Abstract

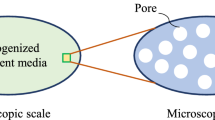

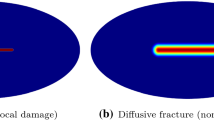

This article presents a constitutive model for the elastic–plastic, viscoplastic and damage behaviour of hard porous rocks. The main hypotheses of the model are based on a large set of experimental data which are also presented in the paper. This constitutive model is of the over-stress type and is formulated within the unified theory of inelastic flow. An energy-based failure surface was considered to describe both short- and long-term behaviours within the same formulation. The inelastic yield surface is of static nature while the failure and damage surfaces are of dynamic nature. The kinetic law is written in terms of internal state variables that allow the description of how the frictional and the cohesive internal strengths of the material evolves. The reversible inelastic behaviour is also modelled using the “under-stress” concept, and considering that, it depends explicitly on the locked energy during the inelastic flow. In addition, this model is adapted to the porous nature of rocks such as iron ore that exhibit strong volumetric deformations and mean stress dependence. A large fraction of the volumetric straining is explained by damage mechanisms that also allow the accelerated creep to be modelled. Model parameters can easily be identified in the laboratory with commonly used mechanical tests. The constitutive model was implemented in a numerical code, and some qualitative simulations and comparisons with experimental curves showed the suitability of the model to reproduce both short- and long-term behaviours of porous rocks similar to iron ore.

Similar content being viewed by others

Abbreviations

- H(x):

-

Heaviside function

- <x> = ½ (x + |x|):

-

Macaulay brackets

- t :

-

Time

- x in :

-

Inelastic component

- x vp :

-

Viscoplastic (time-dependent) component

- \( \underline{\underline{{\dot{\varepsilon }}}} = \underline{\underline{{\dot{\varepsilon }}}}^{\text{e}} + \underline{\underline{{\dot{\varepsilon }}}}^{\text{in}} = \underline{\underline{{\dot{\varepsilon }}}}^{\text{e}} + \underline{\underline{{\dot{\varepsilon }}}}^{\text{p}} + \underline{\underline{{\dot{\varepsilon }}}}^{\text{vp}} \) :

-

Strain partition

- \( \dot{\varepsilon }_{\text{v}}^{\text{in}} = \dot{\varepsilon }_{11}^{\text{in}} + \dot{\varepsilon }_{22}^{\text{in}} + \dot{\varepsilon }_{33}^{\text{in}} \) :

-

Inelastic volumetric strain

- \( \beta = \dot{\varepsilon }_{\text{v}} /\dot{\gamma } \) :

-

Dilatancy coefficient

- \( \sigma_{\text{eq}} = \sqrt {\frac{3}{2}\underline{\underline{s}} :\underline{\underline{s}} } \) :

-

Equivalent (Von Mises) deviatoric stress

- \( \underline{\underline{s}} \) :

-

Deviatoric stress tensor

- K :

-

Elastic bulk modulus

- A :

-

Scaling parameter for kinetic law \( \dot{\gamma }^{\text{in}} \)

- σ 0 :

-

Normalisation parameter (=1 MPa)

- Y o :

-

Initial value of Y

- Y r :

-

Slope of peak surface of plasticity

- Y 2 :

-

Scaling parameter of Y

- η o :

-

Initial value of η

- η 1 :

-

Scaling parameter of η

- w in,tot :

-

Total inelastic work

- \( w_{{{\text{vol}}}}^{\text{in}} \) :

-

Volumetric inelastic work

- w 1 :

-

Scaling parameter of \( w_{{{\text{d }}\hbox{max}}}^{\text{in}} \)

- \( \underline{\underline{{\dot{\varepsilon }}}}^{\text{in*}} \) :

-

“Standard” inelastic* strain

- \( \underline{\underline{{\dot{\varepsilon }}}}^{\text{b}} \) :

-

“Backward” (reverse) inelastic strain

- \( \dot{\gamma }^{\text{f}} \) :

-

“Forward” inelastic distortion

- \( Y^{*} \) :

-

“Standard” frictional strength

- Y f :

-

“Forward” frictional strength

- \( (\gamma^{{{\text{in}}*}} )_{{{ \hbox{max} }}} \) :

-

Maximal distortion

- \( w_{{{\text{d}}\hbox{max}}}^{{{\text{in}}*}} \) :

-

Deviatoric “standard” inelastic* work at failure

- \( w^{{{\text{in}}*,{\text{lock}}}} \) :

-

Locked “standard” inelastic* energy

- \( w_{\hbox{max}}^{{{\text{b,lock}}}} \) :

-

Locked energy available for “backward” strain

- w f,lock :

-

Locked “forward” energy

- C :

-

Scaling parameter for kinetic law \( \dot{\gamma }^{\text{f}} \)

- \( w^{{{\text{in}}*,{\text{diss}}}} \) :

-

Dissipated “standard” inelastic* energy

- D :

-

Isotropic damage variable

- \( w_{{{\text{d}}\,{\text{crit}}}}^{{{\text{in}}*}} \) :

-

Deviatoric inelastic energy at damage onset

- ξ :

-

Scaling parameter of damage function

-

:

: -

Fourth-order elasto-damaged stiffness tensor

- ϕ d :

-

Damage porosity

- ϕ 2 :

-

Scaling parameter for damage porosity

- \( \tilde{H} \) :

-

Conjugate of the Heaviside function

- \( \dot{x} \) :

-

Rate of x

- x e :

-

Elastic (time-independent) component

- x p :

-

Plastic (time-independent) component

- \( \underline{\underline{{\dot{\varepsilon }}}} \) :

-

Strain tensor

- \( \dot{\gamma }^{\text{in}} = \sqrt {\frac{2}{3}\underline{\underline{{\dot{e}}}}^{\text{in}} :\underline{\underline{{\dot{e}}}}^{\text{in}} } \) :

-

Inelastic distortion

- \( \underline{\underline{{\dot{e}}}}^{\text{in}} = \underline{\underline{{\dot{\varepsilon }}}}^{\text{in}} - \frac{1}{3}{\text{tr}}\,\underline{\underline{{\dot{\varepsilon }}}}^{\text{in}} \) :

-

Deviatoric strain tensor

- \( \underline{\underline{\sigma }} \) :

-

Cauchy stress tensor

- \( \sigma_{\text{m}} = \frac{1}{3}{\text{tr }}\underline{\underline{\sigma }} \) :

-

Mean stress

- G :

-

Elastic shear modulus

- F d :

-

Deviatoric yield function

- n :

-

Scaling parameter for kinetic law \( \dot{\gamma }^{\text{in}} \)

- Y :

-

Frictional strength (scalar state variable)

- Y m :

-

Peak value of Y

- Y 1 :

-

Scaling parameter of Y

- η :

-

Cohesive strength (scalar state variable)

- η m :

-

Maximal value of η

- (γ in)max :

-

Maximal inelastic distortion

- \( w_{\text{d}}^{\text{in}} \) :

-

Deviatoric inelastic work

- \( w_{{{\text{d max}}}}^{\text{in}} \) :

-

Deviatoric inelastic work at failure

- w 2 :

-

Scaling parameter of \( w_{{{\text{d }}\hbox{max}}}^{\text{in}} \)

- \( \underline{\underline{{\dot{\varepsilon }}}}^{\text{f}} \) :

-

“Forward” inelastic strain

- \( \dot{\gamma }^{{{\text{in}}*}} \) :

-

“Standard” inelastic* distortion

- \( \dot{\gamma }^{\text{b}} \) :

-

“Backward” (reverse) inelastic distortion

- \( \eta^{*} \) :

-

“Standard” cohesive strength

- \( \eta^{\text{f}} \) :

-

“Forward” cohesive strength

- \( w_{\text{d}}^{\text{in*}} \) :

-

Deviatoric “standard” inelastic* work

- w in,lock :

-

Locked inelastic energy

- x :

-

Recoverable fraction of \( w^{{{\text{in*,lock}}}} \)

- w b,lock :

-

Locked “backward” energy

- B :

-

Scaling parameter for kinetic law \( \dot{\gamma }^{\text{b}} \)

- w in,diss :

-

Dissipated inelastic energy

- \( w^{{{\text{in*,tot}}}} \) :

-

Total “standard” inelastic* energy

- \( w_{\text{vol}}^{\text{in*}} \) :

-

Volumetric “standard” inelastic* work

- F dam :

-

Energy-based damage function

- \( \tilde{F}_{\text{d}} \) :

-

Deviatoric yield function with damage

-

:

: -

Fourth-order elasticity stiffness tensor

- ϕ 1 :

-

Scaling parameter for damage porosity

References

Aktaa J, Schinke B (1997) Unified modelling of time dependent damage taking into account an explicit dependency on backstress. Int J Fatigue 19(3):195–200

Arndt M, Griebel M, Novak V, Roubicek T, Sittner P (2006) Martensitic transformation in NiMnGa single crystals: numerical simulation and experiments. Int J Plast. 22:1943–1961

Atkinson BK (1982) Subcritical crack propagation in rocks: theory, experimental results and applications. J Struct Geol 4:41–56

Atkinson BK (1984) Subcritical crack growth in geological materials. J Geophys Res 89(B6):4077–4114

Atkinson BK, Meredith PG (1987) The theory of subcritical crack growth with applications to minerals and rocks. Fract Mech Rock. Academic Press, London, pp 111–166

Aubertin M, Gill DE, Ladanyi B (1991) A unified viscoplastic model for the inelastic flow of alkali halides. Mech Mater 11:63–82

Aubertin M, Gill DE, Ladanyi B (1993) Modeling the transcient inelastic flow of rocksalt. In: Seventh symposium on salt. Elsevier Science Publishers B.V., Amsterdam, vol 1, pp 93–104

Aubertin M, Yahya OML, Julien M (1999) Modeling mixed hardening of alkali halides with a modified version of an internal state variables model. Int J Plast. 15:1067–1088

Auricchio F, Reali A, Stefanelli U (2007) A three-dimensional model describing stress-induced solid phase transformation with permanent inelasticity. Int J Plast 23:207–226

Bailey RW (1926) Note on the softening of strain hardening metals and its relation to creep. J Inst Metals 35:27–40

Barber DJ, Wenk H-R (1979) On geological aspects of calcite microstructure. Tectonophysics 54:45–60. doi:10.1016/0040-1951(79)90111-2

Baud P, Meredith PG (1997) Damage accumulation during triaxial creep of Darley Dale sandstone from pore volumometry and acoustic emission. Int J Rock Mech Min Sci 34(3–4):371

Baud P, Schubnel A, Wong T-F (2000) Dilatancy, compaction, and failure mode in Solnhofen limestone. J Geophys Res 105(B8):19289–19303

Becker M, Hackenberg H-P (2011) A constitutive model for rate dependent and rate independent inelasticity. Application to IN718. Int J Plast 27(4):596–619

Bieniawski ZT (1967) Mechanism of brittle fracture of rock, parts I, II, III. Int J Rock Mech Min Sci 4:395–430

Blum W (2001) Creep of crystalline materials: experimental basis, mechanisms and models. Mater Sci Eng A319–321, 8–15

Boyko VS, Garber RI, Kossevich AM (1994) Reversible crystal plasticity. American Institute of Physics, New York

Briottet L, Klöcker H, Montheillet F (1998) Damage in a viscoplastic material—part II. Overall behaviour. Int J Plast 14(6):453–471

Cadek J (1987) The back stress concept in power creep law of metals: a review. Mater Sci Eng 9:79–92

Cai W, Bulatov VV, Justo JF, Argon AS, Yip S (2000) Intrinsic mobility of a dissociated dislocation in silicon. Phys Rev Lett 8(15):3346

Chaboche JL (2008) A review of some plasticity and viscoplasticity constitutive theories. Int J Plast 24(10):1642–1693

Charlez PA (1991) Rock mechanics: theoretical fundamentals, vol 1, Editions. Technip

Chen L, Shao JF, Huang HW (2010) Coupled elastoplastic damage modeling of anisotropic rocks. Comput Geotech 37:187–194

Cheng GJ, Shehadeh MA (2006) Multiscale dislocation dynamics analyses of laser shock peening in silicon single crystals. Int J Plast 22:2171–2194

Cicekli U, Voyiadjis GZ, Abu Al-Rub RK (2007) A plasticity and anisotropic damage model for plain concrete. Int J Plast 23(10):1874–1900

Cocks ACF (1989) Inelastic deformation of porous materials. J Mech Phys Solids 37:693–715

Colak OU (2005) Modeling deformation behavior of polymers with viscoplasticity theory based on overstress. Int J Plast 21(1):145–160

Cristescu ND (1993) A general constitutive equation for transient and stationary creep of rock salt. Int J Rock Mech Min Sci Geomech Abstr 30(2):125–140

Croizé D, Renard F, Bjørlykke K, Dysthe DK (2010) Experimental calcite dissolution under stress: evolution of grain contact microstructure during pressure solution creep. J Geophys Res B Solid Earth 115(9):B09207

Dagallier G, Grgic D, Homand F (2002) Mineralogical and microtextural characterisation of the anthropic-origin ageing of iron ore in Lorraine (France). CRAS 334:455–462

De Borst R (2002) Fracture in quasi-brittle materials: a review of continuum damage-based approaches. Eng Fract Mech 69(2):95–112

Duvaut G, Lions LJ (1962) Inequalities in mechanics and physics. Springer, Berlin

Eslami J, Grgic D, Hoxha D (2010) Estimation of the damage of a porous limestone from continuous (P- and S-) wave velocity measurements under uniaxial loading and different hydrous conditions. Geophys J Int 183:1362–1375

Faruque MO, Zaman M, Hossain MI (1996) Creep constitutive modeling of an aluminum alloy under multiaxial and cyclic loading. Int J Plast 12(6):761–780

Fonseka GM, Murrell SAF, Barnes P (1985) Scanning electron microscope and acoustic emission studies of crack development in rock. Int J Rock Mech Min Sci 22:273–289

Freed AD, Walker KP (1993) Viscoplasticity with creep and plasticity bounds. Int J Plast 9:213–242

Gerberich WW, Mook WM, Cordill MJ, Barry Carter C, Perrey CR, Heberlein JV, Girshick SL (2005) Reverse plasticity in single crystal silicon nanospheres. Int J Plast 21(12):2391–2405

Grgic D (2001) Modelling of the short and long-term behavior of rocks of Lorraine (France) ferriferous formation. Ph.D. Thesis, INPL, Nancy (in French)

Grgic D (2011) The influence of CO2 on physico-chemical and mechanical properties of an oolithic limestone. J Geophys Res B Solid Earth 116:B07201. doi:10.1029/2010JB008176

Grgic D, Amitrano D (2009) Creep of a porous rock and associated acoustic emission under different hydrous conditions. J Geophys Res 114:B10201

Grgic D, Homand F, Hoxha D (2003) A short- and long-term rheological model to understand the collapses of iron mines in Lorraine, France. Comput Geotech 30:557–570

Grgic D, Giot R, Homand F, Giraud A (2005) Effect of suction on the mechanical behaviour of iron ore rock. Int J Numer Anal Methods Geomech 29:789–827

Grgic D, Homand F, Giraud A (2006) Modelling of the drying and flooding of underground iron mines in Lorraine (France). Int J Rock Mech Min Sci 43:388–407

Guéry AA-C, Cormery F, Su K, Shao JF, Kondo D (2008) A micromechanical model for the elasto-viscoplastic and damage behavior of a cohesive geomaterial. Phys Chem Earth 33(Suppl 1):S416–S421

Guéry AA-C, Cormery F, Su K, Shao JF, Kondo D (2008) A micromechanical model of elastoplastic and damage behavior of a cohesive geomaterial. Int J Solids Struct 45:1406–1429

Guéry AA-C, Cormery F, Shao JF, Kondo D (2009) A multiscale modeling of damage and time-dependent behavior of cohesive rocks. Int J Numer Anal Methods Geomech 33(5):567–589

Guessous Z, Gill DE, Ladanyi B (1987) Effect of simulated sampling disturbance on creep behaviour of rock salt. Rock Mech Rock Eng 20:261–275

Hadley K (1976) Comparison of calculated and observed crack densities and seismic velocities in Westerley granite. J Geophys Res 81:3484–3487

Hashiguchi K, Okayasu T (2000) Time-dependent elastoplastic constitutive equation based on the subloading surface model and its application to soils. Soils Found 40(3):21–36

Hashiguchi K, Okayasu T, Saitoh K (2005) Rate-dependant inelastic constitutive equation: the extension of elastoplasticity. Int J Plast 21:463–491

Haupt P, Kersten Th (2003) On the modelling of anisotropic material behaviour in viscoplasticity. Int J Plast 19:1885–1915

Heap MJ, Baud P, Meredith PG, Bell AF, Main IG (2009) Time dependent brittle creep in Darley Dale sandstone. J Geophys Res 114:B07203. doi:10.1029/2008JB006212

Heap MJ, Baud P, Meredith PG (2009) Influence of temperature on brittle creep in sandstones. Geophys Res Lett 36(19):L19305. doi:10.1029/2009GL039373

Heeres OM, Suiker ASJ, de Borst R (2002) A comparison between the Perzyna viscoplastic modal and the Consistency viscoplastic model. Eur J Mech A/Solids 21:1–12

Hickman RJ, Gutierrez MS (2007) Formulation of a three-dimensional rate-dependent constitutive model for chalk and porous rocks. Int J Numer Anal Methods Geomech 31(4):583–605

Holt R, Furre A, Horsrud P (1997) Stress dependent wave velocities in sedimentary rock cores: Why and why not? Int J Rock Mech Min Sci Geomech Abstr 34(3–4):399

Horii H, Nemat-Nasser (1983) Overall moduli of solids with microcracks: load-induced anisotropy. J Mech Phys Solids 31(2):151–171

Hoxha D, Giraud A, Homand F (2005) Modelling long-term behaviour of a natural gypsum rock. Mech Mater 37:1223–1241

Hu DW, Zhu QZ, Zhou H, Shao JF (2010) A discrete approach for anisotropic plasticity and damage in semi-brittle rocks. Comput Geotech 37:658–666

Hunshe U, Hampel A (1999) Rock salt—the mechanical properties of the host rock material for a radioactive waste repository. Eng Geol 52:271–291

Itasca Consulting Group Inc. (1998) Flac Lagrangian analysis of continua in 2 dimensions. User’s manual

Jeong H-S, Kang S-S, Obara Y (2007) Influence of surrounding environments and strain rates on the strength of rocks subjected to uniaxial compression. Int J Rock Mech Min Sci 44:321–331

Jiang T, Shao JF, Xu WY (2011) A micromechanical analysis of elastoplastic behavior of porous materials. Mech Res Commun 38:437–442

Jin J, Cristescu ND (1998) An elastic/viscoplastic model for transient creep of rock salt. Int J Plast 14(1–3):85–107

Ju JW (1989) On energy based coupled elastoplastic damage theories: constitutive modeling and computational aspects. Int J Solids Struct 25(7):803–833

Kafka V, Vokoun D (2005) On backstresses, overstresses, and internal stresses represented on the mesoscale. Int J Plast 21(8):1461–1480

Kowalewski ZL, Hayhurst DR, Dyson BF (1994) Mechanisms-based creep constitutive equations for an aluminium alloy. J Strain Anal 29:309–316

Kranz R (1983) Microcracks in rocks: a review. Tectonophysics 100(1–3):449–480

Kruch S, Chaboche J-L (2011) Multi-scale analysis in elasto-viscoplasticity coupled with damage. Int J Plast (in press), corrected proof. Available online 14 April 2011, ISSN 0749-6419. doi:10.1016/j.ijplas.2011.03.007

Lemaitre J (1992) A course on damage mechanics, 2nd edn. Springer, Berlin

Lemaitre J, Chaboche J-L (1990) Mechanics of solids materials. Cambridge University Press, Cambridge

Lin QX, Tham LG, Yeung MR, Lee PKK (2004) Failure of granite under constant loading. Int J Rock Mech Min Sci 41(Suppl 1):1A09, 1–6

Lissenden CJ, Doraiswamy D, Arnold SM (2007) Experimental investigation of cyclic and time-dependent deformation of titanium alloy at elevated temperature. Int J Plast 23(1):1–24

Liu J, Walter JM, Weber K (2002) Fluid-enhanced low-temperature plasticity of calcite marble: microstructures and mechanisms. Geology 30(9):787–790

Lockner D (1993) Room temperature creep in saturated granite. J Geophys Res 98:475–487

Manonukul A, Dunne FPE, Knowles D, Williams S (2005) Multiaxial creep and cyclic plasticity in nickel-base superalloy C263. Int J Plast 21(1):1–20

Maranini E, Yamaguchi T (2001) A non-associated viscoplastic model for the behaviour of granite in triaxial compression. Mech Mater 33:283–293

Marin EB, McDowell L (1996) Associative versus non-associative porous visco-plasticity based on internal state variable concepts. Int J Plast 12(5):629–669

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci 31:643–659

McDowell DL (1992) A nonlinear kinematic hardening theory for cyclic thermoplasticity and thermoviscoplasticity. Int J Plast 8:695–728

McNee KR, Greenwood GW, Jones H (2002) On the mechanisms of dynamic recovery. Scripta Mater 47:619–623

Meredith PG, Atkinson BK (1983) Stress corrosion and acoustic emission during tensile crack propagation in Whin Sill dolerite and other basic rocks. Geophys J Astr Soc 75:1–21

Miguel M-C, Vesignani A, Zapperi S, Weiss J, Grasso JR (2001) Intermittent dislocation flow in viscoplastic deformation. Nature 410:667–671

Mohamad-Hussein A, Shao J-F (2007) Modelling of elastoplastic behaviour with non-local damage in concrete under compression. Comput Struct 85(23–24):1757–1768

Nara Y, Takada M, Igarashi T, Hiroyoshi N, Kaneko K (2007) Subcritical crack growth in rocks in an aqueous environment. Explor Geophys 40(1):163–171

Nemat-Nasser S, Obata M (1988) Microcrack model of dilatancy in brittle materials. J Appl Mech 55:24–35

Nes E, Marthinsen K, Brechet Y (2002) On the mechanisms of dynamic recovery. Scripta Mater 47:607–611

Ohashi Y, Kawai M, Momose T (1986) Effects of prior creep on subsequent plasticity of type 316 stainless steel at elevated temperature. J Eng Mater Technol, ASME 108:69–74

Ohnaka M (1983) Acoustic emission during creep of brittle rock. Int J Rock Mech Min Sci 20:121–134

Ohnaka M, Mogi K (1982) Frequency characteristics of acoustic emission in rocks under uniaxial compression and its relation to the fracturing process to failure. J Geophys Res 87:3873–3884

Onat ET (1981) Representation of inelastic behaviour. In: Proceedings of international conference on creep and fractures in engineering materials and structures. Pineridge Press, Swansea, p 587

Orlova A (1991) On the relation between dislocation structure and internal stress measured in pure metals and single alloys in high temperature creep. Acta Metall Mater 39:2805–2813

Orowan E (1946) The creep of metals. J West Scotl Iron Steel Inst 54:45–68

Perzyna P (1963) The constitutive equations for rate sensitive plastic materials. Q Appl Math 20:321–332

Perzyna P (1966) Fundamental problems in viscoplasticity. Adv Appl Mech 9(2):244–368

Perzyna P (1971) Thermodynamic theory of viscoplasticity. Adv Appl Mech 11:313–354

Plechac P, Roubicek T (2002) Visco-elasto-plastic model for martensitic phase transformation in shape-memory alloys. Math Methods Appl Sci 25:1281–1298

Poirier J-P (1995) Plastic rheology of crystals. In: Arhens TJ (ed) Mineral physics and crystallography. A handbook of physical constants. American Geophysical Union, USA

Pouya A (2000) Micro-macro approach for the rock salt behaviour. Eur J Mech A/Solids 19(16):1015–1028

Rajagopal KR, Roubicek T (2003) On the effect of dissipation in shape-memory alloys. Nonlinear Anal Real World Appl 4:581–597

Rehbinder PA, Lichtman V (1957). Effect of surface active media on strain and rupture in solids. In: Proceedings of international congress of surface activity, II, III, pp 563–580

Renner J, Evans B, Siddiqi G (2002) Dislocation creep of calcite. J Geophys Res 107(B12):2364. doi:10.1029/2001JB001680

Ristinmaa M, Ottosen NS (2000) Consequences of dynamic yield surface in viscoplasticity. Int J Solids Struct 37:4601–4622

Royne A, Bisschop J, Dysthe DK (2011) Experimental investigation of surface energy and subcritical crack growth in calcite. J Geophys Res. doi:10.1029/2010JB008033

Rutter EH (1972) The influence of interstitial water on the rheological behaviour of calcite rocks. Tectonophysics 14:13–33. doi:10.1016/0040-1951(72)90003-0

Rutter EH (1972) On the creep testing of rocks at constant stress and constant force. Int J Rock Mech Min Sci 9:191–195

Rutter EH (1974) The influence of temperature, strain rate and interstitial water in the experimental deformation of calcite rocks. Tectonophysics 22:311–334

Schapery RA (1999) Nonlinear viscoelastic and viscoplastic constitutive equations with growing damage. Int J Fract 97:33–66

Scholz CH (1968) Mechanism of creep in brittle rock. J Geophys Res 73(10):3295–3302. doi:10.1029/JB073i010p03295

Scholz CH (1972) Static fatigue of quartz. J Geophys Res 77(11):2104–2114. doi:10.1029/JB077i011p02104

Schubnel A, Fortin J, Burlini L, Gueguen Y (2005) Damage and recovery of calcite rocks deformed in the cataclastic regime. Geol Soc Spec Pub 245:203–221

Sedláček R, Blum W (1998) Internal stress in dislocation subgrain structures. Comput Mater Sci 13:148–153

Sgaoula J, Aubertin M, Gill DE (1995) Using internal state variables for modelling the viscoplastic behaviour of rocksalt in the semi-brittle regime. In: Daemen JJK, Schultz RA (eds) Rock mechanics. Balkema, Rotterdam. ISBN 90 5410 552 6, pp 749–754

Shao JF, Zhu QZ, Su K (2003) Modeling of creep in rock materials in terms of material degradation. Comput Geotech 30:549–555

Shao JF, Jia Y, Kondo D, Chiarelli AS (2006) A coupled elastoplastic damage model for semi-brittle materials and extension to unsaturated conditions. Mech Mater 38:218–232

Shao JF, Chau KT, Feng XT (2006) Modeling of anisotropic damage and creep deformation in brittle rocks. Int J Rock Mech Min Sci 43:582–592

Shenoy MM, McDowell DL, Neu RW (2006) Transversely isotropic viscoplasticity model for a directionally solidified Ni-base superalloy. Int J Plast 22(12):2301–2326

Suvarova JV, Ohlson NG, Alexeeva SI (2003) An approach to the description of time dependent materials. Mater Des 24:293–297

Swearengen JC, Holbrook JH (1985) Internal variable models for rate-dependent plasticity: Analysis of theory and experiment. Res. Mechanica 13:93

Tapponier P, Brace WF (1976) Development of stress induced microcracks in Westerley granite. Int J Rock Mech Min Sci 13:103–112

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17:389–407

Vajdova V, Baud P, Wong T-F (2004) Compaction, dilatancy, and failure in porous carbonate rocks. J Geophys Res 109(5): B05204 1-16

Vajdova V, Zhu W, Natalie Chen T-M, Wong T-F (2010) Micromechanics of brittle faulting and cataclastic flow in Tavel limestone. J Struct Geol 32(8):1158–1169

Voyiadjis GZ, Abu Al-Rub RK (2003) Thermodynamical framework for coupling of non-local viscoplasticity and non-local anisotropy viscodamage for dynamic localization problems using gradient theory. Int J Plast 19:2121–2147

Voyiadjis GZ, Huang W (1996) Modelling of single crystal plasticity with backstress evolution. Eur J Mech A/Solids 15(4):553–573

Voyiadjis GZ, Taqieddin ZN, Kattan PI (2008) Anisotropic damage—plasticity model for concrete. Int J Plast 24:1946–1965

Wang W (1997) Stationary and propagative instabilities in metals—a computational point of view. Ph.D., TU Delft, Netherlands

Waza T, Kurita K, Mizutani H (1980) The effect of water on the subcritical crack growth in silicate rocks. Tectonophysics 67:25–34

Weng MC, Tsai LS, Hsieh YM, Jeng FS (2010) An associated elastic–viscoplastic constitutive model for sandstone involving shear-induced volumetric deformation. Int J Rock Mech Min Sci 47(8):1263–1273

Winnicki A, Pearce CJ, Bicanic N (2001) Viscoplastic Hoffman consistency model for concrete. Comput Struct 79:7–19

Wong T (1985) Geometric probability approach to the characterization and analysis of microcracking in rocks. Mech Mater 4(3–4):261–276

Xie SY, Shao JF (2006) Elastoplastic deformation of a porous rock and water interaction. Int J Plast 22(12):2195–2225

Yahya OML, Aubertin M, Julien MR (2000) A unified representation of the plasticity, creep and relaxation behaviour of rocksalt. Rock Mech Min Sci 37:787–800

Zhao Y (1998) Crack pattern evolution and a fractal damage constitutive model for rock. Int J Rock Mech Min Sci 35(3):349–366

Zhou H, Jia Y, Shao JF (2008) A unified elastic–plastic and viscoplastic damage model for quasi-brittle rocks. Int J Rock Mech Min Sci 45:1237–1251

Zhu QZ, Kondo D, Shao JF (2008) Micromechanical analysis of coupling between anisotropic damage and friction in quasi brittle materials: role of the homogenization scheme. Int J Solids Struct 45:1385–1405

Zhu W, Baud P, Wong T-F (2010) Micromechanics of cataclastic pore collapse in limestone. J Geophys Res 115:B04405. doi:10.1029/2009JB006610

Zhu QZ, Shao JF, Kondo D (2011) A micromechanics-based thermodynamic formulation of isotropic damage with unilateral and friction effects. Int J Solids Struct 30:316–325

Zolochevsky A, Voyiadjis GZ (2005) Theory of creep deformation with kinematic hardening for materials with different properties in tension and compression. Int J Plast 21:435–462

Acknowledgments

This research was carried out thanks to subsidies from the Ministries for Industry and Research and the Lorraine Region within the GISOS (www.gisos.org) framework. The authors express their gratitude to these organisations.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

1.1 Procedure for the identification of the model parameters

The values of the model parameters can easily be obtained from classical laboratory tests: a set of triaxial compressive tests (i.e. with different confining pressures) at both high (0.004 MPa s−1 in our short-term experiments) and very low (5 × 10−6 MPa s−1 in our long-term experiments) loading rates and some multi-step (i.e. variable stress) creep tests.

1.2 Elastic parameters

The bulk modulus K is determined from an isotropic compressive test. The shear modulus G is determined from triaxial compressive tests at the first unloading–reloading cycle, i.e. at the beginning of the loading when the material is still undamaged.

1.3 Thresholds

The parameters Y o , η o , Y m and η m are the values of \( Y^{*} \) and \( \eta^{*} \) (Eq. 19) for initial and peak surfaces of inelasticity (Fig. 4), respectively. Within the coupled damage–plasticity scheme, η m (Eqs. 19, 20, 26) is the maximal internal cohesion of the undamaged material and has to be defined in such a way that (1 − D max)η m corresponds to the highest position of the damaged yield function (Eq. 38), with D max the maximal value of the damage variable D.

\( (\gamma^{in*} )_{{{ \hbox{max} }}} \), the maximal inelastic distortion the material can support, should be determined from uniaxial or triaxial compressive tests with very slow loading rate, as illustrated in Fig. 23a.

The evolution law of \( w_{{{\text{d max}}}}^{\text{in*}} \) (Eq. 19), the maximal deviatoric energy, is obtained from a set of triaxial compressive tests (i.e. with different confining pressures). It is necessary to plot a graph showing the maximal deviatoric energy of each test versus the stress triaxiality ratio at failure. w 1 is the slope of this curve and w 2 is the maximal deviatoric energy at failure for a uniaxial stress path.

\( w_{{{\text{d crit}}}}^{\text{in*}} \), the deviatoric inelastic energy at the damage onset (Eq. 37), is supposed to be equal to zero. Indeed, according to our experimental results (Fig. 7), damage (i.e. micro-cracking) appears at the very beginning of inelastic flow.

1.4 Viscoplasticity parameters

As supposed in Sect. 3, the volumetric strains are principally due to damage mechanisms. In order to respect this assumption, the inelastic dilatancy coefficient β in (Eqs. 10–11) has to be equal to 0, thus inducing isovolumetric inelasticity.

The scaling parameters Y 1, Y 2 and η 1 of the frictional and cohesive strengths, Y and η (Eq. 19), respectively, have to be determined from a set of triaxial compressive tests (i.e. with different confining pressures) performed with a very slow loading rate in such a way that the maximal inelastic distortion \( (\gamma^{{{\text{in}}*}} )_{{{ \hbox{max} }}} \) is mobilised. A graph needs to be plotted showing the slope and the value at origin of the yield surface for different values of the inelastic distortion. Hence, the parameters Y 1, Y 2 and η 1 can be determined from nonlinear adjusting methods. Figure 23b illustrates the identification procedure for the parameters Y 1 and Y 2 from a set of triaxial compressive tests on iron ore.

The scaling parameters A and n of the kinetic law (Eq. 25) are generally identified from multi-step creep tests, using nonlinear adjusting methods (e.g. numerical nonlinear least squares fitting method). These parameters should be determined for low stress levels, i.e. when damage and therefore volumetric strains are not of great importance. After a complete unloading (i.e. zero stress step) and stabilization of the reverse creep, it is also possible to identify the fraction of the recoverable inelastic energy x (Eq. 21) and the scaling parameter B (Eq. 22). We found almost the same value for the scaling parameters A (Eq. 25) and C (Eq. 24). These parameters were determined from the multi-step creep test on iron ore represented in Figs. 6 and 19.

1.5 Damage-related parameters

For the determination of ξ (Eq. 35), it is necessary to plot the damage variable D (0 < D < 1) versus the ratio \( w_{\text{d}}^{\text{in*}} /w_{{{\text{d max}}}}^{\text{in*}} \). During triaxial compressive tests with constant strain rate, the former is calculated from the decrease of elastic properties (Eqs. 39–40) obtained using unloading–reloading cycles for example, whereas the latter is calculated by measuring the inelastic deformations. A linear regression on the experimental points is then necessary to obtain D max, which corresponds to ξ, for \( w_{\text{d}}^{\text{in*}} /w_{{{\text{d max}}}}^{\text{in*}} { = 1} \). Figure 24a illustrates the identification procedure for the parameter ξ from a triaxial compressive test on iron ore.

The parameters ϕ 1 and ϕ 2 of the damage porosity ϕ d (Eq. 41) can be identified from triaxial compressive tests with constant strain rate. Since we considered that the volumetric strains are principally due to damage mechanisms (i.e. β in = 0), ϕ d corresponds to the volumetric inelastic deformation. It is necessary to plot the volumetric inelastic deformation versus the damage variable D and make a nonlinear regression to determine ϕ 1 and ϕ 2. This is illustrated in Fig. 24b.

Rights and permissions

About this article

Cite this article

Grgic, D. Constitutive modelling of the elastic–plastic, viscoplastic and damage behaviour of hard porous rocks within the unified theory of inelastic flow. Acta Geotech. 11, 95–126 (2016). https://doi.org/10.1007/s11440-014-0356-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-014-0356-6

:

: :

: