Abstract

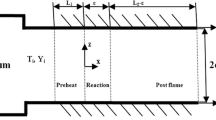

In this study, an analytical investigation of heat and mass transfer in a planar micro-combustor with considering the detailed reaction mechanisms for a methane/air mixture is presented. The primary objective is to propose practical solutions to manage both heat and mass transfer, which are critical problems in micro-combustors. The reactive mixture is divided into pre-flame, reaction, and post-flame zones. Then, the partial differential equations of energy and species are analytically solved in each zone with regard to the detailed reaction mechanisms and matching conditions. Moreover, to make a general investigation, appropriate non-dimensional physical parameters are proposed considering interactions between reactive mixture, solid structure, and ambient. As a result, proper correlations are proposed for the wall temperature distribution under different conditions that can be suitable for the relative numerical simulations. It is shown that a maximum decrease of 45% occurs for the gas temperature at the post-flame zone when flow Peclet number is reduced by 50%. Furthermore, by increasing the solid–fluid thermal diffusion ratio from 50 to 100 and 100 to 200, the CO conversion rate is decreased around 77% and 16%, respectively.

Similar content being viewed by others

Abbreviations

- A :

-

Frequency factor, (cm3 mol−1 s−1)

- \(A_{\text{m}}\) :

-

Matching condition coefficients

- \(A_{\text{n}}\) :

-

Boundary condition coefficients

- Bi:

-

Biot number

- \(C_{\text{p}}\) :

-

Constant pressure specific heat, (J kg−1 K−1)

- D s :

-

Mass diffusivity of species, (m2 s−1)

- d :

-

Half of distance between parallel plates, (m)

- E :

-

Activation energy, (J mol−1)

- H :

-

Enthalpy of reaction, (J m−3)

- h :

-

External heat transfer coefficient (W m−2 K−1)

- IETR:

-

Internal–external thermal resistance

- k :

-

Thermal conductivity, (W m−1 K−1)

- Pe:

-

Flow Peclet number

- Pem :

-

Mass Peclet number

- R :

-

Global gas constant, (J mol−1 K−1)

- SFTDR:

-

Solid–fluid thermal diffusion ratio

- \(S_{\text{T}}\) :

-

Normalized source term of energy equation

- T :

-

Temperature, (K)

- T a :

-

Adiabatic flame temperature, (K)

- \(t_{\text{w}}\) :

-

Wall thickness, (m)

- U :

-

x-direction velocity, (m s−1)

- X :

-

Normalized axial coordinate

- x :

-

Axial coordinate, (m)

- y :

-

Mole fraction

- Z :

-

Normalized perpendicular coordinate

- z :

-

Perpendicular coordinate, (m)

- \(\alpha\) :

-

Thermal diffusivity, (m2 s−1)

- \(\delta\) :

-

Normalized reaction zone thickness

- \(\varepsilon\) :

-

Reaction zone thickness, (m)

- \(\theta\) :

-

Normalized temperature

- ξ :

-

Internal–external thermal resistance

- \(\rho\) :

-

Density, (kg m−3)

- \(\tau\) :

-

Solid–fluid thermal diffusion ratio

- \(\omega_{\text{r}}\) :

-

Net rate of each reaction, (s−1)

- \(\omega_{\text{s}}\) :

-

Net production rate of species, (s−1)

- g :

-

Gas mixture

- i :

-

Inlet

- pre:

-

Pre-flame zone

- post:

-

Post-flame zone

- react:

-

Reaction zone

- w :

-

Wall

References

Zhang S, Zhang Y, Chen J, Yin C, Liu X. Design, fabrication and performance evaluation of an integrated reformed methanol fuel cell for portable use. J Power Sources. 2018;389:37–49.

Aravind B, Khandelwal B, Kumar S. Experimental investigations on a new high intensity dual microcombustor based thermoelectric micropower generator. Appl Energy. 2018;228:1173–81.

Veni K, Sultan M, Ali M. Micro-scale energy harvesting devices: review of methodological performances in the last decade. Renew Sustain Energy Rev. 2016;54:1035–47. https://doi.org/10.1016/j.rser.2015.10.046.

Mustafa KF, Abdullah S, Abdullah MZ, Sopian K. A review of combustion-driven thermoelectric (TE) and thermophotovoltaic (TPV) power systems. Renew Sustain Energy Rev. 2017;71:572–84.

Asadollahi A, Rashidi S, Mohamad AA. Removal of the liquid from a micro-object and controlling the surface wettability by using a rotating shell—numerical simulation by Lattice–Boltzmann method. J Mol Liq. 2018;272:645–55.

Elliott A, Torabi M, Karimi N. Thermodynamics analyses of porous microchannels with asymmetric thick walls and exothermicity: an entropic model of microreactors. J Therm Sci Eng Appl. 2017;9:041013.

Li H, Chen Y, Yan Y, Hu C, Fan H, Feng S. Numerical study on heat transfer enhanced in a microcombustor with staggered cylindrical array for micro-thermophotovoltaic system. J Energy Resour Technol. 2019;140:112204.

Aravind B, Raghuram GKS, Kishore VR, Kumar S. Compact design of planar stepped micro combustor for portable thermoelectric power generation. Energy Convers Manag. 2018;156:224–34. https://doi.org/10.1016/j.enconman.2017.11.021.

Chen J, Gao X, Yan L, Xu D. Millisecond methane steam reforming for hydrogen production: a computational fluid dynamics study. Int J Hydrog Energy. 2018;43:12948–69.

Roychowdhury S, Sundararajan T, Das SK. Conjugate heat transfer studies on steam reforming of ethanol in micro-channel systems. Int J Heat Mass Transf. 2019;139:660–74.

Chen J, Song W, Xu D. Thermal management in catalytic heat-recirculating micro-combustors: a computational fluid dynamics study. Appl Therm Eng. 2019;160:114073.

Kolb G, Keller S, Tiemann D, Schelhaas K-P, Schürer J, Wiborg O. Design and operation of a compact microchannel 5 kWel,net methanol steam reformer with novel Pt/In2O3 catalyst for fuel cell applications. Chem Eng J. 2012;208:388–402. https://doi.org/10.1016/j.cej.2012.06.141.

Iranshahi D, Saeedi R, Azizi K, Nategh M. A novel integrated thermally coupled moving bed reactors for naphtha reforming process with hydrodealkylation of toluene. Appl Therm Eng. 2017;112:1040–56.

Schoegl I, Newcomb SR, Ellzey JL. Ultra-rich combustion in parallel channels to produce hydrogen-rich syngas from propane. Int J Hydrog Energy. 2009;34:5152–63.

Dubey AK, Tezuka T, Hasegawa S, Nakamura H, Maruta K. Analysis of kinetic models for rich to ultra-rich premixed CH4/air weak flames using a micro flow reactor with a controlled temperature profile. Combust Flame. 2019;206:68–82.

Onda T, Nakamura H, Tezuka T, Hasegawa S, Maruta K. Initial-stage reaction of methane examined by optical measurements of weak flames in a micro flow reactor with a controlled temperature profile. Combust Flame. 2019;206:292–307.

Wang S, Li L, Fan A. Suppression of flame instability by a short catalytic segment on the wall of a micro channel with a prescribed wall temperature profile. Fuel. 2018;234:1329–36. https://doi.org/10.1016/j.fuel.2018.08.025.

Nakamura H, Fan A, Minaev S, Sereshchenko E, Fursenko R, Tsuboi Y, et al. Bifurcations and negative propagation speeds of methane/air premixed flames with repetitive extinction and ignition in a heated microchannel. Combust Flame. 2012;159:1631–43.

Maruta K, Kataoka T, Kim N, Minaev S, Fursenko R. Characteristics of combustion in a narrow channel with a temperature gradient. Proc Combust Inst. 2005;30(II):2429–36. https://doi.org/10.1016/j.proci.2004.08.245.

Miyata E, Fukushima N, Naka Y, Shimura M, Tanahashi M, Miyauchi T. Direct numerical simulation of micro combustion in a narrow circular channel with a detailed kinetic mechanism. Proc Combust Inst. 2015;35:3421–7. https://doi.org/10.1016/j.proci.2014.07.057.

Nair A, Kishore VR, Kumar S. Dynamics of premixed hydrogen-air flames in microchannels with a wall temperature gradient. Combust Sci Technol. 2015;187:1620–37.

Kishore VR, Minaev S, Akram M, Kumar S. Dynamics of premixed methane/air mixtures in a heated microchannel with different wall temperature gradients. RSC Adv. 2017;7:2066–73.

Kurdyumov VN, Pizza G, Frouzakis CE, Mantzaras J. Dynamics of premixed flames in a narrow channel with a step-wise wall temperature. Combust Flame. 2009;156:2190–200. https://doi.org/10.1016/j.combustflame.2009.08.001.

Wang Y, Yang W, Zhou J, Yang H, Yao Y, Cen K. Heterogeneous reaction characteristics and their effects on homogeneous combustion of methane/air mixture in micro channels I. Thermal analysis. Fuel. 2018;234:20–9. https://doi.org/10.1016/j.fuel.2018.07.004.

Fanaee SA, Esfahani JA. Two-dimensional analytical model of flame characteristic in catalytic micro-combustors for a hydrogen-air mixture. Int J Hydrog Energy. 2014;39:4600–10.

Kang X, Gollan RJ, Jacobs PA, Veeraragavan A. Numerical study of the effect of wall temperature profiles on the premixed methane-air flame dynamics in a narrow channel. RSC Adv. 2017;7:39940–54.

Fanaee SA. Self-similar nonasymptotic solution of multireaction stationary flow in catalytic microcombustor. J Thermophys Heat Transf. 2018;32:560–9.

Saeed A, Karimi N, Hunt G, Torabi M. On the influences of surface heat release and thermal radiation upon transport in catalytic porous microreactors—a novel porous-solid interface model. Chem Eng Process. 2019;143:107602.

Hunt G, Torabi M, Govone L, Karimi N, Mehdizadeh A. Two-dimensional heat and mass transfer and thermodynamic analyses of porous microreactors with Soret and thermal radiation effects—an analytical approach. Chem Eng Process. 2018;126:190–205.

Guthrie DGP, Torabi M, Karimi N. Energetic and entropic analyses of double-diffusive, forced convection heat and mass transfer in microreactors assisted with nanofluid. J Therm Anal Calorim. 2019;137:637–58.

Saeed A, Karimi N, Hunt G, Torabi M, Mehdizadeh A. Double-diffusive transport and thermodynamic analysis of a magnetic microreactor with non-Newtonian biofuel flow. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08629-3.

Hunt G, Karimi N, Torabi M. Two-dimensional analytical investigation of coupled heat and mass transfer and entropy generation in a porous, catalytic microreactor. Int J Heat Mass Transf. 2018;119:372–91. https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.118.

Guthrie DGP, Torabi M, Karimi N. Combined heat and mass transfer analyses in catalytic microreactors partially filled with porous material—the influences of nanofluid and different porous-fluid interface models. Int J Therm Sci. 2019;140:96–113.

Govone L, Torabi M, Wang L, Karimi N. Effects of nanofluid and radiative heat transfer on the double-diffusive forced convection in microreactors. J Therm Anal Calorim. 2019;135:45–59.

Veeraragavan A, Cadou CP. Flame speed predictions in planar micro/mesoscale combustors with conjugate heat transfer. Combust Flame. 2011;158:2178–87. https://doi.org/10.1016/j.combustflame.2011.04.006.

Veeraragavan A, Cadou C. Theoretical study of conjugate heat transfer effects on temperature profiles in parallel flow with embedded heat sources. Int J Heat Mass Transf. 2010;53:1699–711.

Pourali M, Esfahani JA, Fanaee SA. Two-dimensional analytical investigation of conjugate heat transfer in a finite-length planar micro-combustor for a hydrogen-air mixture. Int J Hydrog Energy. 2019;44:12176–87.

Schoegl I, Sauer VM, Sharma P. Predicting combustion characteristics in externally heated micro-tubes. Combust Flame. 2019;204:33–48.

Goodwin DG, Speth RL, Moffat HK. Cantera: an object-oriented software toolkit for chemical kinetics, thermodynamics, and transport processes, Version 2.4.0. 2018. Available from https://www.cantera.org. https://doi.org/10.5281/zenodo.1174508.

Tang A, Xu Y, Shan C, Pan J, Liu Y. A comparative study on combustion characteristics of methane, propane and hydrogen fuels in a micro-combustor. Int J Hydrog Energy. 2015;40:16587–96.

Acknowledgements

This work was supported by the Brain Pool Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (NRF-2019H1D3A2A01102198).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pourali, M., Abolfazli Esfahani, J., Fanaee, S.A. et al. Developing mathematical modeling of the heat and mass transfer in a planar micro-combustor with detailed reaction mechanisms. J Therm Anal Calorim 143, 2679–2694 (2021). https://doi.org/10.1007/s10973-020-09623-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09623-w