Abstract

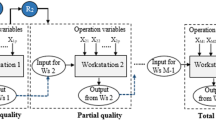

Advances in smart technologies (Industry 4.0) assist managers of Micro Small and Medium Enterprises (MSME) to control quality in manufacturing using sophisticated data-driven techniques. This study presents a 3-stage model that classifies products depending on defects (defects or non-defects) and defect type according to their levels. This article seeks to detect potential errors to ensure superior quality through machine learning and data mining. The proposed model is tested in a medium enterprise—a kitchenware company in Turkey. Using the main features of data set, product, customer, country, production line, production volume, sample quantity and defect code, a Multilayer Perceptron algorithm for product quality level classification was developed with 96% accuracy. Once a defect is detected, an estimation is made of how many re-works are required. Thus, considering the attributes of product, production line, production volume, sample quantity and product quality level, a Multilayer Perceptron algorithm for re-work quantity prediction model was developed with 98% performance. From the findings, re-work quantity has the highest relation with product quality level where re-work quantities were higher for major defects compared to minor/moderate defects. Finally, this work explores the root causes of defects considering production line and product quality level through association rule mining. The top mined rule achieves a confidence level of 80% where assembly and material were identified as main root causes.

Similar content being viewed by others

References

Ahuett-Garza, H., & Kurfess, T. (2018). A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manufacturing Letters, 15, 60–63.

Akter, S., Michael, K., Uddin, M. R., McCarthy, G., & Rahman, M. (2020). Transforming business using digital innovations: The application of AI, blockchain, cloud and data analytics. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03620-w

Arunachalam, D., Kumar, N., & Kawalek, J. P. (2018). Understanding big data analytics capabilities in supply chain management: Unravelling the issues, challenges and implications for practice. Transportation Research Part E: Logistics and Transportation Review, 114, 416–436.

Bagodi, V., Venkatesh, S. T., & Sinha, D. (2020). A study of performance measures and quality management system in small and medium enterprises in India. Benchmarking an International Journal. https://doi.org/10.1108/BIJ-08-2020-0444

Belhadi, A., Zkik, K., Cherrafi, A., & Sha’ri, M. Y. (2019). Understanding big data analytics for manufacturing processes: Insights from literature review and multiple case studies. Computers & Industrial Engineering, 137, 106099.

Belhadi, A., Kamble, S. S., Zkik, K., Cherrafi, A., & Touriki, F. E. (2020). The integrated effect of Big Data Analytics, Lean Six Sigma and Green Manufacturing on the environmental performance of manufacturing companies: The case of North Africa. Journal of Cleaner Production, 252, 119903.

Bumblauskas, D., Nold, H., Bumblauskas, P., & Igou, A. (2017). Big data analytics: Transforming data to action. Business Process Management Journal, 23(3), 703–720.

Carletti, M., Masiero, C., Beghi, A., & Susto, G. A. (2019). Explainable machine learning in industry 4.0: Evaluating feature importance in anomaly detection to enable root cause analysis. In 2019 IEEE international conference on systems, man and cybernetics (SMC) (pp. 21–26).

Carvajal Soto, J. A., Tavakolizadeh, F., & Gyulai, D. (2019). An online machine learning framework for early detection of product failures in an Industry 4.0 context. International Journal of Computer Integrated Manufacturing, 32(4–5), 452–465.

Chahal, A. (2015). The effectiveness of Total Quality Management in the manufacturing industries. International Journal of Management, IT and Engineering, 5(10), 210–225.

Chehbi-Gamoura, S., Derrouiche, R., Damand, D., & Barth, M. (2020). Insights from big Data Analytics in supply chain management: An all-inclusive literature review using the SCOR model. Production Planning & Control, 31(5), 355–382.

Chen, J. F., Do, Q. H., & Hsieh, H. N. (2015). Training artificial neural networks by a hybrid PSO-CS algorithm. Algorithms, 8(2), 292–308.

Chen, V. C. P., Kim, S. B., Oztekin, A., & Duraikannan, S. (2018). Preface: Data mining and analytics. Annals of Operations Research, 263, 1–3.

Chen, Y. T., Sun, E. W., & Lin, Y. B. (2019). Coherent quality management for big data systems: A dynamic approach for stochastic time consistency. Annals of Operations Research, 277(1), 3–32.

Chien, C. F., Liu, C. W., & Chuang, S. C. (2017). Analysing semiconductor manufacturing big data for root cause detection of excursion for yield enhancement. International Journal of Production Research, 55(17), 5095–5107.

Chin, K. S., Tummala, V. R., & Chan, K. M. (2002). Quality management practices based on seven core elements in Hong Kong manufacturing industries. Technovation, 22(4), 213–230.

Çiflikli, C., & Kahya-Özyirmidokuz, E. (2010). Implementing a data mining solution for enhancing carpet manufacturing productivity. Knowledge-Based Systems, 23(8), 783–788.

Davis, J., Edgar, T., Porter, J., Bernaden, J., & Sarli, M. (2012). Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Computers & Chemical Engineering, 47, 145–156.

Dey, S., & Stori, J. A. (2005). A Bayesian network approach to root cause diagnosis of process variations. International Journal of Machine Tools and Manufacture, 45(1), 75–91.

Dubey, R., Gunasekaran, A., Childe, S. J., Bryde, D. J., Giannakis, M., Foropon, C., et al. (2020). Big data analytics and artificial intelligence pathway to operational performance under the effects of entrepreneurial orientation and environmental dynamism: A study of manufacturing organisations. International Journal of Production Economics, 226, 107599.

Essa, E., Hossain, M. S., Tolba, A. S., Raafat, H. M., Elmogy, S., & Muahmmad, G. (2019). Toward cognitive support for automated defect detection. Neural Computing and Applications. https://doi.org/10.1007/s00521-018-03969-x

Fahmideh, M., & Beydoun, G. (2019). Big data analytics architecture design—An application in manufacturing systems. Computers & Industrial Engineering, 128, 948–963.

Ferrando, A., Popov, A., & Udell, G. F. (2017). Sovereign stress and SMEs’ access to finance: Evidence from the ECB’s SAFE survey. Journal of Banking & Finance, 81, 65–80.

Ferreiro, S., Sierra, B., Irigoien, I., & Gorritxategi, E. (2011). Data mining for quality control: Burr detection in the drilling process. Computers & Industrial Engineering, 60(4), 801–810.

Ge, Z., Song, Z., Ding, S. X., & Huang, B. (2017). Data mining and analytics in the process industry: The role of machine learning. IEEE Access, 5, 20590–20616.

Gu, V. C., Zhou, B., Cao, Q., & Adams, J. (2021). Exploring the relationship between supplier development, big data analytics capability, and firm performance. Annals of Operations Research. https://doi.org/10.1007/s10479-021-03976-7

Hazen, B. T., Skipper, J. B., Boone, C. A., & Hill, R. R. (2018). Back in business: Operations research in support of big data analytics for operations and supply chain management. Annals of Operations Research, 270, 201–211.

Hu, Y. C. (2014). Nonadditive similarity-based single-layer perceptron for multi-criteria collaborative filtering. Neurocomputing, 129, 306–314.

Ibrahim, Z., Abdullahb, F., & Ismailc, A. (2016). International business competence and small and medium enterprises. Procedia-Social and Behavioral Sciences, 224, 393–400.

International Monetary Fund. (2019). Financial inclusion of small and medium-sized enterprises in the Middle East and Central Asia. Departmental Paper No: 19/02

Jacob, D. (2017). Quality 4.0 impact and strategy handbook: Getting digitally connected to transform quality management. LNS Research.

Kamble, S. S., Gunasekaran, A., Ghadge, A., & Raut, R. (2020). A performance measurement system for industry 4.0 enabled smart manufacturing system in SMMEs—A review and empirical investigation. International Journal of Production Economics, 229, 107853.

Kingma, D. P., & Ba, J. (2014). Adam: A method for stochastic optimization. In International conference on learning representations (pp. 1–15).

Kiron, D., Prentice, P. K., & Ferguson, R. B. (2014). The analytics mandate. MIT Sloan Management Review, 55(4), 1–25.

Law, D., Gruss, R., & Abrahams, A. S. (2017). Automated defect discovery for dishwasher appliances from online consumer reviews. Expert Systems with Applications, 67, 84–94.

Lee, J., Kao, H. A., & Yang, S. (2014). Service innovation and smart analytics for industry 4.0 and big data environment. Procedia Cirp, 16(1), 3–8.

Lee, S. M., Lee, D., & Kim, Y. S. (2019). The quality management ecosystem for predictive maintenance in the Industry 4.0 era. International Journal of Quality Innovation, 5(1), 4.

Li, L., Lu, R., Choo, K. K. R., Datta, A., & Shao, J. (2016). Privacy-preserving-outsourced association rule mining on vertically partitioned databases. IEEE Transactions on Information Forensics and Security, 11(8), 1847–1861.

Liu, Y. (2014). Big data and predictive business analytics. The Journal of Business Forecasting, 33(4), 40.

Liu, P., & Yi, S. P. (2018). Investment decision-making and coordination of a three-stage supply chain considering Data Company in the Big Data era. Annals of Operations Research, 270(1), 255–271.

Lokrantz, A., Gustavsson, E., & Jirstrand, M. (2018). Root cause analysis of failures and quality deviations in manufacturing using machine learning. Procedia Cirp, 72, 1057–1062.

Mishra, D., Gunasekaran, A., Papadopoulos, T., & Childe, S. J. (2018). Big Data and supply chain management: A review and bibliometric analysis. Annals of Operations Research, 270(1), 313–336.

Peres, R. S., Barata, J., Leitao, P., & Garcia, G. (2019). Multistage quality control using machine learning in the automotive industry. IEEE Access, 7, 79908–79916.

Perzyk, M., Kochanski, A., Kozlowski, J., Soroczynski, A., & Biernacki, R. (2014). Comparison of data mining tools for significance analysis of process parameters in applications to process fault diagnosis. Information Sciences, 259, 380–392.

Savlovschi, L. I., & Robu, N. R. (2011). The role of SMEs in modern economy. Economia, Seria Management, 14(1), 277–281.

Soni, H. K., Sharma, S., & Jain, M. (2016). Frequent pattern generation algorithms for association rule mining: Strength and challenges. In 2016 International conference on electrical, electronics, and optimization techniques (ICEEOT) (pp. 3744–3747).

Sun, Z., Sun, L., & Strang, K. (2018). Big data analytics services for enhancing business intelligence. Journal of Computer Information Systems, 58(2), 162–169.

Tsai, F. M., & Huang, L. J. (2017). Using artificial neural networks to predict container flows between the major ports of Asia. International Journal of Production Research, 55(17), 5001–5010.

Viet, N. Q., Behdani, B., & Bloemhof, J. (2020). Data-driven process redesign: Anticipatory shipping in agro-food supply chains. International Journal of Production Research, 58(5), 1302–1318.

Wamba, S. F., Gunasekaran, A., Akter, S., Ren, S. J. F., Dubey, R., & Childe, S. J. (2017). Big data analytics and firm performance: Effects of dynamic capabilities. Journal of Business Research, 70, 356–365.

Wamba, S. F., Gunasekaran, A., Dubey, R., & Ngai, E. W. (2018). Big data analytics in operations and supply chain management. Annals of Operations Research, 270(1), 1–4.

Wamba, S. F., Queiroz, M. M., Wu, L., & Sivarajah, U. (2020). Big data analytics-enabled sensing capability and organizational outcomes: Assessing the mediating effects of business analytics culture. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03812-4

Windmann, S., Maier, A., Niggemann, O., Frey, C., Bernardi, A., Gu, Y., Pfrommer, H., Steckel, T., Krüger, M., & Kraus, R. (2015). Big data analysis of manufacturing processes. In Journal of physics: Conference series (Vol. 659, No. 1, p. 012055). IOP Publishing.

Wulfsberg, J. P., Hintze, W., & Behrens, B. A. (Eds.). (2019). Machine learning and artificial intelligence in production: Application areas and publicly available data sets. In Production at the leading edge of technology (pp. 493–501). Springer Vieweg, Berlin, Heidelberg.

Yadav, N., Shankar, R., & Singh, S. P. (2020). Impact of Industry4. 0/ICTs, Lean Six Sigma and quality management systems on organisational performance. The TQM Journal. https://doi.org/10.1108/BIJ-08-2020-0444

Yadegaridehkordi, E., Hourmand, M., Nilashi, M., Shuib, L., Ahani, A., & Ibrahim, O. (2018). Influence of big data adoption on manufacturing companies’ performance: An integrated DEMATEL-ANFIS approach. Technological Forecasting and Social Change, 137, 199–210.

Yapi, D., Mejri, M., Allili, M. S., & Baaziz, N. (2015). A learning-based approach for automatic defect detection in textile images. IFAC-PapersOnLine, 48(3), 2423–2428.

Zhang, C., Yu, J., & Wang, S. (2020). Fault detection and recognition of multivariate process based on feature learning of one-dimensional convolutional neural network and stacked denoised auto encoder. International Journal of Production Research. https://doi.org/10.1080/00207543.2020.1733701

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sariyer, G., Mangla, S.K., Kazancoglu, Y. et al. Data analytics for quality management in Industry 4.0 from a MSME perspective. Ann Oper Res (2021). https://doi.org/10.1007/s10479-021-04215-9

Accepted:

Published:

DOI: https://doi.org/10.1007/s10479-021-04215-9