Abstract

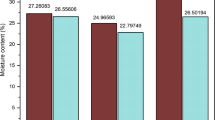

This study assessed bioplastics made from different mass proportions of commercial chitosan and banana plant pseudostem-derived hemicelluloses. The bioplastics were prepared by the casting method and characterized for moisture content, water solubility, opacity, water absorption, tensile strength, and thermogravimetric properties. The formulations with hemicelluloses addition showed higher moisture content and water solubility than the chitosan-only bioplastic, the maximum values of these properties (22.3 and 22.4%) were achieved when hemicelluloses were added at the proportion of 10 and 5%, respectively. A positive linear correlation (r = 0.86) was found between added hemicelluloses and opacity, with the highest opacity (1.95 mm−1) achieved in the formulation with the maximum hemicellulose incorporation. The bioplastics containing hemicelluloses exhibited lower swelling (water absorption) than that made only of chitosan, with the formulation featuring the highest hemicelluloses content showed the lowest swelling (229.2%). A negative linear correlation (r = 0.95) was observed between added hemicelluloses and swelling values. The formulation with the highest hemicelluloses content demonstrated statistically significant differences and exhibited the highest tensile strength (18.7 MPa) and Young’s modulus (66.1 MPa). Thermogravimetric analysis revealed four stages of mass loss in the bioplastics. Hemicelluloses addition decreased the temperature at maximum mass loss, and the formulation with the lowest hemicelluloses content showed a higher degradation rate than the others.

Similar content being viewed by others

References

OECD (2023) Global plastics outlook: plastics use by polymer—projections. https://www.oecd-ilibrary.org/environment/data/global-plastic-outlook_c0821f81-en. Accessed 30 Jan 2023

Plastics Europe (2022) Plastics-the facts 2021. Brussels

Conversio (2020) Global plastics flow 2018. Mainaschaff

OECD (2020) Global plastics outlook: greenhouse gas emissions from primary plastics. https://www.oecd-ilibrary.org/environment/data/global-plastic-outlook_c0821f81-en. Accessed 30 Jan 2023

Abe MM, Branciforti MC, Nallin Montagnolli R et al (2022) Production and assessment of the biodegradation and ecotoxicity of xylan- and starch-based bioplastics. Chemosphere 287:1–10. https://doi.org/10.1016/j.chemosphere.2021.132290

Ponnusamy PG, Mani S (2022) Material and environmental properties of natural polymers and their composites for packaging applications: a review. Polymers (Basel) 14:1–22. https://doi.org/10.3390/polym14194033

Gent S, Twedt M, Gerometta C, Almberg E (2017) Chapter two: introduction to feedstocks. In: Gent S, Twedt M, Gerometta C, Almberg EBT-T and AA of BT (eds) Theoretical and applied aspects of biomass torrefaction. Butterworth-Heinemann, Oxford, pp 17–39

Abe MM, Martins JR, Sanvezzo PB, et al (2021) Advantages and disadvantages of bioplastics production from starch and lignocellulosic components. Polymers (Basel) 13:. https://doi.org/10.3390/polym13152484

Macedo JVC, Abe MM, Sanvezzo PB et al (2022) Xylan-starch-based bioplastic formulation and xylan influence on the physicochemical and biodegradability properties. Polym Bull 1–26. https://doi.org/10.1007/s00289-022-04385-x

Macedo JVC, Martins JR, Abe MM et al (2022) Hemicellulose application for the production of bioplastics and biomaterials. In: Brienzo M (ed) Hemicellulose biorefinery: a sustainable solution for value addition to bio-based products and bioenergy. Springer Nature Singapore, Singapore, pp 231–273

Jacob J, Gomes F, Haponiuk JT et al (2022) Natural polymers: perspectives and applications for a green approach, 1st edn. Taylor & Francis Group, London

Amaraweera SM, Gunathilake C, Gunawardene OHP et al (2021) Development of starch-based materials using current modification techniques and their applications: a review. Molecules 26:1–30. https://doi.org/10.3390/molecules26226880

Priyadarshi R, Rhim J-W (2020) Chitosan-based biodegradable functional films for food packaging applications. Innov Food Sci Emerg Technol 62:1–20. https://doi.org/10.1016/j.ifset.2020.102346

Olorunsola EO, Akpabio EI, Adedokun MO, Ajibola DO (2018) Emulsifying Properties of Hemicelluloses. In: Karakuş S (ed) Science and technology behind nanoemulsions, 1st edn. IntechOpen, London, pp 29–42

Ahmad N, Zakaria MR (2019) Chapter 8: Oligosaccharide from hemicellulose. In: Ariffin H, Sapuan SM, Hassan MABT-L for FB (eds) Lignocellulose for future bioeconomy, 1st ed. Elsevier, Amsterdam, pp 135–152

Zhang X, Tu M, Paice MG (2011) Routes to potential bioproducts from lignocellulosic biomass lignin and hemicelluloses. BioEnergy Res 4:246–257. https://doi.org/10.1007/s12155-011-9147-1

Zhao Y, Sun H, Yang B, Weng Y (2020) Hemicellulose-based film: potential green films for food packaging. Polymers (Basel) 12:1–14. https://doi.org/10.3390/polym12081775

Li J, Tian X, Hua T et al (2021) Chitosan natural polymer material for improving antibacterial properties of textiles. ACS Appl Bio Mater 4:4014–4038. https://doi.org/10.1021/acsabm.1c00078

Huq T, Khan A, Brown D et al (2022) Sources, production and commercial applications of fungal chitosan: a review. J Bioresour Bioprod 7:85–98. https://doi.org/10.1016/j.jobab.2022.01.002

Pellis A, Guebitz GM, Nyanhongo GS (2022) Chitosan: sources, processing and modification techniques. Gels 8:1–27. https://doi.org/10.3390/gels8070393

Zamora Zamora HD, Olayiwola HO, Jacobus AP, et al (2022) Hemicelluloses role in biorefinery systems of cellulosic bioethanol, particleboard, and pulp and paper industries. In: Brienzo M (ed) Hemicellulose biorefinery: a sustainable solution for value addition to bio-based products and bioenergy. Springer Nature Singapore, Singapore, pp 1–37

Moshiul Alam AKM, Beg MDH, Reddy Prasad DM et al (2012) Structures and performances of simultaneous ultrasound and alkali treated oil palm empty fruit bunch fiber reinforced poly(lactic acid) composites. Compos Part A Appl Sci Manuf 43:1921–1929. https://doi.org/10.1016/j.compositesa.2012.06.012

Fernandes ÉS, Bueno D, Pagnocca FC, Brienzo M (2020) Minor Biomass particle size for an efficient cellulose accessibility and enzymatic hydrolysis. ChemistrySelect 5:7627–7631. https://doi.org/10.1002/slct.202001008

Brugnerotto J, Lizardi J, Goycoolea FM et al (2001) An infrared investigation in relation with chitin and chitosan characterization. Polymer (Guildf) 42:3569–3580. https://doi.org/10.1016/S0032-3861(00)00713-8

Yuan Y, Chesnutt BM, Haggard WO, Bumgardner JD (2011) Deacetylation of chitosan: material characterization and in vitro evaluation via albumin adsorption and pre-osteoblastic cell cultures. Materials (Basel) 4:1399–1416. https://doi.org/10.3390/ma4081399

Medina-Jaramillo C, Ochoa-Yepes O, Bernal C, Famá L (2017) Active and smart biodegradable packaging based on starch and natural extracts. Carbohydr Polym 176:187–194. https://doi.org/10.1016/j.carbpol.2017.08.079

Zhao J, Wang Y, Liu C (2022) Film transparency and opacity measurements. Food Anal Methods 15:2840–2846. https://doi.org/10.1007/s12161-022-02343-x

ASTM (2022) D570-22: standard test method for water absorption of plastics. West Conshohocken, United States

ISO (2021) ISO 62:2008: Plastics—determination of water absorption. Vernier

ASTM (2018) D882-18: Standard test method for tensile properties of thin plastic sheeting. West Conshohocken

Zhang X, Wei Y, Chen M et al (2020) Development of functional chitosan-based composite films incorporated with hemicelluloses: effect on physicochemical properties. Carbohydr Polym 246:1–8. https://doi.org/10.1016/j.carbpol.2020.116489

Kusumastuti Y, Putri NRE, Timotius D et al (2020) Effect of chitosan addition on the properties of low-density polyethylene blend as potential bioplastic. Heliyon 6:1–8. https://doi.org/10.1016/j.heliyon.2020.e05280

Patel JP, Parsania PH (2018) 3—Characterization, testing, and reinforcing materials of biodegradable composites. In: Shimpi NGBT-B and BPC (ed) Woodhead Publishing Series in Composites Science and Engineering. Woodhead Publishing, Sawston, pp 55–79

Fry SC (2003) Cell walls and fibers | cell walls. In: Thomas BBT-E of APS (ed) Encyclopedia of applied plant sciences. Elsevier, Oxford, pp 75–87

Luo Y, Wang Q (2014) Recent development of chitosan-based polyelectrolyte complexes with natural polysaccharides for drug delivery. Int J Biol Macromol 64:353–367. https://doi.org/10.1016/j.ijbiomac.2013.12.017

Kumari S, Kishor R (2020) Chapter 1: Chitin and chitosan: origin, properties, and applications. In: Gopi S, Thomas S, Pius ABT-H of C and C (eds) Handbook of Chitin and Chitosan V1. Elsevier, Amsterdam, pp 1–33

Geankoplis C (1993) Transport processes and unit operations, 3rd ed. Prentice-Hall International, Englewood Cliffs

Agusman, Fransiska D, Murdinah et al (2022) Physical properties of bioplastic agar/chitosan blend. IOP Conf Ser Earth Environ Sci 978:1–11. https://doi.org/10.1088/1755-1315/978/1/012046

Merino D, Bellassi P, Paul UC, et al (2023) Assessment of chitosan/pectin-rich vegetable waste composites for the active packaging of dry foods. Food Hydrocoll 108580. https://doi.org/10.1016/j.foodhyd.2023.108580

Rodsamran P, Sothornvit R (2019) Lime peel pectin integrated with coconut water and lime peel extract as a new bioactive film sachet to retard soybean oil oxidation. Food Hydrocoll 97:1–9. https://doi.org/10.1016/j.foodhyd.2019.105173

Rodrigues AAM, da Costa RR, dos Santos LF et al (2021) Properties and characterization of biodegradable films obtained from different starch sources. Food Sci Technol 41:476–482. https://doi.org/10.1590/fst.28520

Batista JTS, Araújo CS, Peixoto Joele MRS et al (2019) Study of the effect of the chitosan use on the properties of biodegradable films of myofibrillar proteins of fish residues using response surface methodology. Food Packag Shelf Life 20:1–10. https://doi.org/10.1016/j.fpsl.2019.100306

Galdeano MC, Wilhelm AE, Mali S, Grossmann MVE (2013) Influence of thickness on properties of plasticized oat starch films. Braz Arch Biol Technol 56:637–644. https://doi.org/10.1590/S1516-89132013000400014

Lavorgna M, Piscitelli F, Mangiacapra P, Buonocore GG (2010) Study of the combined effect of both clay and glycerol plasticizer on the properties of chitosan films. Carbohydr Polym 82:291–298. https://doi.org/10.1016/j.carbpol.2010.04.054

Canevarolo Jr. SV (2010) Ciência dos Polímeros, 2nd ed. Artliber, São Paulo

Fried JR (2014) Physical chemistry of surfaces, 3rd ed. Prentice-Hall International, Hoboken

Provder T, Urban MW (2001) Film formation in coatings: mechanisms, properties, and morphology, 1st edn. American Chemical Society, Washington

Xu J, Xia R, Yuan T, Sun R (2019) Use of xylooligosaccharides (XOS) in hemicelluloses/chitosan-based films reinforced by cellulose nanofiber: effect on physicochemical properties. Food Chem 298:125041. https://doi.org/10.1016/j.foodchem.2019.125041

Moalla S, Ammar I, Fauconnier M-L et al (2021) Development and characterization of chitosan films carrying Artemisia campestris antioxidants for potential use as active food packaging materials. Int J Biol Macromol 183:254–266. https://doi.org/10.1016/j.ijbiomac.2021.04.113

Melati RB, Sass DC, Contiero J, Brienzo M (2023) Xylan Solubilization from partially delignified biomass, and residual lignin removal from solubilized xylan. Polysaccharides 4:176–188. https://doi.org/10.3390/polysaccharides4020013

Ahmad N, Tayyeb D, Ali I et al (2020) Development and characterization of hemicellulose-based films for antibacterial wound-dressing application. Polymers (Basel) 12:1–16. https://doi.org/10.3390/polym12030548

Janik W, Wojtala A, Pietruszka A et al (2021) Environmentally friendly melt-processed chitosan/starch composites modified with PVA and lignin. Polymers (Basel) 13:1–14. https://doi.org/10.3390/polym13162685

Nguyen TT, Thi Dao UT, Thi Bui QP et al (2020) Enhanced antimicrobial activities and physiochemical properties of edible film based on chitosan incorporated with Sonneratia caseolaris (L.) Engl. leaf extract. Prog Org Coatings 140:1–9. https://doi.org/10.1016/j.porgcoat.2019.105487

Abe MM, Branciforti MC, Brienzo M (2021) Biodegradation of hemicellulose-cellulose-starch-based bioplastics and microbial polyesters. Recycling 6:1–21. https://doi.org/10.3390/recycling6010022

Liu Y, Sun B, Wang Z, Ni Y (2016) Mechanical and water vapor barrier properties of bagasse hemicellulose-based films. BioResources 11:4226–4236. https://doi.org/10.15376/biores.11.2.4226-4236

Kamdem DP, Shen Z, Nabinejad O, Shu Z (2019) Development of biodegradable composite chitosan-based films incorporated with xylan and carvacrol for food packaging application. Food Packag Shelf Life 21:1–9. https://doi.org/10.1016/j.fpsl.2019.100344

Solier YN, Schnell CN, Galván MV et al (2022) Fast preparation of flexible wet-resistant and biodegradable films from a stable suspension of xylan/chitosan polyelectrolyte complexes. J Polym Environ 30:114–124. https://doi.org/10.1007/s10924-021-02181-8

Callister WD, Rethwisch DG (2018) Materials science and engineering: an introduction, 10th edn. Wiley, Hoboken

Xu J, Xia R, Zheng L et al (2019) Plasticized hemicelluloses/chitosan-based edible films reinforced by cellulose nanofiber with enhanced mechanical properties. Carbohydr Polym 224:1–9. https://doi.org/10.1016/j.carbpol.2019.115164

Schnell CN, Galván MV, Peresin MS et al (2017) Films from xylan/chitosan complexes: preparation and characterization. Cellulose 24:4393–4403. https://doi.org/10.1007/s10570-017-1411-x

Abdan KB, Yong SC, Chiang ECW, et al (2020) Chapter 6: Barrier properties, antimicrobial and antifungal activities of chitin and chitosan-based IPNs, gels, blends, composites, and nanocomposites. In: Gopi S, Thomas S, Pius ABT-H of C and C (eds) Handbook of Chitin and Chitosan V2. Elsevier, Amsterdam, pp 175–227

Sun K, Li F, Li J et al (2019) Optimisation of compatibility for improving elongation at break of chitosan/starch films. RSC Adv 9:24451–24459. https://doi.org/10.1039/C9RA04053F

Jakubowska E, Gierszewska M, Nowaczyk J, Olewnik-Kruszkowska E (2020) Physicochemical and storage properties of chitosan-based films plasticized with deep eutectic solvent. Food Hydrocoll 108:1–10. https://doi.org/10.1016/j.foodhyd.2020.106007

Zaman NBK, Lin NK, Phing PL (2018) Chitosan film incorporated with Garcinia atroviridis for the packaging of Indian mackerel (Rastrelliger kanagurta). Ciência e Agrotecnologia 42:666–675. https://doi.org/10.1590/1413-70542018426019918

Costa SM, Ferreira DP, Teixeira P et al (2021) Active natural-based films for food packaging applications: the combined effect of chitosan and nanocellulose. Int J Biol Macromol 177:241–251. https://doi.org/10.1016/j.ijbiomac.2021.02.105

Yang H, Yan R, Chen H et al (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Acknowledgements

The authors are grateful to the Brazilian Improvement Coordination of Higher Education Personnel (CAPES), Brazilian National Council for Scientific and Technological Development (Process Number 303039/2021-2), São Paulo Research Foundation and Netherlands Organization for Scientific Research (NWO-FAPESP, Process Number 2017/22401-8; 2021/10839-4) for its financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zamora Zamora, H.D., Ferreira, H., Pich, A. et al. Hemicellulose additive to chitosan-based bioplastic improved the tensile strength and allowed to control the material swelling. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05152-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05152-w