Abstract

This study was conducted to evaluate the properties of lightweight sandwich panels made from low diameter bamboo particles, Phyllostachys Bambusides collected from Gilan province, Iran, as core layer, combined with thin wall bamboo strips as faces. The effects of three individual variables such as density of core layer (350–550 kg/m3), resin consumption in core layer (7.5–9.5%) and resin consumption in faces (175–275 g/m2) on some important physical, mechanical and thermos-acoustic properties of the panels were investigated. Response surface methodology was used to statistically analyse the results and optimization process. The average values for the mechanical properties of the sandwich panels were obtained as 17.16 MPa, 5669 MPa, 0.02 MPa, 17.60 MPa, 1.83 MPa, 0.03 MPa, and 913.3 MPA for modulus of rupture, modulus of elasticity, internal bonding, compression strength parallel to face grain, compression strength perpendicular to face grain, shear strength, and screw holding, respectively. Finally, thermal conductivity and noise reduction coefficient of the panels were respectively gained as 0.01 W/mk and 0.31. The results of technical and thermo- acoustic properties of the panels showed that the light weight sandwich panels from bamboo residues would be a suitable and sustainable alternative as an insulation material for sustainable and green construction.

Similar content being viewed by others

Introduction

It is clear as of today that alternative materials to wood is urgently needed to reduce logging from global forests and reduce the pressure on our forest reserves and to meet the rising demand for wood-based products1,2. According to estimates from the UN FAO, 10 million hectares of forest are destroyed annually3, to be more clear, forestry covered 31.6 percent of the planet’s surface in 1990; by 2022, this number was dropped to 31 percent4,5. Besides, with the improvement of living standards, the demand for environmentally friendly, lightweight, and sustainable structures have increased dramatically. Bamboo as a sustainable alternative to traditional building materials, including wood, has started to gain attention due to its fast growth rate and the short time to harvest, the variety of species, as well as the high yield, and the ability to reach a maximum height of 15–30 m in 2–4 months, and reaching the maximum strength in 3–5 years. According to life-cycle assessment (LCA) results, bamboo is included in the “factor 20”, which means that its impact on the environment is 20 times less compared to modern alternatives6,7. Simply put, the sustainability of bamboo-based building materials is governed by relatively fast harvesting, a more efficient rate of carbon sequestration compared to wood species, as well as low-energy requirement for processing, which creates minimal environmental impact8. Additionally, to make the material more environmentally friendly, bamboo waste can be used in the production of other products including bamboo-based building panels, which have been investigated in this research.

Furthermore, compared to wood species, bamboo has great mechanical characteristics, a shorter rotation, fast and convenient processing, low density, and is biodegradable, all of which have drawn increased attention9,10,11,12. However, the processing of bamboo is different from that of wood because of its heterogeneous structure, which mostly comprises of vascular bundles and parenchyma cells13. Due to its distinctive multi-level pore structures and densely packed fibres/lignin composite as elastic and robust wall material, bamboo, a work of art of nature, exhibits lightweight and great mechanical capabilities14. Bamboo plywood, laminated bamboo lumber, bamboo particleboard, and bamboo fibre reinforced polymer composites are some of the bamboo-based products that have been developed recently15,16,17,18,19,20,21. These products are widely used in a variety of industries, including construction, furniture and flooring22. For instance, with the use of an oriented bamboo fiber mat coated with Phenol Formaldehyde resin, Yu et al. created a unique bamboo scrimber. Additionally, the siliceous and waxy layers were taken out. As a result, the bamboo scrimber's modulus of rupture (MOR) reached 253 MPa, which was significantly higher than those of natural bamboo and conventional bamboo scrimber23. Verma and Chariar24 investigated that a comparative cost and mechanical properties analysis of LLBCs (layered laminated bamboo composites) with teak wood timber indicates that LLBCs could be used as building and general purposes material like, furniture, beam and column, etc., because there is possibility to increase the volume in any shape and in any direction by increasing number of layers. Sharma et al., carried out an investigation into the mechanical properties of bamboo scrimber and laminated bamboo composite to assess their potential for structural applications and to compare them with timber and engineered timber products. The observations showed that an advantage of laminated bamboo to timber and raw bamboo is its bending strength to density ratio namely specific strength. The results of the study indicate that both products; bamboo scrimber and laminated bamboo have properties that compare with or surpass that of timber25. In an experimental study, Fadlelmola et al., investigated the bamboo-concrete sandwich panel, steel–concrete sandwich panel and plain concrete panel under bending load. The failure modes were attributed to bamboo tensile yielding at the middle of the bottom face, followed by Aerated Lightweight Concrete shear cracks at the maximum shear point. The results show that using bamboo in sandwich panels highly increases the structural properties such as moment capacity, ductility and bending stiffness compared to non-reinforced concrete26.

Investigation of physical and mechanical properties of bamboo has an important role in its application in various structures. Structures made of bamboo should be designed and evaluated with respect to the bending, shear, tensile and compressive strength as well as stability in dynamic loading. Studies have been carried out by various researchers that have been summarized in previous section. The major difference in the works mentioned is the type of bamboo panel used and its properties27,28.

In terms of insulating properties of engineered composites, there are environmental issues that should be considered. A sound absorber consisting of synthetic fibers like glass wool, rock wool, or foam glass, which is still utilized in the building sector, is one of the causes that contribute to the global warming problem. Asdrubali discovered that although they are effective at isolating heat and sound, they have the biggest potential for contributing to global warming when compared to natural materials29. Research is now directed towards finding an alternative acoustic absorber made from natural materials. There are some works carried out on the effective role of bamboo structure on its thermoacoustic properties. Khair et al., presents the preliminary study on the effect of the hollow structure of bamboo to absorb sound energy. The result shows good sound absorption at high frequency above 3000 Hz with bamboo sample of 2 cm long and micro-holes of 0.4 mm in diameter. Improvement of absorption coefficient at lower frequency can be achieved by increasing the air gap at the back of the sample30.

The characteristics of sandwich panels made of other materials can also be mentioned. Haseli et al., studied the characteristics of lightweight value-added sandwich panels, block boards and wooden boards, made of palm waste trunks as the core layer along with thin Medium Density Fiberboard as the top layers. Based on the experimental results, palm wood-MDF sandwich panels with good thermal conductivity of about 0.14 W/mK and favourable sound absorption of up to 0.64 and noise reduction coefficients up to 0.15 can be used as heat and sound insulating materials31.

The present study is investigating the suitability of semi-lightweight bamboo sandwich panels made of three layers, where the core is a particleboard consist of low diameter bamboo particles combined by thin bamboo strips as faces for sound insulation. Our study explores the potential of bamboo sandwich panels with three layers. These panels consist of a core made from finely ground bamboo particles, surrounded by thin bamboo strips that help with sound insulation. We’ve come up with a new sandwich design using bamboo from Iran, which is an important type of bamboo in Asia called Phyllostachys Bambusides. We’ve thoroughly studied how this bamboo composite performs physically, mechanically, and in terms of sound insulation. Our findings show that this design works well for making internal walls that don't bear heavy loads but have good insulation. In summary, our research demonstrates how bamboo, especially the Phyllostachys Bambusides from Iran, can be used to create effective sandwich panels. These panels could be used to build sound-insulated internal walls, offering a sustainable and practical solution.

Materials and methods

Raw materials

Four-year-old bamboo (Phyllostachys Bambusides) stems were used in this study. supplied from Lialestan bamboo plant, Gilan, I. R. Iran. The collection of the bamboo samples was carried out according to the Convention on Biological Diversity. In this study, Methylene diphenyl diisocyanate (MDI) resins (solid content: 100%, viscosity: 300 cP, density: 1.27 g cm3) were provided from Karoon Petrochemical co, I. R. IRAN. Polyurethane adhesive (color: cream, pot life: 25 min., density: 1.2 g cm3, solid content: 100%) for face strips attachment was supplied by Mokarrar Industrial Group, I. R. Iran.

Design of experiment

The bamboo strips and flakes were glued with PU and MDI resins according to the design of experiment (Table 1). Response Surface Methodology (RSM) under central composite design in Design Expert version DX13 computer software package was used to design the experiment and analyze the results. In RSM, errors are assumed to be random. The application of RSM for design optimization is to reduce the cost of expensive analysis methods and the numerical irregularities associated with them (such as CFD or finite element analysis). In RSM, convergence towards the optimal element is preferred because they reduce the effects of disorder factors. In this design, 3 variables (density, core layer resin, skin resin) were considered in 5 levels, and as a result, 15 laboratory panels were produced.

To follow the partial factorial design, 15 laboratory lightweight sandwich panels (density of 600 ± 60 kg m3) were manufactured (Table 2).

Fabrication of panels

Strip preparation and treatment

Strip preparation has been carried out in Wood—based material laboratory, Department of Wood and Paper

Science at University of Tehran. Strips were randomly extracted from the length of bamboo culms. This method was chosen to reduce the effect of uncontrollable factors in the final results of the tests, because the presence of nodes along the strip and the extraction location of the strips were not among the variable factors of this research. Bamboo stems (Fig. 1a) were cut into the pieces with around 50 cm were longitudinally cut into the suitable strips (Fig. 1b). For steam treatment, the strips were placed inside a laboratory cooking cylinder (Fig. 1c). Cooking temperature and steaming time inside the cylinder were 150 °C and 1 h, respectively. The pressing operation was performed immediately on the treated strips, in such a way that the strips were placed under a heat press with a temperature of 120 °C and a pressure of 20 kg/cm2 (Fig. 1d). The flattened strips were placed under heavy steel plates for 24 h and prepared for use in the assembly stage (Fig. 1e). To control the moisture content of the strips, they were kept in a conditioning chamber at 20 ± 3 °C and 65 ± 1 percent RH with constant temperature and humidity for a week.

Flake preparation

Bamboo flakes were used to make the middle layer of the sandwich panels. After delivering low quality bamboo strips and scraps to the laboratory, the bamboo pieces were cut into the smaller ones(8 < x < 15) (Fig. 2a). Knife length, using a band saw. The short stems ring flaker (Pallmann, Germany) was used to convert the bamboo chips into the suitable flaker, in order to obtain the appropriate raw material for making the middle layer of the sandwich panels (Fig. 2b). The bamboo flake was placed in a laboratory tray dryer at 105 °C for 24 h to achieve a moisture content around 2%, then passed through a laboratory flat vibratory screen to separate acceptable sizes for 40 ≤ x ≤ 80 mm. Dried and screened flakes were stored in sealed plastic bags before manufacturing the core panel.

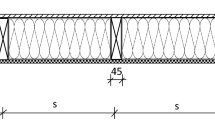

Light weight panel manufacturing

The schematic view of panel manufacturing is shown in Fig. 3. The panel specifications and parameters for making lightweight sandwich wall panel are presented in Table 3.

Diluted adhesive was sprayed onto bamboo particles with coherent parameters using a laboratory rotational drum mixer having an internal spray nozzle. A mixture of bamboo chips and MDI resin was taken out of the gluing machine and manually formed into a 45 × 45 × 2.5 cm frame. At this stage, Burkle laboratory hot press was used. The press temperature was adjusted to 180 °C and a pressure of 24 kg/cm2 was applied for 8 min. Polyurethane (PUR) adhesive used for bamboo strips in outer layers. The press was set at a pressure of 12 kg/cm2, at a temperature of 100 °C, and the panels were pressed for 45 min. Due to the usage of polyurethane resin that does not require heat, we could use no heat for the final assemble, but to speed up the production of the samples, it was decided to use heat during the pressing (Fig. 4).

Panel characterization

All treated panels were stored in a conditioning chamber for two weeks after cold stacking, at 20 ± 3 °C and 65 ± 1 percent RH, in line with (ASTM D103732) until the panels acquired the standard moisture equilibrium content.

Panel characterization

Physical and mechanical properties

Physical and mechanical tests along with thermos-acoustic properties were measured in accordance with DIN EN, ISO and ASTM standards (Table 4). Several standards were used to perform the tests for two reasons. Firstly, it was due to the limitation in the dimensions and number of samples, and the second reason was the availability of equipment in the laboratory, each of which was designed for a specific standard.

Modulus of rupture, Internal bonding, screw holding and compression-shear tests were measured using universal testing machine (Wolpert, Germany), and modulus of elasticity, modulus of rupture and compression strength parallel and perpendicular to the face grain were measured using universal testing machine (Instron 4486) (Fig. 5a–e).

Thermo-accoustical testing

Acoustic absorption coefficients and noise reduction coefficient (NRC) were used to determine acoustical properties of the panels. In this study, measurements were made in accordance with ASTM C423 Standard Method (ASTM C42334) using an impedance tube with two diameters as 99 mm and 29 mm (Fig. 6).

The thermal conductivity of all panels (20 × 20 × 2 cm3) was measured at room temperature and normal pressure using the steadystate Bi-substrate technique (ASTM C17733) (Fig. 7).

Numerical optimization

By numerical optimization in engineering sciences many phenomena according to their own instructions and conditions. However, a number of phenomena do not have the ability to have a suitable mathematical model due to the large number of controlling factors, unknown mechanism or computational complexity. In such cases, the use of experimental modeling methods works. The Response Surface Methodology (RSM) is considered as one of the experimental modeling methods35. RSM was originally developed to model experimental responses and then to model numerical experiments. In physical experiments, experimental errors can occur in a variety of ways, for example, estimating errors when the disorder or error is due to a wrong convergence (e.g., the operator is drowsy or tired or the test materials are heterogeneous) or to define a continuous physical phenomenon in a discrete way if such a thing cannot be done in reality. In RSM, the errors are assumed to be random. The application of RSM to design optimization is to reduce the cost of analytics methods and their associated numerical irregularities (such as CFD or finite element analysis). Also, convergence towards the element is optimal because they reduce the effects of disorder factors.

Ethics statement

Four-year-old bamboo (Phyllostachys Bambusides) stems were used in this study. supplied from Lialestan bamboo plant, Gilan, Iran. The collection of the bamboo samples was carried out according to the Convention on Biological Diversity.

Results and discussion

Physical properties

Density test was used to measure the density of the samples. The average density of all samples was 594.5 kg/m3. The fabricated sample has a low density and according to EN31636 standard test method for fiberboard classification, this panel is in the category of light panels and helps to reduce the overall weight of the building significantly compared to the available materials. Obviously, the density factor of the middle layer affects the overall density of the samples, but the other two factors will not affect this value.

Mechanical properties

Mechanical properties of the panels have been shown in Table 6. According to the EN310 standard test method, the bending strength standard for application in OSB boards with a thickness of 18–25 mm and for general use is equal to 16 MPa. This value is equal to 19.6 MPa for particleboard with a thickness of 25 mm in general use and dry conditions, and equal to 33 MPa for MDF with a thickness of 15 mm. The average modulus of rupture for the samples tested in this study is 19.44 MPa. Considering a model consist of three parameters (A = density, B = core resin and C = face resin), analysis of variance demonstrates a siginificant model (Table 5). The number 4.71 for the F-value indicates the significance of the model, and based on the analaysis of variance only 3.64% error is likely to occur. If the P-value is less than 0.05, the model will be significant. The modulus of rupture can be calculated based on the linear relationship described here (Eq. 1).

Considering the construction of the samples, which consist of a particleboard core and two layers of bamboo strips on both sides, it is possible to analyze their impact on bending loads. The middle board breaks due to the applied load (Fig. 8), and by looking at the failure mode, which is diagonal, it can be concluded that the applied compressive force is distributed as a point along the length of the specimen and a shear failure caused the middle board to break. Due to the construction of the core, which is made of bamboo particles impegranted with Polyurethane adhesive, the amount of force applied which caused a fracture in the middle layer is not high, and the modulus of rupture of the specimens can be considered acceptable. The average modulus of elasticity for the constructed specimens is 5659 MPa. As well as MOR, analysis of variance illustrates a significant model for modulus of elasticity. The F-value of 4.53 indicates the significance of the model and only the possibility for an error is 3.98%. The relationship obtained from the model will be significant and the modulus of elasticity can be calculated using (Eq. 2).

The core has low flexibility, and due to the strength of the strips on the outer surfaces, the resistance of the boards to deformation is very good, which indicates the appropriate modulus of elasticity of these boards (Fig. 9). The results of internal bonding measurements are between 0.01 and 0.08 MPa, and the average is 0.02 MPa. The number 2.72 indicates the significance of the model and 9.55% is likely to encounter an error. The relationship obtained from the model is not significant.

The results of compression strength parallel to face grain measurements showed that this value for the samples is between 10.06 and 26.26 MPa, the average of all the samples tested is 17.6 MPa. The low density of the middle board and its porosity, as well as the amount of adhesive used on the outer surface, have created relatively little adhesion between the strips and the middle board, which disintegrated when the load was applied (Fig. 10). This value will increase as the adhesion improves because the resistance of bamboo strips alone to the parallel compressive force of the fibers is high. This resistance is created due to the structure of bamboo, which is in the form of parallel fibers along the length of its stem. The results of measuring the compression strength perpendicular to face grain showed that this value for the samples is between 1.04 and 11.34 MPa, and the average for all the samples is 4.62 MPa. The analysis of variance in this model shows that it is significant because the F-value is 2.79 and there is only 11.26% possibility for an error (Table 6).

The results of shear test measurements showed that this value for the samples is between 0.01 and 0.532 MPa, the average of all of them is 0.07 MPa (Table 6).

The effect of any of the variable factors on the amount of Compression-shear strength is not significant and based on these variables, the amount of change in this resistance will not be significant (Table 7). The results of measuring the holding force of the screw perpendicular to the surface showed that this value for the samples is between 505 and 1461.70 N, the average of all of them is 931.88 N (Table 6). A value of 7.43 for the F-value indicates the significance of the model and only there are 1.2% chance of possible errors (Table 7). Based on this model, a relationship based on the interaction of factors (density, core resin, face resin) can be defined (Eq. 3) and through it the amount of screw withdrawal resistance (SWR) can be calculated.

The high density and strength of bamboo strips on external surfaces increases the amount of screw withdrawal resistance in the fabricated sample (Fig. 11). The use of bamboo strips in the construction of the samples has made the modulus of elasticity of the product fall into the right category compared to some other products, such as Laminated compressed composite panel from palm fronds, Hybrid plywood from oil palm biomass and Date palm biomass particleboards (Table 7). Due to lower density of this composite and its production method, which includes a core layer made of bamboo particleboard, the modulus of rupture is weaker than that of other products and needs to be improved (Table 7).

Thermo-acoustic performance

Test specimen with code 13 (Table 5) has the highest density among the samples, which is equal to 669.6 kg/m3. To calculate the noise reduction coefficient for a sample, the average sound absorption coefficient at frequencies of 250, 500, 1000 and 2000 must be taken. For sample 13 the absorption coefficient was 0.3125. Test sample with code 6 has the lowest density among the samples, which is 536.74 kg/m3. Due to the low density, it was not possible to cut a disc with a diameter of 29 mm for this test and therefore it was measured only at low frequencies. The average value for this test was obtained from the frequencies of 250, 500 and 1000 which is equal to 0.4633. The average density of the samples is 594.5 kg/m3 and the average thermal conductivity is 0.0199 W/mK. The results of the tests indicate that the product is desirable in terms of sound absorption and thermal conductivity (Tables 8, 9). The average MOR and MOE values obtained from bamboo panels are comparable to other materials as shown in Table 8. High percentage of porosity and low density of boards are effective in increasing the coefficients and comparison of samples with similar products shows the effect of the middle board on both coefficients. It should be noted that the presence of bamboo strips on the two outer surfaces of the boards has an effect on reducing the sound absorption coefficient and has caused the sound to be reflected from the surface of the sample. Due to the use of bamboo and fabrication of low density samples, the thermal conductivity is also very desirable according to the test results (Table 9). These new structures are important in several ways due to their lightness and high insulation properties. The low thickness of this composite (2.5 cm) and at the same time its multiple function is the first point. In addition to its separating function and beauty, this structure is also a very good insulator. Another point is that these structures are more sustainable than other structures. If common materials are used, add-ons should be used on the wall to insulate it, however, these panels are also insulated by themselves. This saves energy and is more sustainable.

Optimization

To select the optimal treatment, the Design Expert software optimization plugin was used. The treatment was selected based on the significant results of the tests to increase the desirability. In the analysis for optimizing, only the significant results were considered, these tests are: modulus of rupture, modulus of elasticity, compressive strength perpendicular to the face grains and screw withdrawal strength. Variable factors that were: middle layer density, core layer resin and outer surface adhesive were considered in their specific range. The selected treatment has a desirability of 1. Tables 10 and 11 show the complete specifications of the optimal treatment.

Conclusion

To conclude, in this paper a series of physical, mechanical and insulating performance of a novel light bamboo sandwich panel (LTBSP) as a sustainable green composite (manily based on waste and renewable resources) from bamboo strips and shavings was investigated.

-

LTBSP stood a better chance to be applied as a wall panel- according to test results that mentioned before- rather than MDF or knauf wall boards.

-

Some of the mechanical properties of LTBSP such as modulus of rupture, modulus of elasticity and resistance to axial withdrawal of screws reached the requirements of DIN-EN 312–320 standard test methods.

-

The thermal conductivity and noise reduction coefficients for LTBSP met the requirements of IS3129-1985 for particleboards.

-

In view of test results obtained in this study and in comparison to other composites, LTBSP is a suitable material as a wall panel, considering its components that are environment-friendly, it can be seen as an alternative to synthetic-based commercial products.

Data availability

The data that support the fndings of this study are available from the corresponding author, AJ, upon reasonable request.

References

Nkeuwa, W. N. et al. Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Compos. B Eng. 235, 109776. https://doi.org/10.1016/j.compositesb.2022.109776 (2022).

Dai, S.-W. et al. Bamboo-inspired mechanically flexible and electrically conductive polydimethylsiloxane foam materials with designed hierarchical pore structures for ultra-sensitive and reliable piezoresistive pressure sensor. Compos. B Eng. 225, 109243. https://doi.org/10.1016/j.compositesb.2021.109243 (2021).

Ritchie, H. & Max, R. Deforestation and forest loss. In Our World in Data (2021). ourworldindata.org/deforestation.

Yuan, T. et al. Study on bamboo longitudinal flattening technology. Polymers 2022, 13. https://doi.org/10.3390/polym14040816 (2013).

The State of the World’s Forests (SOFO) 2022|Knowledge for Policy. Knowledge4policy.ec.europa.eu (2022, accessed 4 May 2022). knowledge4policy.ec.europa.eu/publication/state-worlds-forests-sofo-2022_en.

Mahdavi, M. et al. Development of laminated bamboo lumber: Review of processing, performance, and economical considerations. J. Mater. Civ. Eng. 23(7), 1036–1042. https://doi.org/10.1061/(asce)mt.1943-5533.0000253 (2011).

Zea-Escamilla, E. et al. Industrial or traditional bamboo construction comparative life cycle assessment (LCA) of bamboo-based buildings. Sustainability 10(9), 3096. https://doi.org/10.3390/su10093096 (2018).

Dauletbek, A. et al. A review of basic mechanical behavior of laminated bamboo lumber. J. Renew. Mater. 10(2), 273 (2022).

Yuan, T., Huang, Y., Zhang, T., Wang, X. & Li, Y. Change in micro-morphology and micromechanical properties of thermally modified moso bamboo. Polymers 14, 646. https://doi.org/10.3390/polym14030646 (2022).

Tang, A. et al. Effect of the nanotitanium dioxide (nano-TiO2) coating on the photoaging properties of thermally treated bamboo. Wood Mater. Sci. Eng. 2021, 1–10. https://doi.org/10.1080/17480272.2021.1972334 (2021).

Zhou, X. et al. Clean plasma modification for recycling waste plastic bags: From improving interfacial adhesion with wood towards fabricating formaldehyde-free plywood. J. Clean. Prod. 269, 122196. https://doi.org/10.1016/j.jclepro.2020.122196 (2020).

Cao, Y. et al. Comparative investigation into the interfacial adhesion of plywood prepared by air spray atomization and roller coating. Eur. J. Wood Prod. 79, 887–896. https://doi.org/10.1007/s00107-021-01681-7 (2021).

Mentrasti, L., Molari, L. & Fabiani, M. Poisson’s ratio bounds in orthotropic materials. Application to natural composites: Wood, bamboo and Arundo donax. Compos. B Eng. 209, 108612. https://doi.org/10.1016/j.compositesb.2021.108612 (2021).

Dai, S.-W. et al. Bamboo-inspired mechanically flexible and electrically conductive polydimethylsiloxane foam materials with designed hierarchical pore structures for ultra-sensitive and reliable piezoresistive pressure sensor. Compos. Part B: Eng. 225, 109243. https://doi.org/10.1016/j.compositesb.2021.109243 (2021).

Tokoro, R. et al. How to improve mechanical properties of polylactic acid with bamboo fibers. J. Mater. Sci. 43, 775–787 (2008).

Zhang, H., Liu, J., Wang, Z. & Lu, X. Mechanical and thermal properties of small diameter original bamboo reinforced extruded particleboard. Mater. Lett. 100, 204–206 (2013).

Jin, C., Yao, Q., Li, J., Fan, B. & Sun, Q. Fabrication, superhydrophobicity, and microwave absorbing properties of the magnetic c-Fe2O3/bamboo composites. Mater. Des. 85, 205–210 (2015).

Li, T., Cheng, D. L., Wålinder, M. E. & Zhou, D. G. Wettability of oil heat-treated bamboo and bonding strength of laminated bamboo board. Ind. Crop Prod. 69, 15–20 (2015).

Bahari, S. A., Grigsby, W. & Krause, A. Thermal stability of processed PVC/bamboo blends: Effect of compounding procedures. Eur. J. Wood Prod. 75, 147–159 (2017).

Javadian, A. et al. Bond-behavior study of newly developed bamboo-composite reinforcement in concrete. Constr. Build. Mater. 122, 110–117. https://doi.org/10.1016/j.conbuildmat.2016.06.084 (2016).

Javadian, A. et al. Application of sustainable bamboo-based composite reinforcement in structural-concrete beams: Design and evaluation. Materials 13(3), 696. https://doi.org/10.3390/ma13030696 (2020).

Okubo, K., Fujii, T. & Yamamoto, Y. Development of bamboo-based polymer composites and their mechanical properties. Compos. Part A Appl. Sci. 35, 377–383 (2004).

Yu, Y., Huang, X. & Yu, W. A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Compos. Part B-Eng. 56, 48–53 (2014).

Verma, C. S. & Chariar, V. M. Development of layered laminate bamboo composite and their mechanical properties. Compos. Part B: Eng. 43(3), 1063–1069. https://doi.org/10.1016/j.compositesb.2011.11.065 (2012).

Sharma, B. et al. Engineered bamboo for structural applications. Constr. Build. Mater. 81, 66–73. https://doi.org/10.1016/j.conbuildmat.2015.01.077 (2015).

Fadlelmola, A. et al. Experimental investigation and design method on a lightweight bamboo-concrete sandwich panel under bending load. Structures 34(1), 856–874. https://doi.org/10.1016/j.istruc.2021.08.030 (2021).

Zhou, K. et al. Mechanical properties of large-scale parallel bamboo strand lumber under local compression. Constr. Build. Mater. 271, 121572. https://doi.org/10.1016/j.conbuildmat.2020.121572 (2021).

Dauletbek, A. et al. A review of mechanical behavior of structural laminated bamboo lumber. Sustain. Struct. 1, 1. https://doi.org/10.54113/j.sust.2021.000004 (2021).

Asdrubali, F. Survey on the acoustical properties of new sustainable materials for noise control. In Proceedings of theEuronoise, Tampere, Finland (2006).

Khair, F. A. et al. Preliminary study on bamboo as sound absorber. Appl. Mech. Mater. 554, 76–80. https://doi.org/10.4028/www.scientific.net/amm.554.76 (2014).

Haseli, M. et al. Characterization of blockboard and battenboard sandwich panels from date palm waste trunks. Measurement 124, 329–337. https://doi.org/10.1016/j.measurement.2018.04.040 (2018).

ASTM D1037, 2012 Edition, May 1, 2012—Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials (2012).

ASTM C177, 2019 Edition, January 1, 2019—Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus (2019).

ASTM C423, 2022 Edition, February 1, 2022—Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method (2022).

Cox, D. R. Response surfaces, mixtures, and ridge analyses, 2nd Edition by George E.P. Box, Norman R. Draper. Int. Stat. Rev. 75(2), 265–266. https://doi.org/10.1111/j.1751-5823.2007.00015_17.x (2007).

EN 316:2009—Wood fibre boards—Definition, classification and symbols (2009).

DIN EN 323; Wood-based panels; determination of density; German version EN 323:1993 (1993).

DIN EN 322, 1993 Edition, August 1993—Wood-based panels; determination of moisture content; German version EN 322:1993 (1993).

DIN EN 319; Particleboards and fiberboards; determination of tensile strength perpendicular to the plane of the board; German version EN 319:1993 (2022).

DIN EN 310; Wood-based panels; determination of modulus of elasticity in bending and of bending strength; German version EN 310:1993 (2022).

DIN EN 789; Timber structures—test methods—determination of mechanical properties of wood-based panels; German version EN 789:2004 (2022).

ISO 3132; Determination of the proportional limit (conventional ultimate strength), the load being applied to the whole surface (radial or tangential) of the test piece. In References are made to ISO 3129 and ISO 3130 (2023).

ASTM D143, 2022 Edition, May 15, 2022—Standard Test Methods for Small Clear Specimens of Timber (2022).

ASTM D1761, 2020 Edition, April 15, 2020—Standard Test Methods for Mechanical Fasteners in Wood and Wood-Based Materials (2020).

Khalid, I. et al. Evaluation on layering effects and adhesive rates of laminated compressed composite panels made from oil palm (Elaeis Guineensis) fronds. Mater. Design 68, 24–28. https://doi.org/10.1016/j.matdes.2014.12.007 (2015).

Abdul Khalil, H. P. S. et al. Development and material properties of new hybrid plywood from oil palm biomass. Mater. Design 31(1), 417–424. https://doi.org/10.1016/j.matdes.2009.05.040 (2010).

Amirou, S. et al. Particleboards production from date palm biomass. Eur. J. Wood Wood Prod. 71(6), 717–723. https://doi.org/10.1007/s00107-013-0730-3 (2013).

Hiziroglu, S. Some properties of sandwich type composite panels manufactured from eastern redcedar. Compos. Part B: Eng. 43(8), 3288–3292. https://doi.org/10.1016/j.compositesb.2012.02.009 (2012).

Kawai, S., Norimoto, M. & Hirai, T. Mokuzai mokusituzairyowugaku (in Japanese). Towuyowu Syowutenn Tokyo 289, 313–317 (1997).

Kawai, S. Thermal, sound, and fire resistance performance of low-density particleboard. Mokuzai Gakkaishi 34, 973–979 (1988).

Thoemen, H., Irle, M. & Sernek, M. Wood-Based Panels: An Introduction for Specialists (Brunel University Press, 2010).

Glass, S. V. & Zelinka, S. L. Moisture Relations and Physical Properties of Wood, Wood Handbook—Wood As An Engineering Material (Forest Product Laboratory, 2010).

Casagrande, D., Grossi, P. & Tomasi, R. shake table tests on a full-scale timber-frame building with gypsum fibre boards. Eur. J. Wood Prod. 74(3), 425–442 (2016).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

P.G., Investigation, Writing-original draft, Writing-review & editing. H.Z.H., Investigation, Methodology, Writing-review & editing. D.H., Methodology, Conceptualization. A.J., Writing-original draft, Writing- review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gholizadeh, P., Hosseinabadi, H.Z., Hebel, D.E. et al. Investigation of mechanical, physical and thermoacoustic properties of a novel light-weight dense wall panels made of bamboo Phyllostachys Bambusides. Sci Rep 13, 18396 (2023). https://doi.org/10.1038/s41598-023-45515-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-45515-3

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.