Abstract

Carob fruit (edible part) and carob molasses contains high amount of nutritive components such as minerals (calcium, potassium, phosphorus, iron, etc.), carbohydrates (glucose, fructose and sucrose), polyphenolic compounds with an antioxidant activity and other beneficial components. The carob molasses pulp (CMP) left over from the production of molasses is not utilized properly though it contains important nutritive content such as phytochemicals, antioxidants and especially crude fiber. In this study, dried CMP flour was used instead of wheat flour in the ice cream cone formula. The formulations developed with this finding will make a significant contribution to the increase in the fibre content of ice cream cone. In this study, the chemical (moisture, ash, total sugar, crude fiber, total polyphenol and antioxidant activity) composition of CMP flour and the effects of 5–15% CMP flour addition on physical (crispness and color) and sensory properties (appearance, color, odor, taste, crispness, and overall acceptability) of the cones were investigated. As a result, it is noteworthy that CMP had high crude fiber (29.30%), total phenolic content (3.05% on dry basis) and antioxidant activity (0.91% on dry basis). The results showed that the addition of CMP flour up to 15% into the cone formula reduced L* value, enhanced the desired cacao color and the crispness of cones. The brown color of CMP flour added cones was more appreciated by the panelists significantly. CMP flour addition had no effect on the other sensory properties. Consequently, more nutritious and appreciated cone formulations were developed.

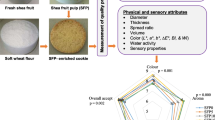

Graphical abstract

Similar content being viewed by others

References

M. Issaoui, G. Flamini, A. Delgado, Sustainability opportunities for mediterranean food products through new formulations based on carob flour (Ceratonia siliqua L.). Sustainability 13, 8026 (2021). https://doi.org/10.3390/su13148026

M.E. Brassesco, T.R.S. Brandao, C.L.M. Silva, M. Pintado, Carob bean (Ceratonia siliqua L.): a new perspective for functional food. Trends Food Sci. Technol. 114, 310–322 (2021). https://doi.org/10.1016/j.tifs.2021.05.037

L. Tounsi, S. Karra, H. Kechaou, N. Kechaou, Processing, physico-chemical and functional properties of carob molasses and powders. Food Meas. 11, 1440–1448 (2017). https://doi.org/10.1007/s11694-017-9523-4

S. Sanli, O. Guneser, S. Kilicarslan, N. Sanli, Screening of eighteen polyphenolic compounds in different carob pekmez by green capillary electrophoresis method. SN Appl. Sci. 2, 576 (2020). https://doi.org/10.1007/s42452-020-2387-y

N. Yaman, S. Durakli Velioglu, Use of attenuated total reflectance-fourier transform infrared (ATR-FTIR) spectroscopy in combination with multivariate methods for the rapid determination of the adulteration of grape, carob and mulberry pekmez. Foods 8, 231 (2019). https://doi.org/10.3390/foods8070231

A. Badem, Z. Alpkent, Production of ice cream with carob bean pekmez (molasses). Int. J. Environ. Agric. Biotechnol. 3(1), 28–32 (2018). https://doi.org/10.22161/ijeab/3.1.5

E. Bytyqi, Production of functional products from fungi belonging to the Basidiomycetes sp. with biotechnological methods. MSc thesis, Akdeniz University Food Engineering Department, Antalya, Turkey, p. 50 (2018)

Y. Ozdemir, B. Oncel, M. Keceli, Purification of crude fiber from carob molasses pulp and uses in traditional Turkish sucuk. Int. J. Gastron. Food Sci. 25, 100410 (2021). https://doi.org/10.1016/j.ijgfs.2021.100410

H. Demirbas, N. Cetinkaya, Determination of chemical composition, in-vitro digestibility, phenolic compounds and antioxidant activity of carob pulp. Manas J. Agric. Vet. Life Sci. 10(2), 103–109 (2020)

S. Ilhan, Production of bakery products added carob (Locust bean). MSc thesis, Mersin University Food Engineering Department, Mersin, Turkey, p. 68 (2013)

D. Rismawati, M.H. Pulungan, N.L. Rahmah, Utilization of corn flour (Zea mays L) as material subtitution for ice cream cone. J. Food Life Sci. 4(1), 24–33 (2020). https://doi.org/10.21776/ub.jfls.2020.004.01.03

M. Austin, Utilization of sunflower (Helianthus annuus L.) seed butter and Manalagi apple (Malus sylvestris Mill.) pomace powder in making waffle cones. Bachelor thesis, Universitas Pelita Harapan, Indonesia, p. 60 (2021)

Shenzhen Oceanpower Industrial Co Ltd, Ice cream cone having health care function. European Patent Application Publication Number: CN1533960A (2004)

M.J. Daniel, A.L. Dodd, And the PDC winner is: KSU’s sweet-tasting and gluten-free waffle cones! Cereal Foods World 55(1), 9–11 (2010)

J. Kigozi, Y. Byaruhanga, A. Kaaya, N. Banadda, Development of the production process for sorghum ice-cream cones. J. Food Technol. 9(6), 143–149 (2011). https://doi.org/10.3923/jftech.2011.143.149

J. Kigozi, Y. Byaruhanga, N. Banadda, A. Kaaya, Characterisation of the physico-chemical properties of selected white sorghum grain and flours for the production of ice cream cones. Open Food Sci. J. 7(1), 23–33 (2013). https://doi.org/10.2174/1874256401307010023

J. Kigozi, N. Banadda, Y. Byaruhanga, A. Kaaya, L. Musoke, Optimization of texture in sorghum ice cream cone production using sensory analysis. Open Food Sci. J. 8, 18–21 (2014). https://doi.org/10.2174/1874256401408010018

J. Kigozi, N. Banadda, Y. Byaruhanga, A. Kaaya, F. Lule, Mathematical modeling of sorghum ice-cream cone texture characteristics using the cone formulation. J. Adv. Food Sci. Technol. 2(2), 71–80 (2015)

J. Kigozi, N. Banadda, Y. Byaruhanga, A. Kaaya, F. Lule, Sorghum ice cream cone texture: correlations between instrumental and sensory analysis. J. Adv. Food Sci. Technol. 3(3), 134–145 (2016)

C. Phuenpipob, D. Thomthong, T. Sakdumrong, Utilization from okara to replace wheat flour in ice-cream cone. Appl. Mech. Mater. 848, 107–110 (2016). https://doi.org/10.4028/www.scientific.net/AMM.848.107

B. Tufan, Evaluation of the effects of legume flour incorporation into wafer sheets. MSc thesis, Middle East Technical University Food Engineering Department, Ankara, Turkey, p. 110 (2018)

M.D. Zanariah, M.H. Nur Zaleqha, M. Lisnurjannah, Utilization of banana peel flour as fibre ingredient in the waffle cones. In: Konvensyen Kebangsaan Kejuruteraan Pertanian dan Makanan, Wisma Tani, Kementerian Pertanian & Industri Asas Tani, Putrajaya, pp. 141–144 (2019)

H. Insiah, M.H. Pulungan, N.L. Rahmah, Ice cream cone product development based on purple sweet potato (Ipomoea batatas L.) (study substituted purple sweet potato flour and baking time). J. Food Life Sci. 4(1), 1–11 (2020). https://doi.org/10.21776/ub.jfls.2020.004.01.01

M.H. Pulungan, E.F.S.M. Santoso, Ice cream cup production using purple sweet potato (Ipomoea batatas L. Poir) as a substitute ingredient. Industria 9(3), 184–194 (2020). https://doi.org/10.21776/ub.industria.2020.009.03.3

Z.M. Dom, N.A.M.Z. Amin, R.K. Basha, Sweet potato peel flour applications in the textural quality of waffle ice cream cone and other food products. Adv. Agric. Food Res. J. 1(2), a0000150 (2020). https://doi.org/10.36877/aafrj.a0000150

R. Charoen, S. Tasana, W. Somprasong, S. Rittisak, W. Saveboworn, Resistant starch from mixed flours (banana, jackfruit seed and job’s tear) and the application in food product. E3S Web Conf. 141, 02004 (2020). https://doi.org/10.1051/e3sconf/202014102004

AACC, International approved methods of analysis. American Association of Cereal Chemists, 11th edn. (AACC International, St. Paul, 2010)

AOAC, Official Methods of Analysis, 15th edn. (Association of Official Analytical Chemist, Washington DC, 1990)

M.K.A. DuBois, Y.K. Gilli, P.A. Hamilton, Colorimetric method for determination of sugars and related substances. Anal. Chem. J. 28, 350–356 (1956). https://doi.org/10.1021/ac60111a017

A. Ben Hsouna, A.S. Alayed, E.M. Abdallah, Evaluation of antimicrobial activities of crude methanolic extract of pods of Ceratonia siliqua L. against some pathogens and spoilage bacteria. Afr. J. Microbiol. Res. 6(14), 3480–3484 (2012). https://doi.org/10.5897/AJMR11.1613

V.L. Singleton, J.A. Rossi, Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 16(3), 144–158 (1965)

W. Brand-Williams, M. Cuvelier, E.C. Berset, Use of a free radical method to evaluate antioxidant activity. Food Sci. Technol. 28, 25–30 (1995). https://doi.org/10.1016/S0023-6438(95)80008-5

A.A.A. Mohamed, R. Jowitt, J.G. Brennan, Instrumental and sensory evaluation of crispness: I—in friable foods. J. Food Eng. 1, 55–75 (1982). https://doi.org/10.1016/0260-8774(82)90013-9

H. Stone, J. Sidel, Sensory evaluation practices, 3rd edn. (Academic Press, 2004), p. 374. https://doi.org/10.1016/B978-0-12-672690-9.X5000-8

Yalım, S. Kaya, Production of high purity sugar syrup from carob bean fruit. PhD thesis, Mersin University Food Engineering Department, Mersin, Turkey, p. 161 (2010)

H.J.F. Zunft, W. Lüder, A. Harde, B. Haber, H.J. Graubaum, C. Koebnick, J. Grünwald, Carob pulp preparation rich in insoluble fibre lowers total and LDL cholesterol in hypercholesterolemic patients. Eur. J. Nutr. 42, 235–242 (2003). https://doi.org/10.1007/s00394-003-0438-y

H. El Batal, A. Hasib, F. Dehbi, N. Zaki, A. Ouatmane, A. Boulli, Assessment of nutritional composition of Carob pulp (Ceratonia Siliqua L.) collected from various locations in Morocco. J. Mater. Environ. Sci 7(9), 3278–3285 (2016)

E. Papaefstathiou, A. Agapiou, S. Giannopoulos, R. Kokkinofta, Nutritional characterization of carobs and traditional carob products. Food Sci. Nutr. (2018). https://doi.org/10.1002/fsn3.776

H. Fidan, N. Petkova, T. Sapoundzhieva, E. Isik Abanoz, Carbohydrate content in Bulgarian and Turkish carob pods and their products. CBU International Conference on Innovations in Science and Education, March 23–25, Prague, Czech Republic, p. 796–802 (2016) https://doi.org/10.12955/cbup.v4.855

A.K. Yousif, H.M. Alghzawi, Processing and characterization of carob powder. Food Chem. 69, 283–287 (2000). https://doi.org/10.1016/S0308-8146(99)00265-4

R.W. Owen, R. Haubner, W.E. Hull, G. Erben, B. Spiegelhalder, H. Bartsch, B. Haber, Isolation and structure elucidation of the major individual polyphenols in carob fibre. Food Chem. Toxicol. 41, 1727–1738 (2003). https://doi.org/10.1016/s0278-6915(03)00200-x

A.M. Requejo Marco, B. Ruiz-Rosa Calvo De Mora, C. Sanjuan Diaz, Natural carob fibre and a procedure for its production. European Patent Application Publication Number: EP0616780 (1996)

V. Goulas, E. Georgiou, Utilization of carob fruit as sources of phenolic compounds with antioxidant potential: Extraction optimization and application in food models. Foods 9(1), 20 (2020). https://doi.org/10.3390/foods9010020

D.P. Makris, P. Kefalas, Carob pods (Ceratonia siliqua L.) as a source of polyphenolic antioxidants. Food Technol. Biotechnol. 42(2), 105–108 (2004)

J. Wang, A. Martínez-Hernández, S. de Lamo-Castellví, M.P. Romero, W. Kaade, M. Ferrando, C. Güell, Low-energy membrane-based processes to concentrate and encapsulate polyphenols from carob pulp. J. Food Eng. 281, 109996 (2020). https://doi.org/10.1016/j.jfoodeng.2020.109996

R. Rodríguez-Solana, J.M. Salgado, E. Pérez-Santín, A. Romano, Effect of carob variety and roasting on the antioxidant capacity, and the phenolic and furanic contents of carob liquors. J. Sci. Food Agric. 99, 2697–2707 (2019). https://doi.org/10.1002/jsfa.9437

I. Boublenza, H.A. Lazouni, L. Ghaffari, K. Ruiz, A.S. Fabiano-Tixier, F. Chemat, Influence of roasting on sensory, antioxidant, aromas, and physicochemical properties of carob pod powder (Ceratonia siliqua L.). J. Food Qual. (2017). https://doi.org/10.1155/2017/4193672

H. Fidan, S. Stankov, N. Petkova, Z. Petkova, A. Iliev, M. Stoyanova, T. Ivanova, N. Zhelyazkov, S. Ibrahim, A. Stoyanova, S. Ercisli, Evaluation of chemical composition, antioxidant potentialand functional properties of carob (Ceratonia siliqua L.) seeds. J. Food Sci. Technol. 57(7), 2404–2413 (2020). https://doi.org/10.1007/s13197-020-04274-z

F. Saci, M.B. Bey, H. Louaileche, L. Gali, C. Bensouici, Changes in anticholinesterase, antioxidant activities and related bioactive compounds of carob pulp (Ceratonia siliqua L.) during ripening stages. J. Food Meas. Charact. 14, 937–945 (2020). https://doi.org/10.1007/s11694-019-00344-9

D.V. Cepo, A. Mornar, B. Nigovic, D. Kremer, D. Radanovic, I.V. Dragojevic, Optimization of roasting conditions as a useful approach for increasing antioxidant activity of carob powder. LWT Food Sci. Technol. 58, 578–586 (2014). https://doi.org/10.1016/j.lwt.2014.04.004

H. Sahin, A. Topuz, M. Pischetsrieder, F. Ozdemir, Effect of roasting process on phenolic, antioxidant and browning properties of carob powder. Eur. Food Res. Technol. 230, 155–161 (2009). https://doi.org/10.1007/s00217-009-1152-7

K.F. Tiefenbacher, The technology of wafers and waffles I: operational aspects, 1st edn. (Academic Press, 2017), p. 712

J.V. Popov-Raljić, J.S. Mastilović, J.G. Laličić-Petronijević, Z.S. Kevrešan, M.A. Demin, Sensory and color properties of dietary cookies with different fiber sources during 180 days of storage. Hemijska Industrija 67(1), 123–134 (2013). https://doi.org/10.2298/HEMIND120327047P

E.E. Babiker, M.M. Ozcan, K. Ghafoor, F.A. Juhaimi, I.A.M. Ahmed, I.A. Almusallam, Physico-chemical and bioactive properties, fatty acids, phenolic compounds, mineral contents, and sensory properties of cookies enriched with carob flour. J. Food Process. Preserv. 44(10), e14745 (2020). https://doi.org/10.1111/jfpp.14745

A. Jain, B.K. Pradhan, P. Mahapatra, S.S. Ray, S. Chakravarty, K. Pal, Development of a low-cost food color monitoring system. Color Res. Appl. 46(2), 430–445 (2021). https://doi.org/10.1002/col.22577

C. Arribas, B. Cabellos, C. Cuadrado, E. Guillamon, M.M. Pedrosa, Cooking effect on the bioactive compounds, texture, and color properties of cold-extruded rice/bean-based pasta supplemented with whole carob fruit. Foods 9, 415 (2020). https://doi.org/10.3390/foods9040415

A. Caglar, N. Erol, M.S. Elgün, Effect of carob flour substitution on chemical and functional properties of Tarhana. J. Food Process Preserv. 37(5), 670–675 (2013). https://doi.org/10.1111/j.1745-4549.2012.00708.x

S. Aydin, Y. Ozdemir, Development and characterization of carob flour based functional spread for increasing use as nutritious snack for children. Hindawi J. Food Qual. (2017). https://doi.org/10.1155/2017/5028150

S. Cakir, Production and quality determination of carob pestil (leather). MSc thesis, Inonu University Graduate School of Natural and Applied Sciences Department of Food Engineering, Malatya, Turkey, p. 63 (2009)

R. Różyło, D. Dziki, U. Gawlik-Dziki, B. Biernacka, M. Wójcik, A. Ziemichód, Physical and antioxidant properties of gluten-free bread enriched with carob fibre. Int. Agrophys. 31, 411–418 (2017). https://doi.org/10.1515/intag-2016-0060

D. Granato, J.C.B. Ribeiro, I.A. Castro, M.L. Masson, Sensory evaluation and physicochemical optimisation of soybased desserts using response surface methodology. Food Chem. 121(3), 899–906 (2010). https://doi.org/10.1016/j.foodchem.2010.01.014

Funding

This research was supported by Toros University and Mersin University. The authors are also grateful to Atışeri (Mersin, Turkey) for supplying carob pulp molasses.

Author information

Authors and Affiliations

Contributions

Conceptualization: YÖ; Data curation: YÖ, ÇÖ; Formal Analysis: ÇÖ, SI; Funding acquisition: YÖ, SI; Investigation: ÇÖ; Methodology: YÖ, SI; Project administration: YÖ; Resources: ÇÖ, SI; Software: ÇÖ; Supervision: YÖ; Validation: SI; Visualization: YÖ, ÇÖ; Writing – original draft: YÖ, ÇÖ, SI; Writing – review & editing: YÖ, ÇÖ.

Corresponding author

Ethics declarations

Conflict of interest

The authors disclose no potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ozdemir, Y., Ozbek, C. & Ilhan, S. Ice cream cone enriched with carob molasses pulp. Food Measure 16, 3782–3791 (2022). https://doi.org/10.1007/s11694-022-01489-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01489-w