Abstract

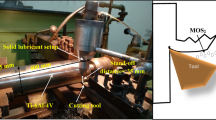

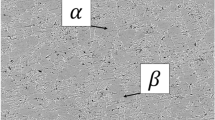

Titanium alloys are well known as difficult-to-machine materials due to their chemical affinity, low thermal conductivity, and low modulus of elasticity, causing premature wear of the tool, compromising the machining quality and increasing costs. Several solutions have been followed to improve the machinability of these alloys: development of new machining techniques, tool geometries, and protection of tools’ surface with coatings, to yield high productivity, good surface finish of the work piece, and extended tool life. In this paper, the contact phenomenon between tool and workwise used for machining operation in various machine tools is simulated to estimate the coefficient of friction (COF), friction force (FF), and wear rate of titanium alloy grade 5 (Ti–6Al–4V). In this work, the experiments are performed on a pin-on-disk apparatus to estimate tribological features of titanium alloy for different speeds and loading conditions. Pins were mounted in a pin holder and fed against a rotating disk at required speeds. The trials were performed on a titanium alloys for duration of 5, 7.5, and 10 min for load of 5 kg, 6 kg, 7 kg, 8 kg, 9 kg, and 10 kg with disk speeds of 400 rpm, 500 rpm, 600 rpm, 700 rpm, 800 rpm, and 900 rpm. The results show that the COF varies with duration of rubbing, normal load, and speeds. In general, COF decreases continuously for certain duration of rubbing and after that it remains constant for the rest of the experimental time. The wear of titanium alloys significantly increases initially as load varies from 7 to 10 kg due to more contents of Al and vanadium. Hence, it becomes imperative to analyze the wear characteristics of different types of titanium alloy.

Similar content being viewed by others

Change history

05 August 2023

A Correction to this paper has been published: https://doi.org/10.1007/s40735-023-00789-y

References

Dewidar M (2006) Improvement of hardness and wear resistance of Ti-6Al-4V alloy by thermal oxidation for biomedical application. J Eng Sci 34(6):1941–1951

Boyer R, Welsch G, Collings EW (1994) Titanium alloys. ASM International, Materials Park. ISBN 978-0-87-170481-8

Buytoz S (2006) Microstructural properties of SiC based hard facing on low alloy steel. Surf Coat Technol 200(12–13):3734–3742

Wang K (1996) The use of titanium for medical applications in the USA. Mater Sci Eng A 213(1–2):134–137

Long M, Rack HJ (1998) Titanium alloys in total joint replacement—a materials science perspective. Biomaterials 19(18):1621–1639

Dong H, Groll EA, Bell T (1999) Potential of improving tribological performance of UHMWPE by engineering the Ti6Al4V counterfaces. Wear 225–229(2):874–884

Long M, Rack HJ (2001) Friction and surface behavior of selected titanium alloys during reciprocating-sliding motion. Wear 249(1–2):157–167

Choubey A, Basu B, Balasubramania R (2005) Tribological behaviour of Ti-based alloys in simulated bodyfluid solution at fretting contacts. Trends Biomater Artif Organs 18(2):141–147

Qu J, Blau PJ, Watkins T, Kulkrani NS (2005) Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces. Wear 258(9):1348–1356

Cui XH, Mao YS, Wei MX, Wang SQ (2012) Wear characteristics of Ti-6Al-4V alloy at 20–400°C. Tribol Trans 55(2):185–190

ASTM standards test method for wear testing with a pin-on-disk apparatus, designation G99-95a (reapproved 2000)

Kumar D, Deepak KB, Muzakkir SM, Wani MF, Lijesh KP (2018) Enhancing tribological performance of Ti-6Al-4V by sliding process. Tribol Mater Surf Interfaces. https://doi.org/10.1080/17515831.2018.1482676

Din SH, Shah MA, Sheikh NA (2018) Tribological performance of titanium alloy Ti–6Al–4V via CVD–diamond coatings. J Superhard Mater 40(1):26–39

Funding

This work is not supported fully or partially by any funding organization or agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was corrected: The spelling of Ch. Ratnam’s name was corrected.

Rights and permissions

About this article

Cite this article

Santhosha Rathnam, G., Ratnam, C. Experimental Investigations on Tribological Characteristics of Ti–6Al–4V Under Wet Conditions. J Bio Tribo Corros 6, 19 (2020). https://doi.org/10.1007/s40735-019-0314-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-019-0314-9