Abstract

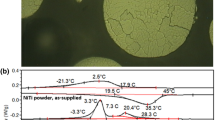

Yttria stabilized zirconia (YSZ) thin wall components were fabricated using laser engineered net shaping (LENS) technique. It was found that after LENS processing, the monoclinic (m) phase in as-received YSZ powders transformed to tetragonal (t) and cubic (c) phases with the lenticular shaped t-ZrO2 embedded in the c-ZrO2 matrix. The relative density of the parts reached up to 98.7%. Our investigation showed that micro cracks within the wall structure were reduced by judiciously choosing laser power parameter. The fabricated parts have surface roughness values that ranged from 20 to 40 μm. The maximum hardness and elastic modulus achieved from the LENSed YSZ parts were 19.8 GPa and 236.1 GPa, respectively. We also demonstrated that dark brown color of the LENSed parts could be removed via heat treatment.

Similar content being viewed by others

References

Garvie R, Hannink R, Pascoe R (1975) Ceramic steel? Nature 258(5537):703–704

Jin X-J (2005) Martensitic transformation in zirconia containing ceramics and its applications. Curr Opinion Solid State Mater Sci 9(6):313–318

Huang H (2003) Machining characteristics and surface integrity of yttria stabilized tetragonal zirconia in high speed deep grinding. Mater Sci Eng A 345(1–2):155–163

Basu B (2005) Toughening of yttria-stabilised tetragonal zirconia ceramics. Int Mater Rev 50(4):239–256

Hagedorn Y-C (2013) Additive manufacturing of high performance oxide ceramics via selective laser melting (No. RWTH-CONV-144031). Lehrstuhl für Lasertechnik (PhD thesis).

Wilkes J, Hagedorn YC, Meiners W, Wissenbach K (2013) Additive manufacturing of ZrO2-Al2O3 ceramic components by selective laser melting. Rapid Prototyp J 19(1):51–57

Bertrand P, Bayle F, Combe C, Goeuriot P, Smurov I (2007) Ceramic components manufacturing by selective laser sintering. Appl Surf Sci 254(4):989–992

Liu Q, Danlos Y, Song B, Zhang B, Yin S, Liao H (2015) Effect of high-temperature preheating on the selective laser melting of yttria-stabilized zirconia ceramic. J Mater Process Technol 222:61–74

Liu Q, Song B, Liao H (2014) Microstructure study on selective laser melting yttria stabilized zirconia ceramic with near IR fiber laser. Rapid Prototyp J 20(5):346–354

Li Y, Hu Y, Cong W, Zhi L, Guo Z (2017) Additive manufacturing of alumina using laser engineered net shaping: effects of deposition variables. Ceram Int 43(10):7768–7775

Balla VK, Bose S, Bandyopadhyay A (2008) Processing of bulk alumina ceramics using laser engineered net shaping. Int J Appl Ceram Technol 5(3):234–242

Niu F, Wu D, Ma G, Zhang B (2015) Additive manufacturing of ceramic structures by laser engineered net shaping. Chin J Mech Eng 28(6):1117–1122

Niu F, Wu D, Ma G, Wang J, Guo M, Zhang B (2015) Nanosized microstructure of Al2O3–ZrO2 (Y2O3) eutectics fabricated by laser engineered net shaping. Scr Mater 95:39–41

Ma G, Yan S, Wu D, Miao Q, Liu M, Niu F (2017) Microstructure evolution and mechanical properties of ultrasonic assisted laser clad yttria stabilized zirconia coating. Ceram Int 43:9622–9629

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH image to ImageJ: 25 years of image analysis. Nat Methods 9(7):671–675

Tsoga A, Nikolopoulos P (1996) Surface and grain-boundary energies in yttria-stabilized zirconia (YSZ-8 Mol%). J Mater Sci 31(20):5409–5413

Fan Z, Lu M, Huang H (2018) Selective laser melting of alumina: a single track study. Ceram Int 44:9484–9493

Aboulkhair NT, Maskery I, Tuck C, Ashcroft I, Everitt NM (2016) On the formation of AlSi10Mg single tracks and layers in selective laser melting: microstructure and nano-mechanical properties. J Mater Process Technol 230:88–98

Khairallah SA, Anderson AT, Rubenchik A, King WE (2016) Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater 108:36–45

Yadroitsev I, Smurov I (2011) Surface morphology in selective laser melting of metal powders. Phys Procedia 12:264–270

Kempen K, Thijs L, van Humbeeck J, Kruth JP (2015) Processing AlSi10Mg by selective laser melting: parameter optimisation and material characterisation. Mater Sci Technol 31(8):917–923

Song B, Dong S, Deng S, Liao H, Coddet C (2014) Microstructure and tensile properties of iron parts fabricated by selective laser melting. Opt Laser Technol 56:451–460

Niu F et al (2017) Process optimization for suppressing cracks in laser engineered net shaping of Al 2 O 3 ceramics. JOM 69(3):557–562

Phillippi C, Mazdiyasni K (1971) Infrared and Raman spectra of zirconia polymorphs. J Am Ceram Soc 54(5):254–258

Li M et al (2003) Study of influence of calcination atmosphere on phase transformation of zirconia by UV Raman spectroscopy. Chin J Catal 24(11):861–866.

Ghosh A, Suri AK, Pandey M, Thomas S, Rama Mohan TR, Rao BT (2006) Nanocrystalline zirconia-yttria system–a Raman study. Mater Lett 60(9–10):1170–1173

Srinivasan R, de Angelis RJ, Ice G, Davis BH (1991) Identification of tetragonal and cubic structures of zirconia using synchrotron x-radiation source. J Mater Res 6(6):1287–1292

Schmid H (1987) Quantitative analysis of polymorphic mixes of zirconia by X-ray diffraction. J Am Ceram Soc 70(5):367–376

Zhou Y, Lei TC, Sakuma T (1991) Diffusionless cubic-to-tetragonal phase transition and microstructural evolution in sintered zirconia–Yttria ceramics. J Am Ceram Soc 74(3):633–640

Sakuma T, Yoshizawa Y-I, Suto H (1985) The microstructure and mechanical properties of yttria-stabilized zirconia prepared by arc-melting. J Mater Sci 20(7):2399–2407

Lin KL, Lin CC (2005) Zirconia-related phases in the zirconia/titanium diffusion couple after annealing at 1100°–1550° C. J Am Ceram Soc 88(10):2928–2934

Lian J, Garay JE, Wang J (2007) Grain size and grain boundary effects on the mechanical behavior of fully stabilized zirconia investigated by nanoindentation. Scr Mater 56(12):1095–1098

Sponchia G, Moshtaghioun BM, Benedetti A, Riello P, Gómez-García D, Domínguez-Rodríguez A, Ortiz AL (2017) Ceramics of ta-doping stabilized orthorhombic ZrO2 densified by spark plasma sintering and the effect of post-annealing in air. Scr Mater 130:128–132

Guo X, Sun Y-Q, Cui K (1996) Darkening of zirconia: a problem arising from oxygen sensors in practice. Sensors Actuators B Chem 31(3):139–145

Moya JS, Moreno R, Requena J, Soria J (1988) Black color in partially stabilized zirconia. J Am Ceram Soc 71(11):C479–C480

Ingo GM (1991) Origin of darkening in 8 wt% Yttria—zirconia plasma-sprayed thermal barrier coatings. J Am Ceram Soc 74(2):381–386

Acknowledgements

The authors would like to thank Ms. Ying Yu for her help in Raman spectroscopic analysis, and Mr. Ron Rasch for valuable discussion on microstructural analysis. The authors also want to acknowledge the facility use in the Australian National Fabrication Facility (ANFF) and the Centre for Microscopy and Microanalysis (CMM) at The University of Queensland.

Funding

This project was partially funded by the UQ CIEF grant and Medical Engineering @ UQ SEED grant.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Fan, Z., Zhao, Y., Lu, M. et al. Yttria stabilized zirconia (YSZ) thin wall structures fabricated using laser engineered net shaping (LENS). Int J Adv Manuf Technol 105, 4491–4498 (2019). https://doi.org/10.1007/s00170-019-03322-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03322-z