Abstract

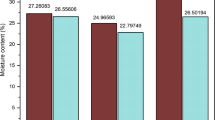

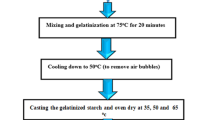

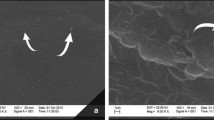

As the traditionally used plastic remains and accumulates in the environment, new biodegradable materials and, preferably, from renewable raw materials, need to be developed. In this regard, this study investigates the influence of xylan from sugarcane bagasse on the mechanical and chemical properties of bioplastics composed of starch and glycerol as a plasticizer. All bioplastics produced have a total proportion of sugars equal to 5% (w/w total mass of the filmogenic solution), and xylan is present in 5, 10, 25, and 50% of the total mass of polysaccharides. Bioplastic-forming solutions were gelatinized and dried by the casting method. Bioplastic solubility in water and its opacity increase as the xylan content increases—the first range between 20.31 and 44.16%, and the latter between 0.44 and 9.77%, with only starch and 50% (w/w) xylan, respectively. The presence of xylan also makes the bioplastics more hydrophilic and less crystalline, and interferes with their mechanical proprieties, while 5 and 10% (w/w) xylan bioplastics have higher tensile stresses, equal to 2.35 and 2.56 MPa, respectively. The elongation at break is greater in bioplastics composed of only starch (208.8%), and 15.8 and 19.3% elongation is reached to the amount of xylan of 25 and 50%, respectively. The bioplastics are completely biodegraded after being buried for 30 days. Starch and xylan (5 and 10%) combination improves the mechanical properties of the film, causing no significant changes in its solubility and producing biodegradable and less opaque bioplastics, with potential application in packaging for transporting seedlings, for example.

Similar content being viewed by others

References

Ali SS, Elsamah YT, Koutra E, Kornaros M, El-Sheekh M, Abdelkarim EA, Zhu D, Sun J (2021) Degradation of conventional plastic wastes in the environment: a review on current status of knowledge and future perspectives of disposal. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2020.144719

Macarthur DE (2017) Beyond plastic waste. Science 358:843. https://doi.org/10.1126/science.aao6749

Nielsen TD, Hasselbalch J, Holmberg K, Stripple J (2019) Politics and the plastic crisis: A review throughout the plastic life cycle. Energy Environ 9:1–18. https://doi.org/10.1002/wene.360

Windsor FM, Durance I, Horton AA, Thompson RC, Tyler CR, Ormerod SJ (2019) A catchment-scale perspective of plastic pollution. Glob Chang Biol 25:1207–1221. https://doi.org/10.1111/gcb.14572

Mitrano DM, Wick P, Nowack B (2021) Placing nanoplastics in the context of global plastic pollution. Nat Nanotechnol 16:491–500. https://doi.org/10.1038/s41565-021-00888-2

Imre B, García L, Puglia D, Vilaplana F (2019) Reactive compatibilization of plant polysaccharides and biobased polymers: review on current strategies, expectations and reality. Carbohydr Polym 209:20–37. https://doi.org/10.1016/j.carbpol.2018.12.082

Macedo JVC, Martins JR, Abe MM, Branciforti MC, Brienzo M (2022) Hemicellulose application for the production of bioplastics and biomaterials. In: Brienzo M (eds) Hemicellulose biorefinery: a sustainable solution for value addition to bio-based products and bioenergy. Clean Energy Production Technologies. Springer, Singapore. https://doi.org/10.1007/978-981-16-3682-0_8

Gao S, Tang G, Hua D, Xiong R, Han J, Jiang S, Huang C (2019) Stimuli-responsive bio-based polymeric systems and their applications. J Mater Chem B. https://doi.org/10.1039/c8tb02491j

Bueno D, de Freitas C, Brienzo M (2022) Enzymatic approach on the hemicellulose chain structural modification and the main enzymes production and purification. In: Brienzo M (eds) Hemicellulose biorefinery: a sustainable solution for value addition to bio-based products and bioenergy. Clean energy production technologies. Springer, Singapore. https://doi.org/10.1007/978-981-16-3682-0_7

Martins JR, Abe MM, Brienzo M (2022) Chemical modification strategies for developing functionalized hemicellulose: advanced applications of modified hemicellulose. In: Brienzo M (eds) Hemicellulose biorefinery: a sustainable solution for value addition to bio-based products and bioenergy. Clean Energy Production Technologies. Springer, Singapore. https://doi.org/10.1007/978-981-16-3682-0

Prabhu TN, Prashantha KA (2018) Review on present status and future challenges of starch based polymer films and their composites in food packaging applications. Polym Compos 39:2161–2596. https://doi.org/10.1002/pc.24236

Melati RB, Shimizu FL, Oliveira G, Pagnocca FC, Souza W, Sant’anna C, Brienzo M, (2019) Key factors affecting the recalcitrance and conversion process of biomass. BioEnergy Res 12(1):1–20. https://doi.org/10.1007/s12155-018-9941-0

Farhat W, Venditti R, Ayoub A, Prochazka F, Fernández-de-Alba C, Mignard N, Taha M, Becquart F (2018) Towards thermoplastic hemicellulose: chemistry and characteristics of poly-(ε-caprolactone) grafting onto hemicellulose backbones. Mater Des 153:298–307. https://doi.org/10.1016/j.matdes.2018.05.013

Zhao Y, Sun H, Yang B, Weng Y (2020) Hemicellulose-based film: potential green films for food packaging. Polymers 12:1775. https://doi.org/10.3390/polym12081775

Braga RS, Poletto M (2020) Preparation and characterization of hemicellulose films from sugarcane bagasse. Materials. https://doi.org/10.3390/ma13040941

Felipuci JP, Schmatz AA, de Angelis DA, Brienzo M (2021) Biological pretreatment improved subsequent xylan chemical solubilization. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-01506-w

Alves RC, Melati RB, Casagrande GMS, Contiero J, Pagnocca FC, Brienzo M (2020) Sieving process selects sugarcane bagasse with lower recalcitrance to xylan solubilization. J Chem Technol Biotechnol 96:327–334. https://doi.org/10.1002/jctb.6541

Freitas C, Carmona EC, Brienzo M (2019) Xylooligosaccharides production process from lignocellulosic biomass and bioactive effects. Bioactive Carbohydr Diet Fibre 18:100184. https://doi.org/10.1016/j.bcdf.2019.100184

Abe MM, Branciforti MC, Brienzo M (2021) Biodegradation of hemicellulose–cellulose-starch-based bioplastics and microbial polyesters. Recycling 6:22. https://doi.org/10.3390/recycling6010022

Forsan CF, Freitas C, Masarin F, Brienzo M (2021) Xylooligosaccharide production from sugarcane bagasse and leaf using Aspergillus versicolor endoxylanase and diluted acid. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-01403-2

Freitas C, Terrone CC, Masarin F, Carmona EC, Brienzo M (2021) In vitro study of the effect of xylooligosaccharides obtained from banana pseudostem xylan by enzymatic hydrolysis on probiotic bacteria. Biocatal Agric Biotechnol 33:101973. https://doi.org/10.1016/j.bcab.2021.101973

Melati RB, Sass DC, Pagnocca FC, Brienzo M (2021) Anatomic influence of sugarcane biomass on xylan solubilization. Ind Crops Prod 164:113–357. https://doi.org/10.1016/j.indcrop.2021.113357

Pereira BS, Castrisana RN, de Freitas C, Contiero J, Brienzo M (2021) Chemical composition determines the bioenergy potential of food waste from pre-and post-production. J Mater Cycles Waste Manag 23:1365–1373. https://doi.org/10.1007/s10163-021-01215-6

Reshmy R, Thomas D, Philip E, Paul SA, Madhavan A, Sindhu R, Sirohi R, Varjani S, Pugazhendhi A, Pandey A, Binod P (2021) Bioplastic production from renewable lignocellulosic feedstocks: a review. Rev Environ Sci Biotechnol 20:167–187. https://doi.org/10.1007/s11157-021-09565-1

Akay O, Altinkok C, Acik G, Yuce H, Ege GK (2021) A bio-based and non-toxic polyurethane film derived from Luffa cylindrica cellulose and ʟ-Lysine diisocyanate ethyl ester. Eur Polymer J 161:110856. https://doi.org/10.1016/j.eurpolymj.2021.110856

Martín-Closas L, Costa J, Pelacho AM (2017) Agronomic effects of biodegradable films on crop and field environment. Soil Degrad Bioplast Sustain Mod Agric. https://doi.org/10.1007/978-3-662-54130-2_4

Bilck AP, Olivato JB, Yamashita F et al (2014) Biodegradable bags for the production of plant seedlings. Polimeros-Ciencia e Tecnologia 24:547–553. https://doi.org/10.1590/0104-1428.1589

Luchese CL, Spada JC, Tessaro IC (2017) Starch content affects physicochemical properties of corn and cassava starch-based films. Ind Crops Prod 109:619–626. https://doi.org/10.1016/j.indcrop.2017.09.020

Abe MM, Branciforti MC, Montagnolli RN, Morales MAM, Jacobus AP, Brienzo M (2022) Production and assessment of the biodegradation and ecotoxicity of xylan- and starch-based bioplastics. Chemosphere 287:132290. https://doi.org/10.1016/j.chemosphere.2021.132290

Acik G, Altinkok C, Acik B (2022) Biodegradable and antibacterial chlorinated polypropylene/chitosan based composite films for biomedical applications. Polym Bull. https://doi.org/10.1007/s00289-021-04064-3

Fernandes ES, Bueno D, Pagnocca FC, Brienzo M (2020) Minor biomass particle size for an efficient cellulose accessibility and enzymatic hydrolysis. ChemistrySelect 5(25):7627–7631. https://doi.org/10.1002/slct.202001008

Brienzo M, Siqueira AF, Milagres AMF (2009) Search for optimum conditions of sugarcane bagasse hemicellulose extraction. Biochem Eng J 46:199–204. https://doi.org/10.1016/j.bej.2009.05.012

Jaramillo CM, Yepes OO, Bernal C, Famá L (2017) Active and smart biodegradable packaging based on starch and natural extracts. Carbohydr Polym 176:187–194. https://doi.org/10.1016/j.carbpol.2017.08.079

Azeredo HMC, Vrettou CK, Moates GK, Wellner N, Cross K, Pereira PHF, Waldron KW (2015) Wheat straw hemicellulose films as affected by citric acid. Food Hydrocolloids 50:1–6. https://doi.org/10.1016/j.foodhyd.2015.04.005

Gounga ME, Xu SY, Wang Z (2007) Whey protein isolate-based edible films as affected by protein concentration, glycerol ratio and pullulan addition in film formation. J Food Eng 83:521–530. https://doi.org/10.1016/j.jfoodeng.2007.04.008

Goksu EI, Karamanlioglu M, Bakir U, Yilmaz L, Yilmazer U (2007) Production and characterization of films from cotton stalk xylan. J Agric Food Chem 55:10685–10691. https://doi.org/10.1021/jf071893i

Yang J, Ching YC, Chuah CH (2019) Applications of lignocellulosic fibers and lignin in bioplastics: a review. Polymers 11:751. https://doi.org/10.3390/polym11050751

Sun Y, Yang L, Lu X, He H (2015) Biodegradable and renewable poly(lactide)–lignin composites: synthesis, interface and toughening mechanism. J Mater Chem A 3:3699–3709. https://doi.org/10.1039/C4TA05991C

Mehyar GF, Han JH (2004) Physical and mechanical properties of high-amylose rice and pea starch films as affected by relative humidity and plasticizer. J Food Sci 69:449–454. https://doi.org/10.1111/j.1365-2621.2004.tb09929.x

Peressini D, Bravin B, Sensidoni A (2004) Tensile properties, water vapor permeability and solubilities of starch–methylcellulose-based edible films. Ital J Food Sci 1:5–16

Bertuzzi MA, Armada M, Gottifredi JC (2007) Physicochemical characterization of starch based films. J Food Eng 82:17–25. https://doi.org/10.1016/j.jfoodeng.2006.12.016

Mali S, Grossmann MVE, Garc AMA, Martino MN, Zaritzky NE (2004) Barrier, mechanical and optical properties of plasticized yam starch films. Carbohydr Polym 56:129–135. https://doi.org/10.1016/j.carbpol.2004.01.004

Shimazu AA, Mali S, Grossmann MVE (2007) Efeitos plastificante e antiplastificante do glicerol e do sorbitol em filmes biodegradáveis de amido de mandioca. Semina Ciências Agrárias, Londrina 28:79–88

Cullity BD (1978) Elements of X-ray diffraction, 2nd edn. Addison-Wesley, Phillippines

Li H, Zhang B, Li C, Fu X, Wang Z, Huang Q (2019) CO2 inclusion complexes of granular V-type crystalline starch: structure and release kinetics. Food Chem 289:145–151. https://doi.org/10.1016/j.foodchem.2019.03.037

Sanyang ML, Sapuan SM, Jawaid M, Ishak MR, Sahari J (2016) Effect of plasticizer type and concentration on physical properties of biodegradable films based on sugar palm (Arenga pinnata) starch for food packaging. J Food Sci Technol 53:326–336. https://doi.org/10.1007/s13197-015-2009-7

Mikkonen KS, Laine C, Kontro I, Talja RA, Serimaa R, Tenkanen M (2015) Combination of internal and external plasticization of hydroxypropylated birch xylan tailors the properties of sustainable barrier films. Eur Polym J 66:307–318. https://doi.org/10.1016/j.eurpolymj.2015.02.034

Seiwert K, Kamdem DP, Kocabaş DS, Ustunol Z (2021) Development and characterization of whey protein isolate and xylan composite films with and without enzymatic crosslinking. Food Hydrocoll 120:106847. https://doi.org/10.1016/j.foodhyd.2021.106847

Gao C, Ren J, Wang S, Sun S, Zhao L (2014) Preparation of polyvinyl alcohol/xylan blending films with 1,2,3,4-butane tetracarboxylic acid as a new plasticizer. J Nanomater 2014:1–8. https://doi.org/10.1155/2014/764031

Wang S, Ren J, Li W, Sun R, Liu S (2014) Properties of polyvinyl alcohol/xylan composite films with citric acid. Carbohydr Polym 103:94–99. https://doi.org/10.1016/j.carbpol.2013.12.030

Naidjonoka P, Hernandez MA, Pálsson GK, Heinrich F, Stålbrand H, Nylander T (2020) On the interaction of softwood hemicellulose with cellulose surfaces in relation to molecular structure and physicochemical properties of hemicellulose. Soft Matter 16:7063–7076. https://doi.org/10.1039/D0SM00264J

Xu J, Xia R, Zheng L, Yuan T, Sun R (2019) Plasticized hemicelluloses/chitosan-based edible films reinforced by cellulose nanofiber with enhanced mechanical properties. Carbohyd Polym 224:115–164. https://doi.org/10.1016/j.carbpol.2019.115164

Gröndahl M, Eriksson L, Gatenholm P (2004) Material properties of plasticized hardwood xylans for potential application as oxygen barrier films. Biomacromol 5:1528–1535. https://doi.org/10.1021/bm049925n

Naidu DS, Hlangothi SP, John MJ (2018) Bio-based products from xylan: a review. Carbohydr Polym 179:28–41. https://doi.org/10.1016/j.carbpol.2017.09.064

Peng X, Ren J, Zhong L, Sun R (2011) Nanocomposite films based on xylan-rich hemicelluloses and cellulose nanofibers with enhanced mechanical properties. Biomacromol 12:3321–3329. https://doi.org/10.1021/bm2008795

Urtiga SCC, Marcelino HR, Egito EST, Oliveira EE (2020) Xylan in drug delivery: a review of its engineered structures and biomedical applications. Eur J Pharm Biopharm 151:199–208. https://doi.org/10.1016/j.ejpb.2020.04.016

Mikkonen KS, Tenkanen M (2012) Sustainable foodpackaging materials based on future biorefinery products: xylans and mannans. Food Sci Technol 28:90–102. https://doi.org/10.1016/j.tifs.2012.06.012

Kechichian V, Ditchfield C, Santos PV, Tadini CC (2010) Natural antimicrobial ingredients incorporated in biodegradable films based on cassava starch. LWT Food Sci Technol 43:1088–1094. https://doi.org/10.1016/j.lwt.2010.02.014

Farhat W, Venditti RA, Hubbe M, Taha M, Becquart F, Ayoub A (2017) A Review of water-resistant hemicellulose-based materials: processing and applications. Chem Sus Chem 10:305–323. https://doi.org/10.1002/cssc.201601047

Luo Y, Pan X, Ling Y, Wang X, Sun R (2014) Facile fabrication of chitosan active film with xylan via direct immersion. Cellulose 21:1873–1883. https://doi.org/10.1007/s10570-013-0156-4

Lucena CAA, da Costa SC, Eleamen GRDA, Mendonça EAM, Oliveira EE (2017) Desenvolvimento de biofilmes à base de xilana e xilana/gelatina para produção de embalagens biodegradáveis. Polimeros 27:35–41. https://doi.org/10.1590/0104-1428.2223

Ruiz HA, Cerqueira MA, Silva HD, Rodríguez-Jasso RM, Vicente AA, Teixeira JA (2013) Biorefinery valorization of autohydrolysis wheat straw hemicellulose to be applied in a polymer-blend film. Carbohydr Polym 92:2154–2162. https://doi.org/10.1016/j.carbpol.2012.11.054

Zhang H, Fu S, Chen Y (2020) Basic understanding of the color distinction of lignin and the proper selection of lignin in color-depended utilizations. Int J Biol Macromol 147:607–615. https://doi.org/10.1016/j.ijbiomac.2020.01.105

Auras R, Harte B, Selke S (2004) An overview of polylactides as packaging materials. Macromol Biosci 4:835–864. https://doi.org/10.1002/mabi.200400043

Kwon S, Orsuwan A, Bumbudsanpharoke N, Yoon C, Choi J, Ko S (2018) A short review of light barrier materials for food and beverage packaging. Korean J Packag Sci Technol 24:141–148. https://doi.org/10.20909/kopast.2018.24.3.141

Abdulkhani A, Mazhar AN, Hedjazi S, Hamzeh Y (2020) Preparation of xylan bio-composite films reinforced with oxidized carboxymethyl cellulose and nanocellulose. Polym Bull 77:6227–6239. https://doi.org/10.1007/s00289-019-03075-5

Danish M, Mumtaz MW, Fakhar M, Rashid U (2016) Response surface methodology based optimized purification of the residual glycerol from biodiesel production process. Chiang Mai J Sci 44:1570–1582

Liang T, Wang L (2017) Thermal treatment of poplar hemicelluloses at 180 to 220 °C under nitrogen atmosphere. BioResources 12:1128–1135. https://doi.org/10.15376/biores.12.1.1128-1135

Sabiha-Hanim S, Aziatul-Akma A (2016) Polymer characterization of cellulose and hemicellulose. In: Mendez-Vilas A, Solano-Martín A (eds) Polymer science: research advances, practical applications and educational aspects. Formatex Research Center, Spain, pp 404–411

Palaniappan A, Yuvaraj SS, Sonaimuthu S, Professor UA (2017) Characterization of xylan from rice bran and finger millet seed coat for functional food applications. J Cereal Sci 75:296–305. https://doi.org/10.1016/j.jcs.2017.03.032

Liu X, Song T, Chang M, Meng L, Wang X, Sun R, Ren J (2018) Carbon nanotubes reinforced maleic anhydride-modified Xylan-g-poly (N-isopropylacrylamide) hydrogel with multifunctional properties. Materials 11:354. https://doi.org/10.3390/ma11030354

Mendes FRS, Bastos MSR, Mendes LG, Silva ARA, Sousa FD, Monteiro-Moreira ANCO, Cheng HN, Biswas A, Moreira RA (2017) Preparation and evaluation of hemicellulose films and their blends. Food Hydrocoll 70:181–190. https://doi.org/10.1016/j.foodhyd.2017.03.037

Gao C, Ren J, Zhao C, Kong W, Dai Q, Chen Q, Liu C, Sun R (2016) Xylan-based temperature/pH sensitive hydrogels for drug controlled release. Carbohydr Polym 151:189–197. https://doi.org/10.1016/j.carbpol.2016.05.075

Nordin N, Othman SH, Rashid SA, Basha RK (2020) Effects of glycerol and thymol on physical, mechanical, and thermal properties of corn starch films. Food Hydrocoll 106:105–884. https://doi.org/10.1016/j.foodhyd.2020.105884

Laohakunjit N, Noomhorm A (2004) Effect of plasticizers on mechanical and barrier properties of rice starch film. Starch/Stärke 56:348–356. https://doi.org/10.1002/star.200300249

Campagner MR, da Silva Moris VA, Pitombo LM, do Carmo JB, de Paiva JMF, (2014) Polymeric films based on starch and lignosulfonates: preparation, properties and evaluation of biodegradation. Polimeros 24:740–751. https://doi.org/10.1590/0104-1428.1700

Lafuente MT, Alférez F (2015) Effect of LED blue light on Penicillium digitatum and Penicillium italicum strains. Photochem Photobiol 91:1412–1421. https://doi.org/10.1111/php.12519

Mesquita-Rocha S (2019) Aspergillus fumigatus: general aspects and importance in contemporary medicine. J Health Sci Inst 37:169–73

Sidrim JJC, Brilhante RSN, Rocha MFG (2004) Aspectos Gerais de fungos filamentosos e dimórficos na apresentação filamentosa. In: Sidrim JJC, Rocha MFG, Micologia Médica à luz de autores contemporâneos. Guanabara Koogan, Rio de Janeiro, pp 83–86

Tortora GJ, Funke BR, Case CL (2017) Microbiologia, 12th edN. Artmed, Porto Alegre

Acknowledgements

The authors acknowledge the São Paulo Research Foundation (FAPESP) (Process Numbers 2019/12997-6; and 2017/22401-8), Coordination of Higher Level Staff Improvement (CAPES) (finance code 001)—for the financial support, and the National Council for Scientific, Technological Development (CNPq) for the scholarship granted under the Process Number: 130499/2019-6, 303239/2021-2. They are also indebted to E. J. de Souza for the assistance in the SEM analyses and Dr. A. O. Sanches for the XRD support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Macedo, J.V.C., Abe, M.M., Sanvezzo, P.B. et al. Xylan-starch-based bioplastic formulation and xylan influence on the physicochemical and biodegradability properties. Polym. Bull. 80, 8067–8092 (2023). https://doi.org/10.1007/s00289-022-04385-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04385-x