Abstract

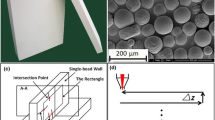

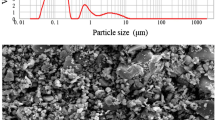

Ceramic is an important material with outstanding physical properties whereas impurities and porosities generated by traditional manufacturing methods limits its further industrial applications. In order to solve this problem, direct fabrication of Al2O3 ceramic structures is conducted by laser engineered net shaping system and pure ceramic powders. Grain refinement strengthening method by doping ZrO2 and dispersion strengthening method by doping SiC are proposed to suppress cracks in fabricating Al2O3 structure. Phase compositions, microstructures as well as mechanical properties of fabricated specimens are then analyzed. The results show that the proposed two methods are effective in suppressing cracks and structures of single-bead wall, arc and cylinder ring are successfully deposited. Stable phase of α-Al2O3 and t-ZrO2 are obtained in the fabricated specimens. Micro-hardness higher than 1700 HV are also achieved for both Al2O3 and Al2O3/ZrO2, which are resulted from fine directional crystals generated by the melting-solidification process. Results presented indicate that additive manufacturing is a very attractive technique for the production of high-performance ceramic structures in a single step.

Similar content being viewed by others

References

LIU Hanlian, SHI Qiang, HUANG Chuanzhen, et al. In-situ fabricated TiB2 particle-whisker synergistically toughened Ti(C, N)-based ceramic cutting tool material[J]. Chinese Journal of Mechanical Engineering, 2015, 28(2): 338–342.

HUANG Chuanzhen, LIU Hanlian, WANG Jun, et al. Multi-scale and multi-phase nanocomposite ceramic tools and cutting performance[J]. Chinese Journal of Mechanical Engineering, 2007, 20(5): 5–7.

YU Juntao, JIAO Zongxia, WU shuai. Design and simulation study on new servo valve direct driven by piezoelectric actuator using hydraulic amplification[J]. Journal of Mechanical Engineering[J], 2013, 49(2): 151–158. (in Chinese)

GUAN Changbin. Introduction to ceramic materials[M]. Harbin: Harbin Engineering University Press, 2005. (in Chinese)

TANG H H, CHIU M L, YEN H C. Slurry-based selective laser sintering of polymer-coated ceramic powders to fabricate high strength alumina parts[J]. Journal of the European Ceramic Society, 2011, 31(8): 1383–1388.

ALLAHVERDI M, DANFORTH S C, JAFARI M, et al. Processing of advanced electroceramic components by fused deposition technique[J]. Journal of the European Ceramic Society, 2001, 21(10): 1485–1490.

LIU F H, LIAO Y S. Fabrication of inner complex ceramic parts by selective laser gelling[J]. Journal of the European Ceramic Society, 2010, 30(16): 3283–3289.

HUANG T S, MASON M S, ZHAO X Y, et al. Aqueous-based freeze-form extrusion fabrication of alumina components[J]. Rapid Prototyping Journal, 2009, 15(2): 88–95.

DAS A, MADRAS G, DASGUPTA N, et al. Binder removal studies in ceramic thick shapes made by laminated object manufacturing[J]. Journal of the European Ceramic Society, 2003, 23(7): 1013–1017.

WILKES J, HAGEDORN Y C, MEINERS W, et al. Additive manufacturing of ZrO2-Al2O3 ceramic components by selective laser melting[J]. Rapid Prototyping Journal, 2013, 19(1): 51–57.

HAGEDORN Y C, WILKES J, MEINERS W, et al. Net shaped high performance oxide ceramic parts by selective laser melting[J]. Physics Procedia, 2010, 5: 587–594.

BERNARD S A, BALLA V K, BOSE S, et al. Direct laser processing of bulk lead zirconate titanate ceramics[J]. Materials Science and Engineering: B, 2010, 172(1): 85–88.

BALLA V K, BOSE S, BANDYOPADHYAY A. Processing of bulk alumina ceramics using laser engineered net shaping[J]. International Journal of Applied Ceramic Technology, 2008, 5(3): 234–242.

BERTRAND P, BAYLE F, COMBE C, et al. Ceramic components manufacturing by selective laser sintering[J]. Applied Surface Science, 2007, 254(4): 989–992.

SHISHKOVSKY I, YADROITSEV I, BERTRAND P, et al. Alumina-zirconium ceramics synthesis by selective laser sintering/ melting[J]. Applied Surface Science, 2007, 254(4): 966–970.

JUSTE E, PETIT F, LARDOT V, et al. Shaping of ceramic parts by selective laser melting of powder bed[J]. Journal of Materials Research, 2014, 29(17): 2086–2094.

LIU Q, SONG B, LIAO H. Microstructure study on selective laser melting yttria stabilized zirconia ceramic with near IR fiber laser[J]. Rapid Prototyping Journal, 2014, 20(5): 346–354.

GRIFFITH M L, SCHLIENGER M E, HARWELL L D, et al. Understanding thermal behavior in the LENS process[J]. Materials & Design, 1999, 20(2): 107–113.

GÄUMANN M, HENRY S, CLETON F, et al. Epitaxial laser metal forming: analysis of microstructure formation[J]. Materials Science and Engineering: A, 1999, 271(1): 232–241.

CHEN Wei. Study on the microstructure evolution of α-Al 2 O 3 in the formation process and it’s controlling[D]. Changsha: Central South University, 2010. (in Chinese)

NIU Fangyong, WU Dongjiang, MA Guangyi, et al. Nano-sized microstructure of Al2O3-ZrO2(Y2O3) eutectics fabricated by laser engineered net shaping[J]. Scripta Materialia, 2015, 95: 39–41.

SCHMID F, VIECHNICKI D. Oriented eutectic microstructures in the system Al2O3/ZrO2[J]. Journal of Materials Science, 1970, 5(6): 470–473.

PARDO J A, MERINO R I, ORERA V M, et al. Piezospectroscopic study of residual stresses in Al2O3-ZrO2 directionally solidified eutectics[J]. Journal of the American Ceramic Society, 2000, 83(11): 2745–2752.

ORERA V M, MERINO R I, PARDO J A, et al. Microstructure and physical properties of some oxide eutectic composites processed by directional solidification[J]. Acta Materialia, 2000, 48(18): 4683–4689.

ORERA V M, PENA J I, OLIETE P B, et al. Growth of eutectic ceramic structures by directional solidification methods[J]. Journal of Crystal Growth, 2012, 360: 99–104.

CICKA R, TRNOVCOVÁ V, STAROSTIN M Y. Electrical properties of alumina-zirconia eutectic composites[J]. Solid State Ionics, 2002, 148(3): 425–429.

LEE J H, YOSHIKAWA A, KAIDEN H, et al. Microstructure of Y2O3 doped Al2O3/ZrO2 eutectic fibers grown by the micro-pullingdown method[J]. Journal of Crystal Growth, 2001, 231(1): 179–185.

LEE J H, YOSHIKAWA A, DURBIN S D, et al. Microstructure of Al2O3/ZrO2 eutectic fibers grown by the micro-pulling down method[J]. Journal of Crystal Growth, 2001, 222(4): 791–796.

ZHANG Yaolei. Technology foundation of laser engineered net shaping of Al 2 O 3- ZrO 2(Y 2 O 3) eutectic ceramic[D]. Dalian: Dalian University of Technology, 2014. (in Chinese)

WU Dongjiang, YANG Ce, WU Nan, et al. Effect of SiC particles on crack susceptivity in laser direct forming Al2O3 ceramic[J]. Optics and Precision Engineering, 2012, 20(7): 1551–1558. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Natural Science Foundation of China(Grant Nos. 51175061, 51402037), Science Fund for Creative Research Groups(Grant No. 51321004), National Basic Research Program of China(973 Program, Grant No. 2015CB057305), and China Postdoctoral Science Foundation Funded Project(Grant No. 2014M551072)

NIU Fangyong, born in 1984, is currently a PhD candidate at Key Laboratory for Precision and Non-traditional Machining Technology of Ministry of Education, Dalian University of Technology, China. He received his master degree from Dalian University of Technology, China, in 2009. His research interest is laser-aided additive manufacture.

WU Dongjiang, born in 1964, is currently an professor at Dalian University of Technology, China. His research interests include laser-aided additive manufacture, laser welding and femtosecond laser processing.

MA Guangyi, born in 1982, is currently a postdoctoral researcher at Key Laboratory for Precision and Non-traditional Machining Technology of Ministry of Education, Dalian University of Technology. His research interests include laser-aided additive manufacture and laser welding.

ZHANG Bi, born in 1957, is currently a professor at Dalian University of Technology, China. His research interests include precision machining and additive manufacturing.

Rights and permissions

About this article

Cite this article

Niu, F., Wu, D., Ma, G. et al. Additive manufacturing of ceramic structures by laser engineered net shaping. Chin. J. Mech. Eng. 28, 1117–1122 (2015). https://doi.org/10.3901/CJME.2015.0608.078

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2015.0608.078