Abstract

Hybrid inorganic–organic superlattice with an electron-transmitting but phonon-blocking structure has emerged as a promising flexible thin film thermoelectric material. However, the substantial challenge in optimizing carrier concentration without disrupting the superlattice structure prevents further improvement of the thermoelectric performance. Here we demonstrate a strategy for carrier optimization in a hybrid inorganic–organic superlattice of TiS2[tetrabutylammonium] x [hexylammonium] y , where the organic layers are composed of a random mixture of tetrabutylammonium and hexylammonium molecules. By vacuum heating the hybrid materials at an intermediate temperature, the hexylammonium molecules with a lower boiling point are selectively de-intercalated, which reduces the electron density due to the requirement of electroneutrality. The tetrabutylammonium molecules with a higher boiling point remain to support and stabilize the superlattice structure. The carrier concentration can thus be effectively reduced, resulting in a remarkably high power factor of 904 µW m−1 K−2 at 300 K for flexible thermoelectrics, approaching the values achieved in conventional inorganic semiconductors.

Similar content being viewed by others

Introduction

There is a rapidly growing interest in flexible thin film thermoelectrics1 for ambient temperature cooling and power generation on the microwatt-to-watt scale, where temperature gradients are moderate, surfaces are irregular, conventional thermoelectric materials with toxic or rare elements are prohibited, and low cost is preferred2,3,4,5,6. Especially, these flexible thin film thermoelectric devices are now under active pursuit for wearable energy harvesting, as they can generate electricity to power sensors by the temperature differences between human body and the environmental atmosphere3. These thermoelectric generators have many merits over the widely used lithium ion batteries, such as safety, long-lasting and maintenance-free, which is considered as a promising wearable power source3.

Conventional high-efficiency thermoelectric materials, such as Bi2Te3 and Skutterudites, are usually covalent- or ionic-bonded, and rigid, which is difficult to make devices mechanically flexible7. In contrast, conducting polymers and polymer composites are much more advantageous for making flexible thermoelectric devices, which combines structural flexibility and solution processibility1. The thermoelectric power factor reached 469 µW m−1 K−2 for pure PEDOT:PSS (poly(3,4-ethylenedioxythiophene): polystyrene sulfonate)8 and recently elevated to 1825 µW m−1 K−2 for PANI/graphene/PANI/DWNT nanocomposites (PANI: polyaniline, DWNT: double-walled carbon nanotubes)9. However, these organic thermoelectric materials are mainly p-type ones while their n-type counterpart is still lacking but in need for the completion of a high-efficiency flexible thermoelectric module. It is very difficult to make high performance n-type organic thermoelectric materials due to the low electron affinity of organic materials. For example, a low power factor of 0.6 µW m−1 K−2 was reported for the n-type polymer poly[N,N′-bis(2-octyl-dodecyl)−1,4,5,8-napthalenedicarboximide-2,6-diyl]-alt-5,5′-(2,2′-bithiophene)] (P(NDIOD-T2)10 and 1.4 µW m−1 K−2 was reported for the self-doped perylene diimides (PDI)11.

To overcome this challenge, inorganic components have been incorporated into polymers to make n-type flexible materials with enhanced thermoelectric performance12,13,14,15,16. For example, by embedding metallic CuxBi2Se3 nanoplates into the polyvinylidene fluoride matrix, an n-type power factor of 103 µW mK−2 was obtained17. Interfacial doping of bismuth into organic materials shows n-type thermoelectric power factor of 108 µW m−1 K−2 18. Transition metal elements were added into polymers to form organometallic poly[metal-ethylenetetrathiolate] complex, in which through-bond coupling between the metal d-orbitals and ligand π-orbitals induces one-dimensional n-type conductivity. The power factor reached 66 µW m−1 K−2 in an earlier report19 and was then improved to 453 µW m−1 K−2 20. However, the power factors of all these n-type polymer composites are still low compared with state-of-the-art inorganic thermoelectric semiconductors, such as Bi2Te3, PbTe, and Skutterudites.

To further improve the power factor of the n-type flexible thermoelectric materials, there is an emerging direction to make a hybrid inorganic/organic superlattice by stacking metallic/semiconducting inorganic materials and organic molecules layer by layer. The thermoelectric power factor could reach that of the inorganic materials while the use of the organic molecules results in low thermal conductivity and greater mechanical flexibility. Atomic layer deposition was used to make hybrid (Zn1−x AlxO)/Hydroquinone superlattice with a power factor of 38 µW m−1 K−2 21,22. We have recently demonstrated a hybrid inorganic–organic superlattice of TiS2 monolayers and organic molecules, with a record-high n-type power factor of 450 µW m−1 K−2 23,24. However, the power factor remains to be improved as the carrier concentration is far from being optimized. Conventionally, chemical doping is used in inorganic materials for carrier concentration optimization by co-firing dopant elements with the pristine material at high temperature. However, this method cannot be applied in the inorganic–organic superlattice, which would decompose before the doping temperature is achieved.

In this paper, we develop a strategy to effectively tune the carrier concentration without disrupting the hybrid superlattice structure. A giant high power factor (904 µW m−1 K−2) is obtained for the flexible n-type material at room temperature, which is even close to that of some high-ZT inorganic materials, such as SnSe (1010 µW m−1 K−2 @ 850 K)25 and Cu2−xSe (1200 µW m−1 K−2@ 1000 K)26.

Results

The dependence of the power factor on carrier concentration

The previously reported hybrid inorganic–organic TiS2(HA)0.08(H2O)0.22(DMSO)0.03 superlattice by us has a power factor of 450 µW m−1 K−2 with a very high carrier concentration of 7.6 × 1020 cm−3 24. The power factor can be remarkably improved if the carrier concentration was reduced, as shown in Supplementary Fig. 1 and Supplementary Note 1. As mentioned earlier, completely different strategies than chemical dopant co-firing should be developed for tuning carrier concentration in an inorganic–organic material. The hybrid superlattice is synthesized through the electrochemical intercalation process24. During this process, electrons are injected into the TiS2 anode, where the negative charges compensate the intercalated organic cations. (Supplementary Fig. 2). Apparently, the electrical neutrality condition between the electron charges in the inorganic material and the organic cations can then be used as the guiding principle to tune the carrier concentration in the hybrid superlattice. In other words, by reducing the organic cation density, the corresponding electron charge inside the inorganic TiS2 layers can be reduced.

Carrier optimization with mono-molecule intercalation

The first attempt was made by simply heating inorganic/organic superlattice in vacuum at higher temperatures, where part of the organic molecules is evaporated, which leads to a reduction of the carrier concentration (Fig. 1a). The percentage of the evaporated molecules can be controlled by the heating conditions, such as the temperature and the heating duration. As shown in Supplementary Fig. 3a, the samples were heated for 1 h at temperatures ranging from 100 to 200 °C. The Seebeck coefficient increases with increasing temperature, suggesting a decrease in carrier concentration. According to the estimation (Supplementary Fig. 1 and the Supplementary Note 1), 180 °C was chosen as heating temperature for the rest of the work as the highest Seebeck coefficient (150 µV K−1) was obtained at this temperature. Then the sample was heated at 180 °C for different durations. It shows that with the increasing time, the Seebeck coefficient quickly increases after 45 min and then saturates even with a duration as long as 3 h. (Supplementary Fig. 3b) Therefore, the heating duration was chosen to be 1 h.

The XRD results in Fig. 1b show a layered structure for both the pristine TiS2 single crystal and the hybrid materials. TiS2(HA) x (DMSO) y is the material after electrochemical intercalation, and TiS2(HA) z represent the composition after vacuum heating the TiS2(HA)x(DMSO)y sample. The interlayer distance (the lattice parameter along the c axis) increases from 5.69 Å for the pristine TiS2 to 18.3 Å for the TiS2(HA) x (DMSO) y , as both HA and DMSO molecules were intercalated in to the van der Waals gap forming a paraffin-like bilayer structure27. After vacuum heating at 180 °C for 1 h, large portion of the organic molecules, including HA and DMSO, were evaporated, which greatly shrinks the interlayer distance. The XRD pattern almost changes back to that of the original TiS2 single crystal, but the (001) peak were shifted and broadened, suggesting the presence of stage disorder in the hybrid materials28. The structure was further confirmed by TEM as shown in Fig. 1c. It shows a disordered high-stage layered structure, in which two or three layers of TiS2 are separated by one organic layer. The results show that the molecules were not uniformly evaporated from the hybrid material. It was shown that in the intercalation compounds, the molecules intercalated into a layered compound increases the strain energy by expanding the interlayer distance29. When there are too few molecules to fill in all the possible interlayer space, these molecules tend to aggregate to form clusters between a single set of the layers, rather than randomly and uniformly distribute in all the interlayer space, because this aggregation can reduce the strain energy of the whole system29. Therefore, when most of the organic molecules are removed from the TiS2(HA) x (DMSO) y hybrid material by vacuum heating, a random high-stage compound is formed to minimize the strain energy, as seen in Fig. 1c.

Nuclear magnetic resonance (NMR) analysis was performed and the composition for the hybrid material after vacuum heating was determined to be TiS2(HA)0.025, which is consistent with the random staging structure, suggested by the XRD and TEM results. There have been some reports showing that both neutral amine and protonated amine coexist in the interlayer space in an intercalated material27. However, in the current approach, organic cation (hexylammonium) dissolved in an aprotic solvent is used as an electrolyte, in which hexylammonium cannot change to neutral amines. Therefore, during the electrochemical intercalation, only the hxylammonium cation with positive charge is intercalated into the layered TiS2. As the hydrogen atoms are sensitive to the charge of the neighboring atoms, NMR spectrum of the hybrid material was examined and was found to be exactly the same as the reference pattern of pure hexylammonium chloride (Supplementary Fig. 4). Therefore, it can be concluded that only hexylammonium cations (protonated amine) are present in the hybrid material, which correspond to the electrons in the TiS2 layers due to the electrical neutrality requirement.

The in-plane thermoelectric properties of the vacuum-heated TiS2(HA)0.025 were measured using the similar procedures reported in ref. 24 and the results are shown in Fig. 2. The thermoelectric properties of the TiS2 single crystal and the previously reported TiS2(HA)0.08(H2O)0.22(DMSO)0.03 were also included for comparison. The electrical conductivity of TiS2(HA)0.025 is comparable to that of the TiS2 single crystal but much lower than that of TiS2(HA)0.08(H2O)0.22(DMSO)0.03. The results of the Hall measurement were shown in Table 1. The carrier concentration of TiS2(HA)0.025 is slightly higher than that of the TiS2 single crystal but much lower than TiS2(HA)0.08(H2O)0.22(DMSO)0.03. The pristine TiS2 single crystal is in fact a narrow band gap semiconductor and a tiny amount of Ti atoms can be self-intercalated into the van der Waals gap during the crystal growth process, introducing additional electrons30. TiS2(HA)0.08(H2O)0.22(DMSO)0.03 was prepared by an electrochemical intercalation method, in which the TiS2 layers were reduced and the electron density was equal to the density of the organic cations according to the electroneutrality requirement. When the density of organic cations is very high, the corresponding carrier concentration is also high, resulting in a low Seebeck coefficient and thus the low power factor. In TiS2(HA)0.025, most of the organic cations were evaporated, which significantly reduces the corresponding carrier concentration. The results confirm that the carrier concentration can be effectively tuned by the removal of organic cations.

Since electrons mainly move inside the inorganic TiS2 layers, the mobility of the intercalated layered materials remain very high. However, they are all lower than the TiS2 single crystal, as the intercalated organic cations can scatter electrons due to the electrostatic force23. In addition, it has been further confirmed that polar neutral solvent molecules, such as H2O and DMSO, surrounding the cations can reduce the electrostatic force by the dielectric screening effect. However, in TiS2(HA)0.025, the polar organic molecules DMSO have been completely evaporated, so the mobility is lower compared with TiS2(HA)0.08(H2O)0.22(DMSO)0.03, due to the absence of the dielectric screening effect by the polar organic molecules.

The Seebeck coefficient is consistent with the results of carrier concentration. The Seebeck coefficient of TiS2(HA)0.025 is lower than that of TiS2 but is significantly higher than that of TiS2(HA)0.08(H2O)0.22(DMSO)0.03. As a result of the enhanced Seebeck coefficient, the power factor of TiS2(HA)0.025 is almost doubled compared with that of the previous TiS2(HA)0.08(H2O)0.22(DMSO)0.03, which is among the best n-type flexible thermoelectric materials3.

The in-plane thermal conductivities of the three materials were plotted in Fig. 2d. Apparently, the thermal conductivity in the hybrid materials is significantly reduced compared with that of the TiS2 single crystal. As suggested by the molecular dynamics simulations, the heat-carrying phonons in the hybrid inorganic/organic superlattices are vigorously damped by the randomly dangling organic molecules24. However, the thermal conductivity of TiS2(HA)0.025 is much higher than that of TiS2(HA)0.08(H2O)0.22(DMSO)0.03. This is because: (1) There are fewer organic molecules in TiS2(HA)0.025 than that in TiS2(HA)0.08(H2O)0.22(DMSO)0.03. (2) The structure is randomly staged and organic molecules are intercalated in every two or three layers. It has been shown24 that the extremely low thermal conductivity of the TiS2/organic superlattice along the in-plane direction is due to organic molecules that are chemically bonded to the TiS2 layers. Molecular dynamics simulations suggest that the organic molecules have random and independent vibrations that strongly disturb phonon transport inside the TiS2 layers. In the high-stage structure, a large portion of the TiS2 layers is not chemically bonded to the organic molecules, for which the disturbing effect of the organic molecules disappears. Therefore, the stage-1 structure is preferred to ensure that every possible TiS2 layer is bonded to the organic molecules for a low thermal conductivity. This is consistent with a recent paper on intercalated graphite compound, which shows that the thermal conductivity of lithiated graphite compounds with a stage-2 structure (LiC18) has a higher in-plane thermal conductivity than a stage-1 structure (LiC6)31.

As shown in Fig. 2e, ZT value of TiS2(HA)0.025 is comparable to that of TiS2(HA)0.08(H2O)0.22(DMSO)0.03, but much larger than that of the TiS2 single crystal. Even though the power factor is remarkably improved by reducing the carrier concentration when organic cations are evaporated, the increase of thermal conductivity prevents further improvement of the ZT value.

Carrier optimization with dual-molecules intercalation

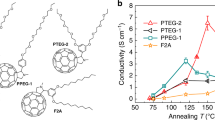

The reduction of carrier concentration remarkably increases the power factor, but fails to improve the ZT value, as the thermal conductivity is increased as a result of formation of the random high-staging structure. The thermal conductivity can potentially be further reduced with small amount of organic molecules if the molecules are distributed uniformly inside the van der Waals gaps of the layered TiS2 single crystal, forming a stage-1 structure. We have thus developed an innovative strategy to evaporate the organic molecules while maintaining the stage-1 structure. Here we co-intercalate two kinds of organic molecules with different atomic weight and boiling points. When heated in vacuum at an intermediate temperature between the two boiling points, the small molecules with a lower boiling point are evaporated, which leads to the reduction of carrier concentration according to the electroneutrality requirement. Meanwhile, the heavy molecules with a higher boiling point remain uniformly distributed in the TiS2 van der Waals gaps and can pillar the layered structure to maintain the stage-1 structure. The great advantage of this strategy is that the amount of evaporated low-boiling point molecules can be adjusted by changing the ratio between the two kinds of molecules, which results in great tunability of carrier concentration. (Supplementary Fig. 5)

The results reported above confirmed that large amounts of HA molecules can be evaporated by vacuum heating at 180 °C for 1 h. Therefore, HA was chosen as the low-boiling point component. Tetrabutylammonium (TBA) molecules with a high atomic weight and a high boiling point (>200 °C) was chosen as another component. In a preliminary experiment (Supplementary Fig. 6), pure TBA molecules were electrochemically intercalated and heated in vacuum at 180 °C for 1 h. The Seebeck coefficient was slightly changed from −59.6 to −63.8 µV K−1, suggesting that most TBA molecules were maintained, resulting in a slight decrease of carrier concentration. Therefore, by intercalating a mixture of TBA and HA molecules into TiS2 and heating the hybrid material at 180 °C for 1 h, most TBA molecules remained uniformly distributed in the van der Waals gaps as it was intercalated, with stage-1 final structure for the hybrid superlattice. In addition, the ratio between the TBA and HA molecules can be tuned by the relative concentration of the two molecules in the electrolyte solution. The XRD patterns for the electrochemical intercalated products with different electrolyte solutions were shown in Supplementary Fig. 7. The interlayer distance for the products with different [TBA]/[HA] ratios were all around 1.6 nm and the patterns are similar, suggesting that the structure is similar. After vacuum heating, the interlayer distance decreases to 1.1 nm and the XRD patterns are also similar (Supplementary Fig. 8), except the [TBA]/[HA] = 1:10 case. Seebeck coefficients of the different compositions were measured and shown in Supplementary Fig. 9. With decreasing [TBA]/[HA] ratio (TBA mole fraction), the Seebeck coefficient increases gradually, suggesting a decrease in carrier concentration.

Samples with high Seebeck coefficients were selected, in which the initial ratio between TBA and HA molecules is 1:5 and 1:7 in the electrolyte solution, respectively. (The 1:10 sample was excluded, as the XRD pattern is close to the previous random stage TiS2(HA)0.025 sample in Fig. 1b, indicating the formation of a staging disorder structure). NMR was first used to analyze the compositions. For the [TBA]:[HA] = 1:5 sample, the electrochemical intercalation gives a hybrid material with a composition of TiS2(TBA)0.026(HA)0.054(DMSO)0.034. The ratio between TBA and HA deviates from the original 1:5 in the electrolyte solution due to the different intercalation ability of the two molecules. After vacuum heating at 180 °C, the composition becomes TiS2(TBA)0.025(HA)0.012. The neutral DMSO molecules were all evaporated as they were weakly bonded with the organic ions. A large portion of the lower boiling point HA molecules was also evaporated, resulting in a reduction of the number in the chemical formula. The heavy TBA molecules with a higher boiling point almost did not evaporate, and the change of the molecular proportion before and after vacuum heating remains within experimental errors. For the [TBA]:[HA] = 1:7 case, the composition of the electrochemical intercalated material was determined to be TiS2(TBA)0.015(HA)0.074(DMSO)0.079. After vacuum heating, the composition became TiS2(TBA)0.013(HA)0.019. The amount of the remaining molecules was much fewer than the [TBA]:[HA] = 1:5 case. The results also suggest the final compositions of the hybrid sample can be effectively tuned by the initial ratio between the TBA and HA ions in the electrolyte solution, rendering the tunability of carrier concentration.

The HRTEM picture of the TiS2(TBA)0.013(HA)0.019 sample, as shown in Fig. 3, clearly suggests a stage-1 layered structure, where the inorganic layers (bright area) and the organic layers stack alternatively. The interlayer distance is 1.1 nm, which is in good agreement with the XRD patterns. The result suggests that the stage-1 superlattice is well maintained by mixing TBA ions and the HA ions. The mixture of the two molecules is initially uniformly distributed in the interlayer space to form a stage-1 compound. When heated at a temperature between two boiling points of HA and TBA, most of the HA molecules are evaporated. However, the TBA molecules remain at their original positions as they were initially intercalated, because the temperature is not high enough to drive the TBA molecules to be mobile. Therefore, the stage-1 structure can be maintained. Furthermore, a hybrid inorganic–organic stage-1 TiS2(TBA) x (HA) y superlattice with tunable x and y has been synthesized by electrochemical intercalation of TiS2 with mixed solution of (TBA) x (HA) y . By selectively evaporating the lower boiling point organic cations, the carrier concentration in the hybrid superlattice can be easily tuned.

a Evolution of structure and carrier concentration of TiS2 single crystal with the electrochemical intercalation of HA/TBA molecules and vacuum heating. b XRD patterns of TiS2 single crystal, TiS2(TBA)0.015(HA)0.074(DMSO)0.079 and TiS2(TBA)0.013(HA)0.019. c Magnified HAADF-STEM image of TiS2(TBA)0.013(HA)0.019

The in-plane thermoelectric properties were measured and shown in Fig. 4. Both the electrical conductivities of the TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 samples are lower than the previously reported TiS2(HA)0.08(H2O)0.22(DMSO)0.03 sample, but much higher than that of the TiS2 single crystal. The results of the Hall measurements are shown in Table 1. The variation of carrier concentrations can account for the difference between the electrical conductivities. The results confirm that the evaporation of low-boiling point organic molecules have successfully decreased the carrier concentration, which is much lower than the TiS2(HA)0.08(H2O)0.22(DMSO)0.03 sample. According to the electroneutrality principle, the total carrier concentration can be estimated from the chemical composition. Supposing that each organic cation corresponds to one elementary charge, the carrier concentration for the TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 sample can be estimated to be 3.3 × 1020 cm−3 and 2.8 × 1020 cm−3, respectively. By adding the electron density (1.8 × 1020 cm−3) inside the original TiS2 single crystal due to the interstitial Ti atoms (Table 1), the final carrier concentration is determined to be 5.1 × 1020 cm−3 and 4.6 × 1020 cm−3, which is in reasonable agreement with the measured values. It also shows that by changing the initial ratio between TBA and HA molecules, the carrier concentration can be effectively tuned as expected.

In-plane thermoelectric properties of TiS2(TBA)0.025(HA)0.012, TiS2(TBA)0.013(HA)0.019 compared with TiS2 single crystal and TiS2(HA)0.08(H2O)0.22(DMSO)0.03: a in-plane electrical conductivity, b in-plane Seebeck coefficient, c in-plane power factor, d in-plane thermal conductivity, e in-plane thermoelectric figure of merit, ZT

The electron mobilities are all lower than the values of the TiS2 single crystal and the previously reported TiS2(HA)0.08(H2O)0.22(DMSO)0.03. It is believed that organic cations in the hybrid superlattices can scatter electrons due to electrostatic force, which results in a reduction of electron mobility compared with the TiS2 single crystal. Both TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 have much lower cation densities than that of TiS2(HA)0.08(H2O)0.22(DMSO)0.03 and are therefore supposed to show higher electron mobility. However, as discussed earlier, the polar DMSO and H2O molecules in TiS2(HA)0.08(H2O)0.22(DMSO)0.03 can effectively screen the electrostatic potential of the organic cations, thereby restoring the electron mobility in the TiS2 layers. In the current TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 compositions, polar DMSO molecules have been evaporated with the HA ions left. Therefore, the dielectric screening effect disappears and the electron mobility decreases compared with TiS2(HA)0.08(H2O)0.22(DMSO)0.03.

The Seebeck coefficients of the TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 samples are all much higher than that of the TiS2(HA)0.08(H2O)0.22(DMSO)0.03 due to the lower carrier concentration shown in Table 1. The Seebeck coefficient of the TiS2(TBA)0.013(HA)0.019 sample is higher than the TiS2(TBA)0.025(HA)0.012 sample, also because of the lower carrier concentration. The power factors of the samples are shown in Fig. 4c. As predicted in the Supplementary Fig. 1, the power factor increases as a function of the reduced carrier concentration. The power factors of the TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 samples are remarkably improved compared with that of the TiS2(HA)0.08(H2O)0.22(DMSO)0.03 sample. For TiS2(TBA)0.025(HA)0.012, the power factor reaches 904 µW m−1 K−2 at 300 K, which is among the best n-type flexible thermoelectric materials. Only recently it has been realized that a high power factor is also very important for thermoelectric power generation32. This is more significant in organic thermoelectric materials than in inorganic thermoelectric materials because organic materials always have low thermal conductivity to maintain the temperature difference in a thermoelectric module in real applications. It is believed the main obstacle for organic materials is its low power factor compared with the inorganic materials, which is most critical for their power output33.

The thermal conductivities of the TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 samples are all much lower than the TiS2 single crystal (Fig. 4d). Using the Wiedemann–Franz law, the electronic thermal conductivities were calculated and the lattice thermal conductivities were obtained by substracting the electronic contribution from the total thermal conductivity. The lattice thermal conductivities were estimated to be 0.92 and 0.87 W m−1 K−1 for the TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 samples, respectively, which are significantly lower than the pristine TiS2 samples (4.5 W m−1 K−1). Molecular dynamic simulations have clarified the mechanism of the thermal conductivity24. It has been found that the acoustic phonons, especially transverse acoustic phonons were significantly scattered by the organic molecules that are chemically bonded to the TiS2 layers, leading to a large reduction of phonon mean free path and thermal conductivity. Meanwhile, it is also found that the reduction of thermal conductivity is not as huge as the TiS2(HA)0.08(H2O)0.22(DMSO)0.03 sample24. It is related with the reduction in the amount of organic molecules. In TiS2(HA)0.08(H2O)0.22(DMSO)0.03, the total amount of organic molecules is about 0.33 mole per unit cell of TiS2. The value becomes 0.037 and 0.032 for the TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 samples, which are ten times lower than that in TiS2(HA)0.08(H2O)0.22(DMSO)0.03. Therefore, the phonon scattering strength is weakened and the lattice thermal conductivity is not as low as the previous TiS2(HA)0.08(H2O)0.22(DMSO)0.03 sample.

Due to the large improvement of the power factor, the ZT value of the TiS2(TBA)0.025(HA)0.012 sample was improved to be 0.33 at 413 K, which is among the highest in the n-type flexible thermoelectric materials. It shows great potential in flexible thermoelectric modules as a counterpart of the p-type conducting polymers, such as PEDOT-PSS.

Thermal stability of the inorganic/organic superlattices were examined using the TG-DTA measurement as shown in Fig. 5a. These two materials are stable until 175 °C in air atmosphere without detectable mass loss. It suggests that the organic molecules that are spatially confined in the van der Waals gap of TiS2 layers can have better thermal stability than their ordinary liquid state. Therefore, energy harvesting and Peltier cooling around room temperature for the hybrid material can be guaranteed.

a TG-DTA curve of TiS2 single crystal, TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019. b The sheet resistance R as a function of bending radius for a TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 crystals, where R 0 is the corresponding value of its original state before bending. c Power factor of TiS2(TBA)0.025(HA)0.012 and TiS2(TBA)0.013(HA)0.019 compared with the other n-type flexible thermoelectric materials

The mechanical flexibility of the hybrid inorganic/organic superlattices was further measured and shown in Fig. 5b. The materials were attached to the surface of glass tube with different radii. The electrical resistance was measured as a function of the bending radius. It can be found the resistance of both materials can be maintained within 5% of its original state until a bending radius of 2.5 mm, suggesting an excellent flexibility. The interlayer expansion by the soft organic molecules can account for the flexibility.

Discussion

To summarize, we developed a strategy to tune the carrier concentration of the hybrid inorganic/organic superlattices without breaking the layer-by-layer structure. We electrochemically intercalate two kinds of organic materials TBA and TA molecules with different boiling points into the van der Waals gap between the inorganic layers. By vacuum heating, the materials at an intermediate temperature between the two boiling points, HA molecules were evaporated which reduces the carrier density in the TiS2 layers due to the electroneutrality requirement. The stage-1 structure is remained with the high boiling point TBA molecules uniformly distributed in the van der Waals gaps. The carrier concentrations can be effectively reduced by 2–3 times. A remarkably high power factor of 904 µW m−1 K−2 was obtained, which is very high among the recently developed n-type flexible thermoelectric materials (Fig. 5c) and even approaches the level of the inorganic materials. Together with a high thermal stability and good flexibility, the TiS2-based inorganic/organic superlattices have shown great promise in flexible modules for wearable energy harvesting or personal temperature management.

Methods

Synthesis

TiS2 single crystals with a typical size of 4 mm × 4 mm × 100 µm were fabricated by chemical vapor transport method30. Organic molecules were electrochemically intercalated into the TiS2 crystals, as shown in Supplementary Fig. 2. The TiS2 single crystals and platinum plate were used as cathode and anode, respectively. TBA and HA chloride dissolved into DMSO was used as electrolyte. The electrochemical intercalation was performed under a constant voltage of 1.5 V. The obtained hybrid inorganic–organic materials were then vacuum heated to selectively evaporate the organic molecules.

Characterization and measurement

The structure was analyzed using XRD and HAADF-STEM. The composition was quantitatively analyzed by 1H NMR using dimethyl sulfone as a reference material. The thermal stability was measured using a TG-DTA system (TG8120, Rigaku). The hall measurement was performed in a commercial system (ResiTest8300, Rigaku). The electrical conductivity and Seebeck coefficients were measured using a home-made apparatus, which had been well calibrated. The thermal diffusivity was measured using laser flash method as introduced in Supplementary Fig. 10. The heat capacity was measured using DSC method and the thermal conductivity was calculated as a product of thermal diffusivity, heat capacity, and density. The resistance as a function of bending radius was described in Supplementary Fig. 11.

Data availability

The data that support the findings of this study are available from the corresponding author on request.

References

Eslamian, M. Inorganic and organic solution-processed thin film devices. Nano Micro Lett. 9, 1–23 (2017).

Avery, A. D. et al. Tailored semiconducting carbon nanotube networks with enhanced thermoelectric properties. Nat. Energy 1, 16033-1-9 (2016).

Bahk, J. H., Fang, H., Yazawa, K. & Shakouri, A. Flexible thermoelectric materials and device optimization for wearable energy harvesting. J. Mater. Chem. C 3, 10362–10374 (2015).

Crispin, X. Carbon nanotubes get high. Nat. Energy 1, 16037-1-2 (2016).

We, J. H., Kim, S. J. & Cho, B. J. Hybrid composite of screen-printed inorganic thermoelectric film and organic conducting polymer for flexible thermoelectric power generator. Energy 73, 506–512 (2014).

Yadav, A., Pipe, K. P. & Shtein, M. Fiber-based flexible thermoelectric power generator. J. Power Sources 175, 909–913 (2008).

Snyder, G. J. & Toberer, E. S. Complex thermoelectric materials. Nat. Mater. 7, 105–114 (2008).

Kim, G. H., Shao, L., Zhang, K. & Pipe, K. P. Engineered doping of organic semiconductors for enhanced thermoelectric efficiency. Nat. Mater. 12, 719–723 (2013).

Cho, C. et al. Completely organic multilayer thin film with thermoelectric power factor rivaling inorganic tellurides. Adv. Mater. 27, 2996–3001 (2015).

Schlitz, R. A. et al. Solubility-limited extrinsic n-type doping of a high electron mobility polymer for thermoelectric applications. Adv. Mater. 26, 2825–2830 (2014).

Russ, B. et al. Power factor enhancement in solution-processed organic n-type thermoelectrics through molecular design. Adv. Mater. 26, 3473–3477 (2014).

Shi, K. et al. Toward high performance n-type thermoelectric materials by rational modification of BDPPV backbones. J. Am. Chem. Soc. 137, 6979–6982 (2015).

Zhang, B., Sun, J., Katz, H. E., Fang, F. & Opila, R. L. Promising thermoelectric properties of commercial PEDOT:PSS materials and their Bi2Te3 powder composites. ACS Appl. Mat. Interfaces 2, 3170–3178 (2010).

Wang, Z. H. et al. Electronic transport properties of KxC70 thin-films. Phys. Rev. B 48, 10657–10660 (1993).

Menke, T., Ray, D., Meiss, J., Leo, K. & Riede, M. In-situ conductivity and Seebeck measurements of highly efficient n-dopants in fullerene C-60. Appl. Phys. Lett. 100, 093304-1-4 (2012).

Kim, S. L., Choi, K., Tazebay, A. & Yu, C. Flexible power fabrics made of carbon nanotubes for harvesting thermoelectricity. ACS Nano 8, 2377–2386 (2014).

Dun, C. et al. Flexible n-type thermoelectric films based on Cu-doped Bi2Se3 nanoplate and polyvinylidene fluoride composite with decoupled seebeck coefficient and electrical conductivity. Nano Energy 18, 306–314 (2015).

Huang, D. Z. et al. Bismuth interfacial doping of organic small molecules for high performance n-type thermoelectric materials. Angew. Chem. Int. Edit. 55, 10672–10675 (2016).

Sun, Y. et al. Organic thermoelectric materials and devices based on p- and n-type poly(metal 1,1,2,2-ethenetetrathiolate)s. Adv. Mater. 24, 932–937 (2012).

Sun, Y. et al. Flexible n-type high-performance thermoelectric thin films of poly(nickel-ethylenetetrathiolate) prepared by an electrochemical method. Adv. Mater. 28, 3351–3358 (2016).

Karttunen, A. J., Tynell, T. & Karppinen, M. Layer-by-layer design of nanostructured thermoelectrics: First-principles study of ZnO:organic superlattices fabricated by ALD/MLD. Nano Energy 22, 338–348 (2016).

Tynell, T., Terasaki, I., Yamauchi, H. & Karppinen, M. Thermoelectric characteristics of (Zn,Al)O/hydroquinone superlattices. J. Mater. Chem. A 1, 13619–13624 (2013).

Wan, C. et al. Dielectric mismatch mediates carrier mobility in organic-intercalated layered TiS2. Nano Lett. 15, 6302–6308 (2015).

Wan, C. et al. Flexible n-type thermoelectric materials by organic intercalation of layered transition metal dichalcogenide TiS2. Nat. Mater. 14, 622–627 (2015).

Zhao, L. D. et al. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 508, 373–377 (2014).

Liu, H. L. et al. Copper ion liquid-like thermoelectrics. Nat. Mater. 11, 422–425 (2012).

Schollho, R. & Weiss, A. Cation-exchange reactions and layer solvate complexes of ternary phases MxMoS2. J. Less Common Met. 36, 229–236 (1974).

Inagaki, M. & Tanaike, O. Formation of Na-THF-graphite intercalation compounds. J. Phys. Chem. Solids 57, 795–798 (1996).

Dresselhaus, M. S. & Dresselhaus, G. Intercalation compounds of graphite. Adv. Phys. 51, 1–186 (2002).

Kukkonen, C. A. et al. Transport and optical-porperties of Ti1+x S2. Phys. Rev. B 24, 1691–1709 (1981).

Qian, X., Gu, X. K., Dresselhaus, M. S. & Yang, R. G. Anisotropic tuning of graphite thermal conductivity by lithium intercalation. J. Phys. Chem. Lett. 7, 4744–4750 (2016).

Liu, W. S., Kim, H. S., Jie, Q. & Ren, Z. F. Importance of high power factor in thermoelectric materials for power generation application: a perspective. Scripta Mater. 111, 3–9 (2016).

Russ, B., Glaudell, A., Urban, J. J., Chabinyc, M. L. & Segalman, R. A. Organic thermoelectric materials for energy harvesting and temperature control. Nat. Rev. Mater. 1, 1–14 (2016).

Acknowledgements

C.W. acknowledges financial support from 1000 Plan Program for Young Talents of China. K.K. acknowledges financial support from JSPS KAKENHI Grant no. 25289226 and NEDO-TherMat. R.Y. acknowledges the support from the US National Science Foundation (Grant No. 1512776).

Author information

Authors and Affiliations

Contributions

C.W. initiated the concepts and designed the experiments. C.W., R.T., M.C., and P.Z. conducted the experiments, including the synthesis, characterization, and the measurements. C.W. and R.Y. did the analysis and wrote the manuscript. All of the authors contributed to manuscript preparation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wan, C., Tian, R., Kondou, M. et al. Ultrahigh thermoelectric power factor in flexible hybrid inorganic-organic superlattice. Nat Commun 8, 1024 (2017). https://doi.org/10.1038/s41467-017-01149-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-017-01149-4

This article is cited by

-

Fully inkjet-printed Ag2Se flexible thermoelectric devices for sustainable power generation

Nature Communications (2024)

-

Recent advances on liquid intercalation and exfoliation of transition metal dichalcogenides: From fundamentals to applications

Nano Research (2024)

-

Core/hybrid-shell structures boost thermoelectric performance of flexible inorganic/organic nanowire films

Nano Research (2023)

-

Rational design of stretchable and highly aligned organic/inorganic hybrid nanofiber films for multidirectional strain sensors and solar-driven thermoelectrics

Science China Materials (2023)

-

Ultrahigh transverse thermoelectric power factor in flexible Weyl semimetal WTe2

Nature Communications (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.