Abstract

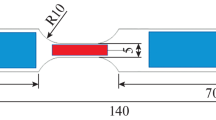

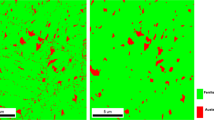

Quench and partitioning steels offer a valuable combination of high strength and ductility. Here we report on microstructural evolution in a QP980 steel during deformation. This is measured using a range of techniques including in-situ tensile tests coupled with scanning electron microscopy, ex-situ interrupted tensile tests coupled with electron back scattered diffraction, and X-ray diffraction measurements. Microstrain partitioning among ferrite, martensite, and retained austenite is quantified using microscopic digital image correlation. The average true strain in ferrite is approximately two and three times that in martensite and blocky retained austenite, respectively, consistent with nanohardness measurements of each phase. The combination of high strength and ductility of this steel is attributed to co-deformation of ferrite and tempered martensite. Some of the retained austenite blocks located at ferrite and martensite interfaces are almost fully transformed to martensite through transformation-induced plasticity, also contributing to ductility. Cracking of large blocky retained austenite in regions with more intense strain localization starts at relatively lower global strains. However, this appears to have little impact on the final failure process. Rather, it is the formation of large cavities in regions with higher martensite volume fraction that provides the primary mechanism of damage and failure.

Similar content being viewed by others

Notes

It is important to distinguish here between true ductility, defined as the true strain at fracture and measured using the reduction in cross-sectional area at fracture, from the engineering ductility, defined as percent elongation. These can be quite different. Moreover, the elongation is sensitive to sample dimensions, in particular the gauge length, while the true ductility is not, so long as the sample dimensions are many times the grain size.

References

1. E. De Moor, S. Lacroix, A. Clarke, J. Penning and J. Speer, Metallurgical and Materials Transactions A, 2008, vol. 39, p. 2586.

2. M. Santofimia, J. Speer, A. Clarke, L. Zhao and J. Sietsma, Acta Materialia, 2009, vol. 57, pp. 4548-4557.

3. H. Li, X. Lu, W. Li and X. Jin, Metallurgical and Materials Transactions A, 2010, vol. 41, pp. 1284-1300.

4. Q. Lai, O. Bouaziz, M. Gouné, A. Perlade, Y. Bréchet and T. Pardoen, Materials Science and Engineering: A, 2015, vol. 638, pp. 78-89.

5. Q. Lai, O. Bouaziz, M. Gouné, L. Brassart, M. Verdier, G. Parry, A. Perlade, Y. Bréchet and T. Pardoen, Materials Science and Engineering: A, 2015, vol. 646, pp. 322-331.

6. J. Speer, D. Matlock, B. De Cooman and J. Schroth, Acta materialia, 2003, vol. 51, pp. 2611-2622.

7. Y. Takahama, M. Santofimia, M. Mecozzi, L. Zhao and J. Sietsma, Acta Materialia, 2012, vol. 60, pp. 2916-2926.

8. D. Edmonds, K. He, F. Rizzo, B. De Cooman, D. Matlock and J. Speer, Materials Science and Engineering: A, 2006, vol. 438, pp. 25-34.

9. M. Santofimia, L. Zhao, R. Petrov, C. Kwakernaak, W. Sloof and J. Sietsma, Acta Materialia, 2011, vol. 59, pp. 6059-6068.

10. G. Avramovic-Cingara, Y. Ososkov, M. Jain and D. Wilkinson, Materials Science and Engineering: A, 2009, vol. 516, pp. 7-16.

11. S.-H. Joo, J.K. Lee, J.-M. Koo, S. Lee, D.-W. Suh and H.S. Kim, Scripta Materialia, 2013, vol. 68, pp. 245-248.

12. H. Ghassemi-Armaki, R. Maaß, S. Bhat, S. Sriram, J. Greer and K. Kumar, Acta Materialia, 2014, vol. 62, pp. 197-211.

J. Samei, D.E. Green, J. Cheng and M.S. de CarvalhoLima, Mater. Des., 2016, vol. 92, pp. 1028-1037.

14. J. Samei, L. Zhou, J. Kang and D.S. Wilkinson, International Journal of Plasticity, 2019, vol. 117, pp. 58-70.

15. M. Santofimia, L. Zhao and J. Sietsma, Scripta Materialia, 2008, vol. 59, pp. 159-162.

16. M. Santofimia, L. Zhao and J. Sietsma, Metallurgical and Materials Transactions A, 2009, vol. 40, p. 46.

17. Y. Toji, G. Miyamoto and D. Raabe, Acta Materialia, 2015, vol. 86, pp. 137-147.

18. I. de Diego-Calderón, D. De Knijf, M. Monclús, J. Molina-Aldareguia, I. Sabirov, C. Föjer and R. Petrov, Materials Science and Engineering: A, 2015, vol. 630, pp. 27-35.

19. I. de Diego-Calderón, I. Sabirov, J. Molina-Aldareguia, C. Föjer, R. Thiessen and R. Petrov, Materials Science and Engineering: A, 2016, vol. 657, pp. 136-146.

20. J. Kang, M. Jain, D. Wilkinson and J. Embury, The Journal of Strain Analysis for Engineering Design, 2005, vol. 40, pp. 559-570.

21. J. Kang, Y. Ososkov, J.D. Embury and D.S. Wilkinson, Scripta Materialia, 2007, vol. 56, pp. 999-1002.

22. A. Devaraj, Z. Xu, F. Abu-Farha, X. Sun and L.G. Hector, JOM, 2018, vol. 70, pp. 1752-1757.

S. Li, D. Zou, C. Xia and J. He, Steel Res. Intl., 2016, vol. 87, pp. 1302-1311.

24. J. Min, L.G. Hector Jr, L. Zhang, J. Lin, J.E. Carsley and L. Sun, Materials Science and Engineering: A, 2016, vol. 673, pp. 423-429.

25. F. Abu-Farha, X. Hu, X. Sun, Y. Ren, L.G. Hector, G. Thomas and T.W. Brown, Metallurgical and Materials Transactions A, 2018, vol. 49, pp. 2583-2596.

V. Savic and L.G. Hector Jr, SAE Trans., 2007, pp. 218–228.

W. Poling, V. Savic, L. Hector, A. Sachdev, X. Hu, A. Devaraj and F. Abu-Farha, Report No. 0148-7191, SAE Technical Paper 2016.

28. M. Mazinani and W. Poole, Metallurgical and materials transactions A, 2007, vol. 38, pp. 328-339.

29. J. Hidalgo, K. Findley and M. Santofimia, Materials Science and Engineering: A, 2017, vol. 690, pp. 337-347.

30. R. Blondé, E. Jimenez-Melero, L. Zhao, J. Wright, E. Brück, S. Van der Zwaag and N. Van Dijk, Materials Science and Engineering: A, 2014, vol. 618, pp. 280-287.

31. X. Xiong, B. Chen, M. Huang, J. Wang and L. Wang, Scripta Materialia, 2013, vol. 68, pp. 321-324.

32. Q. Han, Y. Kang, P.D. Hodgson and N. Stanford, Scripta Materialia, 2013, vol. 69, pp. 13-16.

33. J. Marteau, H. Haddadi and S. Bouvier, Experimental Mechanics, 2013, vol. 53, pp. 427-439.

34. M. Kapp, T. Hebesberger and O. Kolednik, International Journal of Materials Research, 2011, vol. 102, pp. 687-691.

35. C.C. Tasan, M. Diehl, D. Yan, M. Bechtold, F. Roters, L. Schemmann, C. Zheng, N. Peranio, D. Ponge and M. Koyama, Annual Review of Materials Research, 2015, vol. 45, pp. 391-431.

36. C.C. Tasan, J.P. Hoefnagels, M. Diehl, D. Yan, F. Roters and D. Raabe, International Journal of Plasticity, 2014, vol. 63, pp. 198-210.

37. Q. Furnémont, M. Kempf, P. Jacques, M. Göken and F. Delannay, Materials Science and Engineering: A, 2002, vol. 328, pp. 26-32.

38. H. Matsuda, R. Mizuno, Y. Funakawa, K. Seto, S. Matsuoka and Y. Tanaka, Journal of alloys and compounds, 2013, vol. 577, pp. S661-S667.

Acknowledgments

The materials used in this study were provided by General Motors R&D Centre, Warren, MI. Partial funding was provided by the Natural Sciences and Engineering Research Council of Canada.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 5, 2019.

Rights and permissions

About this article

Cite this article

Salehiyan, D., Samei, J., Amirkhiz, B.S. et al. Microstructural Evolution During Deformation of a QP980 Steel. Metall Mater Trans A 51, 4524–4539 (2020). https://doi.org/10.1007/s11661-020-05882-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05882-2