Abstract

Ti–10 wt% Mo–1 wt% B4C composite samples were SPSed under the circumstances of 5 min dwell time, 50 MPa external pressure and sintering temperatures of 1150 °C, 1300 °C and 1450 °C. The role of sintering temperature on the relative density, microstructure and mechanical characteristics of as-sintered specimens were studied. Near fully dense relative density was obtained for the samples sintered at 1450 °C. The best mechanical properties including UTS, elongation, bending strength and micro/macro hardness were achieved for the composites SPSed at the highest temperature. The XRD results and also microscopic photographs disclosed the formation of TiB + TiC in-situ phases. However, there was not any evidence for chemical reaction between Mo and other phases. The role of produced in-situ phases on the grain growth also studied using SEM fractographs.

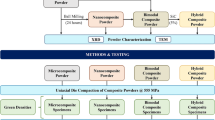

Graphic Abstract

Similar content being viewed by others

References

B.A. Obadele, O.O. Ige, P.A. Olubambi, Fabrication and characterization of titanium-nickel-zirconia matrix composites prepared by spark plasma sintering. J. Alloys Compd. 710, 825–830 (2017). https://doi.org/10.1016/j.jallcom.2017.03.340

S.A. Delbari, A. Sabahi Namini, M. Shahedi Asl, Hybrid Ti matrix composites with TiB2 and TiC compounds. Mat. Today Comm. (2019). https://doi.org/10.1016/j.mtcomm.2019.100576

A. Sabahi Namini, S.A.A. Dilawary, A. Motallebzadeh, M. Shahedi Asl, Effect of TiB2 addition on the elevated temperature tribological behavior of spark plasma sintered Ti matrix composite. Compos. Part B Eng. 172, 271–280 (2019). https://doi.org/10.1016/j.compositesb.2019.05.073

M.D. Hayat, H. Singh, Z. He, P. Cao, Titanium metal matrix composites: an overview. Compos. Part A Appl. Sci. Manuf. 121, 418–438 (2019). https://doi.org/10.1016/j.compositesa.2019.04.005

E.L. Calvert, A.J. Knowles, J.J. Pope, D. Dye, M. Jackson, Novel high strength titanium–titanium composites produced using field-assisted sintering technology (FAST). Scr. Mater. 159, 51–57 (2019). https://doi.org/10.1016/j.scriptamat.2018.08.036

X. Wang, L. Wang, F. Yang, L. Luo, H. Yan, X. Liu, X. Li, R. Chen, Y. Su, J. Guo, H. Fu, Hydrogen induced microstructure evolution of titanium matrix composites. Int. J. Hydrogen Energy. 43, 9838–9847 (2018). https://doi.org/10.1016/j.ijhydene.2018.04.030

T. Fujii, K. Tohgo, M. Iwao, Y. Shimamura, Fabrication of alumina-titanium composites by spark plasma sintering and their mechanical properties. J. Alloys Compd. 744, 759–768 (2018). https://doi.org/10.1016/j.jallcom.2018.02.142

S. Decker, J. Lindemann, L. Krüger, Metal matrix composites based on Ti-6242 synthesized by Spark Plasma Sintering. Mater. Sci. Eng. A. 732, 35–40 (2018). https://doi.org/10.1016/j.msea.2018.06.103

F.-C. Wang, Z.-H. Zhang, Y.-J. Sun, Y. Liu, Z.-Y. Hu, H. Wang, A.V. Korznikov, E. Korznikova, Z.-F. Liu, S. Osamu, Rapid and low temperature spark plasma sintering synthesis of novel carbon nanotube reinforced titanium matrix composites. Carbon N. Y. 95, 396–407 (2015). https://doi.org/10.1016/j.carbon.2015.08.061

M. Shahedi Asl, A. Sabahi Namini, A. Motallebzadeh, M. Azadbeh, Effects of sintering temperature on microstructure and mechanical properties of spark plasma sintered titanium. Mater. Chem. Phys. 203, 266–273 (2018). https://doi.org/10.1016/j.matchemphys.2017.09.069

S. Li, K. Kondoh, H. Imai, B. Chen, L. Jia, J. Umeda, Microstructure and mechanical properties of P/M titanium matrix composites reinforced by in-situ synthesized TiC–TiB. Mater. Sci. Eng. A. 628, 75–83 (2015). https://doi.org/10.1016/j.msea.2015.01.033

H. Duan, Y. Han, W. Lu, L. Wang, J. Mao, D. Zhang, Configuration design and fabrication of laminated titanium matrix composites. Mater. Des. 99, 219–224 (2016). https://doi.org/10.1016/j.matdes.2016.03.061

H. Yuanfei, K. Wei, Y. Xiaofang, L. Jiuxiao, H. Guangfa, L. Weijie, Z. Di, Effect of La and B Addition on the Microstructure and Mechanical Properties of Titanium Matrix Composite. Rare Met. Mater. Eng. 45, 3104–3107 (2016). https://doi.org/10.1016/S1875-5372(17)30062-0

A. Muthuchamy, G.D.J. Ram, V.S. Sarma, Spark plasma consolidation of continuous fiber reinforced titanium matrix composites. Mater. Sci. Eng. A. 703, 461–469 (2017). https://doi.org/10.1016/j.msea.2017.07.085

X.N. Mu, H.N. Cai, H.M. Zhang, Q.B. Fan, F.C. Wang, Z.H. Zhang, Y. Wu, Y.X. Ge, S. Chang, R. Shi, Y. Zhou, D.D. Wang, Uniform dispersion of multi-layer graphene reinforced pure titanium matrix composites via flake powder metallurgy. Mater. Sci. Eng. A. 725, 541–548 (2018). https://doi.org/10.1016/j.msea.2018.04.056

E. Sheydaeian, E. Toyserkani, A new approach for fabrication of titanium–titanium boride periodic composite via additive manufacturing and pressure-less sintering. Compos. Part B Eng. 138, 140–148 (2018). https://doi.org/10.1016/j.compositesb.2017.11.035

K. Shirvanimoghaddam, E. Ghasali, A. Pakseresht, S.M.R. Derakhshandeh, M. Alizadeh, T. Ebadzadeh, M. Naebe, Super hard carbon microtubes derived from natural cotton for development of high performance titanium composites. J. Alloys Compd. 775, 601–616 (2019). https://doi.org/10.1016/j.jallcom.2018.10.121

Z. Hu, G. Tong, Q. Nian, R. Xu, M. Saei, F. Chen, C. Chen, M. Zhang, H. Guo, J. Xu, Laser sintered single layer graphene oxide reinforced titanium matrix nanocomposites. Compos. Part B Eng. 93, 352–359 (2016). https://doi.org/10.1016/j.compositesb.2016.03.043

W. Zhang, Y. Liu, B. Liu, X. Li, H. Wu, J. Qiu, A new titanium matrix composite reinforced with Ti–36Nb–2Ta–3Zr–0.35O wire. Mater. Des. 117, 289–297 (2017). https://doi.org/10.1016/j.matdes.2016.12.029

A. Sabahi Namini, A. Motallebzadeh, B. Nayebi, M. Shahedi Asl, M. Azadbeh, Microstructure–mechanical properties correlation in spark plasma sintered Ti–4.8 wt% TiB2 composites. Mater. Chem. Phys. 223: 789–796 (2019). https://doi.org/10.1016/j.matchemphys.2018.11.057

K.S. Munir, Y. Li, J. Lin, C. Wen, Interdependencies between graphitization of carbon nanotubes and strengthening mechanisms in titanium matrix composites. Materialia. 3, 122–138 (2018). https://doi.org/10.1016/j.mtla.2018.08.015

Z. Cao, X. Wang, J. Li, Y. Wu, H. Zhang, J. Guo, S. Wang, Reinforcement with graphene nanoflakes in titanium matrix composites. J. Alloys Compd. 696, 498–502 (2017). https://doi.org/10.1016/j.jallcom.2016.11.302

Y. Han, J. Li, G. Huang, Y. Lv, X. Shao, W. Lu, D. Zhang, Effect of ECAP numbers on microstructure and properties of titanium matrix composite. Mater. Des. 75, 113–119 (2015). https://doi.org/10.1016/j.matdes.2015.03.018

C. Han, Y. Li, X. Liang, L. Chen, N. Zhao, X. Zhu, Effect of composition and sintering temperature on mechanical properties of ZrO2 particulate-reinforced titanium-matrix composite. Trans. Nonferrous Met. Soc. China. 22, 1855–1859 (2012). https://doi.org/10.1016/S1003-6326(11)61397-6

J.B. Fruhauf, J. Roger, O. Dezellus, S. Gourdet, N. Karnatak, N. Peillon, S. Saunier, F. Montheillet, C. Desrayaud, Microstructural and mechanical comparison of Ti+15%TiCp composites prepared by free sintering, HIP and extrusion. Mater. Sci. Eng. A. 554, 22–32 (2012). https://doi.org/10.1016/j.msea.2012.05.096

M. Eriksson, D. Salamon, M. Nygren, Z. Shen, Spark plasma sintering and deformation of Ti–TiB2 composites. Mater. Sci. Eng. A. 475, 101–104 (2008). https://doi.org/10.1016/j.msea.2007.01.161

A. Sabahi Namini, M. Azadbeh, M. Shahedi Asl, Effects of in-situ formed TiB whiskers on microstructure and mechanical properties of spark plasma sintered Ti–B4C and Ti–TiB2 composites. Sci. Iran. 25, 762–771 (2018). https://doi.org/10.24200/sci.2017.4499

A. Sabahi Namini, M. Azadbeh, Microstructural characterisation and mechanical properties of spark plasma-sintered TiB2-reinforced titanium matrix composite. Powder Metall. 60, 22–32 (2017). https://doi.org/10.1080/00325899.2016.1265805

L.L. Dong, B. Xiao, Y. Liu, Y.L. Li, Y.Q. Fu, Y.Q. Zhao, Y.S. Zhang, Sintering effect on microstructural evolution and mechanical properties of spark plasma sintered Ti matrix composites reinforced by reduced graphene oxides. Ceram. Int. 44, 17835–17844 (2018). https://doi.org/10.1016/j.ceramint.2018.06.252

H. Attar, S. Ehtemam-Haghighi, D. Kent, M.S. Dargusch, Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. Int. J. Mach. Tools Manuf. 133, 85–102 (2018). https://doi.org/10.1016/j.ijmachtools.2018.06.003

X. Zhang, F. Song, Z. Wei, W. Yang, Z. Dai, Microstructural and mechanical characterization of in-situ TiC/Ti titanium matrix composites fabricated by graphene/Ti sintering reaction. Mater. Sci. Eng. A. 705, 153–159 (2017). https://doi.org/10.1016/j.msea.2017.08.079

A. Sabahi Namini, M. Azadbeh, M. Shahedi Asl, Effect of TiB2 content on the characteristics of spark plasma sintered Ti–TiBw composites. Adv. Powder Technol. 28, 1564–1572 (2017). https://doi.org/10.1016/j.apt.2017.03.028

K.S. Munir, Y. Zheng, D. Zhang, J. Lin, Y. Li, C. Wen, Microstructure and mechanical properties of carbon nanotubes reinforced titanium matrix composites fabricated via spark plasma sintering. Mater. Sci. Eng. A. 688, 505–523 (2017). https://doi.org/10.1016/j.msea.2017.02.019

K.S. Munir, Y. Zheng, D. Zhang, J. Lin, Y. Li, C. Wen, Improving the strengthening efficiency of carbon nanotubes in titanium metal matrix composites. Mater. Sci. Eng. A. 696, 10–25 (2017). https://doi.org/10.1016/j.msea.2017.04.026

L. Huang, L. Wang, M. Qian, J. Zou, High tensile-strength and ductile titanium matrix composites strengthened by TiB nanowires. Scr. Mater. 141, 133–137 (2017). https://doi.org/10.1016/j.scriptamat.2017.08.007

A. Miklaszewski, Ultrafast densification and microstructure evolution of in situ Ti/TiB metal matrix composite obtained by PPS approach. Int. J. Refract. Met. Hard Mater. 65, 34–38 (2017). https://doi.org/10.1016/j.ijrmhm.2016.10.007

Y. Jiao, L. Huang, L. Geng, Progress on discontinuously reinforced titanium matrix composites. J. Alloys Compd. 767, 1196–1215 (2018). https://doi.org/10.1016/j.jallcom.2018.07.100

S. Tkachenko, J. Cizek, R. Mušálek, K. Dvořák, Z. Spotz, E.B. Montufar, T. Chráska, I. Křupka, L. Čelko, Metal matrix to ceramic matrix transition via feedstock processing of SPS titanium composites alloyed with high silicone content. J. Alloys Compd. 764, 776–788 (2018). https://doi.org/10.1016/j.jallcom.2018.06.086

W.H. Lee, J.G. Seong, Y.H. Yoon, C.H. Jeong, C.J. Van Tyne, H.G. Lee, S.Y. Chang, Synthesis of TiC reinforced Ti matrix composites by spark plasma sintering and electric discharge sintering: A comparative assessment of microstructural and mechanical properties. Ceram. Int. 45, 8108–8114 (2019). https://doi.org/10.1016/j.ceramint.2019.01.062

S.A. Delbari, B. Nayebi, E. Ghasali, M. Shokouhimehr, M. Shahedi Asl, Spark plasma sintering of TiN ceramics codoped with SiC and CNT. Ceram. Int. 45, 3207–3216 (2019). https://doi.org/10.1016/j.ceramint.2018.10.223

M. Shahedi Asl, S.A. Delbari, F. Shayesteh, Z. Ahmadi, A. Motallebzadeh, Reactive spark plasma sintering of TiB2–SiC–TiN novel composite. Int. J. Refract. Met. Hard Mater. 81, 119–126 (2019). https://doi.org/10.1016/j.ijrmhm.2019.02.022

S.W. Maseko, A.P.I. Popoola, O.S.I. Fayomi, Characterization of ceramic reinforced titanium matrix composites fabricated by spark plasma sintering for anti-ballistic applications. Def. Technol. 14, 408–411 (2018). https://doi.org/10.1016/j.dt.2018.04.013

F. Shayesteh, S.A. Delbari, Z. Ahmadi, M. Shokouhimehr, M. Shahedi Asl, Influence of TiN dopant on microstructure of TiB2 ceramic sintered by spark plasma, Ceram. Int. (2018). doi:10.1016/j.ceramint.2018.11.228.

V.S. Balaji, S. Kumaran, Densification and microstructural studies of titanium–boron carbide (B4C) powder mixture during spark plasma sintering. Powder Technol. 264, 536–540 (2014). https://doi.org/10.1016/j.powtec.2014.05.050

L. Jia, S. Li, H. Imai, B. Chen, K. Kondoh, Size effect of B4C powders on metallurgical reaction and resulting tensile properties of Ti matrix composites by in-situ reaction from Ti–B4C system under a relatively low temperature. Mater. Sci. Eng. A. 614, 129–135 (2014). https://doi.org/10.1016/j.msea.2014.07.020

L. Jia, X. Wang, B. Chen, H. Imai, S. Li, Z. Lu, K. Kondoh, Microstructural evolution and competitive reaction behavior of Ti–B4C system under solid-state sintering. J. Alloys Compd. 687, 1004–1011 (2016). https://doi.org/10.1016/j.jallcom.2016.06.280

S. Xu, C. Zhou, Y. Liu, B. Liu, K. Li, Microstructure and mechanical properties of Ti–15Mo–xTiC composites fabricated by in-situ reactive sintering and hot swaging. J. Alloys Compd. 738, 188–196 (2018). https://doi.org/10.1016/j.jallcom.2017.12.124

C.L. Yeh, W.Z. Lin, Combustion synthesis of UHTC composites from Ti–B4C solid state reaction with addition of VIb transition metals. Coatings. 7, 73 (2017). https://doi.org/10.3390/coatings7060073

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sabahi Namini, A., Shahedi Asl, M. & Delbari, S.A. Influence of Sintering Temperature on Microstructure and Mechanical Properties of Ti–Mo–B4C Composites. Met. Mater. Int. 27, 1092–1102 (2021). https://doi.org/10.1007/s12540-019-00469-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00469-y