Abstract

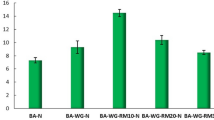

The main purpose of the paper is to prepare and characterize sustainable geopolymer composites with high potential to resist sulfate attack. The produced eco-friendly composites were produced from metakaolin as well blast furnace slag incorporating 10% of either silica fumes or glass waste powder as control mixes. multiwall carbon nanotube (MWCNT) was added from 0.01 up to 0.09% by weight. Addition of MWCNT results in an increased sulfate resistance up to 0.07% for both matrices incorporating glass waste or silica fume. This encourages the sustainability of the produced composites in marine environments. However, glass waste mixes exhibited greater stability and high mechanical properties than silica fume mixes as related to difference in their reactivity. Differential thermal gravimetric, FTIR, and XRD of hardened geopolymer composites with carbon nanotube of 0.01 up to 0.09 wt% depicted an increased amorphous geopolymer as well as hydrating phases with little evidence of ettringite formation up to 0.07%.

Geopolymerization process from dissolution of aluminosiicate materials, gelation, polymerization, and finally three dimensional grain growth of geopolymer chains.

Similar content being viewed by others

References

Palomo A, Fernández-Jiménez A, López-Hombrados C, Léyda JL (2004) Precast elements made of alkali-activated f1y ash concrete, 8th CANMET/ACI International Conference on f1y ash, silica fume, slag and natural pozzolans in concrete, Las Vegas (USA). Supplementary Volume pp. 545–558

Davidovits J (1991) Geopolymers – inorganic polymeric new materials. J Therm Anal 37(8):1633–1656

Provis JL (2014) Geopolymers and other alkali activated materials — why, how, and what? Mater Struct 47:11–25

Torres-Carrasco M, Puertas F (2015) Waste glass in the geopolymer preparation mechanical and microstructural characterization. J Clean Prod 90:397–408. https://doi.org/10.1016/j.jclepro.2014.11.074

Duxson P, Provis JL, Lukey GC, Van Deventer JSJ (2007) The role of inorganic polymer Technology in the Development of green concrete. Cem Concr Res 37(12):1590–1597

Davidovits J (1988) Geopolymer chemistry and properties. In: Davidovits J, Orlinski J (eds) Geopolymer’ 88, first European conference on soft Mineralurgy, vol 1. Geopolymer Institute and Technical University, Compie’gne, France, pp 25–48

Abdel-Gawwad HA, Heikal M, Mona S, El-Aleem SA, Hassan HS, Vàsquez-García SR, Alomayri T (2019) Sustainable disposal of cement kiln dust in the production of cementitious materials. J Clean Prod 232:1218–1229

Kriven WM, Gordon M, Bell J (2004) Geopolymers: nanoparticulate, nanoporous ceramics made under ambient conditions. In: Anderson IM, Price R, Hall E, Clark E, McKernan S (eds) Proceedings of the 62nd annual meeting of microscopy Society of America, Vol. 10. University of Cambridge, Savannah, Georgia, pp 404–405

Morsy MS, Aglan HA (2007) Development and characterization of nanostructured– perlite–Cementitious surface compounds. J Mater Sci 42:10188–10195

Aglan H, Morsy M, Allie A, Fouad F (2009) Evaluation of fiber reinforced nanostructured perlite–cementitious surface compound for building skin applications. Constr Build Mater 23:138–145

Shebl SS, Allie L, Morsy MS, Aglan HA (2009) Mechanical behavior of activated nano silicate filled cement binders. J Mater Sci 44:1600–1606

Saafi M, Andrew K, Tang PL, Ghon DM, Taylor S, Rahman M, Yang S, Zhou X (2013) Multifunctional properties of carbon nanotube/fly ash geopolymeric nanocomposites. Constr Build Mater 49:46–55

Chen SJ, Collins FG, Macleod A JN, Pan Z, Duan WH, Wang CM (2011) Carbon nanotube-cement: a retrospect. The ISE Journal Part A: Civil Struct Eng 4(4):254–265. https://doi.org/10.1007/s42114-020-00170-4

Khater HM, Abd el Gawwad HA (2015) Characterization of alkali activated geopolymer mortar doped with MWCNT. Construction and Building Materials 102 (2016):329–337

Heister E, Lamprecht C, Neves V, Tîlmaciu C, Datas L, Emmanuel Flahaut E (2010) Higher dispersion efficacy of functionalized carbon nanotubes in chemical and biological environments. ACS Nano 4(5):2615–2626

Bakharev T (2005) Durability of geopolymer materials in sodium and magnesium sulfate solutions. Cem Concr Res 35:1233–1246

Ismail I, Bernal SA, Provis JL, Hamdan S, van Deventer JSJ (2013) Microstructural changes in alkali activated fly ash/slag geopolymers with sulfate exposure. Mater Struct 46:361–373

Khater HM (2013) Effect of cement kiln dust on Geopolymer composition and its resistance to sulphate attack. Green Material Journal 1(1):36–46

Khater HM (August 2019) Hybrid slag geopolymer composites with durable characteristics activated by cement kiln dust. Construction and Building Materials Journal 228:116708. https://doi.org/10.1016/j.conbuildmat.2019.116708

Khater HM (2012) Effect of calcium on Geopolymerization of alumino silicate wastes. J Mater Civ Eng 24(1):92–101

Wenying G, Guolin W, Jianda W, Ziyun W, Suhong Y (2008) Preparation and performance of Geopolymers. Journal of Wuhan University of Technology- Mater Sci Ed 23(3):285–430

Han B, Yu X, Ou J (2011) Multifunctional and smart carbon nanotube reinforced cement-based materials. Springer, Nanotechnology in Civil Infrastructure, pp 1–47

Collins F, Lambert F, Duan WH (2012) The influence of admixtures on the dispersion, workability, and strength of carbon nanotube–OPC paste mixtures. Cem Concr Compos 34(9):1067–1074

Weitzel B, Hansen MR, Kowald TL, Müller T, Spiess HW, Trettin HFR (3–8 July 2011) Influence of multiwalled carbon nanotubes on the microstructure of CSH-phases. In Proceeding of 13th congress on the Chemistry of Cement, Madrid, Spain

El-Sayed HA, Abo El-Enein SA, Khater HM, Hasanein SA (2011) Resistance of alkali activated water cooled slag geopolymer to sulfate attack. Ceramics – Silikáty 55:153–160

ASTM (2016) C1012/C1012M, “Test method for length change of hydraulic cement mortars exposed to a sulfate solution”. Annual book of ASTM standards. ASTM International, West Conshohocken, PA, USA

Saikia N, Usami A, Kato S, Kojima T (2004) Hydration behavior of ecocement in presence of metakaolin. Resource Progressing Journal 51:35–41

Taha AS, El-Didamony H, Abo El-Enein SA, Amer HA (1981) Physicochemical properties of supersulphated cement pastes. Zement-Kalk-Gips 34:351–353

ASTM (2016) C109M, “Standard test method for compressive strength of hydraulic cement mortars”, Annual book of ASTM standards. ASTM International, West Conshohocken, PA, USA

Panias D, Giannopoulou IP, Perraki T (2007) Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Colloids and Surfaces A: Physicochem Eng Aspects 301:246–254

de Vargas AS, Molin DCCD, Masuero ÂB, Vilela ACF, Castro-Gomes J, Gutierrez RM (2014) Strength development of alkali-activated fly ash produced with combined NAOH and CA(OH)2 activators. Cem Concr Compos 53:341–349

Phair JW, Van Deventer JSJ (2002) Effect of silicate activator pH on the microstructural characteristics of waste-based geopolymers. Int J Miner Process 66:121–143

Alamri H, Low IM (2013) Effect of water absorption on the mechanical properties of nanoclay filled recycled cellulose fiber reinforced epoxy hybrid nanocomposites. Composites A 44:23–31

Khater HM, Abd el Gawaad HA (2015) Effect of firing temperatures on alkali activated Geopolymer mortar doped with MWCNT. Adv Nano Res “Techno Press” 3(4):225–242

Mollah MYA, Lu F, Cocke DL (1998) An X-ray diffraction (XRD) and Fourier transform infrared spectroscopic (FT-IR) characterization of the speciation of arsenic(V) in Portland cement type-V. Sci Total Environ 224:57

Jiang X, Kowald T, Staedler T, Trettin R (2005) Carbon nanotubes as a new reinforcement material for modern cement-based binders. RILEM Proceedings, 2nd International Symposium on Nanotechnology in Construction, pp 209–213

Bernal SA, Provis JL, Rose V, Mejía de Gutiérrez R (2011) Evolution of binder structure in sodium silicate-activated lag metakaolin blends. Cem Concr Compos 33(1):46–54

Chen J, Poon C (2009) Photocatalytic construction and building materials: from fundamentals to applications. Build Environ 44(9):1899–1906

Bakharev T, Sanjayan JG, Cheng YB (2002) Sulfate attack on alkali-activated slag concrete. CemConcr Res 32(2):211–216

Brown PW, Bothe JV (1993) The stability of ettringite. Adv Cem Res 5:47–63

Famy C (1999) Expansion of heat-cured mortars. PhD Thesis, Univ. of London, p 256

Alarcon-Ruiz L, Platret G, Massieu E, Ehrlacher A (2005) The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem Concr Res 35(3):609–613

Bernal SA, Mejia de Gutiérrez R, Provis JL, Rose V (2010) Effect of silicate modulus and metakaolin incorporation on the carbonation of alkali silicateactivated slag. Cem Concr Res 40(6):898–907

Engelhardt G, Felsche J, Sieger P (1992) The Hydrosodalite system Na6+x[SiAlO4]6(OH)x.nH2O: formation, phase composition, and De- and rehydration studied by 1H, 23Na, and 29Si MAS-NMR spectroscopy In Tandem with thermal analysis, X-ray diffraction, and IR spectroscopy. J Am Chem Soc 114:1173–1182

Lemougna PN, MacKenzie KJD, Melo UFC (2011) Synthesis and thermal properties of inorganic polymers (geopolymers) for structural and refractory applications from volcanic ash. Ceram Int 37(8):3011–3018

Wallah SE, Rangan BV (2006) “Low-calcium fly ash-based geopolymer concrete-long-term properties”, Research report GC 2. Curtin University of Technology Perth, Australia, Faculty of Engineering

Khater HM (2013) Effect of silica fume on the characterization of the Geopolymer materials. Int J Adv Struct Eng (Springer Open Journal) 5(12):1–10. https://doi.org/10.1007/s42114-020-00170-4

Duxson P, Mallicoat SW, Lukey GC, Kriven WM, Van Deventer JSJ (2006) Mechanical properties of metakaolin-based geopolymers. Colloids Surf A – Physicochem Eng Asp 292:8–20

Peyvandi A, Soroushian P, Abdol N (2013) Surface-modified graphite nanomaterials for improved reinforcement efficiency in cementitious paste. Carbon 63:175–186

Khater HM (2015) Influence of electric arc furnace slag on characterisation of the produced geopolymer composites. építôanyag J Silicate Based Compos Mater 67(3):82–88

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khater, H.M., El-Nagar, A.M. Preparation of sustainable of eco-friendly MWCNT-geopolymer composites with superior sulfate resistance. Adv Compos Hybrid Mater 3, 375–389 (2020). https://doi.org/10.1007/s42114-020-00170-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-020-00170-4