Abstract

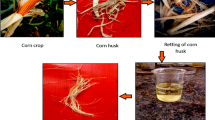

This study investigates a novel composite material that combines siliceous rock dust and Urtica dioica fiber in vinyl ester matrix for sustainable material applications. This research explores the importance of waste rock dust as potential replacement for commercially used ceramics in composite development. The composites were developed via typical hand layup process and characterized for composite’s mechanical strength, fatigue resistance, and hydrophobic properties as per ASTM standards. Mechanically, the composite containing fiber and rock dust of 3 vol% (VNS2) displays exceptional properties, with a tensile strength of 148 MPa, flexural strength of 199 MPa, compression strength of 174 MPa, and a notable impact energy of 5.4 J. However, the composite containing fiber and rock dust of 5 vol% (VNS3) displays, on the other hand, and stands out for its impressive hardness, registering at 82. In fatigue testing, the composite containing fiber and rock dust of 3 vol% (VNS2) exhibits superior performance, enduring 22,199 cycles at 25% UTS, 20,838 cycles at 50% UTS, and 19,935 cycles at 75% UTS, underscoring its exceptional durability. Regarding hydrophobicity, the composite initially displays a contact angle of 98°, indicating water repellency. However, the introduction of Urtica dioica fibers and siliceous rock dust particles marginally increased hydrophilicity, with the composite containing fiber and rock dust of 5 vol% (VNS3) showing a lower contact angle of 82°. Moreover the wear results show that the composite VNS3 gives lowest COF of 0.18 and sp. wear rate of 0.008 mm3/Nm. Similarly the thermogravimetry results revealed that the composite VNS3 gives lowest mass loss of 2.12% with lower DTG. Same way, the addition of rock dust particle into the resin improved the flame retardant properties of composite with V-0 flame rating. These composites promise various applications, including aerospace, construction, marine, and automotive industries where high load bearing, fire proofing, and fire stopping phenomenon are required.

Similar content being viewed by others

Data availability

All the data are available in the manuscript itself.

References

Mujtaba M, Fraceto L, Fazeli M, Mukherjee S, Savassa SM, de Medeiros GA, ... Vilaplana F (2023) J Clean Prod 136815

Zheng G, Kang X, Ye H, Fan W, Sonne C, Lam SS, ... Ge S (2023) Chin Chem Lett 108817

Ilyas RA, Zuhri MYM, Norrrahim MNF, Misenan MSM, Jenol MA, Samsudin SA, ... Omran AAB (2022) Polym 14(1):182

Rochman T, Arifi E, Cahya EN, Wicaksono AM (2023) J Build Eng 76:107205

Prakash SO, Sahu P, Madhan M, Johnson Santhosh A (2022) Int J Polym Sci 2022:1–15

Khan FM, Shah AH, Wang S, Mehmood S, Wang J, Liu W, Xu X (2022) Adv Fiber Mater 4(4):683–704

Bogard F, Bach T, Abbes B, Bliard C, Maalouf C, Bogard V, ... Polidori G (2022) J Nat Fibers 19(14):8205-8229

Mahendrakumar N, Thyla PR, Mohanram PV, Sabareeswaran A, Manas RB, Srivatsan S (2015) Mater Express 5(6):505–517

Kant S, Jawalkar C (2022) Study on mechanical properties and delamination factor evaluation of chemically treated urtica dioica fiber reinforced polymer composites. https://doi.org/10.21203/rs.3.rs-1189002/v1

Nandi P, Das D (2023) Eur Polymer J 186:111860

Masłowski M, Aleksieiev A, Miedzianowska J, Strzelec K (2021) Materials 14(7):1616

Prasad L, Kumain A, Patel RV, Yadav A, Winczek J (2022) J Nat Fibers 19(7):2632–2647

Arnott A, Galagedara L, Thomas R, Cheema M, Sobze J-M (2021) The potential of rock dust nanoparticles to improve seed germination and seedling vigor of native species: a review. Sci Total Environ 775:145139

Buss W, Hasemer H, Ferguson S, Borevitz J (2024) Stabilisation of soil organic matter with rock dust partially counteracted by plants. Glob Change Biol 30(1):e17052

Torbati-Fard N, Hosseini SM, Razzaghi-Kashani M (2020) Polym J 52(10):1223–1234

Vuluga Z, Paceagiu J, Iorga M, Coarna M (2015) Rev Rom Mater 45(4):370

Jakubowska P, Borkowski G, Brząkalski D, Sztorch B, Kloziński A, Przekop RE (2022) Materials 15(1):338

Mishagin K, Gotlib E, Yamaleeva E, Sokolova A, Khatsrinov A (2023) E3S web of conferences (Vol. 410, p. 01001). EDP Sciences

Raji M, Nekhlaoui S, El Hassani IEEA, Essassi EM, Essabir H, Rodrigue D, Bouhfid R (2019) Compos B Eng 165:47–54

Setiyawan K, Sugiantoro B, Prabowo NR (2021) Materials Science Forum (Vol. 1029, pp. 65–72). Trans Tech Publications Ltd

Kornev YV, Semenov NA, Vlasov AN, Valiev KK (2021) Journal of Physics: Conference Series (Vol. 1942, No. 1, p. 012031). IOP Publishing

Alshahrani H, Arun Prakash V (2023). Biomass Conv Bioref. https://doi.org/10.1007/s13399-023-04926-y

Prakash VA, Bourchak M, Alshahrani H, Juhany KA (2023) Int J Biol Macromol 127068. https://doi.org/10.1016/j.ijbiomac.2023.127068

Pankaj, Jawalkar C, Kant S (2023) J Nat Fibers 20(1):2135053. https://doi.org/10.1080/15440478.2022.2135053

Kolli M, Dasari SN, Potluri NS, Ramprasad AVS (2023) Aust J Mech Eng 21(1):329–338. https://doi.org/10.1080/14484846.2020.1842299

Xu Z, Long H, Liu Q, Yu H, Zhang X, Hui D (2023) Constr Build Mater 387:131622. https://doi.org/10.1016/j.conbuildmat.2023.131622

BR A, Ghosh D (2023) Influence of nanofiller agglomeration on mechanical properties of nanocomposites: a multiscale study. In AIAA SCITECH 2023 forum (p. 1715). https://doi.org/10.2514/6.2023-1715

Bourchak M, Ajaj R, Khalid M, Juhany KA, VR AP, Alshahrani H (2023) J Vinyl Addit Technol 29(3):448–457. https://doi.org/10.1002/vnl.21990

Surianarayanan P, Balaji N, Balasubramanian K (2023) Biomass conversion and biorefinery 1–14. https://doi.org/10.1007/s13399-023-03882-x

Ben Samuel J, Julyes Jaisingh S, Ramadoss R, Maridurai T (2023) Silicon 15(8):3525–3533. https://doi.org/10.1007/s12633-022-02281-7

Sakthivel SN, Kathuria A, Singh B (2023) Int J Pavement Eng 24(1):2259575. https://doi.org/10.1080/10298436.2023.2259575

Mudoi MP, Sinha S, Parthasarthy V (2022) Carbohyd Polym 296:119937

Alshahrani H, Prakash VA (2022) J Clean Prod 374:133931. https://doi.org/10.1016/j.jclepro.2022.133931

Jagadeesh P, Puttegowda M, ThyavihalliGirijappa YG, Shivanna P, MavinkereRangappa S, Siengchin S (2023). J Vinyl Addit Technol. https://doi.org/10.1002/vnl.22008

Uyanik MC, Erturk AT (2023) In Journal of Physics: Conference Series (Vol. 2549, No. 1, p. 012001). IOP Publishing. DOI https://doi.org/10.1088/1742-6596/2549/1/012001

Mohammed M, Jawad AJAM, Mohammed AM, Oleiwi JK, Adam T, Osman AF, Jaafar M (2023) Polymer testing 108083. https://doi.org/10.1016/j.polymertesting.2023.108083

Eatson JL, Gordon JR, Cegielski P, Giesecke AL, Suckow S, Rao A, ... Buzza DMA (2023) Langmuir 39(17):6006–6017. https://doi.org/10.1021/acs.langmuir.3c00016

Yang C, Pang Y, Li G, Chen Y, Li H (2023) Biomass Convers Bioref 1–14. https://doi.org/10.1007/s13399-023-04124-w

Alshahrani H, Vincent Rethnam AP (2024) Effect of abaca bracts biocarbon volume and infill ratio on mechanical, wear, fatigue and hydrophobic behaviour of acrylonitrile butadiene styrene biocomposites tailored using 3D printing. Fibers Polym. https://doi.org/10.1007/s12221-024-00475-x

Khan MKA, Faisal M, Arun Prakash VR (2024) Damage investigations on natural fiber-epoxy human prosthetic composites toughened using echinoidea spike β-chitin biopolymer. Biomass Conv Bioref. https://doi.org/10.1007/s13399-024-05421-8

Rajadurai A (2016) Thermo-mechanical characterization of siliconized E-glass fiber/hematite particles reinforced epoxy resin hybrid composite. Appl Surf Sci 384:99–106

Alshahrani H, Arun Prakash VR (2024) Characterisation of microcrystalline cellulose from waste green pea pod sheath and its sunn hemp fibre-polyester composite: a step towards greener manufacturing. Physiol Plant 176(1):e14166

Gokilakrishnan GGRVCU et al. (2024) Mechanical, wear, and flammability of chitin-rich endoskeleton of Sepioteuthis Sepioidea powder-dispersed pineapple fiber-reinforced polyester composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-024-05345-3

Kumar JVSP, Kaliappan S, Natrayan L et al (2024) Isolation of biosilica from biomass waste Setaria italica husks and its reinforcement effect on banana fiber-epoxy composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-024-05334-6

Author information

Authors and Affiliations

Contributions

A. Anbuchezian and P. Sumathi: research and manuscript drafting.

Corresponding author

Ethics declarations

Ethics approval

NA.

Consent to participate

Yes.

Consent for publication

Yes.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Anbuchezian, A., Sumathi, P. Effect of adding Urtica dioica–chopped fiber on load bearing, wear, fatigue, thermal stability, flammability, and water absorption behavior of rock dust dispersed vinyl ester composite. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05537-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05537-x