Abstract

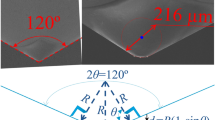

A Rockwell C 120° diamond indenter with a spherical tip radius of 100 µm was used to measure the coefficient of friction by microscratch test under different normal loads. The measured friction coefficient was found to increase with normal load, which was rationalised by a geometrical intersection model. Although plastic deformation increases with normal load, its contribution into the total deformation becomes smaller with the increase in normal load. Elastic deformation predominates in the total deformation under large normal loads. It is the adhesion shear stress over the contact area that causes plastic deformation. Lateral force was found to be proportional to penetration depth, especially under large normal loads when elastic deformation predominated the deformation, with the proportionality representing deformation or shearing resistant toughness.

Similar content being viewed by others

References

Venkataraman, S., Kohlstedt, D.L., Gerberich, W.W.: Microscratch Analysis of the Work of Adhesion for Pt Thin-Films on NiO. J. Mater. Res. 7(5), 1126–1132 (1992). https://doi.org/10.1557/Jmr.1992.1126

Beegan, D., Chowdhury, S., Laugier, M.T.: Comparison between nanoindentation and scratch test hardness (scratch hardness) values of copper thin films on oxidised silicon substrates. Surf. Coat. Technol. 201(12), 5804–5808 (2007). https://doi.org/10.1016/j.surfcoat.2006.10.031

Wredenberg, F., Larsson, P.L.: Scratch testing of metals and polymers: Experiments and numerics. Wear. 266(1–2), 76–83 (2009). https://doi.org/10.1016/j.wear.2008.05.014

Akono, A.T., Randall, N.X., Ulm, F.J.: Experimental determination of the fracture toughness via microscratch tests: Application to polymers, ceramics, and metals. J. Mater. Res. 27(2), 485–493 (2012). https://doi.org/10.1557/jmr.2011.402

Bard, R., Ulm, F.J.: Scratch hardness—strength solutions for cohesive-frictional materials. Int. J. Numer. Anal. Methods Geomech. 36(3), 307–326 (2012)

Miyake, S., Yamazaki, S.: Nanoscratch properties of extremely thin diamond-like carbon films. Wear. 305(1–2), 69–77 (2013). https://doi.org/10.1016/j.wear.2013.05.005

Wang, Z., Zeng, Q., Zheng, J.: Adsorption and Lubricating Behavior of Salivary Pellicle on Dental Ceramic. Lubrication Engineering: (2017)

Burnett, P.J., Rickerby, D.S.: The relationship between hardness and scratch adhession. Thin Solid Films 154(1–2), 403–416 (1987)

Ollendorf, H., Schneider, D.: A comparative study of adhesion-test methods for hard coatings. Surf. Coat. Technol. 113(1–2), 86–102 (1999). https://doi.org/10.1016/S0257-8972(98)00827-5

Matthews, A., Franklin, S., Holmberg, K.: Tribological coatings: contact mechanisms and selection. J. Phys. D 40(18), 5463–5475 (2007). https://doi.org/10.1088/0022-3727/40/18/S07

Bhushan, B., Gupta, B.K., Azarian, M.H.: Nanoindentation, microscratch, friction and wear studies of coatings for contact recording applications. Wear 181(95), 743–758 (1995)

Zhao, X.Z., Bhushan, B.: Material removal mechanisms of single-crystal silicon on nanoscale and at ultralow loads. Wear. 223(1–2), 66–78 (1998). https://doi.org/10.1016/S0043-1648(98)00302-0

Beake, B.D., Goodes, S.R., Shi, B.: Nanomechanical and nanotribological testing of ultra-thin carbon-based and MoST films for increased MEMS durability. J. Phys. D 42(6), 065301 (2009). https://doi.org/10.1088/0022-3727/42/6/065301

Wu, T.W.: Microscratch and Load Relaxation Tests for Ultra-Thin Films. J. Mater. Res. 6(2), 407–426 (1991). https://doi.org/10.1557/Jmr.1991.0407

Burnett, P.J., Rickerby, D.S.: The scratch adhesion test—an elastic–plastic indentation analysis. Thin Solid Films. 157(2), 233–254 (1988). https://doi.org/10.1016/0040-6090(88)90006-5

Sekler, J., Steinmann, P.A., Hintermann, H.E.: The scratch test - different critical load determination techniques. Surf. Coat. Technol. 36(1–2), 519–529 (1988). https://doi.org/10.1016/0257-8972(88)90179-X

Andriy, K., Yury, G., Vladislav, D., Ali, E.: Phase transformations in silicon under dry and lubricated sliding. Tribol. Trans. 45(3), 372–380 (2002)

Charitidis, C., Logothetidis, S., Gioti, M.: A comparative study of the nanoscratching behavior of amorphous carbon films grown under various deposition conditions. Surf. Coat. Technol. 125(1–3), 201–206 (2000). https://doi.org/10.1016/S0257-8972(99)00546-0

Huang, L.Y., Xu, K.W., Lu, J.: Evaluation of scratch resistance of diamond-like carbon films on Ti alloy substrate by nano-scratch technique. Diam. Relat. Mater. 11(8), 1505–1510 (2002). https://doi.org/10.1016/S0925-9635(02)00054-7

Meng, B.B., Zhang, Y., Zhang, F.H.: Material removal mechanism of 6H-SiC studied by nano-scratching with Berkovich indenter. Appl. Phys. A. 122(3), 247 (2016). https://doi.org/10.1007/s00339-016-9802-7

AlMotasem, A.T., Bergstrom, J., Gaard, A., Krakhmalev, P., Holleboom, L.J.: Atomistic insights on the wear/friction behavior of nanocrystalline ferrite during nanoscratching as revealed by molecular dynamics. Tribol. Lett. 65(3), 101 (2017). https://doi.org/10.1007/s11249-017-0876-y

Diez-Ibarbia, A., Fernandez-Del-Rincon, A., Garcia, P., De-Juan, A., Iglesias, M., Viadero, F.: Assessment of load dependent friction coefficients and their influence on spur gears efficiency. Meccanica(3), 1–21 (2017)

Zhang, H.D., Takeuchi, Y., Chong, W.W.F., Mitsuya, Y., Fukuzawa, K., Itoh, S.: Simultaneous in situ measurements of contact behavior and friction to understand the mechanism of lubrication with nanometer-thick liquid lubricant films. Tribol. Int. 127, 138–146 (2018). https://doi.org/10.1016/j.triboint.2018.05.043

Wang, J., Ma, L., Li, W., Zhou, Z.R.: Influence of different lubricating fluids on friction trauma of small intestine during enteroscopy. Tribol. Int. 126, 29–38 (2018). https://doi.org/10.1016/j.triboint.2018.05.002

Sterner, O., Aeschlimann, R., Zurcher, S., Scales, C., Riederer, D., Spencer, N.D., Tosatti, S.G.P.: Tribological classification of contact lenses: From coefficient of friction to sliding work. Tribol. Lett. 63(1), 9 (2016). https://doi.org/10.1007/s11249-016-0696-5

Zhang, S., Zeng, X., Igartua, A., Rodriguez-Vidal, E., van der Heide, E.: Texture design for reducing tactile friction independent of sliding orientation on stainless steel sheet. Tribol. Lett. 65(3), 89 (2017). https://doi.org/10.1007/s11249-017-0869-x

Lu, P., Wood, R.J.K., Gee, M.G., Wang, L., Pfleging, W.: A novel surface texture shape for directional friction control. Tribol. Lett. 66(1), 51 (2018). https://doi.org/10.1007/s11249-018-0995-0

Szlufarska, I., Chandross, M., Carpick, R.W.: TOPICAL REVIEW: Recent advances in single-asperity nanotribology. J. Phys. D 41(12), 1854–1862 (2008)

Udaykant Jadav, P., Amali, R., Adetoro, O.B.: Analytical friction model for sliding bodies with coupled longitudinal and transverse vibration. Tribol. Int. 126, 240–248 (2018). https://doi.org/10.1016/j.triboint.2018.04.018

Li, S., Li, Q., Carpick, R.W., Gumbsch, P., Liu, X.Z., Ding, X., Sun, J., Li, J.: The evolving quality of frictional contact with graphene. Nature. 539(7630), 541–545 (2016). https://doi.org/10.1038/nature20135

Saravanan, P., Selyanchyn, R., Watanabe, M., Fujikawa, S., Tanaka, H., Lyth, S.M., Sugimura, J.: Ultra-low friction of polyethylenimine / molybdenum disulfide (PEI/MoS2)15 thin films in dry nitrogen atmosphere and the effect of heat treatment. Tribol. Int. 127, 255–263 (2018). https://doi.org/10.1016/j.triboint.2018.06.003

Westlund, V., Heinrichs, J., Jacobson, S.: On the role of material transfer in friction between metals: initial phenomena and effects of roughness and boundary lubrication in sliding between aluminium and tool steels. Tribol. Lett. 66(3), 97 (2018). https://doi.org/10.1007/s11249-018-1048-4

Lee, C., Li, Q., Kalb, W., Liu, X.Z., Berger, H., Carpick, R.W., Hone, J.: Frictional characteristics of atomically thin sheets. Science. 328(5974), 76–80 (2010). https://doi.org/10.1126/science.1184167

Gabriel, P., Thomas, A.G., Busfield, J.J.C.: Influence of interface geometry on rubber friction. Wear. 268(5–6), 747–750 (2010). https://doi.org/10.1016/j.wear.2009.11.019

Ben-David, O., Fineberg, J.: Static Friction Coefficient Is Not a Material Constant. Phys. Rev. Lett. 106(25), 254301 (2011)

Zhou, C.J., Hu, B., Qian, X.L., Han, X.: A novel prediction method for gear friction coefficients based on a computational inverse technique. Tribol. Int. 127, 200–208 (2018). https://doi.org/10.1016/j.triboint.2018.06.005

Maegawa, S., Itoigawa, F., Nakamura, T.: Effect of normal load on friction coefficient for sliding contact between rough rubber surface and rigid smooth plane. Tribol. Int. 92, 335–343 (2015). https://doi.org/10.1016/j.triboint.2015.07.014

Yamaguchi, T., Sugawara, T., Takahashi, M., Shibata, K., Moriyasu, K., Nishiwaki, T., Hokkirigawa, K.: Effect of porosity and normal load on dry sliding friction of polymer foam blocks. Tribol. Lett. 66(1), 34 (2018). https://doi.org/10.1007/s11249-018-0988-z

Yamaguchi, T., Sugawara, T., Takahashi, M., Shibata, K., Moriyasu, K., Nishiwaki, T., Hokkirigawa, K.: Dry sliding friction of ethylene vinyl acetate blocks: Effect of the porosity. Tribol. Int. 116, 264–271 (2017). https://doi.org/10.1016/j.triboint.2017.07.022

Maegawa, S., Itoigawa, F., Nakamura, T.: A role of friction-induced torque in sliding friction of rubber materials. Tribol. Int. 93, 182–189 (2016). https://doi.org/10.1016/j.triboint.2015.08.030

Scheibert, J., Dysthe, D.K.: Role of friction-induced torque in stick-slip motion. EPL. 92(5), 620–622 (2010). https://doi.org/10.1209/0295-5075/92/54001

Mcadams, S.D., Tsui, T.Y., Oliver, W.C., Pharr, G.M.: Effects of interlayers on the scratch adhesion performance of ultra-thin films of copper and gold on silicon substrates. MRS Online Proc. Libr. Arch. (1994). https://doi.org/10.1557/PROC-356-809

Scharf, T.W., Barnard, J.A.: Nanotribology of ultrathin a: SiC/SiC-N overcoats using a depth sensing nanoindentation multiple sliding technique. Thin Solid Films. 308(1), 340–344 (1997). https://doi.org/10.1016/S0040-6090(97)00568-3

Li, K.J., Ni, B.Y.H., Li, J.C.M.: Stick-slip in the scratching of styrene-acrylonitrile copolymer. J. Mater. Res. 11(6), 1574–1580 (1996). https://doi.org/10.1557/Jmr.1996.0197

Gao, C.H., Liu, M.: Characterization of spherical indenter with fused silica under small deformation by Hertzian relation and Oliver and Pharr’s method. Vacuum. 153, 82–90 (2018). https://doi.org/10.1016/j.vacuum.2018.03.061

Field, J.S., Swain, M.V.: A simple predictive model for spherical indentation. J. Mater. Res. 8(2), 297–306 (1993). https://doi.org/10.1557/Jmr.1993.0297

Gao, C.H., Yao, L.G., Liu, M.: Berkovich nanoindentation of borosilicate K9 glass. Opt. Eng. 57(3) (2018). https://doi.org/10.1117/1.Oe.57.3.034104

Zhao, G.F., Liu, M., An, Z.N., Ren, Y., Liaw, P.K., Yang, F.Q.: Electromechanical responses of Cu strips. J. Appl. Phys. 113(18) (2013). https://doi.org/10.1063/1.4804938

Beake, B.D., Liskiewicz, T.W., Smith, J.F.: Deformation of Si(100) in spherical contacts—comparison of nano-fretting and nano-scratch tests with nano-indentation. Surf. Coat. Technol. 206(7), 1921–1926 (2011)

Belak, J.: Nanotribology: modeling atoms when surfaces collide-energy and technology review. Energy Technol. Rev. (1994)

Bowden, F.P., Tabor, D.: The friction and lubrication of solids. Clarendon, Oxford (1950)

Carreon, A.H., Funkenbusch, P.D.: Material specific nanoscratch ploughing friction coefficient. Tribol. Int. 126, 363–375 (2018). https://doi.org/10.1016/j.triboint.2018.05.027

Benjamin, P., Weaver, C.: Measurement of Adhesion of thin films. Proc. Royal Soc. Lond. 254(1277), 163–176 (1960)

Laugier, M.T.: An energy approach to the adhesion of coatings using the scratch test. Thin Solid Films. 117(4), 243–249 (1984). https://doi.org/10.1016/0040-6090(84)90354-7

Laugier, M.T.: Adhesion of Tic and Tin coatings prepared by chemical vapor-deposition on Wc-Co-based cemented carbides. J. Mater. Sci. 21(7), 2269–2272 (1986). https://doi.org/10.1007/Bf01114266

Beegan, D., Chowdhury, S., Laugier, M.T.: A nanoindentation study of copper films on oxidised silicon substrates. Surf. Coat. Technol. 176(1), 124–130 (2003). https://doi.org/10.1016/S0257-8972(03)00774-6

Liu, M.: Finite element analysis of large contact deformation of an elastic–plastic sinusoidal asperity and a rigid flat. Int. J. Solids Struct. 51(21–22), 3642–3652 (2014). https://doi.org/10.1016/j.ijsolstr.2014.06.026

Liu, M., Proudhon, H.: Finite element analysis of contact deformation regimes of an elastic-power plastic hardening sinusoidal asperity. Mech. Mater. 103, 78–86 (2016). https://doi.org/10.1016/j.mechmat.2016.08.015

Zok, F.W., Miserez, A.: Property maps for abrasion resistance of materials. Acta Mater. 55(18), 6365–6371 (2007). https://doi.org/10.1016/j.actamat.2007.07.042

Shih, M.H., Yu, C.Y., Kao, P.W., Chang, C.P.: Microstructure and flow stress of copper deformed to large plastic strains. Scripta Mater. 45(7), 793–799 (2001)

Barenblatt, G.I.: The mathematical theory of equilibrium cracks in brittle fracture. Adv. Appl. Mech. 7, 55–129 (1962)

Akono, A.T., Reis, P.M., Ulm, F.J.: Scratching as a fracture process: from butter to steel. Phys. Rev. Lett. 106(20), 204302 (2011). https://doi.org/10.1103/PhysRevLett.106.204302

Akono, A.T., Ulm, F.J.: Fracture scaling relations for scratch tests of axisymmetric shape. J. Mech. Phys. Solids. 60(3), 379–390 (2012). https://doi.org/10.1016/j.jmps.2011.12.009

Akono, A.T., Ulm, F.J.: Scratch test model for the determination of fracture toughness. Eng. Fract. Mech. 78(2), 334–342 (2011). https://doi.org/10.1016/j.engfracmech.2010.09.017

Singh, A., Tang, L., Dao, M., Lu, L., Suresh, S.: Fracture toughness and fatigue crack growth characteristics of nanotwinned copper. Acta Mater. 59(6), 2437–2446 (2011). https://doi.org/10.1016/j.actamat.2010.12.043

Acknowledgements

This project is supported by National Natural Science Foundation of China (Grant Nos. 51705082 and 51875106) and Fujian Provincial Collaborative Innovation Center for High-end Equipment Manufacturing (No. 0020-50006103). M. Liu is also grateful for the support from Fujian Provincial Minjiang Scholar Program (N0. 0020-510486).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, C., Liu, M. Effects of Normal Load on the Coefficient of Friction by Microscratch Test of Copper with a Spherical Indenter. Tribol Lett 67, 8 (2019). https://doi.org/10.1007/s11249-018-1124-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1124-9