Abstract

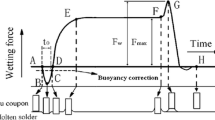

The wettability of SACR lead-free solder alloy on the surface of Cu leading wire with tiny Ni addition and different soldering parameters by adopting commercial no-clean flux was investigated by means of wetting balance methods. Obtained results show that the SACR–xNi solder alloy has better wetting match proprieties on the surface of Φ0.6 × 30 mm Cu leading wire with the addition of 0.1 % Ni at soldering temperature of 255 °C, soldering time of 4 s, dipping speed of 20 mm/s and dipping depth of 3 mm, i.e. it has higher wetting force, smaller wetting angle and shorter wetting time. The wettability can meet the standard to the lead-free solders of surface mount technology industry.

Similar content being viewed by others

References

M.L. Huang, X.F. Feng, J.F. Zhao, Z.J. Zhang, Cu–Ni cross-solder interaction in Cu/Sn–58Bi/Ni interconnect undergoing liquid–solid electro-migration. Chin. J. Nonferrous Metals 25(4), 967–974 (2015)

Y.L. Wang, K.K. Zhang, L.J. Han, H.H. Wen, Microstructure and growth behavior of Cu6Sn5 for Sn–2.5Ag–0.7Cu(0.1RE)/Cu solder joint interface. Chin. J. Nonferrous Metals 19(4), 708–713 (2009)

I.T. Wang, J.G. Duh, C.Y. Cheng, J. Wang, Interfacial reaction and elemental redistribution in Sn3.0Ag0.5Cu–xPd/immersion Au/electroless Ni solder joints after aging. Mat. Sci. Eng. B 177, 278–282 (2012)

Y. Liu, F.L. Sun, Effect of Ni and Bi addition on growth rate of intermetallic compound of SnAgCu soldering. Chin. J. Nonferrous Metals 22(2), 460–464 (2012)

L. Meinshausen, H. Frémont, K. Weide-Zaage, B. Plano, Electro- and thermomigration-induced IMC formation in SnAg3.0Cu0.5 solder joints on nickel gold pads. Microelectron. Reliab. 53, 1575–1580 (2013)

Y.L. Wang, K.K. Zhang, X.H. Qiao, N.N. Qian, H. Pan, J. Lü, K.Y. Lü, Y.F. Ruan, Effects of RE on properties of Sn2.5Ag0.7Cu/Cu solder joints. Chin. J. Nonferrous Metals 22(5), 1407–1411 (2012)

C.F. Tseng, C.Y. Ho, J. Lee, J.G. Duh, Crystallographic characterization and growth behavior of (Cu, Ni, Pd)6Sn5 intermetallic compound in Ni(P)/Pd/Au/SnAgCu/Cu assembled solder joint. J. Alloys Compd. 600, 21–28 (2014)

S.C. Yang, C.C. Chang, M.H. Tsai, C.R. Kao, Effect of Cu concentration, solder volume, and temperature on the reaction between SnAgCu solders and Ni. J. Alloys Compd. 499, 149–153 (2010)

Y.W. Wang, Y.W. Lin, C.T. Tu, C.R. Kao, Effects of minor Fe Co, and Ni additions on the reaction between SnAgCu solder and Cu. J. Alloys Compd. 478, 121–127 (2009)

H.K. Cheng, C.W. Huang, H. Lee, Y.L. Wang, T.F. Liu, C.M. Chen, Interfacial reactions between Cu and SnAgCu solder doped with minor Ni. J. Alloys Compd. 622, 529–534 (2015)

Y.W. Lin, K.L. Lin, Nucleation behaviors of the intermetallic compounds at the initial interfacial reaction between the liquid Sn3.0Ag0.5Cu solder and Ni substrate during reflow. Intermetallics 32, 6–11 (2013)

W.C. Huang, G.S. Gan, M. Tang, T. Wang, M.M. Cao, The effect of Nano-Ni particles on the wettability and oxidation resistance of Sn0.65 Cu hypoeutectic solder. J. Netshape Form. Eng. 5(1), 52–57 (2013)

Y.Z. Ma, H.T. Luo, Y.J. Li, W.S. Liu, G.J. Huang, Effects of isothermal aging on In3Ag/Cu interface microstructure evolution characteristics. Chin. J. Nonferrous Metals 25(5), 1256–1263 (2015)

B.S.S.C. Rao, J. Weng, L. Shen, T.K. Lee, K.Y. Zeng, Morphology and mechanical properties of intermetallic compounds in SnAgCu solder joints. Microelectron. Eng. 87, 2416–2422 (2010)

G.S. Gan, C.H. Du, H.B. Xu, B. Yang, Z.K. Li, T. Wang, W.C. Huang, Low-temperature soldering technology with stirring for nano-Ni particle-reinforced lead-free Sn–Cu–Ag composite solders. Chin J Nonferrous Metals 23(10), 2875–2881 (2013)

Y.W. Wang, C.C. Chang, C.R. Kao, Minimum effective Ni addition to SnAgCu solders for retarding Cu3Sn growth. J. Alloys Compd. 478, L1–L4 (2009)

Q.Y. Zhang, H.S. Zhuang, Brazing and Soldering Manual (China Machine Press, Beijing, 1999)

G.J. Shao, R. Wang, H.X. Dong, Physical Chemistry (Harbin Institute of Technology Press, Harbin, 1998)

Acknowledgments

This work was supported by the program for Innovation Scientists and Technicians Troop Construction Projects of Henan Province under Grant No. 154200510022 and Innovative Research Team in Science and Technology in Henan Province under Grant No. 13IRTSTHN003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Fang, Z., Ma, N. et al. Wettability of SACR–xNi solder alloy on Cu leading wire with no-clean flux. J Mater Sci: Mater Electron 28, 94–99 (2017). https://doi.org/10.1007/s10854-016-5496-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5496-z