Abstract

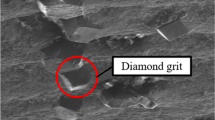

In the present study, molecular dynamics simulation (MDS) is employed to study the wear mechanism of single crystal diamond tool during nanocutting of copper beryllium (CuBe). Two edge configurations, i.e., both sharp and worn out tools, are chosen to study the tool and workpiece interaction during the nanocutting of CuBe. Further, the study involves the experimental characterization techniques viz. scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and Raman spectroscopy to confirm the simulation results. The results of the molecular dynamics simulation (MDS) show that the presence of Be as a hard particle in workpiece material influences the cutting forces which subsequently causes degradation of the sharp edge of the diamond tool. Furthermore, the carbon (C) atoms removed from the tool react with Be particles and as a result, it causes the formation of beryllium carbide (BeC). Beryllium interaction with the blunt edge configuration of the tool causes amorphization at the tool edge. Raman spectroscopy of the used diamond tool on CuBe reveals the similar phenomena of amorphization of the diamond at the tool edge. Moreover, surface generation is dependent on the tool edge condition as blunt edge tool leads to smoother surface compared to the surface generated by sharp edge configuration.

Similar content being viewed by others

References

Balasubramaniam R, Sarepaka RV, Subbiah S (2017) Diamond turn machining: theory and practice. CRC Press 1:27–45

Zhang SJ, To S, Zhang GQ (2017) Diamond tool wear in ultra-precision machining. Int J Adv Manuf Technol 88:613–641

Crone WC (2000) Compositional variation and precipitate structures of copper–beryllium single crystals grown by the Bridgman technique. J Cryst Growth 218:381–389

Hung NP, Zhong ZW, Lee KK, Chai CF (1999) Precision grinding and facing of copper-beryllium alloys. Precis Eng 23:293–304

Wada R, Kodama H, Nakamura K, Mizutani Y, Shimura Y, Takenaka N (1980) Wear characteristics of single crystal diamond tool. CIRP Ann - Manuf Technol 29:47–52

Paul E, Evans CJ, Mangamelli A, McGlauflin ML, Polvani RS (1996) Chemical aspects of tool wear in single point diamond turning. Precis Eng 18:4–19

Shimada S, Tanaka H, Higuchi M, Yamaguchi T, Honda S, Obata K (2004) Thermo-chemical wear mechanism of diamond tool in machining of ferrous metals. CIRP Ann - Manuf Technol 53:57–60

Zhou M, Ngoi BKA, Yusoff MN, Wang XJ (2006) Tool wear and surface finish in diamond cutting of optical glass. J Mater Process Technol 174:29–33

Li XP, He T, Rahman M (2005) Tool wear characteristics and their effects on nanoscale ductile mode cutting of silicon wafer. Wear 259:1207–1214

Han XS, Lin B, Yu SY, Wang SX (2002) Investigation of tool geometry in nanometric cutting by molecular dynamics simulation. J Mater Process Technol 129:105–108

Narulkar R, Bukkapatnam S, Raff LM, Komanduri R (2009) Graphitization as a precursor to wear of diamond in machining pure iron: a molecular dynamics investigation. Comput Mater Sci 45:358–366

Zhang Z, Yan J, Kuriyagawa T (2011) Study on tool wear characteristics in diamond turning of reaction-bonded silicon carbide. Int J Adv Manuf Technol 57:117–125

Zareena AR, Veldhuis SC (2012) Tool wear mechanisms and tool life enhancement in ultra-precision machining of titanium. J Mater Process Technol 212:560–570

Ding X, Rahman M (2012) A study of the performance of cutting polycrystalline Al 6061 T6 with single crystalline diamond micro-tools. Precis Eng 36:593–603

Zou L, Dong G, Zhou M (2013) Investigation on frictional wear of single crystal diamond against ferrous metals. Int J Refract Met Hard Mater 41:174–179

Zou L, Huang Y, Zhou M, Xiao G (2017) Thermochemical wear of single crystal diamond catalyzed by ferrous materials at elevated temperature. Crystals 7:1–10

Otieno T, Abou-El-Hossein K (2017) Molecular dynamics analysis of nanomachining of rapidly solidified aluminium. Int J Adv Manuf Technol:121–131

Lai M, Zhang X, Fang F, Wang Y, Feng M, Tian W (2013) Study on nanometric cutting of germanium by molecular dynamics simulation. Nanoscale Res Lett 8:13

Evans C, Bryan JB (1991) Cryogenic diamond turning of stainless steel. CIRP Ann - Manuf Technol 40:571–575

Mir A, Luo X, Cheng K, Cox A (2017) Investigation of influence of tool rake angle in single point diamond turning of silicon. Int J Adv Manuf Technol:1–13

Foiles SM, Baskes MI, Daw MS (1986) Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys Rev B 33:7983–7991

Erhart P, Albe K (2005) Analytical potential for atomistic simulations of silicon, carbon, and silicon carbide. Phys Rev B:1–14

Björkas C, Juslin N, Timko H, Vörtler K, Nordlund K, Henriksson K et al (2009) Interatomic potentials for the Be–C–H system. J Phys Condens Matter 21(44):1–16

Sharma A, Datta D, Balasubramaniam R (2018) An investigation of tool and hard particle interaction in nanoscale cutting of copper beryllium. Comput Mater Sci 145:208–223

Inamura T, Takezawa N (1992) Atomic-scale cutting in a computer using crystal models of copper and diamond. CIRP Ann - Manuf Technol 41:121–124

Lin Z-C, Huang J-C (2004) A nano-orthogonal cutting model based on a modified molecular dynamics technique. Nanotechnology 15:510–519

Shi J, Wang Y, Yang X (2013) Nano-scale machining of polycrystalline coppers—effects of grain size and machining parameters. Nanoscale Res Lett 8:1–18

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117:1–19

Stukowski A (2009) Visualization and analysis of atomistic simulation data with OVITO—the open visualization tool. Model Simul Mater Sci Eng 18(15012):1–7

Tsai DH (1979) The virial theorem and stress calculation in molecular dynamics. J Chem Phys 70:1375–1382

Zhou M (2003) A new look at the atomic level virial stress: on continuum-molecular system equivalence. Proc R Soc London A: Math Phys Eng Sci 459:2347–2392

Zimmerman JA, WebbIII EB, Hoyt JJ, Jones RE, Klein PA, Bammann DJ (2004) Calculation of stress in atomistic simulation. Model Simul Mater Sci Eng 12:S319–S332

Xu F, Fang F, Zhang X (2017) Hard particle effect on surface generation in nano-cutting. Appl Surf Sci 425:1020–1027

Li J, Fang Q, Liu B, Liu Y (2016) Applied surface science the effects of pore and second-phase particle on the mechanical properties of machining copper matrix from molecular dynamic simulation. Appl Surf Sci 384:419–431

Wang Z, Chen J, Wang G, Bai Q, Liang Y (2017) Anisotropy of single-crystal silicon in nanometric cutting. Nanoscale Res Lett 12(300):1–11

Dychalska A, Popielarski P, Franków W, Fabisiak K, Paprocki K, Szybowicz M (2015) Study of CVD diamond layers with amorphous carbon admixture by Raman scattering spectroscopy. Mater Sci 33:799–805

Oomen JM, Eisses J (1992) Wear of monocrystalline diamond tools during ultraprecision machining of nonferrous metals. Precis Eng 14:206–218

Tanaka H, Shimada S, Higuchi M, Yamaguchi T, Kaneeda T, Obata K (2005) Mechanism of cutting edge chipping and its suppression in diamond turning of copper. CIRP Ann - Manuf Technol 54:51–54

Zong WJ, Sun T, Li D, Cheng K, Liang YC (2008) XPS analysis of the groove wearing marks on flank face of diamond tool in nanometric cutting of silicon wafer. Int J Mach Tools Manuf 48:1678–1687

Goel S, Luo X, Reuben RL, Pen H (2012) Influence of temperature and crystal orientation on tool wear during single point diamond turning of silicon. Wear 284–285:65–72

Goel S, Luo X, Reuben RL (2012) Molecular dynamics simulation model for the quantitative assessment of tool wear during single point diamond turning of cubic silicon carbide. Comput Mater Sci 51:402–408

Cheng X, Zong WJ (2000) Diamond polishing : the dependency of friction and wear on load and crystal orientation. J Phys D Appl Phys 33(8):985–990

Pastewka L, Moser S, Gumbsch P, Moseler M (2010) Anisotropic mechanical amorphization drives wear in diamond. Nat Mater 10:34–38

Yang N, Zong W, Li Z, Sun T (2014) Amorphization anisotropy and the internal of amorphous layer in diamond nanoscale friction. Comput Mater Sci 95:551–556

Zong WJ, Cheng X, Zhang JJ (2016) Atomistic origins of material removal rate anisotropy in mechanical polishing of diamond crystal. Carbon 99:186–194

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, A., Datta, D. & Balasubramaniam, R. A molecular dynamics simulation of wear mechanism of diamond tool in nanoscale cutting of copper beryllium. Int J Adv Manuf Technol 102, 731–745 (2019). https://doi.org/10.1007/s00170-018-03246-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-03246-0