Abstract

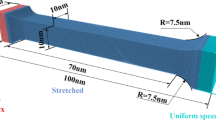

The aim of the current research was to explore the influence of bismuth (Bi) nanoparticles on the single-crystal iron (Fe) nano-cutting process using molecular dynamics (MD) simulations. The existence of Bi nanoparticles in the workpiece affected the variation of cutting force, Von_mises stress distribution and dislocation generation during nano-cutting process. Thus, based on the study of one nanoparticle presence in this paper, the influences of different cutting depths and nanoparticle distribution were also considered separately. The results demonstrated that when the tool cut through Bi nanoparticles, the cutting force and Von_mises stress in the cutting zone were both decreased owing to the smaller hardness of Bi nanoparticles than Fe substrate and the nanoparticles undergo deformation. Dislocation Analysis (DXA) analysis revealed that the presence of Bi soft nanoparticles hindered the dislocation generation, which is unlike the presence of hard nanoparticles, and the BCC Defect Analysis (BDA) analysis showed dislocations, twins and vacancy defects in the workpiece. In addition, the cutting force, workpiece temperature and Von_mises stress increased with the cutting depth, yet the cutting force still decreased when the tool cut through the upper surface of the Bi nanoparticles without contacting the Bi nanoparticles, which was caused by the deformation of Bi nanoparticles under the stress of the shear deformation zone. When two Bi nanoparticles were present in the Fe matrix, the second Bi nanoparticle impedes the movements of the generated dislocations and the cutting force would be reduced when the tool cut over two nanoparticles. This research contributes to understanding the role of Bi nanoparticles in free-cutting steels from the nano perspective.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author on request.

References

Y.N. Wang, Y.P. Bao, M. Wang, L.C. Zhang, Precipitation and control of BN inclusions in 42CrMo steel and their effect on machinability. Int. J. Miner. Metall. Mater. (2013). https://doi.org/10.1007/s12613-013-0805-5

T. Akasawa, H. Sakurai, M. Nakamura, T. Tanaka, K. Takano, Effects of free-cutting additives on the machinability of austenitic stainless steels. J. Mater. Process. Technol. (2003). https://doi.org/10.1016/S0924-0136(03)00321-2

Y. Li, T. Suzuki, N. Tang, Y. Koizumi, A. Chiba, Microstructure evolution of SUS303 free-cutting steel during hot compression process. Mater. Sci. Eng. A. (2013). https://doi.org/10.1016/j.msea.2013.06.069

N. Ånmark, A. Karasev, P.G. Jönsson, The effect of different non-metallic inclusions on the machinability of steels. Materials (Basel). (2015). https://doi.org/10.3390/ma8020751

Z. Li, D. Wu, W. Lv, Low environmental impact machining processes of free cutting austenitic stainless steels without lead addition. Adv. Mater. Res. (2012). https://doi.org/10.4028/www.scientific.net/AMR.512-515.1923

J. Yu Liu, C. Song Liu, R. Juan Bai, W. Wang, Q. Bo Wang, H. Zhang, H. Wei Ni, Morphological transformation of elongated MnS inclusions in non-quenched and tempered steel during isothermal heating. J. Iron Steel Res. Int. (2023). https://doi.org/10.1007/s42243-022-00829-w

S. Guei Lin, H. Hua Yang, Y. Hao Su, K. Ling Chang, C. Han Yang, S. Kang Lin, CALPHAD-assisted morphology control of manganese sulfide inclusions in free-cutting steels. J. Alloys Compd. (2019). https://doi.org/10.1016/j.jallcom.2018.11.290

N. Liu, J. Xie, P. Shen, X. Xu, J. Fu, In-situ study of microstructures and sulphides and machinability of Bi-bearing free-cutting steels, Ironmak. Steelmak. (2023). https://doi.org/10.1080/03019233.2022.2108245

Z. Li, D. Wu, Effect of free-cutting additives on machining characteristics of austenitic stainless steels. J. Mater. Sci. Technol. (2010). https://doi.org/10.1016/S1005-0302(10)60134-X

J. Bo Xie, T. Fan, Z. Qi Zeng, H. Sun, J. Xun Fu, Bi-sulfide existence in 0Cr18Ni9 steel: correlation with machinability and mechanical properties. J. Mater. Res. Technol. (2020). https://doi.org/10.1016/j.jmrt.2020.06.043

X. Wang, H. Zhang, J. Wang, R. Zhu, Y. Zhu, F. Lu, J. Li, Z. Jiang, Effect of bismuth and telluride on the inclusions of sulfur free-cutting steel. Metals (Basel). (2023). https://doi.org/10.3390/met13030486

X. Kong, W. Wang, M. Wang, L. Yang, Influence of temperature on the cutting performance of single-crystal beryllium: a molecular dynamics simulation investigation. Appl. Phys. A Mater. Sci. Process. (2021). https://doi.org/10.1007/s00339-021-04943-6

P.M. Agrawal, L.M. Raff, S. Bukkapatnam, R. Komanduri, Molecular dynamics investigations on polishing of a silicon wafer with a diamond abrasive. Appl. Phys. A Mater. Sci. Process. (2010). https://doi.org/10.1007/s00339-010-5570-y

H. Dai, G. Chen, Q. Fang, J. Yin, The effect of tool geometry on subsurface damage and material removal in nanometric cutting single-crystal silicon by a molecular dynamics simulation. Appl. Phys. A Mater. Sci. Process. (2016). https://doi.org/10.1007/s00339-016-0319-x

Y. Wang, F. Wang, Z. Qi, Y. Wang, W. Yu, Thermal behavior of Bi-Ni core-shell nanoparticles with different Ni shell thicknesses: a molecular dynamics study. Comput. Mater. Sci. (2022). https://doi.org/10.1016/j.commatsci.2022.111557

Y. Wang, F. Wang, W. Yu, Y. Wang, Z. Qi, Y. Wang, Effects of pressure on volatilisation of pure Bi nanoparticles and Bi–Fe core–shell nanoparticles during continuous heating: a molecular dynamics study. Mol. Phys. (2022). https://doi.org/10.1080/00268976.2022.2121232

A. Sharma, D. Datta, R. Balasubramaniam, A molecular dynamics simulation of wear mechanism of diamond tool in nanoscale cutting of copper beryllium. Int. J. Adv. Manuf. Technol. (2019). https://doi.org/10.1007/s00170-018-03246-0

F. Xu, F. Fang, X. Zhang, Hard particle effect on surface generation in nano-cutting. Appl. Surf. Sci. (2017). https://doi.org/10.1016/j.apsusc.2017.07.089

P. Zhao, Q. Zhang, Y. Guo, H. Liu, Z. Deng, Atomistic simulation study of nanoparticle effect on nano-cutting mechanisms of single-crystalline materials. Micromachines. (2020). https://doi.org/10.3390/mi11030265

M. Wang, F. Wang, J. Zhang, H. Wang, Y. Wang, H. Wu, Effects of h-BN additives on tensile mechanical behavior of Fe matrix: a molecular dynamics study. Comput. Mater. Sci. 223, 112136 (2023). https://doi.org/10.1016/j.commatsci.2023.112136

N. Vu-Bac, T. Lahmer, H. Keitel, J. Zhao, X. Zhuang, T. Rabczuk, Stochastic predictions of bulk properties of amorphous polyethylene based on molecular dynamics simulations. Mech. Mater. (2014). https://doi.org/10.1016/j.mechmat.2013.07.021

N. Vu-Bac, P.M.A. Areias, T. Rabczuk, A multiscale multisurface constitutive model for the thermo-plastic behavior of polyethylene. Polymer (Guildf). (2016). https://doi.org/10.1016/j.polymer.2016.10.039

N. Vu-Bac, M.A. Bessa, T. Rabczuk, W.K. Liu, A multiscale model for the quasi-static thermo-plastic behavior of highly cross-linked glassy polymers. Macromolecules (2015). https://doi.org/10.1021/acs.macromol.5b01236

M.B. Cai, X.P. Li, M. Rahman, Study of the temperature and stress in nanoscale ductile mode cutting of silicon using molecular dynamics simulation. J. Mater. Process. Technol. (2007). https://doi.org/10.1016/j.jmatprotec.2007.04.028

F. Shimizu, S. Ogata, J. Li, Theory of shear banding in metallic glasses and molecular dynamics calculations. Mater. Trans. (2007). https://doi.org/10.2320/matertrans.MJ200769

A.P. Thompson, H.M. Aktulga, R. Berger, D.S. Bolintineanu, W.M. Brown, P.S. Crozier, P.J. in’t Veld, A. Kohlmeyer, S.G. Moore, T.D. Nguyen, R. Shan, M.J. Stevens, J. Tranchida, C. Trott, S.J. Plimpton, LAMMPS—a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. (2022). https://doi.org/10.1016/j.cpc.2021.108171

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model. Simul. Mater. Sci. Eng. (2010). https://doi.org/10.1088/0965-0393/18/1/015012

P. Hirel, Atomsk: a tool for manipulating and converting atomic data files. Comput. Phys. Commun. (2015). https://doi.org/10.1016/j.cpc.2015.07.012

M.I. Mendelev, S. Han, D.J. Srolovitz, G.J. Ackland, D.Y. Sun, M. Asta, Development of new interatomic potentials appropriate for crystalline and liquid iron. Philos. Mag. (2003). https://doi.org/10.1080/14786430310001613264

H. Zhou, D.E. Dickel, M.I. Baskes, S. Mun, M.A. Zaeem, A modified embedded-atom method interatomic potential for bismuth. Model. Simul. Mater. Sci. Eng. (2021). https://doi.org/10.1088/1361-651X/ac095c

J. Tersoff, Modeling solid-state chemistry: interatomic potentials for multicomponent systems. Phys. Rev. B. (1989). https://doi.org/10.1103/PhysRevB.39.5566

V.P. Filippova, S.A. Kunavin, M.S. Pugachev, Calculation of the parameters of the Lennard-Jones potential for pairs of identical atoms based on the properties of solid substances. Inorg. Mater. Appl. Res. (2015). https://doi.org/10.1134/S2075113315010062

A. Arkundato, Z. Su’ud, M. Abdullah, W. Sutrisno, Molecular dynamic simulation on iron corrosion-reduction in high temperature molten lead-bismuth eutectic. Turkish J. Phys. (2013). https://doi.org/10.3906/fiz-1112-12

B. Xue, D.B. Harwood, J.L. Chen, J.I. Siepmann, Monte Carlo simulations of fluid phase equilibria and interfacial properties for Water/Alkane mixtures: an assessment of nonpolarizable water models and of departures from the Lorentz-Berthelot combining rules. J. Chem. Eng. Data. (2018). https://doi.org/10.1021/acs.jced.8b00757

J.Y. Xie, N.X. Chen, J. Shen, L. Teng, S. Seetharaman, Atomistic study on the structure and thermodynamic properties of Cr 7C3, Mn7C3, Fe7C 3. Acta Mater. (2005). https://doi.org/10.1016/j.actamat.2005.02.039

S. Hao, N.X. Chen, Atomistic simulation on the phase stability, site preference and lattice parameters for Nd(Fe, T)12with Nd(Fe, Ti)12Nx. Phys. Lett. Sect. A Gen. At. Solid State Phys. (2002). https://doi.org/10.1016/S0375-9601(02)00371-7

T.Y. Lai, T.H. Fang, T.H. Chen, Mechanical and thermal conductivity properties of BiSbTe nanofilms using molecular dynamics. Phys. E Low-Dimensional Syst. Nanostruct. (2020). https://doi.org/10.1016/j.physe.2020.114300

J. Wang, X. Zhang, F. Fang, F. Xu, R. Chen, Z. Xue, Study on nano-cutting of brittle material by molecular dynamics using dynamic modeling. Comput. Mater. Sci. (2020). https://doi.org/10.1016/j.commatsci.2020.109851

K. Maekawa, A. Itoh, Friction and tool wear in nano-scale machining-a molecular dynamics approach. Wear (1995). https://doi.org/10.1016/0043-1648(95)06633-0

J.J. Möller, E. Bitzek, BDA: A novel method for identifying defects in body-centered cubic crystals. MethodsX. 3, 279–288 (2016). https://doi.org/10.1016/j.mex.2016.03.013

Acknowledgements

This work was supported by the Key Research and Development Projects of Shaanxi Province Project of Shaanxi Province, China [Grant number 2022GY-399].

Author information

Authors and Affiliations

Contributions

MGW, HBW, and JCZ are involved in the simulation, calculation, verification, and writing the paperwork; XNZ visualized the post-processing; FZW guided the writing; HW supervised the funding support.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, M., Wang, F., Wang, H. et al. Effects of bismuth nanoparticles on the nano-cutting properties of single-crystal iron materials: a molecular dynamics study. Appl. Phys. A 129, 687 (2023). https://doi.org/10.1007/s00339-023-06953-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06953-y