Abstract

Preparation of epoxidized tung oil ethyl ester (ETOEE) was explored in this work via a two-step approach to produce bio-lubricant with enhanced thermal-oxidative stability. Transesterification of tung oil with ethanol was first carried out with KOH as the catalyst at 60 °C and a molar ratio of tung oil to ethanol of 1:20 for 2 h. The obtained tung oil ethyl ester (TOEE) was subjected to epoxidation in the presence of hydrogen peroxide and formic acid (FA). The highest conversion (93.6%, based on reduction of iodine value) was achieved by reacting 10 g of TOEE with 14.5 g of hydrogen peroxide and 5.86 g of FA at 50 °C for 3 h. Under these conditions, the resulting ETOEE has an oxirane number or epoxy value of 5.1%, and the presence of epoxy groups was confirmed by Fourier transform infrared spectroscopic analysis. The resulting ETOEE was further analyzed of its thermal stability under both oxidative and non-oxidative atmospheres. The viscosity index was determined and improvements in both thermal stability and lubricity were observed with the aid of a modular compact rheometer and a thermos-gravimetric analyzer, respectively. The ETOEE produced may be suitable for use as lubricating oil in gear boxes and engines.

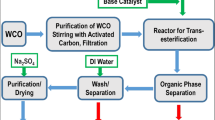

Graphic Abstract

Similar content being viewed by others

References

Salimon, J., Salih, N., Yousif, E.: Biolubricants: raw materials, chemical modifications and environmental benefits. Eur. J. Lipid Sci. Technol. 112, 519–530 (2010). https://doi.org/10.1002/ejlt.200900205

Zhang, L., Jia, B., Tan, X., Thammina, C.S., Long, H., Liu, M., Wen, S., Song, X., Cao, H.: Fatty acid profile and unigene-derived simple sequence repeat markers in tung tree (Vernicia fordii). PLoS ONE (2014). https://doi.org/10.1371/journal.pone.0105298

Yang, J., Feng, Y., Zeng, T., Guo, X., Li, L., Hong, R., Qiu, T.: Synthesis of biodiesel via transesterification of tung oil catalyzed by new Brönsted acidic ionic liquid. Chem. Eng. Res. Des. 117, 584–592 (2017). https://doi.org/10.1016/j.cherd.2016.09.038

Chen, Y.H., Chen, J.H., Chang, C.Y., Chang, C.C.: Biodiesel production from tung (Vernicia montana) oil and its blending properties in different fatty acid compositions. Bioresour. Technol. 101, 9521–9526 (2010). https://doi.org/10.1016/j.biortech.2010.06.117

Mei, D., Luo, Y., Shen, X., Lu, D., Yuan, Y.: Lubrication properties of fatty acid methyl esters as low-sulfur diesel enhancers. Trans Chin Soc Agric Eng 32, 193–197 (2016). https://doi.org/10.11975/j.issn.1002-6819.2016.09.027

Nicolau, C., Klein, A., Silva, C., Fiorucci, A., Stropa, J., Santos, E., Borges, K., da Silva, R., de Oliveira, L., Simionatto, E., Scharf, D., Simionatto, E., Nicolau, C.L., Klein, A.N.V., Silva, C.A.A., Fiorucci, A.R., Stropa, J.M., Santos, E.O., Borges, K.C.S., da Silva, R.C.L., de Oliveira, L.C.S., Simionatto, E.L., Scharf, D.R., Simionatto, E.: Thermal properties of the blends of methyl and ethyl esters prepared from babassu and soybean oils. J. Braz. Chem. Soc. 29, 1672–1679 (2018). https://doi.org/10.21577/0103-5053.20180040

Miyake, T., Makino, T., Taniguchi, S.I., Watanuki, H., Niki, T., Shimizu, S., Kojima, Y., Sano, M.: Alcohol synthesis by hydrogenation of fatty acid methyl esters on supported Ru-Sn and Rh-Sn catalysts. Appl. Catal. A Gen. 364, 108–112 (2009). https://doi.org/10.1016/j.apcata.2009.05.036

Mashhadi, F., Habibi, A., Varmira, K.: Enzymatic production of green epoxides from fatty acids present in soapstock in a microchannel bioreactor. Ind. Crops Prod. 113, 324–334 (2018). https://doi.org/10.1016/j.indcrop.2018.01.052

Sustaita-Rodríguez, A., Ramos-Sánchez, V.H., Camacho-Dávila, A.A., Zaragoza-Galán, G., Espinoza-Hicks, J.C., Chávez-Flores, D.: Lipase catalyzed epoxidation of fatty acid methyl esters derived from unsaturated vegetable oils in absence of carboxylic acid. Chem. Cent. J. 12, 1–7 (2018). https://doi.org/10.1186/s13065-018-0409-2

Gorla, G., Kour, S.M., Padmaja, K.V., Karuna, M.S.L., Prasad, R.B.N.: Preparation and properties of lubricant base stocks from epoxidized karanja oil and its alkyl esters. Ind. Eng. Chem. Res. 52, 16598–16605 (2013). https://doi.org/10.1021/ie4024325

Zheng, M., Xhang, M., Hu, L., Bo, C., Zhou, Y.: Synthesis and properties of epoxidized tung oil methyl ester from tung oil methyl ester with quaternary ammonium phosphotungstate as catalyst. Chem. Ind. For. Prod. 37, 61–66 (2017). https://doi.org/10.3969/j.issn.0253-2417.03.008

Lee, P.L., Wan Yunus, W.M.Z., Yeong, S.K., Abdullah, D.K., Lim, W.H.: Optimization of the epoxidation of methyl ester of palm fatty acid distillate. J. Oil Palm Res. 21, 675–682 (2009)

Dinda, S., Patwardhan, A.V., Goud, V.V., Pradhan, N.C.: Epoxidation of cottonseed oil by aqueous hydrogen peroxide catalysed by liquid inorganic acids. Bioresour. Technol. 99, 3737–3744 (2008). https://doi.org/10.1016/j.biortech.2007.07.015

Galli, F., Nucci, S., Pirola, C., Bianchi, C.L.: Epoxy methyl soyate as bio-plasticizer: two different preparation strategies. Chem. Eng. Trans. 37, 601–606 (2014). https://doi.org/10.3303/CET1437101

Sharma, R.V., Somidi, A.K.R., Dalai, A.K.: Preparation and properties evaluation of biolubricants derived from canola oil and canola biodiesel. J. Agric. Food Chem. 63, 3235–3242 (2015). https://doi.org/10.1021/jf505825k

Borugadda, V.B., Goud, V.V.: Epoxidation of castor oil fatty acid methyl esters (COFAME) as a lubricant base stock using heterogeneous ion-exchange resin (IR-120) as a catalyst. Energy Procedia 54, 75–84 (2014). https://doi.org/10.1016/j.egypro.2014.07.249

Holser, R.A.: Transesterification of epoxidized soybean oil to prepare epoxy methyl esters. Ind. Crops Prod. 27, 130–132 (2008). https://doi.org/10.1016/J.INDCROP.2007.06.001

Liu, W., Duan, F., Bi, Y.: Fast and simple transesterification of epoxidized soybean oil to prepare epoxy methyl esters at room temperature. RSC Adv. 8, 13048–13053 (2018). https://doi.org/10.1039/c8ra00982a

Wang, J., Zhao, X., Liu, D.: Preparation of epoxidized fatty acid methyl ester with in situ auto-catalyzed generation of performic acid and the influence of impurities on epoxidation. Waste Biomass Valoriz. 9, 1881–1891 (2018). https://doi.org/10.1007/s12649-017-9945-6

Sutanto, S., Go, A.W., Chen, K.-H., Nguyen, P.L.T., Ismadji, S., Ju, Y.-H.: Release of sugar by acid hydrolysis from rice bran for single cell oil production and subsequent in situ transesterification for biodiesel preparation. Fuel Process. Technol. (2017). https://doi.org/10.1016/j.fuproc.2017.07.014

Ogundiran, M.B., Ojo, A.S.: Determination of fat contents, iodine values, trace and toxic metals in commonly consumed frozen fish in Nigeria. Am. J. Food Technol. 7, 34–42 (2012). https://doi.org/10.3923/ajft.2012.34.42

Ahmetli, G., Cerit, A.: Effects of functional groups on the thermal properties of modified polystyrene 2006, 2249–2253 (2006). https://doi.org/10.1002/app

ASTM International: ASTM D2270–04 “Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 and 100 & #xB0; C 1 Liquid Petroleum Products and Opaque Liquids (and the Calculation of Dynamic Viscosity)”. ASTM International, West Conshohocken (2007)

Borugadda, V.B., Goud, V.V.: Improved thermo-oxidative stability of structurally modified waste cooking oil methyl esters for bio-lubricant application. J. Clean. Prod. 112, 4515–4524 (2016). https://doi.org/10.1016/j.jclepro.2015.06.046

Doll, K.M., Sharma, B.K., Erhan, S.Z.: Friction reducing properties and stability of epoxidized oleochemicals. Clean: Soil, Air, Water 36, 700–705 (2008). https://doi.org/10.1002/clen.200800063

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All author decares that they have no competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ju, YH., Sari, N.N.F., Go, A.W. et al. Preparation of Epoxidized Fatty Acid Ethyl Ester from Tung Oil as a Bio-lubricant Base-Stock. Waste Biomass Valor 11, 4145–4155 (2020). https://doi.org/10.1007/s12649-019-00749-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00749-z