuel cells. J. Alloys Compd. 752, 148–154 (2018). https://doi.org/10.1016/j.jallcom.2018.04.176

D. Kennouche, Y.-C.K. Chen-Wiegart, K.J. Yakal-Kremski, J. Wang, J.W. Gibbs, P.W. Voorhees, S.A. Barnett, Observing the microstructural evolution of Ni-Yttria-stabilized zirconia solid oxide fuel cell anodes. Acta Mater. 103, 204–210 (2016). https://doi.org/10.1016/j.actamat.2015.09.055

S.D. Angelis, P.S. Jørgensen, E.H.R. Tsai, M. Holler, K. Kreka, J.R. Bowen, Three dimensional characterization of nickel coarsening in solid oxide cells via ex-situ ptychographic nano-tomography. J. Power. Sour. 383, 72–79 (2018). https://doi.org/10.1016/j.jpowsour.2018.02.031

K.-C. Lee, M.-B. Choi, D.-K. Lim, B. Singh, S.-J. Song, Effect of humidification on the performance of intermediate-temperature proton conducting ceramic fuel cells with ceramic composite cathodes. J. Power. Sour. 232, 224–233 (2013). https://doi.org/10.1016/j.jpowsour.2013.01.001

M.-B. Choi, B. Singh, E.D. Wachsman, S.-J. Song, Performance of La0.1Sr0.9Co0.8Fe 0.2O3-δ and La0.1Sr0.9Co 0.8Fe0.2O3-δ-Ce0.9Gd 0.1O2 oxygen electrodes with Ce0.9Gd 0.1O2 barrier layer in reversible solid oxide fuel cells. J. Power Sour. 239, 361–373 (2013). https://doi.org/10.1016/j.jpowsour.2013.03.154

Y. Liu, L. Yang, M. Liu, Z. Tang, M. Liu, Enhanced sinterability of BaZr0.1Ce0.7Y 0.1Yb0.1O3-δ by addition of nickel oxide. J. Power Sour. 196, 9980–9984 (2011). https://doi.org/10.1016/j.jpowsour.2011.08.047

A. VahidMohammadi, Z. Cheng, Fundamentals of synthesis, sintering issues, and chemical stability of BaZr 0.1 Ce 0.7 Y 0.1 Yb 0.1 O 3-δ proton conducting electrolyte for SOFCs. J. Electrochem. Soc. 162, F803–F811 (2015). https://doi.org/10.1149/2.0021508jes

K. Yang, J.X. Wang, Y.J. Xue, M.S. Wang, C.R. He, Q. Wang, H. Miao, W.G. Wang, Synthesis, sintering behavior and electrical properties of Ba(Zr 0.1Ce0.7Y0.2)O3-δ and Ba(Zr0.1Ce0.7Y0.1Yb0.1)O 3-δ proton conductors. Ceram. Int. 40, 15073–15081 (2014). https://doi.org/10.1016/j.ceramint.2014.06.115

B. Mirfakhraei, F. Ramezanipour, S. Paulson, V. Birss, V. Thangadurai, Effect of sintering temperature on microstructure, chemical stability, and electrical properties of transition metal or Yb-doped BaZr 0.1 Ce 0.7 Y 0.1 M 0.1 O 3-δ (M = Fe, Ni Co, and Yb). Front. Energy Res. 2, 1–10 (2014). https://doi.org/10.3389/fenrg.2014.00009

K.-R. Lee, S.H. Choi, J. Kim, H.-W. Lee, J.-H. Lee, Viable image analyzing method to characterize the microstructure and the properties of the Ni/YSZ cermet anode of SOFC. J. Power. Sour. 140, 226–234 (2005). https://doi.org/10.1016/j.jpowsour.2004.06.031

S.-M. Bae, K.-S. Kang, C.-S. Park, J.-H. Hwang, Microstructural characterization of multiphase GDC/NiO composites using image processing. J. Ceram. Process. Res. 10, 710–715 (2009)

M.A. Kaiyum, A. Ahmed, M.H. Hasnat, S. Rahman, Effect of MgO on physical and mechanical properties of dental porcelain. J. Korean Ceram. Soc. 58, 42–49 (2021). https://doi.org/10.1007/s43207-020-00083-4

N.Y. Mohammed, M.M.S. Wahsh, I.T. Motawea, H.A. Essawy, Fabrication and characterization of polymer-infiltrated ceramic network materials based on nano-tetragonal zirconia. J. Korean Ceram. Soc. 58, 359–372 (2021). https://doi.org/10.1007/s43207-020-00102-4

K.K. Kandi, G. Punugupati, P. Madhukar, C.S.P. Rao, Effect of boron nitride (BN) on mechanical and dielectric properties of fused silica ceramic composites. J. Korean Ceram. Soc. 59, 565–577 (2022). https://doi.org/10.1007/s43207-021-00184-8

A. Wang, S. Wang, H. Yin, P. Zhou, D. Liu, Study on the pore/scratch-strength response of ZrB2–SiC ceramic via laser processing. J. Korean Ceram. Soc. 59, 803–810 (2022). https://doi.org/10.1007/s43207-022-00219-8

C.A. Klein, Characteristic strength, Weibull modulus, and failure probability of fused silica glass. Opt. Eng. 48, 113401 (2009). https://doi.org/10.1117/1.3265716

L. Wang, R. Dou, G. Wang, Y. Li, M. Bai, D. Hall, Y. Chen, Fracture strength and Weibull analysis of Ba0.5Sr0.5Co0.8Fe0.2O3−δ oxygen transport membranes evaluated by biaxial and uniaxial bending tests. Mater. Sci. Eng. A 670, 292–299 (2016). https://doi.org/10.1016/j.msea.2016.06.029

X.-V. Nguyen, C.-T. Chang, G.-B. Jung, S.-H. Chan, W.C.-W. Huang, K.-J. Hsiao, W.-T. Lee, S.-W. Chang, I.-C. Kao, Effect of sintering temperature and applied load on anode-supported electrodes for SOFC application. Energies 9, 701 (2016). https://doi.org/10.3390/en9090701

J. Bu, P.G. Jönsson, Z. Zhao, The effect of NiO on the conductivity of BaZr0.5Ce0.3Y0.2O3-δ based electrolytes. RSC Adv. 6, 62368–62377 (2016). https://doi.org/10.1039/C6RA09936J

M. Al-Amin, H.T. Mumu, S. Sarker, M.Z. Alam, M.A. Gafur, Effects of sintering temperature and zirconia content on the mechanical and microstructural properties of MgO, TiO2 and CeO2 doped alumina–zirconia (ZTA) ceramic. J. Korean Ceram. Soc. 60, 141–154 (2023). https://doi.org/10.1007/s43207-022-00194-0

Acknowledgements

This work was supported by Core Technology Development Program to Future Hydrogen Energy and Basic Science Research Program through the National Research Foundation of Korea (NRF-2021M3I3A108483012).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, S., Kim, EI., Singh, B. et al. Quantification of correlation between microstructure and mechanical properties of Ni–BaZrxCe0.8−xY0.1Yb0.1O3-δ (x = 0.1, 0.5) cermet anodes by image analysis. J. Korean Ceram. Soc. (2024). https://doi.org/10.1007/s43207-023-00363-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43207-023-00363-9